Mmaraka oa lefats'e oa libarele tsa screw e le 'ngoe o ntse o tsoela pele ho hola, o fihla ho USD 840 milione ka 2024 mme o lebelletsoe ho fihla ho USD 1.38 bilione ka 2034. Likhetho tse holimo joalo ka Zhejiang Jinteng Single Screw Barrel, Xaloy X-800, le tse ling li fana ka ts'ebetso e ntle bakeng sa.Pipe ea PVC e nang le sekoti se le seng, PE pipe extruder single screw barrel, lemoqomo o le mong wa screw bakeng sa ho bopalits'ebetso.

| Metric/Sebaka | Boleng (2024) | Forecast (2025-2034) |

|---|---|---|

| 'Maraka o le Mong oa Screw Feed Barrel | Ho feta $ 840 limilione tse | $ 1.38 limilione tse likete |

| Kabelo ea 'Maraka oa Asia Pacific | 35.24% | Sekhahla sa kholo ea 6.3% |

Seo U ka se Batlang ka Moqomong o le Mong oa Screw

Lintlha tsa bohlokoa tsa ts'ebetso

Phapang ea likhohlano tsa likhohlano lipakeng tsa polymer le barrel kapa screw surfaces e ama haholo matla a ho tsamaisa. Haeba khohlano pakeng tsa polymer le barrel e phahame haholo ho feta pakeng tsa polymer le screw, thepa e ea pele ka katleho, e hlahisang tlhahiso e phahameng le botsitso bo betere ba ts'ebetso. Li-barrel tse bokelitsoeng li eketsa matla a khohlano, li matlafatsa bokhoni ba ho fetisa le botsitso ba tlhahiso, e leng litekanyetso tsa bohlokoa tsa ts'ebetso ho extrusion.

Baenjiniere ba boetse ba nahana ka lintlha tse 'maloa tsa tekheniki ha ba hlahloba aMoqomo o le Mong oa Screw:

- Kabo ea nako ea bolulo, e lekanyang ho phalla le ho kopanya katleho.

- Boitšoaro ba Rheological, ho kenyelletsa le viscosity le sekhahla sa ho kuta.

- Khatello le boemo ba mocheso haufi le screw.

- Ho fetisa bokhoni le botsitso ba tlhahiso.

- Likarolo tsa mochini tse joalo ka "screw displacement" le kotsi ea ho koala screw-up.

- Boitšoaro bo qhibilihang le bokhoni ba ho kopanya.

- Ho tsitsa ha ts'ebetso tlas'a maemo a fapaneng.

Ho lumellana ha Lintho

Ho khetha moqomo o nepahetseng ho bolela ho utloisisa hore na o sebelisana joang le lipolasetiki tse fapaneng. Tafole e ka tlase e akaretsa thepa ea bohlokoa le bohlokoa ba eona:

| Thepa ea Lintho | Bohlokoa ba ho tsamaellana le polasetiki ka har'a libarele tse le 'ngoe tsa Screw |

|---|---|

| Thermal Sensitivity | E hloka taolo e hlokolosi ea mocheso le ho hatella butle-butle ho qoba ho senyeha nakong ea extrusion. |

| Hygroscopicity | Lisebelisoa tse monyang mongobo li tlameha ho omisoa pele ho extrusion ho thibela likoli tse kang li-voids kapa ho senyeha. |

| Boima ba Bongata | Lisebelisoa tsa bongata bo tlase li ka baka mathata a phepo 'me li ka hloka likhakanyo tse phahameng tsa khatello kapa meralo e khethehileng ea karolo ea phepelo. |

| Compressibility | Lisebelisoa tse hatellehang haholo li ama phepelo 'me li ka hloka hore ho lokisoe moralo oa li-screw ho netefatsa phallo e tsitsitseng. |

| Qhibiliha Fluidity | E susumetsa bolelele le moepa oa karolo ea khatello; li-polymers tse nang le metsi a phahameng a qhibiliha li ka mamella libaka tse khuts'oane, tse nang le khatello e phahameng haholo. |

| Screw Surface Lubricity | Lubricity e phahameng (mohlala, chrome plating) e thibela thepa ho khomarela le ho khothaletsa phetiso e bonolo ea polasetiki e qhibilihisitsoeng. |

| Ho thatafala | Hoa hlokahala bakeng sa ho hanyetsa ho roala, haholo-holo ha ho etsoa metsoako ea abrasive e nang le likhoele kapa likaroloana tsa khalase. |

| Hlakola | Ho lumellana ho tiileng pakeng tsa screw le barrel ho thibela ho khutla hape ho boloka ts'ebetso e ntle ea tlhahiso. |

