Bottle Blow molding screw barrel moralo o eme ka thoko ho ente ea ente ka lebaka la bolelele ba eona bo bolelele le tekanyo e phahameng ea compression. Sena se thusa ho theha li-parison tse tšoanang, tse ntlafatsang ho hlaka le matla a botlolo. Ha 'maraka oa lefats'e oa polasetiki o bōpiloeng o ntse o hola, hoHo Fafatsa Screw BarrelleFilimi Blown Screwfana ka melting e sebetsang hantle, ho kopanya, le ho boloka matla holim'aMoqomo o le Mong oa Plastic Screw.

Screw Barrel Function in Molding Processes

Ho Qhibiliha ha Lintho le ho Fetisa Likarolo

The screw barrel e sebetsa joalo ka pelo ea mochini o bopang ka bobeli oa botlolo le mochini oa ente. Mosebetsi oa eona o ka sehloohong ke ho qhibilihisa li-pellets tsa polasetiki le ho tsamaisa thepa e qhibilihisitsoeng pele. Ha ho etsoa ente, screw e potoloha ka har'a barrel e futhumetseng, e hatella le ho qhibilihisa polasetiki. Hang ha polasetiki e qhibiliha, screw e e sutumelletsa ka har'a hlobo ka khatello e phahameng. Mokhoa ona o etsa hore polasetiki e be likarolo tse tiileng.

Ka har'a botlolo ba botlolo, moqomo oa screw o boetse o qhibilihisa polymer. Leha ho le joalo, tsela eo e tsamaisang thepa ka eona e ka fetoha. Mohlala, ha ho bopa seboko sa extrusion, screw e ka fetoha e sa khaotse kapa ka mehato. E sutumelletsa polasetiki e qhibilihisitsoeng joalo ka tšupu, e bitsoang parison. Ebe moea o fokela ka har'a parishe ho etsa botlolo. Ha ho etsoa ente, screw e kenya polasetiki e qhibilihisitsoeng ka har'a hlobo ho etsa preform, eo hamorao e fetohang botlolo. The screw barrel e fetola karolo ea eona ho ipapisitse le mokhoa oa ho bopa, empa kamehla e shebana le ho qhibiliha le ho tsamaisa polasetiki hantle.

Keletso:Sekoti se entsoeng hantle se etsa bonnete ba hore polasetiki e qhibiliha ka ho lekana 'me e phalla hantle, e thusang ho thibela likoli sehlahisoa sa ho qetela.

Ho Kopanya le Homogeneity Liphello

Ho kopanya le homogeneity ho phetha karolo e kholo ho boleng ba sehlahisoa. Sekoti se tlameha ho kopanya polasetiki le li-additives efe kapa efe hore karolo ea ho qetela e shebahale le ho sebetsa kamoo ho lebelletsoeng. Meetso e fapaneng ea li-screw e ka fetola tsela eo polasetiki e kopanyang hantle ka eona. Ka mohlala, li-screws tse nang le likanale tse khethehileng kapa likarolo tse kopanyang li thusa ho aba mebala le li-additives ka ho lekana. Sena se lebisa 'mala o motle le matheba a fokolang a fokolang.

Hangata bahlahisi ba leka hore na sekurufu se kopane hantle hakae ka ho sheba mocheso le 'mala oa polasetiki e qhibilihisitsoeng. Ba batla esita le mocheso le mebala e boreleli. A ka tlaasekheloha e tloaelehilenglitekong tsena ho bolela ho kopanya ho molemo. Li-screw tse ling tse tsoetseng pele, joalo ka litšitiso kapa liqapi tse ngata, li bonts'a motsoako o ntlafalitsoeng le ho qhibiliha ho hoholo. Likarolo tsena li thusa ho theha libotlolo le likarolo tse matla, tse hlakileng, tse se nang mela kapa lipululana.

| Karolo ea Tekanyo | Tlhaloso ea Mokhoa | Seo E se Bontšang |

|---|---|---|

| Thermal Homogeneity | Sheba mocheso oa ho qhibiliha ntlheng ea screw | Esita le ho futhumatsa |

| Homogeneity ea lintho tse bonahalang | Sekaseka motsoako oa mebala ka lisampole tse qhibilihisitsoeng | Esita le ho kopanya |

| Screw Performance Index | E kopanya homogeneity ea mocheso le thepa | Ka kakaretso qhibiliha boleng |

Sekurufu barrel e tsoakaneng hantle e fa bahlahisi taolo e eketsehileng holim'a boleng ba sehlahisoa le ho fokotsa litšila.

