Li-fin screw extrudersphetha karolo ea bohlokoa tlhahisong ea sejoale-joale ka ho netefatsa mekhoa ea tlhahiso e sebetsang hantle le e baballang chelete e ngata. Moqapi oa bona o tsoetseng pele o thusa bahlahisi ho finyella lihlahisoa tse phahameng ha ba ntse ba fokotsa litšila le tšebeliso ea matla.

- Mmaraka oa lefats'e oa "twin screw extruder" o fihlile ho $ 1,128.1 milione ka 2022.

- Ho hakanngoa hore e tla hola ho $ 1,649.5 milione ka 2031.

- Mmaraka o ntse o hola ho CAGR e tsitsitseng ea 4.5%, e totobatsang tlhoko ea bona e ntseng e eketseha.

Mechini ena, ho kenyeletsoa metjhini e kopanyang li-screw le lithapo tse peli tsa screw extrusion, e fana ka nako e telele e ke keng ea lekanngoa le ho ikamahanya le maemo, e etsa hore e be tsa bohlokoa haholo indastering lefatšeng ka bophara. Ho feta moo, mechini ea extrusion ea li-tube e eketsa bokhoni ba tlhahiso, e tiisa bohlokoa ba mahlale a marang-rang lefapheng la tlhahiso.

Ho utloisisa Twin Screw Extruders

Li-Twin Screw Extruders ke Life?

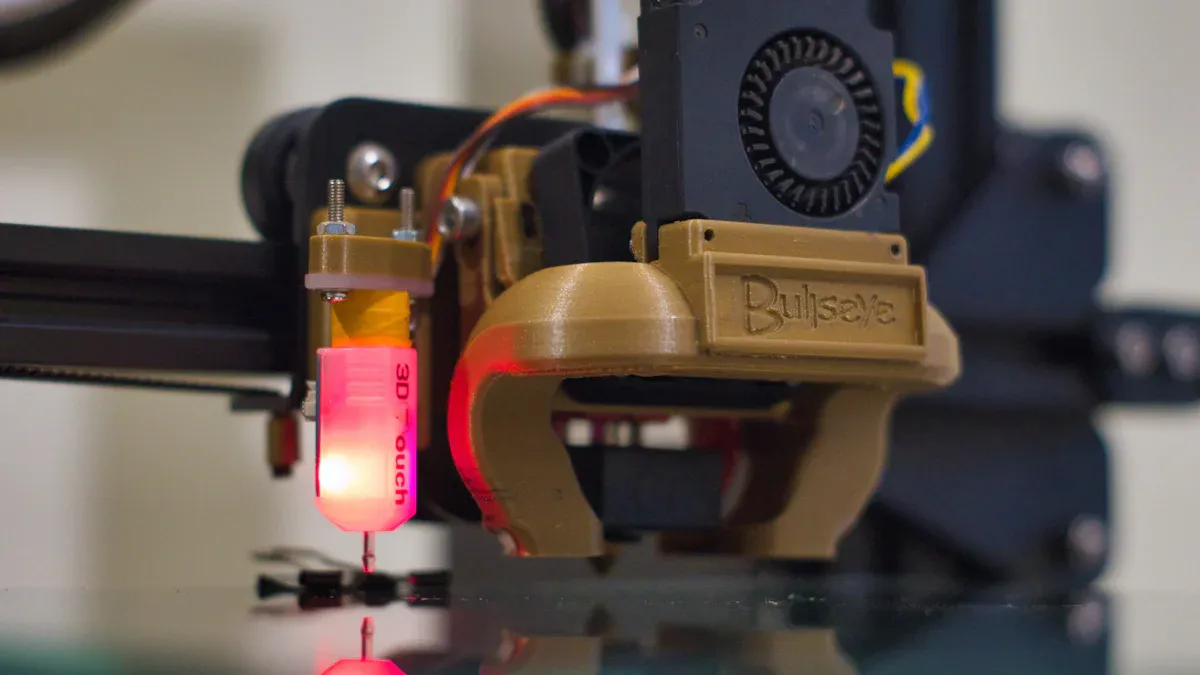

Twin screw extruders ke mechini e tsoetseng pele e etselitsoeng ts'ebetso e tsoelang pele ea lisebelisoa. Li na le li-screw tse peli tsa intermeshing tse kentsoeng ka har'a moqomo. Li-screws tsena lia potoloha ho fetisa, ho kopanya, le ho sebetsa thepa hantle. Likarolo tsa sebopeho li kenyelletsa mainframe, lebokose la li-gearbox, sisteme ea lubrication, sistimi ea metsi a pholileng, sistimi ea vacuum le sistimi ea phepelo. Li-screws li entsoe ka thepa e tšoarellang joalo ka tšepe ea nitriding, e netefatsang ts'ebetso ea nako e telele. Libarele li etselitsoe ho nkeloa sebaka habonolo le tlhokomelo, e leng ho ntlafatsang ts'ebetso e sebetsang hantle.