Tšireletseho le Bophelo

Ho tšoarella ho lula e le ntho e tlang pele ho bahlahisi. Libarele tsa boleng bo holimo li sebelisa lisebelisoa tse kang tšepe ea nitrided kapa li-alloys tsa bimetallic ho hanela ho hohla le ho bola. Likarolo tsena li lelefatsa bophelo ba ts'ebeletso, haholo ha ho sebetsoa li-plastiki tse tlatsitsoeng kapa tse nchafalitsoeng. Moralo o ntlafalitsoeng oa screw le barrel o boetse o ntlafatsa homogeneity ea ho qhibiliha le ho fokotsa nako, e thusang ho boloka tlhahiso e tsitsitseng le ho theola tšebeliso ea matla.

Tlhokomelo le Bonolo ba Tšebeliso

Tlhokomelo ea kamehla e netefatsa ts'ebetso e tsitsitseng mme e lelefatsa bophelo ba lisebelisoa.

- Ho hloekisa kamehla ho thibela ho bokellana ha thepa le ho boloka ts'ebetso e le holimo.

- Tlhahlobo ea ho taboha le ho taboha e bohlokoa hobane ho khoholeha le ho bola ho eketsa lekhalo lipakeng tsa screw le barrel, ho theola tlhahiso le boleng ba sehlahisoa.

- Tlhokomelo ea li-thrust bearings le litiiso li thibela ho se tsamaisane hantle, ho thothomela le ho lutla.

- Ho tsamaisana hantle le tsitsipano ea sistimi ea koloi ho netefatsa phetisetso e nepahetseng ea matla.

- Calibration ea li-sensor le li-control li boloka taolo e nepahetseng ea ts'ebetso.

Mesebetsi ena e thusa ho fokotsa nako, ho ntlafatsa boleng ba sehlahisoa, le ho ntlafatsa tšebeliso ea matla.

Li-Screw Barrels tse holimo ka ho Fetisisa tsa 2025

Zhejiang Jinteng Single Screw Barrel Review

Zhejiang Jinteng Machinery Manufacturing Co., Ltd. e hlahella e le moetsi ea ka sehloohong indastering ea extrusion ea polasetiki. Khamphani e sebetsatheknoloji e tsoetseng pele ea bimetallicle taolo e tiileng ea boleng ho hlahisa Li-Barrels tsa Single Screw tse fanang ka ts'ebetso e tšepahalang le bophelo bo bolelele ba ts'ebeletso. Likhetho tse nepahetseng tsa ho etsa le ho li etsa li lumella basebelisi ho bapisa libarele le litlhoko tsa bona tse ikhethang tsa extrusion.

| Specification Aspect | Lintlha/Maemo |

|---|---|

| Lisebelisoa tsa Motheo | 38CrMoAlA, 42CrMo, SKD61 |

| Lisebelisoa tsa Bimetallic | Stellite 1, 6, 12, Nitralloy, Colmonoy 56, Colmonoy 83 |

| Ho thatafala ka mor'a ho thatafala le ho halefa | HB280-320 |

| Ho thatafala ha Nitriding | HV850-1000 |

| Alloy Hardness | HRC50-65 |

| Chromium Plating Hardness (post-nitriding) | ≥ 900HV |

| Bokhopo ba Sekaho | Ra 0.4 |

| Screw Sightness | 0.015 limilimithara |

| Botebo ba Alloy | 0.8-2.0 limilimithara |

| Chromium Plating botebo | 0.025-0.10 limilimithara |

| Litšobotsi tse Ikhethang | Theknoloji e tsoetseng pele ea bimetallic, QC e tiileng, ho nepahala, ho iketsetsa, ho paka ka matla, ho fana ka matsatsi a 20-30 |