Liphapang tse ka Sehloohong ho Moralo oa Screw Barrel

Geometry le Litekanyo

Screw barrel geometry e bopa kamoo polasetiki e tsamaeang le ho qhibiliha ka har'a mochini. Ka har'a ho bopa ha botlolo, moqomo oa screw hangata o na le tekanyo e telele ea bolelele ho isa ho bophara (L/D) ha e bapisoa le ente. Bolelele bona bo eketsehileng bo fa polasetiki nako e eketsehileng ea ho qhibiliha le ho kopanya, e leng ntho ea bohlokoa bakeng sa ho etsa libotlolo tse matla, tse hlakileng. Bottle Blow molding screw barrel hangata e na le "taper" butle butle le likanale tse tebileng tsa phepelo. Likhetho tsena tsa moralo li thusa screw ho sebetsana le phallo e tsitsitseng ea polasetiki le ho etsa parison e ts'oanang.

Ka lehlakoreng le leng, li-screw barrel tsa ente li atisa ho ba khutšoanyane. Ba tsepamisitse maikutlo tabeng ea ho qhibiliha ka potlako le ho kenya polasetiki ka har'a hlobo. Bolelele bo khuts'oane bo thusa ho potlakisa nako ea potoloho le ho lumellana le tlhaho e potlakileng ea ho bopa ente. Jiometry ea moqomo o mong le o mong oa screw o lumellana le litlhoko tsa ts'ebetso ea eona, ho leka-lekanya ho qhibiliha, ho kopanya le khatello.

Tlhokomeliso: Jiometry e nepahetseng e ka ntlafatsa boleng ba ho qhibiliha le ho fokotsa tšebeliso ea matla ka ho laola hore na ho kuta le ho futhumatsa bo bokae ba polasetiki.

Karolelano ea Compression le Libaka tsa Ts'ebetso

The compression ratio ke karolo ea bohlokoa ea moralo oa screw barrel. E lekanya hore na screw e hatella polasetiki e kae ha e tloha sebakeng sa phepelo ho ea sebakeng sa metering. Ha ho etsoa botlolo ea botlolo, "Bottle Blow molding screw barrel" hangata e sebelisa tekanyo e phahameng ea compression. Sena se thusa ho haha khatello e hlokahalang ho theha parishe e boreleli, e se nang lipudula. Karolelano e phahameng e boetse e ntlafatsa ho kopanya le ho qhibiliha homogeneity, e leng se lebisang ho hlaka le matla a botlolo e ntle.

Li-screw barrel tsa ente li ka sebelisa tekanyo e tlase kapa e itekanetseng ea compression, ho latela thepa. Ka mohlala, karo-karolelano e tlaase ea compression e ka baka liphoso tse kang splay ho polystyrene, ha tekanyo e phahameng e ntlafatsa ho kopana le ho fokotsa nako ea potoloho. Leha ho le joalo, haeba karo-karolelano e phahame haholo bakeng sa lisebelisoa tse itseng tse kang ABS, e ka baka ho se tsitse ha ts'ebetso le ho qhibiliha ho sa phetheheng. Moralo oa libaka tse sebetsang - phepelo, phetoho le metering - le tsona li phetha karolo e kholo. Ho fetola botebo le bolelele ba libaka tsena ho fetola tsela eo polasetiki e qhibilihang le ho phalla ka eona, ho ama khatello le ts'ebetso ea screw.

- Karolelano ea compression e tlameha ho lumellana le mofuta oa polymer le litlhoko tsa ts'ebetso.

