Li-extruder tsa profil ea PVC tse nang le li-alloy tse peli ke mechini e tsoetseng pele e etselitsoeng ho hlahisa liprofaele tsa PVC tse tšoarellang. Li kopanya lisebelisoa tse peli tse matla, ho etsa likarolo tse hanyetsanang le ho senya le ho senya. Liindasteri tse kang tsa kaho le tsa tlhahiso li itšetlehile ka li-extruder tsena ho sebetsana le maemo a thata. Apvc pipe single screw barrel fektherihangata e sebelisa theknoloji ena ho netefatsa ts'ebetso e tšoarellang nako e telele. Themochini o kopanyang li-twin screw extrusione ntlafatsa ts'ebetso ka ho fana ka taolo e nepahetseng nakong ea tlhahiso.

Li-Extruders tsa Dual-Alloy PVC Profile ke life?

Kakaretso ea Theknoloji ea Dual-Alloy

Theknoloji ea li-alloy tse peli e kopanya lisebelisoa tse peli tse fapaneng ho etsa likarolo tse nang le ts'ebetso e tsitsitseng le ts'ebetso. Mokhoa ona o phahamisa matla a thepa e 'ngoe le e' ngoe, joalo ka ho hanyetsa le ho tiea, ho hlahisa li-extruder tse khonang ho mamella maemo a boima. Ka ho sebelisa mekhoa e tsoetseng pele ea tlhahiso, li-alloy tse peliLi-extruders tsa profil ea PVCfinyella ho leka-lekana pakeng tsa matla le ho tenyetseha. Sena se etsa hore e be tse loketseng liindasteri tse hlokang lisebelisoa tse tšepahalang bakeng sa tšebeliso ea nako e telele.

Moralo oa li-alloy tse peli o boetse o netefatsa hore likarolo tsa bohlokoa, joalo ka li-screw le libarele, li khona ho sebetsana le khatello ea maikutlo ntle le ho senya ts'ebetso. Tlhahiso ena e fetotse tlhahiso ea li-profiles tsa PVC, e fana ka tharollo e fokotsang ho senyeha ha ho ntse ho eketsa tlhahiso.