TheMoqomo o le Mong oa Screwho tsoa ho lisebelisoa tsa Zhejiang Jintenglisebelisoa tsa premium bimetallic, e fanang ka moaparo o babatsehang le ho hanyetsa kutu. Kaho ena e lebisa bophelong bo bolelele ba ts'ebeletso le litšenyehelo tse tlase tsa tlhokomelo. Hangata bareki ba rorisa sehlahiswa ka boleng ba sona, ditheko tse utlwahalang, le tshebeletso ya botsebi. Tsepamiso ea k'hamphani ho tlhahiso e tsoetseng pele le netefatso ea boleng e netefatsa hore moqomo o mong le o mong o kopana le maemo a holimo a indasteri. Likarolo tsena li etsa hore Zhejiang Jinteng Single Screw Barrel e be khetho e holimo bakeng sa lisebelisoa tsa polasetiki tsa extrusion moo ho tšoarellang le ho nepahala ho leng bohlokoa.

Tlhokomeliso: Zhejiang Jinteng e fana ka mokhoa o ikhethileng o ipapisitseng le lits'oants'o tsa bareki, ho netefatsa ho lekana hantle bakeng sa mechini e fapaneng ea extrusion.

Tlhahlobo ea Xaloy X-800 Single Screw Barrel

Xaloy X-800 Single Screw Barrel e sebelisa thepa e tsoetseng pele le boenjineri ho fana ka ts'ebetso e hlahelletseng libakeng tse batlang li feta. Likaroloana tsa Tungsten carbide li qhalakantsoe ka mokhoa o ts'oanang ka har'a matrix ea nickel alloy e thibelang ho bola, e fa moqomo o hanyetsanang ka mokhoa o ikhethang oa ho roala le ho bola. Moralo ona o lumella moqomo hore o sebetsane le lisebelisoa tse thata ho qhibiliha joalo ka HMW-HDPE le LLDPE habonolo.

- Xaloy X-800 e sebetsana le metsoako ea abrasive e tletseng haholo, ho kenyelletsa le tse nang le 25% kapa ho feta fiber fiber kapa mineral fillers.

- Boenjineri bo nepahetseng le mekhoa ea sebōpi e laoloang ke k'homphieutha e netefatsa kabo e tšoanang ea bimetallic carbide.

- Mohaho o se nang moeli, o fihlang ho 6100 mm ka bolelele, o felisa likotsi tsa ho senyeha kapa ho silafala.

- Ts'epe ea tšehetso ea thepa e fokotsa khatello ea maikutlo mme e ntlafatsa ho otloloha nakong ea potoloho ea mocheso.

Basebelisi ba indasteri ba amohela Xaloy X-800 e le maemo a lefats'e bakeng sa libarele tse holang le tse hanang ho bola. Bophelo bo bolelele ba ho sebetsa ha moqomo le li-geometri tsa screw tse ntlafalitsoeng li thusa ho fokotsa mathata a ho qala le ho ntlafatsa ts'ebetso e sebetsang hantle. Boitseanape ba Xaloy, ka lilemo tse fetang 75 tsa theknoloji ea ho lahla le litokelo tse fetang 25, li ts'ehetsa ts'epo le tlhahiso ea Single Screw Barrel ka mefuta e mengata ea lits'ebetso tsa extrusion.

Tlhahlobo ea Nordson BKG Single Screw Barrel

Li-Barrels tsa Nordson BKG Single Screw li etselitsoe libaka tse phahameng tsa tlhahiso. Libarele tsena li tšehetsa tlhahiso e tsitsitseng le phallo e phahameng, e leng se etsang hore e be tse loketseng bakeng sa bahlahisi ba hlokang ts'ebetso e tšepahalang tlas'a maemo a boima.

- Nordson BKG Master-Line ka tlas'a metsi pelletizers e ka sebetsa ho fihlela ho liponto tse 4,400 ka hora.