- Moralo o nepahetseng oa libaka tse sebetsang o netefatsa ho qhibiliha ho tsitsitseng le ho thibela mefokolo.

- Ho lokisa likarolo tsena hantle ho ka ntlafatsa boleng ba ho qhibiliha le ho matlafatsa matla a semela.

Litlhoko tsa ho sebetsana le thepa le polasetiki

Mekhoa e fapaneng ea ho bopa e na le litlhoko tse ikhethang tsa polasetiki. The Bottle Blow molding screw barrel e tlameha ho sebetsana le mefuta e mengata ea lisebelisoa, ho tloha polyethylene e phahameng haholo (HDPE) ho ea ho polypropylene (PP). E hloka ho qhibiliha le ho kopanya lisebelisoa tsena ka ho lekana ho etsa parishe e nang le botenya bo tsitsitseng. Sena ke sa bohlokoa hobane ho qhibiliha ho sa lekaneng ho ka lebisa matheba a fokolang kapa libotlolo tse nang le maru.

Li-screw barrel tsa ente li shebana le ho qhibilihisa polasetiki kapele le ho e kenya ka har'a hlobo. Hangata ba sebetsa ka lisebelisoa tse hlokang taolo e nepahetseng ea mocheso le polasetiki e potlakileng. Lisebelisoa tse ling, joalo kali-resin tse nang le li-viscosity tse phahameng, e ka ba phephetso ho sebetsa ka ente blow blowing. Moralo oa screw barrel o tlameha ho ikarabella bakeng sa liphapang tsena ho netefatsa ts'ebetso e bonolo.

| Karolo | Extrusion Blow Molding (EBM) | Ente Blow Molding (IBM) |

|---|---|---|

| Matlakala | 5% ho isa ho 30% e setseng, e hloka ho tsosolosoa, e eketsa phapang. | Sekhechana se fokolang se nang le lisebelisoa tse nepahetseng; feela ho tloha qalong kapa ho fetoha ha mmala. |

| Polasetiki Orientation | Parison e foka ka mocheso o phahameng haholo, sebaka se senyenyane. | Boikutlo bo itseng nakong ea ente, e ntlafatsa thepa. |

| Theko ea Lisebelisoa | E tlase, e ntle bakeng sa matha a manyane. | E phahameng, empa e sebetsa hantle bakeng sa mabelo a maholo. |

| Ho hlaka | Lithapo tse ka bang teng kapa liphoso. | Hlakola lijana ka lebaka la taolo e ntle. |

| Sekhahla se tlase sa Pinch-off | Hona joale, e ka ama ponahalo. | Ha ho letho, ponahalo le matla a betere. |

| Tlase Push-off | Ho thata ho feta ka lebaka la ho omella. | Ho bonolo haholoanyane ka li-plug tse huleloang. |

Keletso: Ho tsamaisana lemoralo oa moqomo oa screwho lisebelisoa le ts'ebetso ho thusa ho fokotsa likhechana, ho ntlafatsa ho hlaka, le ho etsa libotlolo tse matla.

Apara Resistance le Material Compatibility

Wear resistance ke bothata bo boholo bakeng sa ho bopa ha botlolo le ho bopa ente. Sekurufu le barrel li tobana le likhohlano tse sa khaotseng le khatello ea polasetiki e tsamaeang. Li-filler le li-additives ka polasetiki li ka mpefatsa le ho feta. Thepa ea Botlolo ea Botlolosekoti barrelhangata e sebelisa tšepe ea boleng bo holimo ea nitrided, li-alloys tsa bimetallic, kapa litlolo tse khethehileng tse kang tungsten carbide ho loantša ho senyeha le ho senya. Lisebelisoa tsena li thusa screw ho tšoarella nako e telele, leha e ntse e sebetsana le li-polymer tse senyang kapa tse senyang.