Lisebelisoa le Mokhoa oa Tlhahiso

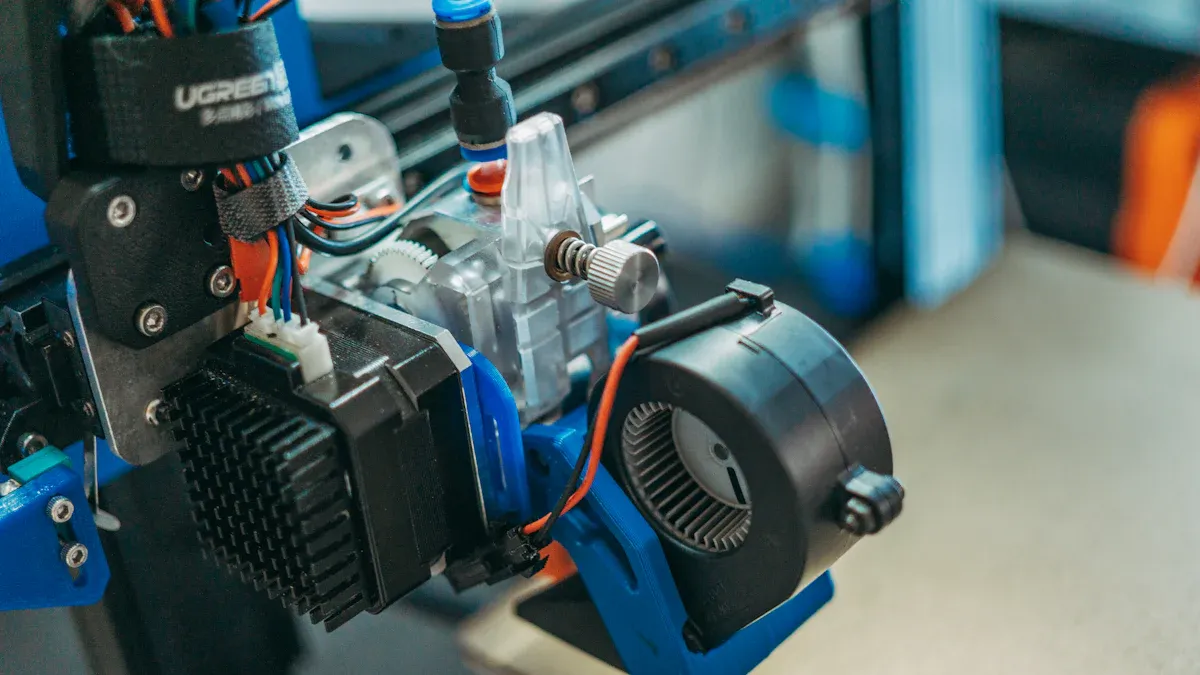

Mokhoa oa ho etsa li-extruder tsa profil ea PVC tse nang le li-alloy tse peli o kenyelletsa boenjiniere bo nepahetseng le lisebelisoa tsa boleng bo holimo. Likarolo tse kang li-screws le libarele li fumana kalafo tse ngata ho ntlafatsa thepa ea tsona. Ka mohlala, ho tima lenitriding ntlafatsa ho thatafalale ho hanyetsa ho apara. Tafole e latelang e totobatsa litšobotsi tsa bohlokoa tsa tekheniki tsa li-extruder tsena:

| Sebopeho | Boleng |

|---|---|

| Ho thatafala ka mora ho tima | HB280-320 |

| Matla a Nitrided | HV920-1000 |

| Nitrided Case Depth | 0.50-0.80mm |

| Nitrided Brittleness | Ka tlase ho Kereiti ea 2 |

| Bokhopo ba Sekaho | Ra 0.4 |

| Screw Sightness | 0.015 limilimithara |

| Bongata ba Chromium-Plating | ≥900HV |

| Botebo ba Chromium-Plating | 0.025-0.10mm |

| Alloy Hardness | HRC55-65 |

| Botebo ba Alloy | 2.0-3.0mm |

Litlhaloso tsena li netefatsa hore li-extruder li khona ho sebetsana le maemo a feteletseng ha li ntse li boloka ho nepahala. Tšebeliso ea lisebelisoa tse peli tsa alloy e boetse e fokotsa litlhoko tsa tlhokomelo, ho boloka nako le litšenyehelo bakeng sa bahlahisi.

Karolo ea Phatlalatso ea Phatlalatso ea PVC

Li-extruder tsa profil ea PVC tse nang le li-alloy tse peli li bapala karolo ea bohlokoa ho hlahiseng li-profile tsa boleng bo holimo tsa PVC. Moqapi oa bona o tsoetseng pele o lumella ho kopanya ho holimo le ho qhibiliha ha thepa, ho netefatsa liphello tse tsitsitseng. Li-extruder tse peli-screw, haholo-holo, li ipabola ho theha tikoloho e sebetsang hantle ea ho kopanya. Sena se netefatsa phallo e ntle ea li-additives, tse bohlokoa bakeng sa ho fihlela thepa e lakatsehang ho li-profile tsa PVC.