- Li-hubs tse ncha tsa li-cutter le meralo ea lehare li eketsa ts'ebetso le ho fokotsa ho khathala, ho fokotsa nako le tlhokomelo.

- Screw-resistant screw le lisebelisoa tsa barrel li boloka ts'ebetso leha e na le metsoako e tlatsitsoeng haholo.

- The X8000 screw encapsulation le X800 barrel inlay lisebelisoa li fana ka mokhoa o ikhethang oa ho abrasion le ho hanyetsa ha kutu.

- Sistimi ea Quantum e fokotsa nako ea ho hlaphoheloa ha screw ka liperesente tse 10 ho isa ho tse 15, e ts'ehetsa tlhahiso e potlakileng.

Tsepamiso ea Nordson holim'a thepa e tsoetseng pele le boenjiniere e netefatsa hore Single Screw Barrel ea bona e boloka ts'ebetso le tlhahiso e tsitsitseng. Likarolo tsena li thusa bahlahisi ho fihlela tlhahiso e tsitsitseng, ho fokotsa litšenyehelo tsa tlhokomelo, le ho eketsa tlhahiso.

Tlhahlobo ea Reiloy Wear-Resistant Single Screw Barrel

Reiloy Wear-Resistant Single Screw Barrels e sebelisa li-alloys tse thata le theknoloji e tsoetseng pele ea ho lahla ho fana ka matla a holimo le ho hanyetsa ho bola. Khampani e hlahisa li-powders tsa eona tsa alloy, tse netefatsang boleng bo tsitsitseng le ts'ebetso.

- Libarele tsa Reiloy li na le kaho ea bimetallic e nang le nickel-cobalt kapa li-alloys tse thehiloeng ho nickel tse nang le li-carbide tse kholo le mekhahlelo ea ceramic.

- Lisebelisoa tse kang R121 (tšepe e nang le chrome carbides) le R239/R241 (e thehiloeng ho nickel e nang le tungsten carbides) e fana ka tšireletso e khethehileng bakeng sa lisebelisoa tse fapaneng.

- Teko e matla ea centrifugal le tlhahlobo e matla e tiisa hore libarele ha li na ho sothoa, tse tšoarellang nako e telele.

- Libarele li sebetsa hantle ka lisebelisoa tse hoholang kapa tse senyang, ho kenyeletsoa le lipolasetiki tse nang le fiber ea khalase e fihlang ho 30% kapa litaba tse phahameng tsa liminerale.

- Li-Screw li fumana liphekolo tsa bobeli tse kang hard chrome plating, nitriding, le carbide encapsulation bakeng sa khanyetso e eketsehileng.

Reiloy e rala libarele le li-screw ho ntlafatsa ts'ebetso ea li-resin le lits'ebetso tse ikhethileng. Mokhoa ona o ntlafatsa boleng ba ho qhibiliha, o lelefatsa bophelo ba tšebeletso, 'me o boloka tlhahiso e phahameng, esita le ka thepa e thata.

Lethathamo la Papiso ea Moqomo o le Mong

Feature Overview

Themehlala ea pele ea 2025bonts'a ts'ebetso e matla ea tekheniki le likarolo tse shebaneng le basebelisi. Tafole e ka tlase e totobatsa lintlha tsa bohlokoa le lintlha tsa tšehetso bakeng sa khetho e 'ngoe le e 'ngoe ea Single Screw Barrel:

| Mofuta oa Mohlala | Screw Diameter (mm) | Karolelano ea L/D | Bokhoni ba tlhahiso (kg/hr) | Matla a Enjene (kW) | Litheko (USD) | Tiisetso | Ka mor'a-Thekiso Tšehetso |

|---|---|---|---|---|---|---|---|

| Zhejiang Jinteng | 30-200 | 24:1–36:1 | 10 – 1,500+ | 15-180 | 280 - 1,860 | 12 khoeli. | Theknoloji ea 1-on-1, ea lefats'e ka bophara |

| Xaloy X-800 | 30-200 | 24:1–36:1 | 10 – 1,500+ | 15-180 | 1,000 - 1,800 | 12 khoeli. | Tšehetso ea litsebi, ho fana ka potlako |

| Nordson BKG | 60 - 120 | 33:1–38:1 | 150 - 1,300 | 55 - 315 | 1,200 - 1,860 | 12 khoeli. | Setifikeiti sa CE, tšebeletso e potlakileng |

| Reiloy Wear-Resistant | 30-200 | 24:1–36:1 | 10 – 1,500+ | 15-180 | 1,000 - 1,800 | 12 khoeli. | Moralo o hlophisitsoeng, o netefalitsoeng ke ISO |