Moralo oa li-scruder tse mafahla o netefatsa hore ho na le li-axial le radial clearances tse nepahetseng. Ho nepahala hona ho ntlafatsa boleng ba ts'ebetso le ho fokotsa litšila tsa thepa. Ho feta moo, metjhini e ka amohela libaka tse ngata tsa phepelo, e etsa hore e tšoanelehe bakeng sa ho sebetsana le lisebelisoa libakeng tse fapaneng. Ho ikamahanya le maemo le kaho e matla li etsa hore e be motheo oa tlhahiso ea morao-rao.

Li-Twin Screw Extruders li sebetsa Joang?

Li-extruder tse peli tsa screw li sebetsa ka motsoako oa mekhoa ea mechine le ea mocheso. Li-screws li potoloha ka har'a barrel ho fetisa, ho kopanya, ho qhibiliha le ho etsa lisebelisoa tsa homogenize. Karolo e 'ngoe le e' ngoe e phetha karolo ea bohlokoa ho finyella ts'ebetso e nepahetseng.

| Karolo | Mosebetsi |

|---|---|

| Moqomo le Screw | Potoloha ho fetisa, ho kopanya, ho qhibilihisa, le ho etsa lisebelisoa tsa homogenize; e etselitsoeng litlhoko tse khethehileng tsa ho sebetsa. |

| Sistimi ea ho khanna | Matla le litsamaiso ho potoloha ha screw, ho netefatsa katleho le boleng ts'ebetsong ea extrusion. |

| Gearbox | E fetola phapang ea lebelo la screw, e susumetsang ho kuta, ho kopanya, le liketso tsa ho luba. |

| Taolo le Tlhokomelo | E lumella ho beha leihlo le ho lokisoa ha liparamente joalo ka lebelo la screw le profaele ea mocheso. |

Sistimi ea phepelo e feto-fetohang e etsa hore ho be le taolo e nepahetseng holim'a ho kenya thepa, ho netefatsa boleng bo tsitsitseng ba tlhahiso. Sistimi ea taolo e tsoetseng pele e beha leihlo liparamente tse joalo ka lebelo la screw le thempereichara, e lumellang basebelisi ho hlophisa tšebetso hantle. Boemo bona ba taolo bo netefatsa ts'ebetso e nepahetseng le ho fokotsa tšebeliso ea matla.

Lisebelisoa tsa Bohlokoa ho Tlhahiso

Twin screw extruder ke metjhini e feto-fetohang e sebelisoang liindastering tse fapaneng. Holefapha la polasetiki, li bohlokoa bakeng sa ho hlahisa lihlahisoa tsa boleng bo holimo tse kang liphaephe, lifilimi, le litlaleho. Indasteri ea meriana e itšetlehile ka mechini ena bakeng sa granulation e tsoelang pele ea metsi, ho kopanya boima ba gelatin e metsi, le ho theha li-dispersions tse tiileng tsa amorphous ho ntlafatsa ho qhibiliha ha lithethefatsi. Li boetse li phetha karolo ea bohlokoa ho kenya lithethefatsi ka har'a li-polymer bakeng sa lisebelisoa tse tsamaisang lithethefatsi.

| Kopo | Boholo ba Mmaraka (2025) | CAGR (%) |

|---|---|---|

| Lihlahisoa tsa polasetiki | limilione tse XX | XX% |

| Lijo le Fepa Extrusion | limilione tse XX | XX% |

| Meriana ea meriana | limilione tse XX | XX% |

Ho ikamahanya le maemo ha li-extruder tsa mafahla ho lumella bahlahisi ho sebelisa lisebelisoa tse tšoanang bakeng sa lipatlisiso le tlhahiso. Scalability ena e ba etsa khetho e nepahetseng bakeng sa liindasteri tse hlokang ho tenyetseha le ho sebetsa hantle. Bokhoni ba bona ba ho sebetsana le lisebelisoa le lits'ebetso tse fapaneng bo netefatsa bohlokoa ba bona bo tsoelang pele tlhahisong ea sejoale-joale.