Libarele tsa ente li ka sebelisa lisebelisoa tse kang Nitralloy nitride, D2 tool steel, CPM 10V, kapa carbide bakeng sa mesebetsi e thata. Ntho e 'ngoe le e' ngoe e fana ka maemo a fapaneng a tšireletso khahlanong le ho senyeha le ho senya. Ka mohlala, CPM 10V e sebetsa hantle ka lipolasetiki tse tletseng likhalase kapa tse thibelang malakabe, ha libarele tsa carbide li molemo ka ho fetisisa bakeng sa lisebelisoa tse senyang haholo. Ho tsamaisana le lisebelisoa tsa screw le barrel ho bohlokoa ho qoba mathata ka ho atolosoa ha mocheso le ho tlama.

- Litaba tse tloaelehileng tsa ho apara li kenyelletsa ho roala machato, ho roala ka maqeba, le ho apara ka tsela e fosahetseng.

- Ho sebelisa lisebelisoa tse nepahetseng le liphahlo ho eketsa bophelo ba barrel ea screw.

- Ho hlahloba khafetsa mekhoa ea moaparo ho ka thusa ho bona mathata esale pele le ho tataisa ntlafatso ea moralo.

Hopola: Sesebelisoa se khethiloeng hantle sa screw barrel se boloka mochini o sebetsa hantle mme se fokotsa nako ea ho lokisoa.

Bottle Blow Molding Screw Barrel Features

Litlhophiso tsa Moralo bakeng sa Boleng ba Parison

Baetsi ba qapa sekoti sa Bottle Blow se nang le likarolo tse 'maloa ho ntlafatsa boleng ba parison. Liphetoho tsena li thusa ho etsa libotlolo tse nang le marako a lekanang le libaka tse boreleli. Mona ke tse ling tsa likhetho tsa bohlokoa ka ho fetisisa tsa moralo:

- The screw barrel e fana ka taolo e nepahetseng ea hore na polasetiki e qhibiliha le ho phalla joang. Taolo ena e thusa ho boloka junifomo ea botenya ba lebota la parison, e lebisang ho libotlolo tse shebahalang hantle.

- Baenjineri ba sebelisa lisebelisoa tsa boemo bo holimo joalo ka tšepe ea nitrided, li-alloys tsa bimetallic, le liaparo tsa tungsten carbide. Lisebelisoa tsena li etsa hore screw barrel e tšoarelle ho feta le hore e se ke ea sebetsa, kahoo e lula e sebetsa hantle ha nako e ntse e ea.

- Ho itloaetsa ho tloaelehile. Baetsi ba ka fetola bophara ba screw, bolelele-ho-diameter ratio (L/D), sebopeho sa sefofane, le masela a bokaholimo. Likhetho tsena li ba tlohelle hore ba ts'oane le barrel ea screw ho li-plastiki tse fapaneng le litlhoko tsa tlhahiso.

- Likarolo tsena tsa moralo li thusa ho ntlafatsa lintlha tsa bohlokoa tsa ts'ebetso. Ka mohlala, ba ka khutsufatsa linako tsa potoloho, ba ntlafatsa ho pholisa, 'me ba etsa hore boholo ba libotlolo bo nepahale haholoanyane.

E entsoeng hantleBottle Blow molding barrele fa lik'hamphani taolo e eketsehileng holim'a sehlahisoa sa ho qetela, ho etsa hore ho be bonolo ho hlahisa libotlolo tse shebahalang hantle le tse sebetsang hantle.

Taolo ea Mocheso le Homogeneity

Taolo ea mocheso e bapala karolo e kholo ho bōpeheng ha molumo. Sekoti se tlameha ho boloka polasetiki e le mochesong o nepahetseng ho etsa bonnete ba hore e qhibiliha ka ho lekana le ho phalla hantle. Haeba mocheso o phahame haholo kapa o le tlase haholo, polasetiki e ka 'na ea se ke ea etsa parishe e ntle.