Tlhokomeliso: Mefuta eohle e fana ka likarolo tse tsoetseng pele joalo ka libaka tsa phepelo tse grooved, libarele tse kentsoeng, le kopanyo ea servo drive bakeng sa ts'ebetso e ntle le taolo.

Kakaretso ea Melemo le Mathata

Mofuta o mong le o mong oa Single Screw Barrel o tlisa matla a ikhethang ho extrusion ea polasetiki. Tafole e ka tlase e akaretsa melemo le meeli ea mantlha:

| Sebopeho/Sebopeho | Melemo | Mefokolo |

|---|---|---|

| Litšenyehelo | Lisebelisoa tse tlase le litšenyehelo tsa tlhahiso | E sa sebetseng hantle bakeng sa ho kopanya ho rarahaneng |

| Ho Rata Moralo | Moqapi o bonolo, tlhokomelo e bonolo | Ha e feto-fetohe joaloka twin-screwbakeng sa mesebetsi e tsoetseng pele |

| Katleho | E ka tšeptjoa bakeng sa extrusion e tloaelehileng, e sebetsang hantle ka matla | Botsitso ba ho feta bo ka theoha ka lebelo le phahameng |

| Ho Tšoaneleha Kopo | E loketse bakeng sa li-polymer tsa mantlha tsa extrusion le viscous | Ha e loketse ho kopanya mehato e mengata kapa ho nepahala |

| Ka mor'a-Thekiso Tšehetso | Ts'ehetso e matla ea tekheniki le likhetho tsa ho iketsetsa | Nako ea tiisetso e lekanyelitsoe ho likhoeli tse 12 |

Keletso: Basebelisi ba lokela ho bapisa likarolo tsa barrel le litlhoko tsa bona tsa tlhahiso bakeng sa liphetho tse ntle.

Ho Khetha Moqomo o Loketseng o le Mong oa Screw bakeng sa Litlhoko tsa Hao

Bakeng sa Tlhahiso ea Moqolo o Phahameng

Baetsi ba batlang tlhahiso e phahameng ba lokela ho tsepamisa maikutlo ho lintlha tsa tekheniki tse eketsang katleho le ho tšoarella. Lintlha tsa bohlokoa li kenyelletsa bophara ba sekoti, tekanyo ea bolelele-ho-diameter (L/D) le matla a motlakase. Tafole e ka tlase e totobatsa metrics ea bohlokoa bakeng sa extrusion ea molumo o phahameng:

| Metric ea Ts'ebetso | Tlhaloso / Phello |

|---|---|

| Screw Diameter | Li-diameter tse kholo li eketsa bokhoni ba tlhahiso. |

| Karolelano ea L/D | Li-screw tse telele li ntlafatsa ho kopanya le ho futhumatsa, ho tšehetsa tlhahiso e phahameng. |