Theko-Katleho ea Twin Screw Extruders

Tšebeliso e Ntle ea Matla le Litšila tse Fokotseng

Li-extruder tse peli tsa screw li ipabola ka ho sebetsa hantle ha matla, ho li etsa atharollo e theko e boima bakeng sa bahlahisi. Moralo oa bona o tsoetseng pele o fokotsa ts'ebeliso ea matla ka ho ntlafatsa ts'ebetso ea mochini le mocheso o amehang ho phatloheng ha thepa. Li-screws tsa intermeshing li netefatsa phallo e tsitsitseng ea thepa, e fokotsa tlhokahalo ea ho kenya matla a feteletseng. Ho feta moo, litsamaiso tse nepahetseng tsa taolo li lumella basebelisi ho hlophisa liparamente hantle joalo ka mocheso le lebelo la screw, e leng ho ntlafatsang ho boloka matla.

Phokotso ea litšila ke molemo o mong oa bohlokoa. Bokhoni bo sebetsang ba ho kopanya le homogenization ba li-screw extruder tse peli bo netefatsa tahlehelo e nyane ea thepa nakong ea ts'ebetso. Ka ho boloka boleng bo sa fetoheng ba tlhahiso, mechini ena e fokotsa tlhoko ea ho sebetsa bocha kapa ho lahla, ho boloka nako le lisebelisoa. Liindasteri tse etelletsang pele botsitso li rua molemo haholo tšobotsing ena, kaha e ikamahanya le merero ea tsona ea tikoloho ha e ntse e fokotsa litšenyehelo tsa ts'ebetso.

Keletso:Ho tsetela ho lisebelisoa tse baballang matla joalo ka li-twin screw extruder ha ho theole feela likoloto tsa ts'ebeliso empa hape ho kenya letsoho ts'ebetsong ea tlhahiso e tala.

Nako e telele e tšoarellang le ROI

Themoaho o matla wa dikurufu tse mafahlae netefatsa nako e telele ea nako e telele, e leng se etsang hore e be khetho e ka tšeptjoang bakeng sa tlhahiso ea lihlahisoa tse phahameng. Likarolo tse kang li-screw le barrel li entsoe ka lisebelisoa tse matla joalo ka tšepe ea nitriding, e mamellang ho senyeha le ho taboha ka nako e telele. Mekhoa e tsoetseng pele ea tlhahiso, ho kenyelletsa ho tima le ho etsa nitriding, e ntlafatsa nako e telele ea likarolo tsena, ho fokotsa khafetsa ea ho nkela sebaka.

Ho tšoarella hona ho fetolela phaello e phahameng ea matsete (ROI). Baetsi ba rua molemo ka litšenyehelo tse fokotsehileng tsa tlhokomelo le nako e fokolang, e amang tlhahiso ka kotloloho. Ha nako e ntse e ea, letsete la pele ho "twin screw extruder" le lefa ka ts'ebetso e tsitsitseng le litšenyehelo tse tlase tsa ts'ebetso. Likhamphani tse batlang ho eketsa ROI ea tsona hangata li khetha mechini ena bakeng sa ts'epo ea tsona e netefalitsoeng le ho sebetsa hantle ha tsona.

Moralo oa Modular bakeng sa ho Fetolana

Moralo oa modular oa li-twin screw extruder o fana ka mefuta-futa e ke keng ea lekanngoa, e lumellang bahlahisi ho ikamahanya le lisebelisoa ho latela litlhoko tse fapaneng tsa tlhahiso. Mechini ena e ka etsoa ka li-screw, libarele le likarolo tse ling ho sebetsana le lisebelisoa le lits'ebetso tse fapaneng. Ho feto-fetoha ha maemo hona ho etsa hore li tšoanelehe bakeng sa mefuta e mengata ea likopo, ho tloha ho polasetiki le meriana ho ea ho tlhahiso ea lijo le lijo.