Ntle le moo, li-extruder tsena li ntlafatsa ts'ebetso ea tlhahiso ka ho fokotsa litšila tsa thepa le ho etsa hore litefiso tse phahameng tsa tlhahiso. Bokhoni ba ho hlophisa liparamente tsa ts'ebetso li li etsa hore li feto-fetohe, li lumella bahlahisi ho sebetsana le libopeho tse fapaneng tsa PVC. Ho ikamahanya le maemo ho bohlokoa haholo liindastering tse kang tsa kaho le tsa likoloi, moo lintlha tse nepahetseng li leng bohlokoa.

| Molemo | Tlhaloso |

|---|---|

| Bokhoni bo Phahameng ba Ho Kopanya | Li-extruder tse peli tsa "twin-screw" li theha tikoloho e sebetsang hantle haholo ea ho kopanya, ho netefatsa phallo e ntle ea li-additives. |

| Ntlafatso ea Ts'ebetso ea Ts'ebetso | Li etsa hore ho be le litekanyetso tse phahameng tsa tlhahiso le ho fokotsa tšenyo ea thepa ka ho tsamaisa le ho qhibiliha hamolemo. |

| Ho Fetolana ho Hoholoanyane | Bokhoni ba ho hlophisa li-parameter tsa ts'ebetso bo u lumella ho sebetsana le mefuta le litlhaloso tse fapaneng tsa PVC. |

Ka ho kopanya nako e telele, ts'ebetso, le ho feto-fetoha ha maemo, li-extruder tsa profil ea PVC tse peli li fetohile tsa bohlokoa haholo tlhahisong ea sejoale-joale. Bokhoni ba bona ba ho fana ka ts'ebetso e tsitsitseng tlas'a maemo a thata bo ba etsa khetho e ratoang ke liindasteri lefatšeng ka bophara.

Lintlha tsa Bohlokoa le Melemo ea Dual-Alloy PVC Profile Extruders

Ho hanyetsa ho Corrosion le ho Rra

Li-extruder tsa profil ea PVC tse nang le li-alloy tse peli li hahiloe hore li tšoarelle, leha e le libakeng tse thata ka ho fetisisa. Kaho ea bona e ikhethang e kopanya lisebelisoa tse peli, e 'ngoe le e' ngoe e khethiloe bakeng sa bokhoni ba eona ba ho hanyetsa tšenyo. Mokhoa ona o li etsa hore li se ke tsa bola ka lebaka la mongobo, lik'hemik'hale kapa lintho tse ling tse thata. Bakeng sa liindasteri tse kangkaho le tlhahiso, tšobotsi ena e tiisa hore thepa e sebetsa ka botšepehi ha nako e ntse e ea.

Wear resistance ke molemo o mong o hlahelletseng. Li-screws le libarele tse ka har'a li-extruder tsena li fumana kalafo e kang nitriding le quenching. Mekhoa ena e thatafatsa bokaholimo, e etsa hore ho se khonehe hore e senyehe nakong ea ts'ebetso. Ka lebaka leo, bahlahisi ba ka tsamaisa mechini ea bona nako e telele ntle le ho tšoenyeha ka ho lokisoa khafetsa kapa ho nkeloa sebaka se seng. Ho tšoarella hona ha ho boloke nako feela empa hape ho fokotsa litšenyehelo tsa ts'ebetso.

Tshebetso ya Mocheso o Phahameng

Ho sebetsa libakeng tse nang le mocheso o phahameng ho ka ba thata ho mechini e mengata. Leha ho le joalo, li-extruders tsa profil ea PVC tse peli-alloy li ipabola tlas'a maemo a joalo. Lisebelisoa tsa bona tse tsoetseng pele le moralo li ba lumella ho boloka ts'ebetso le ha ba pepesehetse mocheso o feteletseng. Bokhoni bona bo bohlokoa bakeng sa liindasteri tse hlokang tlhahiso e tsitsitseng, ho sa natsoe ho fetoha ha mocheso.

Liphuputso li bontša hore ha mocheso o phahama ho tloha ho 10 ° C ho ea ho 60 ° C, boima ba ho hlōleha ha likarolo tse thehiloeng ho PVC bo fokotseha ka 25.08%. Ka nako e ts'oanang, phallo e phahameng ea ho falla e eketseha ka 74,56%. Sena se bolela hore mocheso o phahameng o ntlafatsa ductility ea thepa, e leng ho nolofalletsang ho sebetsa. Li-extruder tse nang le li-alloy tse peli li sebelisa monyetla oa thepa ena, li etsa bonnete ba hore li sebetsa hantle leliphetho tsa boleng bo holimoesita le ka mocheso o phahameng. Sena se ba etsa khetho e tšepahalang bakeng sa lits'ebetso tse batlang.