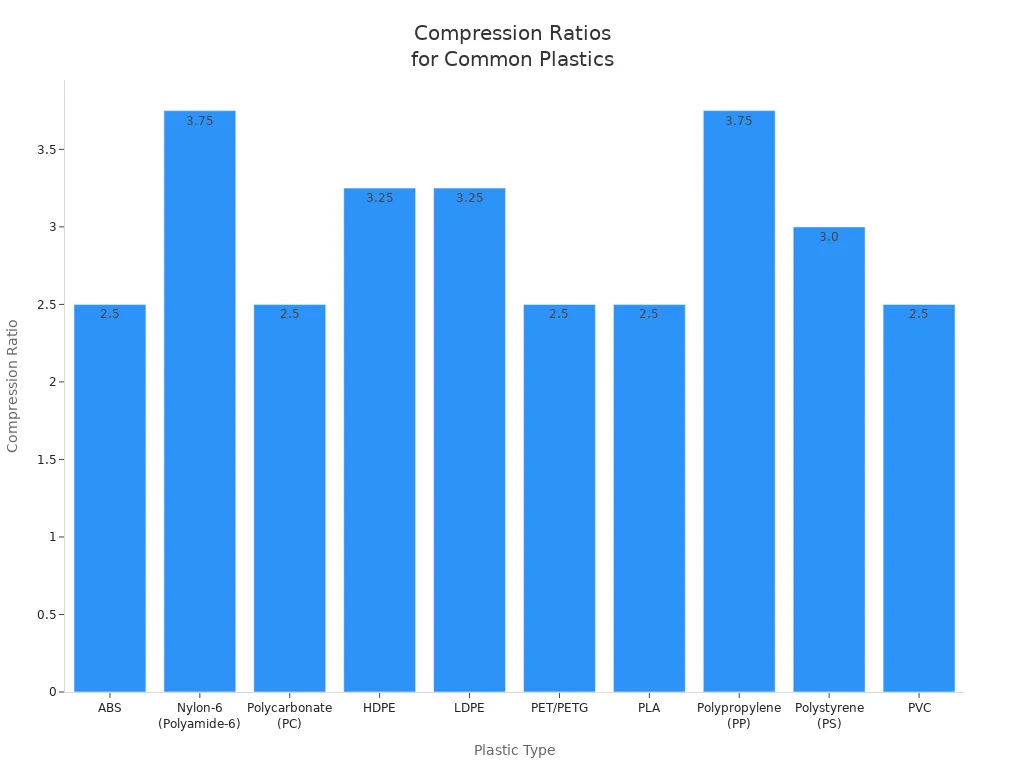

| Compression ratio | E netefatsa polasetiki e felletseng bakeng sa boleng bo tsitsitseng. |

| Botebo ba Groove | E ama ho fetisa le ho kopanya; e tlameha ho leka-lekanya matla le ho tšoana. |

| Lekhalo Pakeng tsa Screw le Barrel | Likheo tse thata li thibela ho lutla le ho boloka botsitso ba khatello. |

