Li-screws tse peli tsa conical li bohlokoa tlhahisong ea liphaephe tsa PVC, moo ho nepahala le ho sebetsa hantle li leng bohlokoa. Tlhokahalo ea lefats'e ea likarolo tsena tse ikhethileng, ho kenyeletsoa sekoti sa conical twin bakeng sa pipe ea PVC, e totobatsa bohlokoa ba tsona.

- Mmaraka oa Counter Rotating Twin-screw Extruder ho hakanngoa hore e tla hola ho tloha ho $ 1.2 bilione ka 2024 ho isa ho $ 2.5 billion ka 2033, ka CAGR e tsotehang ea 8.9%.

- Keketseho ea tlhahiso ea thepa ea kaho, haholo tikolohong ea Asia-Pacific, e tsamaisa tlhokahalo ena e ntseng e eketseha.

Mekhoa e mecha ea sejoale-joale, joalo kaLi-screws tsa PVC tsa conical, ntlafatsa homogeneity ea lintho tse bonahalang le ho fokotsa litekanyetso tsa ho kuta, ho netefatsa extrusion e tsitsitseng. Lintlafatso tsena li fana ka tlhoko e ntseng e hola ea litharollo tsa ts'ebetso e phahamengPVC phala tlhahiso parallel twin screwlitsamaiso, ho kenyelletsalibarele tse peli tse tšoanang tsa screw.

Kakaretso ea Conical Twin Screw Bakeng sa Pipe ea PVC

Moralo le Tshebetso

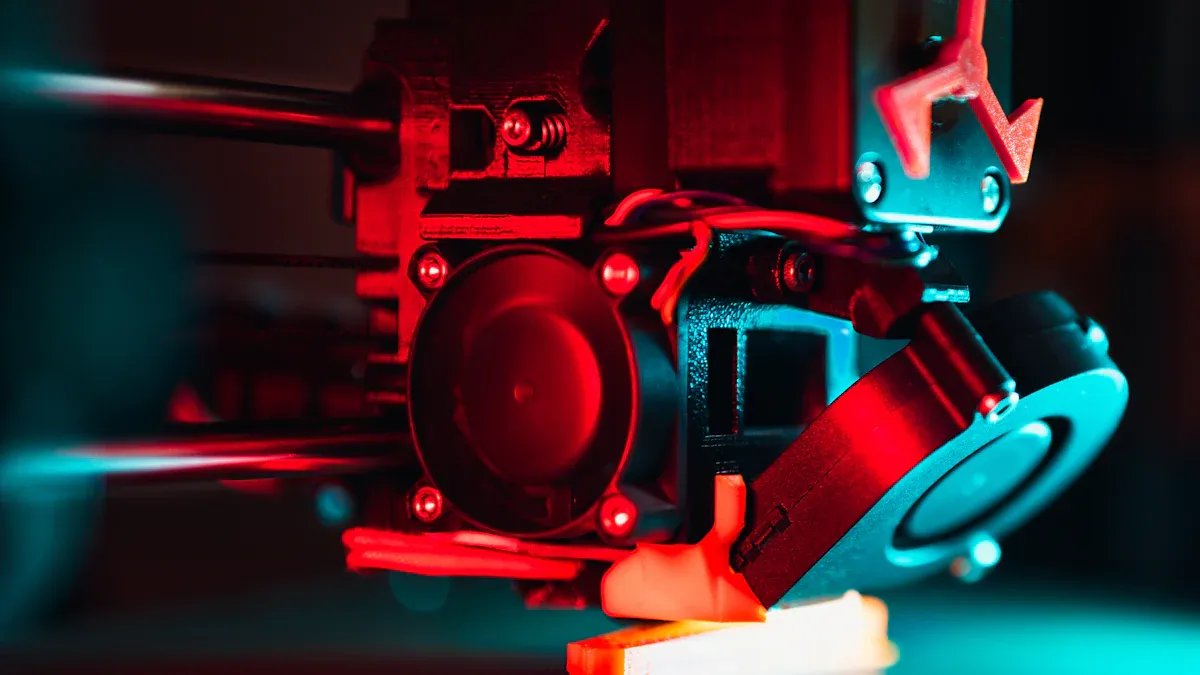

Li-extruder tsa conical twin screw li bapala karolo ea bohlokoa tlhahisong ea lipeipi tsa PVC ka ho ntlafatsa ts'ebetso ea ts'ebetso ea thepa. Moqapi oa bona o shebane le ho finyella ho kopanya ho holimo le homogenization, tse bohlokoa bakeng sa ho hlahisa liphaephe tsa boleng bo phahameng. Litsamaiso tsena li hatella le ho qhibilihisa lisebelisoa tse tala, ho netefatsa hore polasetiki e sa fetohe. Li-screw li na le litlhophiso tse ntlafalitsoeng, ho kenyeletsoa taolo e nepahetseng ea mocheso le khatello, ho boloka ho tšoana ho sehlahisoa sa ho qetela.