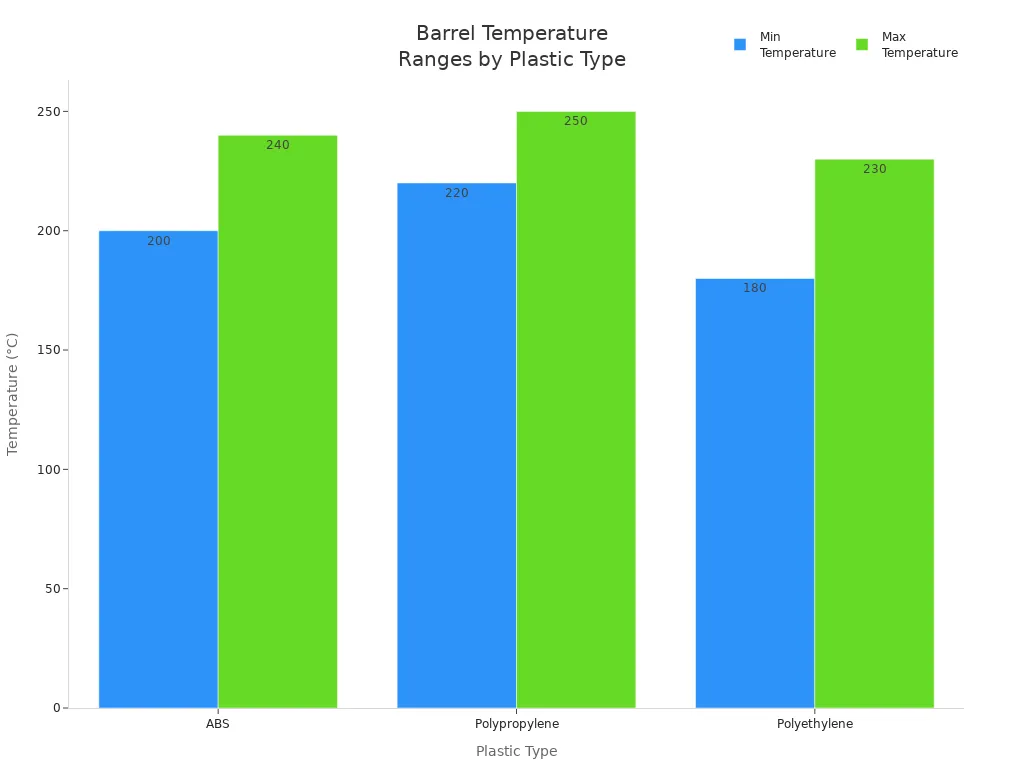

| Mofuta oa polasetiki | Thempereichara e Tloaelehileng ea Barel (°C) |

|---|---|

| ABS | 200 - 240 |

| Polypropylene | 220 - 250 |

| Polyethylene | 180 - 230 |

Basebelisi ba sebelisa lihlopha tsa heater le lisensara ho laola mocheso ona. Moralo oa screw o boetse o ama tsela eo polasetiki e futhumatsang hantle le ho tsoakana. Libaka tse chesang li ka hlaha sebakeng sa phetoho ea screw, e leng se etsang hore mocheso o phahame. Ho lokisa sena, bahlahisi ba ka fetola lebelo la screw, ba eketsa li-fan tse pholileng, kapa ba kenya li-heaters tsa insulate. Mehato ena e thusa ho boloka mocheso oa ho qhibiliha o tsitsitse, e leng senotlolo sa ho etsa libotlolo ka boleng bo tsitsitseng.

Sebopeho se setle sa Botlolo ea Botlolomoralo oa moqomo oa screwe boetse e ntlafatsa homogeneity. Likarolo tse joalo ka likurufu tsa grooved feed le lifofane tse tebileng li thusa polasetiki ho qhibiliha le ho tsoakana hantle. Likarolo tse kopanyang lithibelo haufi le pheletso ea screw li kopanya polymer ka ho lekana. Ho qhibiliha hona ha junifomo ho lebisa sebopehong se tsitsitseng sa pharishe le mefokolo e fokolang.

Ha mocheso o lula o tsitsitse mme ho qhibiliha ho tšoana, ts'ebetso e tsamaea hantle 'me libotlolo li tsoa li le matla le ho hlaka.