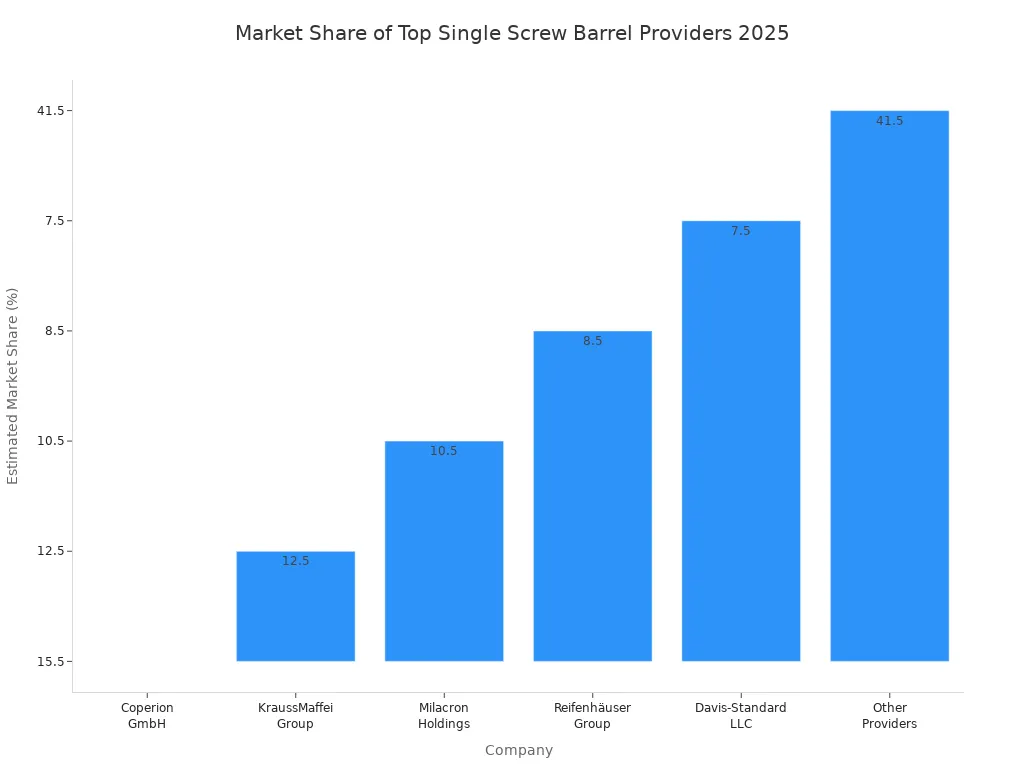

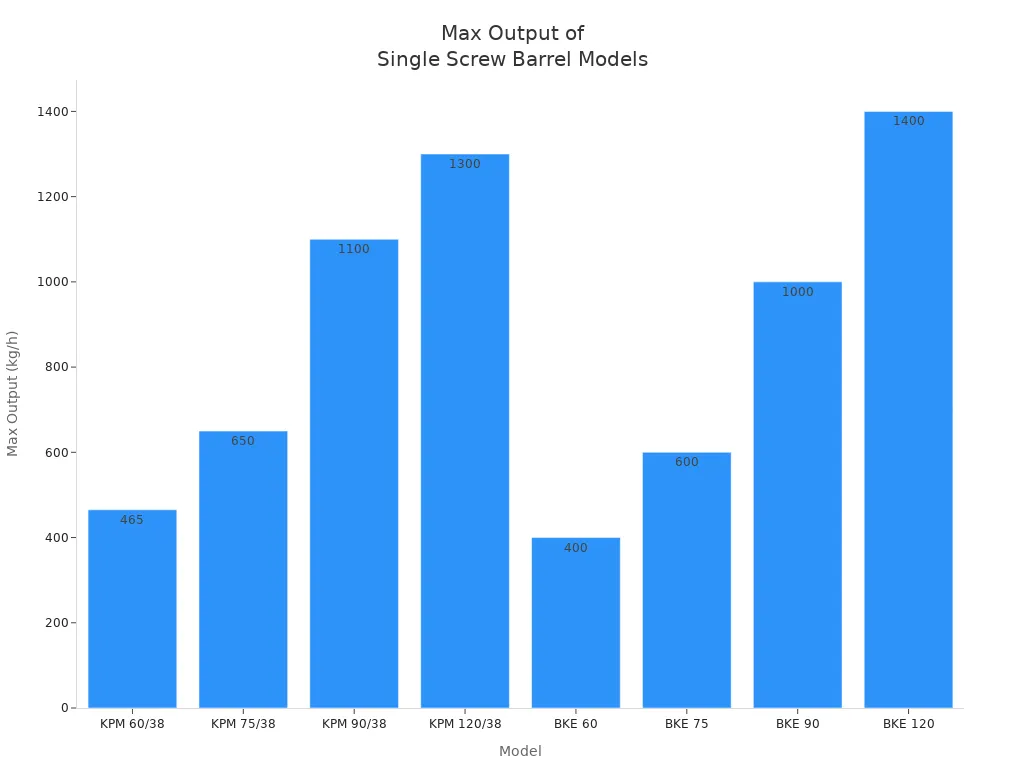

Mefuta e kang KPM 120/38 le BKE 120 e fana ka lihlahisoa tse fihlang ho 1,400 kg/h, e leng se etsang hore e be tse loketseng ts'ebetso e kholo. Lisebelisoa tse tsoetseng pele letaolo e nepahetseng ea mochesoho eketsa ts'epo le nako ea bophelo.