Ts'ebetsong, moralo oa conical twin screw o totobatsa lebelo le laoloang la screw le kabo ea torque. Sena se etsa bonnete ba ho hasana ka katleho ha li-additives, ho fella ka 'mala o ts'oanang le botsitso ba sebopeho. Bokhoni ba ho sebetsana le lits'ebetso tse hlahisoang haholo ha u ntse u boloka boleng ba sehlahisoa bo etsa hore li-extruder tsena e be tsa bohlokoa haholo tlhahisong ea sejoale-joale.

Likopo ho PVC Pipe Manufacturing

Litsamaiso tsa conical twin screw li fana ka litlhoko tse fapaneng tsa tlhahiso ea liphaephe tsa PVC. Ho ikamahanya le maemo ho lumella bahlahisi ho fetola li-diameter tsa barrel, ho ntlafatsa litekanyetso tsa tlhahiso le boleng ba ho qhibiliha. Mekhoa ea morao-rao ea ho laola e kopantsoeng le li-extruder tsena e laola mocheso, khatello le lebelo, ho tiisa hore ho na le liphello tse tsitsitseng.

| Karolo ea Kopo | Tlhaloso |

|---|---|

| Phetoho ea Diameter ea Barrel | Ho ntlafatsa bophara ba "screw" ho eketsa litekanyetso tsa tlhahiso le boleng ba ho qhibiliha, bo etselitsoeng litlhoko tsa lipeipi tsa PVC. |

| Ho kopanngoa ha Mekhoa ea Mehleng ea Kajeno ea Taolo | Litaolo tsa sejoale-joale li laola mocheso, khatello, le lebelo, li netefatsa boleng bo tsitsitseng ba sehlahisoa. |

| Tlhokomelo nakong ea Tlhahiso | Tlhokomelo e haufi ea maemo a ts'ebetso e thusa ho hlahisa liphaephe tsa boleng bo holimo tsa PVC. |

Likarolo tsena li etsa hore li-screws tsa conical e be khetho e tšepahalang bakeng sa bahlahisi ba ikemiselitseng ho fihlela litekanyetso tse thata tsa boleng.

Melemo ea Moqapi oa Conical

Themoralo oa conical o fana ka melemo e mengataholim'a litsamaiso tse tloaelehileng tsa screw. E etsa bonnete ba polasetiki e ts'oanang le ho kopanya, tse bohlokoa bakeng sa boleng bo tsitsitseng ba sehlahisoa. Moqapi o tšehetsa tlhahiso e phahameng ea lihlahisoa, e etsa hore e tšoanelehe bakeng sa ts'ebetso e kholo.

| Molemo/Molemo | Tlhaloso |

|---|---|

| Uniform plasticization le ho kopanya | E netefatsa boleng bo tsitsitseng sehlahisoa sa ho qetela. |

| Phaello e phahameng | E khona ho hlahisa bongata bo boholo ba thepa e fetisitsoeng hantle. |

| Boleng bo tsitsitseng | E boloka boleng ba sehlahisoa ha nako e ntse e ea, e fokotsa ho fetoha. |

| Ho ikamahanya le maemo ho pharaletseng | E ka sebetsana le mefuta e fapaneng ea thermoplastics, haholo-holo phofo e thata ea PVC. |

| Bophelo bo bolelele ba tšebeletso | E etselitsoe hore e tšoarelle nako e telele, e lebisang ho theola litšenyehelo tsa ho nchafatsa. |

| Ho bopa ka kotloloho ea phofo ea PVC | E lumella tlhahiso ea hang-hang ea lihlahisoa tsa polasetiki ntle le mehato e eketsehileng ea ho sebetsa. |

| Ts'ebetso e ntle ea polasetiki | E qhibilihisa ka katleho le ho kopanya lisebelisoa bakeng sa extrusion e nepahetseng. |

| Matla a extrusion a matle | E khona ho sebetsana le likhatello tse phahameng nakong ea ts'ebetso ea extrusion. |

Melemo ena e totobatsa hore na hobaneng sekoti sa conical twin bakeng sa pipe ea PVC e ntse e le khetho e ratoang ke baetsi lefatšeng ka bophara. Bokhoni ba eona ba ho fana ka ts'ebetso e tsitsitseng, ho tšoarella, le ho ikamahanya le maemo ho netefatsa bohlokoa ba eona ka 2025 le ho feta.