Nako e telele le ka katleho ea litšenyehelo

E 'ngoe ea melemo e meholo ea li-extruder tsa profil ea PVC ea li-alloy tse peli ke nako e telele ea bophelo. Kaho ea tsona e matla e fokotsa ho senyeha, ho fokotsa tlhokahalo ea ho hlokomeloa khafetsa. Nako ena ea nako e telele e fetolela ho boloka litšenyehelo tse kholo bakeng sa bahlahisi. Ka ho tsetela lisebelisoa tse tšoarellang nako e telele, lik'hamphani li ka fokotsa litšenyehelo tsa tsona ka kakaretso le ho ntlafatsa phaello ea tsona ho tsetelo.

Theko ea litšenyehelo ea li-extruder tsena e hlaka le ho feta ha u sheba lipalo. Ka mor'a ho ntlafatsa theknoloji ea li-alloy tse peli, bahlahisi ba tlalehile phokotso ea 45.8% ea litšila tsa thepa le phokotso ea 28.7% ea tšebeliso ea matla ka kilogram ea tlhahiso. Ho feta moo, phaello ea nako ea matsete e theohile ho tloha ho lilemo tse 5.2 ho ea ho tse 3.8 feela. Lintlafatso tsena li totobatsa melemo ea lichelete ea ho sebelisa li-extruder tse peli tsa alloy, e leng se etsang hore e be khetho e bohlale bakeng sa likhoebo tse ikemiselitseng ho ntlafatsa ts'ebetso ea tsona.

| Metric | Phahamisa pele | Kamor'a Ntlafatso | Ntlafatso |

|---|---|---|---|

| Tšilafalo ea Lintho | 12% | 6.5% | Phokotso ea 45.8%. |

| Tšebeliso ea matla/kg | 8.7 kWh | 6.2 kWh | 28.7% Poloko |

| Nako ea ROI | Lilemo tse 5.2 | Lilemo tse 3.8 | 26.9% Ka potlako |

Ka ho kopanya nako e telele, ts'ebetso ea mocheso o phahameng, le ts'ebetso ea litšenyehelo, li-extruder tsa profil ea PVC tse nang le li-alloy tse peli li fana ka boleng bo ke keng ba lekanngoa. Ha li ntlafatse tlhahiso feela empa hape li thusa likhoebo ho boloka chelete ha nako e ntse e ea.

Likopo le Maemo a Tšebeliso ea Indasteri

Kaho le Lisebelisoa

Li-extruder tse nang le li-alloy tse peli li fetohile phetoho ea lipapali hokaho le meahomafapha. Mechini ena e hlahisa liprofaele tsa PVC tse sebelisoang lifensetereng, mamating le litsing tsa lipeipi. Bokhoni ba bona ba ho sebetsana le maemo a thata bo etsa hore ba phethahale bakeng sa lisebelisoa tsa ka ntle. Mohlala, li-profiles tsa PVC tse entsoeng ka li-extruder tse nang le li-alloy tse peli li hanela kutu e tsoang ho pula, mongobo le lintlha tse ling tsa tikoloho. Ho tšoarella hona ho tiisa hore meaho e lula e le matla ebile e tšepahala ka lilemo.

Ho feta moo, ho nepahala ha li-extruder tsena ho lumella bahlahisi ho etsa li-profile ka boholo bo nepahetseng. Ho nepahala hona ho bohlokoa bakeng sa merero ea kaho moo milimithara e 'ngoe le e 'ngoe e leng ea bohlokoa. Bahahi le litsebi tsa meralo ba khetha litlaleho tsena hobane li kopanya matla le thepa e bobebe, ho etsa hore lipalangoang le ho kenya li be bonolo.