Baetsi ba ka boela ba lekanya ts'ebetso ea bona hantle ka li-modular twin screw extruder. Ka ho ntlafatsa likarolo tse itseng kapa ho eketsa lisebelisoa tse thusang, ba ka eketsa bokhoni ba tlhahiso ntle le ho nkela mochine oohle sebaka. Ho ikamahanya le maemo hona ha ho fokotse litšenyehelo tsa chelete feela empa hape ho netefatsa hore lisebelisoa li lula li sebetsa ha litlhoko tsa tlhahiso li ntse li fetoha.

Hlokomela:Modular twin screw extruder ke khetho e ntle bakeng sa likhoebo tse batlang bopaki ba nakong e tlang lits'ebetso tsa bona tsa tlhahiso.

Tlhahiso e Phahameng ka ho Fetisisa e nang le Twin Screw Extruders

Co-Rotating Screw Technology

Theknoloji ea co-rotating screw e ntlafatsa ts'ebetso ea "twin screw extruder" ka ho ntlafatsa phallo ea thepa le ho kopanya. Moqapi ona o tiisa ho kuta ka mokhoa o tsitsitseng le kabo ea mocheso, e leng ea bohlokoa bakeng sa tlhahiso ea boleng bo phahameng. Li-screws li pota-pota ka lehlakoreng le le leng, li etsa hore motho a itšepe e thibela ho bokellana ha thepa le ho ntlafatsa ts'ebetso ea ts'ebetso.

| Ntlha | Tlhaloso |

|---|---|

| Taolo ea Khatello | Likhatello tse phahameng li ka lebisa ho lutla ha sefofane se phahameng, ho ama mocheso oa ho qhibiliha le ho senyeha ho ka bang teng. |

| Screw Design | Khetho ea li-screw e susumetsa sekhahla sa khatello le katleho e akaretsang ea ts'ebetso ea extrusion. |

| Mekhahlelo ea Ts'ebetso | Lintho tse kang nako ea bolulo, sebaka se ka holim'a metsi, le maemo a vacuum li ama haholo ts'ebetso ea devolatilization. |

Theknoloji ena e tšehetsa litekanyetso tsa tlhahiso ea ho fihla ho 1800 kg / hr (4000 lb / hr), e etsa hore e be e loketseng bakeng sa indasteri e hlokang tlhahiso e kholo. Bokhoni ba eona ba ho sebetsana le lisebelisoa tse fapaneng ka nepo bo netefatsa boleng bo tsitsitseng le litšila tse fokotsehileng.

Mekhoa e tsoetseng pele ea ho laola

Sistimi ea taolo e tsoetseng pele e bapala karolo ea bohlokoa ho ntlafatseng ts'ebetso ea li-twin screw extruder. Sistimi ena e hlokomela le ho lokisa maemo a bohlokoa joalo ka mocheso, lebelo la screw, le phallo ea thepa ka nako ea nnete. Ts'ebetsong ea li-algorithms tsa taolo ea neuron-PID bakeng sa mocheso oa moqomo o ntlafalitse haholo ho nepahala le ho fokotsa ho feta.

| Sebopeho | Extruder ea hajoale | Meetso e Tšoanang |

|---|---|---|

| Viscosity ea enke | Phahameng | Tlase |

| Melumo e Hlahisang | E fetohang | E tsitsitse |

| Taolo ea ho Khutlela | E tsoetseng pele | Motheo |

| Litšenyehelo | Tlholisano | E phahameng |

Taolo ea PSO-neuron-PID e tsoela pele ho ntlafatsa ts'ebetso ea ts'ebetso ka ho fokotsa litlamorao tsa ho kopanya ho futhumatsa. Litlhahiso tsena li netefatsa boleng bo tsitsitseng ba tlhahiso le ho boloka matla, ho etsa hore li-scruder tse peli e be khetho e tšepahalang bakeng sa tlhahiso ea boleng bo phahameng.

Scalability bakeng sa Tlhahiso e Kholo

Li-extruder tsa Twin screw li fana ka scalability e ke keng ea lekanngoa, e nolofalletsang baetsi ho fihlela litlhoko tse ntseng li eketseha tsa tlhahiso. Moralo oa bona oa modular o lumella lintlafatso tse bonolo le ho li etsa, ho netefatsa ho ikamahanya le maemo ho latela litlhoko tse eketsehileng tsa bokhoni.

- Bokhabane ba Bongaka ba Tube:Khamphani ea thepa ea bongaka ea Europe e sebelisitse "twin screw extruder" e ikhethileng ho ntlafatsa ts'ebetso ea tlhahiso le ho nepahala bakeng sa li-tubing tsa bongaka tsa PVC.