Likarolo le Litlhaloso Tse Molemo Tsa ho Khanna

Plasticizing Performance le Material Homogeneity

Ts'ebetso ea polasetiki ea li-screws tsa mafahla a conical e netefatsa hore lisebelisoa tsa PVC lia qhibiliha le ho tsoakoa ka mokhoa o ts'oanang. Ts'ebetso ena e bohlokoa bakeng sa ho hlahisa liphaephe tse nang le boleng bo tsitsitseng le botšepehi ba sebopeho. Moralo o tsoetseng pele oa screw o ntlafatsa homogeneity ea thepa ka ho holisa bolelele ba screw e sebetsang, e fokotsang sekhahla sa ho hana le ho ntlafatsa katleho ea tlhahiso ka kakaretso.

Keletso: Ho kopanya lintho tse homogeneous ho fokotsa liphoso sehlahisoa sa ho qetela, ho netefatsa hore liphaephe li finyella litekanyetso tse thata tsa indasteri.

Ho kopanngoa ha taolo ea torque e tobileng ho ntlafatsa le ho feta polasetiki. Ka ho boloka screw RPM e sa feleng, tšobotsi ena e fokotsa phapang ea tlhahiso le tšenyo ea thepa. Ho feta moo, lisebelisoa tsa ho futhumatsa li-screw ka hare li fana ka taolo e nepahetseng ea mocheso, e ntlafatsang boleng ba ho qhibiliha le ho netefatsa liphetho tse tsitsitseng tsa extrusion.

| Sebopeho | Molemo |

|---|---|

| Bokhoni ba Tlhahiso e Phahameng | E etsa hore liphaephe tse ngata li hlahisoe ka potlako, li fihlelle linako tse behiloeng ntle le boleng ba boleng. |

| E ntlafalitsoeScrew Design | E hlahisa bolelele bo bolelele bo sebetsang ba screw, e hlahisang homogeneous ho qhibiliha le ho fokotsa litekanyetso tsa ho lahloa. |

| Taolo ea Torque e otlolohileng | E netefatsa RPM e sa khaotseng, e fokotsa ho fapana ha boleng le ho fokotsa tšenyo. |

| Pholiso ea ka Hare Screw | E fana ka taolo e nepahetseng holim'a mocheso oa ho qhibiliha, ho ntlafatsa boleng ba liphaephe le ho netefatsa tlhahiso e tsitsitseng. |

Matla a Matla le Matlafatso ea Matla

Matla a matla ke ntlha ea bohlokoa ho phalloeng ea lipeipi tsa PVC tsa sejoale-joale. Li-screws tse peli tsa conical li sebetsa hantle sebakeng sena ka ho kenyelletsa lisebelisoa tsa ho khanna tse baballang matla. Litsamaiso tsena li fana ka ts'ebetso e ikhethang ha li ntse li sebelisa matla a fokolang, li fokotsa litšenyehelo tsa ts'ebetso le phello ea tikoloho.

The optimized screw geometry e fokotsa tahlehelo ea matla nakong ea ts'ebetso ea extrusion. Moqapi ona o etsa bonnete ba hore matla a mechine a fetoha ka katleho matla a mocheso, a bohlokoa bakeng sa ho qhibiliha thepa ea PVC. Ho feta moo, bokhoni ba ho sebetsa ka mocheso o tlase bo fokotsa tšebeliso ea matla ntle le ho senya boleng ba sehlahisoa sa ho qetela.

Hlokomela: Mekhoa e sebetsang hantle ea matla ha e fokotse litšenyehelo feela empa e lumellana le lipakane tsa ts'ebetso ea lefats'e, e leng se etsang hore e be khetho e ratoang ke bahlahisi.

Ho ikamahanya le maemo ho liforomo tsa PVC le boholo ba Pipe

Li-screws tse peli tsa conicalbonts'a ho feto-fetoha ho tsotehang ha ho sebetsana le libopeho tse fapaneng tsa PVC le boholo ba liphaephe. Moralo oa bona o amohela mefuta e fapaneng ea letsoalo le leholo, e sebetsa joalo ka pompo ea lisebelisoa tsa phepelo e nepahetseng. Bokhoni bona bo netefatsa litefiso tse sa fetoheng tsa tlhahiso, leha boima ba resin ea PVC bo fetoha.