Tšusumetso ho Botlolo e hlakileng le Matla

Moqapi oa "screw barrel" o na le phello e tobileng mabapi le hore na libotlolo tse phethiloeng li hlakile ebile li matla hakae. Sekurufu se selelele se nang le bophahamokaro-karolelano ea bolelele le bophara (hangata lipakeng tsa 24:1 le 30:1)e fa polasetiki nako e eketsehileng ea ho qhibiliha le ho kopanya. Karo-karolelano e phahameng ea khatello, hangata e ka bang 3.5: 1, e thusa ho theha ho qhibiliha ho se nang bubble. Likarolo tsena li sebetsa 'moho ho ntlafatsa phallo ea polasetiki le boleng ba parishe.

Tsoelo-pele ea theknoloji ea screw barrel e entse hore ho be bonolo ho hlahisa libotlolo tse bobebe ntle le ho lahleheloa ke matla. Phallo ea thepa e ntlafetseng e fokotsa litšitiso 'me e boloka tlhahiso e sebetsa. Ho fetisoa ha mocheso o ntlafalitsoeng ho thusa ho boloka mocheso o motle ka ho fetisisa oa ho sebetsa, o lebisang ho boleng bo ntlafetseng ba ho qhibiliha le libotlolo tse tsitsitseng haholoanyane. Lisebelisoa tse tšoarellang joalo ka tšepe ea alloy e tšetsoeng mocheso li bolela litokiso tse fokolang le nako e fokolang.

Baetsi ba ka boela ba etsa sekoaelo barrel ho lumellana le litlhoko tse fapaneng tsa tlhahiso. Ba bang ba sebelisa li-sensor tse kopaneng ho lekola khatello ea mocheso le mocheso ka nako ea nnete. Sena se lumella liphetoho tse potlakileng le ho thusa ho thibela mathata pele a ama sehlahisoa.

- Li-screws tsa phepelo ea grooved le lifofane tse tebileng li ntlafatsa ho qhibiliha le ho kopanya resin, e leng ea bohlokoa bakeng sa ho etsa libotlolo tse hlakileng.

- Likarolo tsa ho kopanya litšitiso li netefatsa hore polymer e kopana ka mokhoa o ts'oanang, e fokotsa li-streaks le matheba a fokolang.

- Likarolo tse phahameng tsa khatello li lumella mabota a botlolo a masesaane, a bobebe ha a ntse a boloka a le matla.

Ka lintlafatso tsena tsa meralo, lik'hamphani li ka etsa libotlolo tse seng bobebe feela empa hape tse hlakileng le tse thata, tse fihlelang litlhoko tsa indasteri ea kajeno ea ho paka.

Tafole ea Papiso: Botlolo ea Botlolo ea Botlolo vs. Injection Molding Screw Barrels

Kakaretso ea Sebopeho

Ha ho bapisa ho bopa ha botlolo leente molding screw barrel, liphapang tse 'maloa lia ikhetha. Tafole e ka tlase e totobatsa likarolo tsa bohlokoa ka ho fetesisa:

| Sebopeho | Bottle Blow Molding Screw Barrel | Ente Molding Screw Barrel |

|---|---|---|

| Mokhoa oa ho qhibiliha oa polasetiki | E qhibilihisa le ho ntša polasetiki ho etsa pharishe e se nang letho | E qhibilihisa le ho kenya polasetiki ka har'a hlobo ea preform |

| Boemo ba Sehlahisoa | E etsa lihlahisoa tse se nang letho tsa 2D joalo ka libotlolo le lijana | E hlahisa likarolo tse sekoti tsa 3D ka nepo e phahameng |

| Lintho Tse Sebelisitsoeng | HDPE, PP, PET | Acrylic, Polycarbonate, POM, PE |

| Moqapi oa Mold & Precision | Moralo o feto-fetohang, ho nepahala ho tlase | Ho nepahala ho phahameng, ho phalla ho nepahetseng ha resin |

| Moloko oa Letlapa | E hlahisa flash e hlokang ho kuta | Ha e na litšila, ha ho hlokahale ho kuta |

| Litšenyehelo tsa Lisebelisoa | Lisebelisoa tse tlase, tse tenyetsehang | E phahameng, e fokolang haholo |