- Ho Matlafatsa Batho ba Bacha ka Litharollo tsa Turnkey:Moetsi e mocha o sebelisitse lisebelisoa tse lokiselitsoeng ho holisa ts'ebetso hantle, ho fihlela litlhoko tsa mmaraka habonolo.

Lipale tsena tsa katleho li totobatsa ho feto-fetoha le ho ts'epahala ha li-scruder tse mafahla tlhahisong e kholo. Bokhoni ba bona ba ho fana ka ts'ebetso e ts'oanang lits'ebetsong tse fapaneng bo netefatsa boleng ba nako e telele bakeng sa likhoebo.

Ho Khetha le ho Boloka Twin Screw Extruders

Lintlha Tseo U Lokelang ho li Nahana ha U Khetha Extruder

Ho khetha "twin screw extruder" e nepahetseng ho hloka tlhahlobo e hlokolosi ea lintlha tse 'maloa. Baetsi ba lokela ho qala ka ho lekola mofuta oa thepa le litlhoko tsa ts'ebetso. Ka mohlala, lisebelisoa tsa abrasive kapa tse thibelang mocheso li ka 'na tsa hloka meralo e khethehileng ea li-screw kapa li-barrel cores. Bokhoni ba tlhahiso ke taba e 'ngoe ea bohlokoa. Mechini e nang le bokhoni bo phahameng ba ho sebetsa e lumellana le ts'ebetso e kholo, athe mefuta e menyenyane e ka lekana bakeng sa lipatlisiso kapa lits'ebetso tsa niche.

Modularity ea extruder le eona e phetha karolo ea bohlokoa. Likarolo tse ka tloahelehang, joalo ka li-screws le libarele, li lumella bahlahisi ho ikamahanya le mochini bakeng sa lits'ebetso tse fapaneng. Litsamaiso tse tsoetseng pele tsa taolo li ntlafatsa ho nepahala le ho sebetsa hantle, ho etsa hore e be tsa bohlokoa haholo bakeng sa indasteri e hlokang boleng bo tsitsitseng. Ho phaella moo, botumo ba moetsi le boteng ba tšehetso ea ka mor'a thekiso ha boa lokela ho hlokomolohuoa. Likhamphani tse kang Zhejiang Jinteng Machinery Manufacturing Co., Ltd. li fana ka meralo e matla le tšebeletso e tšepahalang ea bareki, e netefatsang boleng ba nako e telele.

Mekhoa ea Kameho ea Tlhokomelo

Tlhokomelo ea nako le nako e netefatsa bophelo bo bolelele le bokhoni ba li-twin screw extruder. Mekhoa ea mantlha e kenyelletsa:

- Ho etsa liteko tsa vibrate ho li-gearbox ka mor'a likhoeli tse ling le tse ling tse tšeletseng ho isa ho tse 12 ho bona mathata a ka bang teng.

- Ho sebelisa lik'hamera tsa litšoantšo tse futhumatsang ho lekola litsamaiso tsa ho futhumatsa le ho tsidifatsa bakeng sa liphoso.

- Ho hlahloba libarele le likurufu bakeng sa ho khathala le ho li fetola kapa ho li aha bocha ha ho hlokahala.

- Ho fetola oli ea gearbox khafetsa le ho e sekaseka ho thibela ho hloleha ho hoholo.

Mekhoa ena e fokotsa ho lokisoa ha tšohanyetso le ho fokotsa nako ea ho theoha. Ho boloka litlaleho tse qaqileng tsa tlhahlobo le tokiso ho thusa ho tseba mekhoa le ho bolela esale pele litlhoko tsa tlhokomelo ea nako e tlang. Tlhokomelo e tsoelang pele ha e lelekise bophelo ba mochini feela empa hape e netefatsa boleng bo tsitsitseng ba tlhahiso.

Ho Rarolla Mathata a Tloaelehileng

Mathata a ts'ebetso a ka hlaha le ka li-extruder tse hlokometsoeng hantle. Ho beha leihlo tšebetso e ikhethileng ho thusa ho ntlafatsa boemo ba ho tlatsa, ho netefatsa ts'ebetso e ntle ea lihlahisoa tse ncha. Litekanyo tse khethehileng tsa matla li senola tšebeliso ea matla k'hilograma ka 'ngoe ea thepa, e thusang ho tseba ho se sebetse hantle ha matla.