Baetsi ba rua molemo ho tsoa ho likarolo tse kang li-screw cores le meralo ea li-gearbox, tse lumellang maemo a fapaneng a makoloi. Sistimi ea ho futhumatsa meqomo e fana ka maemo a bonolo ka ho koahela mefuta e mengata e fapaneng ea liphetho, e etsa hore lisekere tsena li tšoanele litlhoko tse fapaneng tsa tlhahiso.

| Sebopeho | Tlhaloso |

|---|---|

| Screw Core | E lumellana le litsamaiso tsohle tsa screw tempering. |

| Moqapi oa Gearbox | E lumella maemo a 'maloa a fapaneng a makoloi (mofuta oa U kapa Z). |

| Sistimi ea ho futhumatsa moqomo | Li-processor li ka khetha pakeng tsa litsamaiso tse fapaneng, tse koahelang mefuta e mengata ea liphetho. |

| Matla a Khatello ea Ts'ebetso | E ka sebetsa ka likhatello ho fihla ho 520 bar (7500 psi), e loketseng li-profiles tse nyane kapa tse tšesaane. |

| Ho Hloekisa ka Potlako | Linako tse fokolang tsa bolulo li nolofalletsa ho fetoha ha mebala ka potlako, ho boloka thepa. |

Ho feta moo, li-screws tse peli tsa conical li sebelisa matla a fokolang ha li bapisoa le li-extruder tsa screw e le 'ngoe bakeng sa litefiso tse tšoanang tsa tlhahiso. Bokhoni bona, bo kopantsoeng le ho ikamahanya le maemo, bo ba etsa khetho e nepahetseng bakeng sa bahlahisi ba ikemiselitseng ho hlahisa liphaephe tsa boleng bo holimo tsa PVC ka boholo le libopeho tse sa tšoaneng.

Tsoelo-pele ho Moralo oa Conical Twin Screw bakeng sa 2025

Litlhahiso ho Lisebelisoa tsa Screw le Geometry

Tsoelo-pele ea morao-rao ea lisebelisoa tsa screw le geometry e fetotse ts'ebetso le ho tšoarella ha li-screw tse mafahla. Baetsi ba sebelisa theknoloji ea morao-rao ho ntlafatsa ts'ebetso le ho ikamahanya le maemo ha likarolo tsena. Litlhahiso tsa bohlokoa li kenyelletsa:

- Tšebeliso ea lisebelisoa tse tsoetseng pele tse bobebe, tse tšoarellang nako e telele, le tse hanyetsanang le ho bola, tse netefatsang bophelo bo bolelele ba tšebeletso le ho fokotsa litšenyehelo tsa tlhokomelo.

- Ho kopanngoa ha mahlale a bohlale bakeng sa ho lekola nako ea sebele le liphetoho nakong ea tlhahiso, ho ntlafatsa taolo ea tšebetso ka kakaretso.

- Kamohelo ea theknoloji ea khatiso ea 3D bakeng sa prototyping e potlakileng le tlhahiso ea lijeometri tse rarahaneng, tse nang le monyetla oa ho fokotsa litšenyehelo tsa tlhahiso ka 90%.

- Meetso ea modular e lumellang ho itloaetsa ho hoholo, e nolofalletsang bahlahisi ho fihlela litlhoko tse fapaneng tsa tlhahiso habonolo.

Lintlafatso tsena ha li ntlafatse ts'ebetso eali-screws tse peli tsa conicalempa hape e ikamahanye le tlhokahalo e ntseng e hola ea litharollo tsa tlhahiso ea moshoelella le tse baballang chelete e ngata. Ka ho kenyelletsa mekhoa ena e mecha, bahlahisi ba ka finyella litekanyetso tse phahameng tsa tlhahiso le boleng bo botle ba sehlahisoa, ho etsa hore sekoti sa conical twin bakeng sa pipe ea PVC e be khetho e ratoang indastering.

Ho kopanngoa ha Smart Control Systems

Ho kopanngoa ha litsamaiso tse bohlale tsa taolo ho meralo ea conical twin screw ho ntlafalitse tlhahlobo le ts'ebetso ea tlhahiso haholo. Lits'ebetso tse bohlale tsa ho lekola ts'ebetso hona joale li sebelisa mahlale a tsoetseng pele a tekanyo le mefuta ea AI ho ntlafatsa lits'ebetso tsa extrusion. Litsamaiso tsena li sekaseka mefuta ea litšitiso ka nako ea nnete, li fana ka pono ea litekanyo tse kahare ka li-dashboards tse bonolo tsa basebelisi.

Mohlala, ho khutlisetsa li-screw press tse seng li ntse li le teng ka theknoloji ea ho beha leihlo ka bohlale ho bonts'itse ntlafatso e makatsang ts'ebetsong. Ka ho sebelisa mekhoa ea ntlafatso e hlophisitsoeng e kang CRISP-DM, bahlahisi ba ka tseba le ho sebetsana le ho se sebetse hantle mosebetsing oa tlhahiso. Mokhoa ona o netefatsa boleng bo tsitsitseng ba tlhahiso ha o ntse o fokotsa litšila tsa thepa.