Bakeng sa Lipolasetiki tse khethehileng

Ho sebetsa lipolymers tsa boenjiniere kapa bioplastics ho hloka tlhokomelo e hlokolosi ho thepa ea thepa le moralo oa lisebelisoa. Li-extruder tsa screw tse le 'ngoe li sebetsana le lipolasetiki tse khethehileng tse kang polycarbonate, nylon, le PLA hantle ha li na le meralo e ikhethileng ea sekurufu le taolo e tsoetseng pele ea mocheso. Likhetho tsa metallurgic, tse kang li-alloys tse thibelang kutu, li thibela tšenyo ea lisebelisoa le ho netefatsa boleng ba sehlahisoa. Basebelisi ba tlameha ho hlokomela mocheso lelebelo la sekotihaufi-ufi ho qoba tshenyeho kapa mefokolo. Tlhokomelo ea kamehla le ts'ebetso e nang le boiphihlelo e thusa ho rarolla mathata a kang ho qhibiliha ho sa tsitsang kapa ho feto-fetoha ha khatello.

Keletso: Sebelisana 'moho le barekisi ba lisebelisoa ho etsa tlhophiso ea screw le barrel bakeng sa lisebelisoa tse bobebe kapa tse ikhethang.

Bakeng sa Bareki ba Hlokomelang Lichelete

Litharollo tsa extrusion tse baballang litšenyehelo hangata li itšetleha ka bonolo le ho feto-fetoha ha li-scruder tse le 'ngoe. Mechini ena e fana ka matsete a tlase a pele le litšenyehelo tse fokotsehileng tsa tlhokomelo ha li bapisoa le litsamaiso tse peli tsa screw. Thepa e sebelisitsoeng e tsoang mefuteng e tsebahalang e ka fokotsa litšenyehelo ntle le ho tela ho tšepahala. Moralo o otlolohileng o ts'ehetsa mefuta e mengata ea lits'ebetso, ho kenyeletsoa liphaephe, lifilimi le maqephe, e leng se etsang hore e be khetho e sebetsang bakeng sa likhoebo tse nang le lichelete tse fokolang.

- Li-extruder tsa screw tse le 'ngoe lia theko e tlaase ebile ho bonolo ho li hlokomela.

- Mechini e sebelisitsoeng e fana ka chelete e eketsehileng.

- Mefuta e fapaneng e tšehetsa litlhoko tse fapaneng tsa tlhahiso.

Tlhahlobo e hlokolosi ea katleho, boleng, le litšenyehelo tsa nako e telele li netefatsa boleng bo botle ba ts'ebetso e amanang le tekanyetso.

Thelibarele tse holimo tsa extruder bakeng sa 2025fana ka botšepehi, ho boloka matla, le bophelo bo bolelele ba tšebeletso. Basebelisi ba phahameng ba rua molemo ho tsoa ho meralo e matla le litaolo tse tsoetseng pele. Li-processor tse khethehileng li lokela ho khetha libarele tse nang le boenjiniere ba tloaelo leliaparo tse tšoarellang. Bareki ba shebaneng le litekanyetso tsa lichelete ba rua molemo ho tsoa likhethong tse bonolo, tsa tlhokomelo e tlase. Basebelisi ba lokela ho bapisa likarolo tsa lisebelisoa le litlhoko tsa bona tsa tlhahiso.

LBH

Molemo o ka sehloohong oa sekoti se le seng ka har'a extrusion ea polasetiki ke ofe?

Libarele tse le 'ngoe tsa screw li fana ka ts'ebetso e tšepahalang, tlhokomelo e bonolo, le ts'ebetso ea litšenyehelo. Li sebetsa hantle bakeng sa lisebelisoa tse ngata tse tloaelehileng tsa polasetiki.

Ke hangata hakae basebetsi ba lokelang ho hlahloba barrel e le 'ngoe ea screw bakeng sa ho roala?

Basebelisi ba lokela ho hlahloba moqomo ka mor'a likhoeli tse ling le tse ling tse tharo ho isa ho tse tšeletseng. Licheke tsa kamehla li thusa ho boloka boleng ba lihlahisoa le ho lelefatsa nako ea bophelo ba lisebelisoa.

Na sekoti se le seng se ka sebetsana le mefuta e fapaneng ea polasetiki?

Ee. Bahlahisi ba rala libarele tse le 'ngoe tsa screw ho sebetsana le mefuta e mengata ea polasetiki, ho kenyeletsoaPVC, PE, PP, le li-polymer tse khethehileng.

Nako ea poso: Jul-18-2025