Ho roala holim'a li-screws le libarele ke taba e tloaelehileng e bakoang ke lisebelisoa tse senyang, ho se tsamaisane hantle, kapa katoloso ea mocheso. Ho metha bophara ba barrel khafetsa le ho etsa bonnete ba hore e tsamaisana hantle ho ka fokotsa mathata ana. Ho boloka screw screw letsohong ho fokotsa nako ea ho theoha nakong ea ho nchafatsa. Ho sebetsana le lintlha tsena hang-hang ho thibela tšenyo e 'ngoe hape ho boloka ts'ebetso e nepahetseng.

Keletso:Tlhokomelo e matla le ho kenella ka nako ho bohlokoa bakeng sa ho qoba litokiso tse bitsang chelete e ngata le ho netefatsa tlhahiso e sa sitisoeng.

Li-fin screw extrudersfana ka melemo e ke keng ea lekanngoa bakeng sa tlhahiso e theko e tlaase, e phahameng haholo. Moralo oa bona o tsoetseng pele o tiisa ho ntlafala ho kopanya, bokhoni bo phahameng, le ts'ebetso e pharalletseng ea lisebelisoa. Mechini ena e boetse e ntlafatsa boleng ba sehlahisoa le ts'ebetso ea matla ha e ntse e boloka taolo e nepahetseng ea ts'ebetso.

| Molemo | Tlhaloso |

|---|---|

| Ho Kopanya ho Ntlafetseng | E ntlafatsa ho tšoana ha kabo ea thepa le taolo holim'a mokhoa oa ho kopanya. |

| Bokhoni ba Tlhahiso e Phahameng | E fumana tšebetso e phahameng ha e bapisoa le li-scruders tse le 'ngoe, tse molemo bakeng sa lits'ebetso tse kholoanyane. |

| Mokhoa o Pharalletseng oa Ts'ebetso | E khona ho sebetsana le lisebelisoa tse fapaneng, ho kenyelletsa le tse nang le viscosity e phahameng le kalafo e khethehileng. |

| Ntlafatso ea boleng ba Sehlahisoa | Ho kopanya ho tsitsitseng le ho hlahisa lihlahisoa ho ntlafatsa boleng ba sehlahisoa, ho bohlokoa bakeng sa ho kopanya le ho hlahisa masterbatch. |

| Matla a Matla a Ntlafetseng | E eketsa tšebeliso ea matla le ho fokotsa khatello ea maikutlo, e lebisang ho bolokeng litšenyehelo tsa nako e telele. |

| Taolo ea Ts'ebetso e Ntlafetseng | E boloka liparamente tsa ts'ebetso ka har'a maemo a behiloeng bakeng sa liphetho tse nepahetseng likarolong tse pharalletseng. |

Khetho e nepahetseng le tlhokomelo ea "twin screw extruder" e netefatsa ts'epo le ts'ebetso ea nako e telele. Ho tsetela ka litharollo tsa boleng bo holimo ho tiisa ts'ebetso e tsitsitseng, ho e etsa letlotlo la bohlokoa bakeng sa tlhahiso ea sejoale-joale.

LBH

Ke lisebelisoa life tse ka sebetsanang le li-screw extruder tse mafahla?

Li-extruder tse peli tsa li-screw li sebetsana le polasetiki, rabara, meriana, lijo, le lisebelisoa tsa phepelo. Moralo oa bona oa modular o lumella ho itlhophisa bakeng sa thepa e khethehileng ea thepa le litlhoko tsa ts'ebetso.

Tlhokomelo e lokela ho etsoa hangata hakae?

Tlhokomelo e tloaelehileng e lokela ho etsoa khoeli le khoeli, ka tlhahlobo e qaqileng likhoeli tse ling le tse ling tse tšeletseng. Liphetoho tsa kamehla tsa oli le licheke tsa ho apara li netefatsa ts'ebetso e nepahetseng le bophelo bo bolelele.

Ke eng e etsang hore li-scruder tse mafahla li boloke matla?

Li-screws tsa bona tsa intermeshing li ntlafatsa phallo ea thepa le ho fokotsa ho kenya matla. Litsamaiso tse tsoetseng pele tsa ho laola li-parameter hantle, ho fokotsa litšila le ho ntlafatsa katleho.

Nako ea poso: Apr-27-2025