Sistimi ea taolo e bohlale e boetse e thusa litokiso tse nepahetseng ho mocheso, khatello le lebelo la sekoti, ho netefatsa hore polasetiki e ntle le homogeneity ea thepa. Likarolo tsena li etsa hore li-screws tsa sejoale-joale tsa conical e be tsa bohlokoa bakeng sa bahlahisi ba ikemiselitseng ho fihlela litekanyetso tse thata tsa tlhahiso ea liphaephe tsa PVC.

Mekhoa ea Indasteri e Behang Meralo ea Bokamoso

Bokamoso ba meralo ea conical twin screw bo ntse bo bōptjoa ke mekhoa e mengata ea bohlokoa ea indasteri. Litloaelo tsena li bonts'a litlhoko tse ntseng li tsoela pele tsa bahlahisi le bareki, hammoho le tsoelo-pele ea theknoloji le botsitso.

| Tloaelo | Tšusumetso ho Meetso ea Conical Twin Screw |

|---|---|

| Moshoelella | Keketseho e ntseng e eketseha ea lisebelisoa tse ka senyehang, e lebisang tlhophisong ea meralo bakeng sa ho sebetsana le li-polymers tse sebetsang hantle. |

| Boiketsetso | Ho kopanngoa ha mechini e tsoetseng pele ho ntlafatsa mela ea tlhahiso, ho ntlafatsa tlhahiso le boleng ba sehlahisoa. |

| Boikemisetso | Moralo oa modular o lumella liphetoho tse potlakileng ho li-parameter tsa ts'ebetso, ho fana ka likhetho tse ikhethang tsa bareki. |

| Digitalization | Litlhahlobo tse ntlafalitsoeng tsa data bakeng sa tlhahlobo ea ts'ebetso ea nako ea nnete, ho ntlafatsa ho etsa liqeto le ho pepeseha ha tlhahiso. |

| Khōlo ea 'Maraka | CAGR e reriloeng ea ho feta 6% lilemong tse hlano tse tlang, e susumetsoang ke matsete ho R&D bakeng sa ts'ebetso le ts'ebetso. |

Litloaelo tsena li totobatsa bohlokoa ba popontshwa le ho feto-fetoha ha moralo oa li-screws tse peli tsa conical. Ka ho amohela lichifi tsena, bahlahisi ba ka lula ka pele ho tlholisano mme ba fihlela tlhoko e ntseng e eketseha ea liphaephe tsa boleng bo holimo tsa PVC.

Li-screws tse peli tsa conical li lula li le bohlokoa ho extrusion ea pipe ea PVC, ho netefatsa ts'ebetso le boleng. Tsa bonalikarolo tse tsoetseng pele, joalo ka ho ntlafatsa matla le ho ikamahanya le maemo, ho khanna tlhahiso ea indasteri. Lintlafatso tsa morao-rao tsa litsamaiso tse bohlale le meralo e tšoarellang li li beha e le lisebelisoa tsa bohlokoahali. Li-screw tsena li tla tsoela pele ho theha bokamoso ba tlhahiso ea PVC e sebetsang hantle.

LBH

Ke eng e etsang hore li-screws tse peli tsa conical li tšoanelehe bakeng sa extrusion ea pipe ea PVC?

Li-screws tsa conical li fana ka polasetiki e phahameng, ho kopanya thepa e sa fetoheng, le tlhahiso e phahameng. Ho ikamahanya le maemo ho mefuta e fapaneng ea li-PVC ho netefatsa tlhahiso e sebetsang hantle le ea boleng bo holimo.

Litsamaiso tse bohlale tsa taolo li ntlafatsa mekhoa ea extrusion joang?

Sistimi ea taolo e bohlale e ntlafatsa mocheso, khatello le lebelo la screw. Li ntlafatsa homogeneity ea thepa, li fokotsa litšila, 'me li netefatsa boleng bo tsitsitseng ba sehlahisoa ka ho beha leihlo le ho lokisa ka nako ea nnete.

Hobaneng ho sebetsa hantle ha matla ho le bohlokoa ho meralo ea conical twin screw?

Meralo e baballang matla e theola litšenyehelo tsa ts'ebetso le phello ea tikoloho. Optimized screw geometry le li-drive tse tsoetseng pele li fokotsa tšebeliso ea matla ha li ntse li boloka ts'ebetso e phahameng ea extrusion.

Nako ea poso: Apr-24-2025