Lik'hemik'hale le Lisebelisoa tsa Indasteri

Liindasteri tse sebetsanang le lik'hemik'hale le lintho tse bohale li itšetlehile haholo ka li-extruder tse peli tsa alloy. Mechini ena e hlahisa li-profile tsa PVC tse ka mamellang ho pepesetsoa li-acids, alkalis le lisebelisoa tse ling tse senyang. Ka mohlala, limela tsa lik'hemik'hale li sebelisa lintlha tsena litankeng tsa polokelo, liphaephe le mekoallo e sireletsang. Ho hanyetsa ho apara le ho senya ho tiisa hore thepa e tšoarella nako e telele, esita le libakeng tse thata.

Ho feta moo, li-extruder tse nang le li-alloy tse peli li ntlafatsa katleho maemong a indasteri. Bonafokotsa litšila tsa lintho tse bonahalangle tšebeliso ea matla, e thusang lik'hamphani ho boloka chelete. Sena se ba etsa khetho e nepahetseng bakeng sa likhoebo tse batlang ho ntlafatsa ts'ebetso ea tsona ha li ntse li boloka maemo a boleng bo holimo.

Liindasteri tsa Likoloi le tsa Aerospace

Liindasteri tsa likoloi le tsa lifofane li batla lisebelisoa tse bobebe le tse tšoarellang nako e telele. Li-extruder tse nang le li-alloy tse peli li kopana le tlhoko ena ka ho hlahisa li-profile tsa PVC tse nang le likarolo tse ikhethang tsa boima ba 'mele. Li-profile tsena li sebelisoa ka hare ho koloi, tsamaiso ea likhoele, esita le likarolo tsa meralo. Ho hanyetsa ha bona mocheso le ho apara ho tiisa hore ba sebetsa hantle tlas'a maemo a feteletseng, a kang lebelo le phahameng kapa ho fetoha ha mocheso.

Sebakeng sa sefofane, ho nepahala ke ntho e 'ngoe le e 'ngoe. Li-extruder tse nang le li-alloy tse peli li lumella bahlahisi ho etsa li-profiles tse nang le mamello e tiileng, ho netefatsa polokeho le ts'epahalo. Theknoloji ena e butse menyetla e mecha ea ho rala likarolo tsa lifofane tse bobebe, ho fokotsa tšebeliso ea mafura, le ho ntlafatsa ts'ebetso e akaretsang.

Li-extruder tsa profil ea Dual-alloy PVC li fana ka nako e telele le ts'ebetso e ke keng ea lekanngoa. Bokhoni ba bona ba ho hanela ho roala le ho sebetsana le maemo a feteletseng bo fokotsa litlhoko tsa tlhokomelo le ho lelefatsa bophelo ba tšebeletso.

Liindasteri tse batlang litharollo tse tšepahalang, tsa nako e telele tsa extrusion li lokela ho nahana ka ho sebelisa theknoloji ena. Ke letsete le bohlale le matlafatsang ts'ebetso le ho theola litšenyehelo tsa ts'ebetso.

LBH

Ke eng e etsang hore li-extruder tsa profil ea PVC tse peli-alloy li fapane le li-extruder tse tloaelehileng?

Li-extruder tse peli tsa alloy li kopanya lisebelisoa tse peli bakeng sa ho tšoarella nako e telele. Li hanela ho khathala, ho bola le mocheso o phahameng, e leng se etsang hore e be sebaka se loketseng tikolohong e thata.

Na li-extruder tsa li-alloy tse peli li ka fokotsa litšenyehelo tsa tlhokomelo?

Ee! Moralo oa bona o matla o fokotsa ho senyeha, ho fokotsa khafetsa ho lokisoa. Baetsi ba boloka nako le chelete ka lisebelisoa tse fokolang.

Nako ea poso: May-19-2025