| Lebelo la Tlhahiso | Butle-butle, bokhoni ba ho sebetsa bo bohlokoa | Ka potlako, e loketse molumo o phahameng |

| Mefuta ea Lihlahisoa | Lijana tse kholoanyane, libopeho tse rarahaneng, li tšoara | Likarolo tse nyane, tse nepahetseng tse nang le mamello e thata |

| Boima le Taolo ea Lintho | Ha e nepahale, ho thata ho lekanya botenya ba lebota | Boima bo nepahetseng le kabo ea thepa e tšoanang |

| Setshelo Size Range | Ka tlase ho 1 oz. ho fihlela ho lilithara tse 55 | Molemo ka ho fetisisa bakeng sa 5 oz. kapa ka tlase ho moo, eseng ka chelete e fetang 16 oz. |

| Litlhoko tsa hlobo | Mofuta o le mong oa hlobo | E hloka ente le hlobo |

Keletso:Tlhokomelo ea kamehla e boloka mefuta e 'meli ea li-screw barrel e sebetsa hantle. Bakeng sa ho bopa ha botlolo, basebetsi ba hloekisa screw le barrel hangata ho thibela ho bokellana ha masalla. Ba boetse ba hlokomela mocheso le ho tlotsa likarolo tse tsamaeang. Ha ho etsoa ente, lihlopha li hlahloba screw le barrel selemo se seng le se seng, li hlahloba mefuta e fapaneng ea ts'ebetso, 'me li boloke lihlopha tsa oli ea hydraulic le heater. Mehato ena e thusa ho netefatsa boleng bo tsitsitseng ba sehlahisoa le ho lelefatsa bophelo ba lisebelisoa.

Baetsi ba bona liphapang tse hlakileng moralong oa screw barrel bakeng sa ho bopa ho otla ha botlolo le ho bopa ente. The Bottle Blow molding screw barrel e sebelisa geometry e telele le taolo e nepahetseng ea mocheso ho matlafatsa boleng ba parison. Lintlha tsa bohlokoa joalo ka sebopeho sa screw, khetho ea thepa, le ho beha leihlo ka nako ea nnete li thusa ho ntlafatsa ts'ebetso le ho tsitsa ha sehlahisoa.

- Screw geometry libopeho ho qhibiliha le ho kopanya, ho fokotsa litšila le ho ntlafatsa boleng.

- Khetho e hlokolosi ea thepa e thibela ho roala le ho chesa haholo, haholo-holo ka lipolasetiki tse hlabang.

| Phephetso | Tšusumetso ho Tlhahiso |

|---|---|

| Khetho ea lintho tse bonahalang | E thibela ho roala le ho lelefatsa nako ea bophelo |

| Taolo ea mocheso | E boloka ho hlaka le matla a sehlahisoa |

| Mekhoa ea ts'ebetso | E fokotsa nako ea ho phomola le liphoso |

Ho khetha moralo o nepahetseng oa screw barrel ho lebisa ho libotlolo tse betere, litšila tse fokolang, le tlhahiso e bobebe.

LBH

Ke eng e etsang hore moqomo oa screw molding o fapane le barrel ea screw molding ea ente?

Ho bopa ho otlasekoti barrele telele mme e sebelisa tekanyo e phahameng ea khatello. Moqapi ona o thusa ho theha liparishe tse tšoanang bakeng sa libotlolo tse matla, tse hlakileng.

Moralo oa screw barrel o ama boleng ba botlolo joang?

The screw barrel e laola ho qhibiliha le ho tsoakana. Moralo o motle o lebisa botenya ba lebota, ho hlaka ho betere, le libotlolo tse matla.

Na bahlahisi ba ka sebelisa sekoti se tšoanang bakeng sa lits'ebetso ka bobeli?

Che, ts'ebetso e 'ngoe le e' ngoe e hloka barrel e khethehileng ea screw. Ho sebelisa moralo o nepahetseng ho netefatsa ts'ebetso e boreleli le lihlahisoa tsa boleng bo holimo.

Nako ea poso: Jul-25-2025