Li-twin screw extruder li bapala karolo ea bohlokoa lits'ebetsong tsa tlhahiso, haholo lipolasetiki le tlhahiso ea rabara. Tlhokomelo ea kamehla ea "twin screw extruder" e bohlokoa ho boloka mechini ena e sebetsa hantle. Ho hlahloba likarolo tse kang tsapolasetiki extruder screwfor wear, aligning themafahla sekoti extruder dikarolo barrel, le ho beha leihlo taolo ea khatello ea maikutlo ho netefatsa tlhahiso e tsitsitseng. Mekhoa ena e lelefatsa bophelo ba lisebelisoa, ho kenyelletsa lepolasetiki ea mochini oa extrusion screw, le ho fokotsa nako ea ho theoha, ho boloka nako le chelete bakeng sa basebetsi.

Mekhoa ea Bohlokoa ea Tlhokomelo bakeng sa Li-Twin Screw Extruders

Ho Hloekisa Kamehla le ho Hloekisa Lintho

Ho boloka "twin screw extruder" e hloekile ho bohlokoa bakeng sa ho boloka ts'ebetso ea eona. Lintho tse setseng li ka lebisa tšilafalong, tse amang boleng ba sehlahisoa. Ho hloekisa khafetsa ka resin e hloekileng kapa lisebelisoa tse khethehileng tsa ho hloekisa ho thusa ho tlosa litšila tse kang li-gel le li-additives. Mona ke mekhoa e meng e sebetsang ea ho hloekisa:

- Hlatsoa sisteme ka resin e hloekileng kapa lisebelisoa tsa ho hloekisa ho tlosa masala.

- Sebelisa li-resin tsa purge ho tlosa litšila tse manganga.

- Nahana ka mekhoa e tsoetseng pele joalo ka ho hloekisa disco bakeng sa ho hloekisa hantle.

Ho utloisisa hore na lisebelisoa tsa ho hloekisa li sebetsa joang ho ka etsa hore mokhoa oa ho hloekisa o atlehe haholoanyane. Extruder e hloekileng ha e netefatse tlhahiso e tsitsitseng feela empa e boetse e lelefatsa bophelo ba mochini.

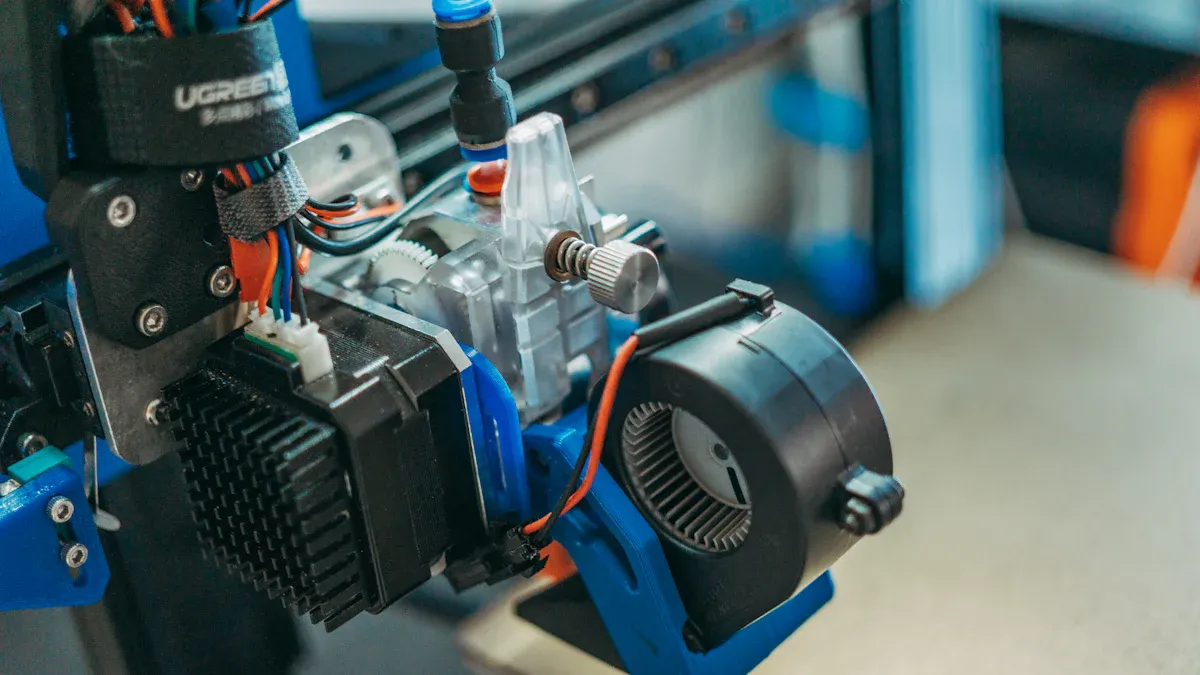

Lubrication e Nepahetseng ea Likarolo Tse Tsamaeang

Lubrication e bapala karolo ea bohlokoa ho boloka likarolo tse tsamaeang tsa "twin screw extruder" li le maemong a holimo. Ntlesetlolo se nepahetseng, khohlano ea eketseha, e lebisang ho taboheng le ho taboha. Lisebelisoa tsa boleng bo holimo li fokotsa khohlano, li lelefatsa bophelo ba likaroloana, 'me li ntlafatsa ts'ebetso e akaretsang.

| Molemo | Tlhaloso |

|---|---|

| E thellang | E fella ka khohlano e fokolang |

| Bophelo bo bolelele | E eketsa bophelo ba likere, li-bearings le litiiso |

| Mocheso | E fokotsa mocheso oa lisebelisoa le lerata |

| Viscosity | E boloka viscosity ho sa tsotellehe ho kuta mochine |

| Mocheso o Phahameng | E boloka viscosity e phahameng ka mocheso o phahameng |

Ho hlahloba khafetsa le ho tlatsa litlolo ho netefatsa hore extruder e sebetsa hantle, esita le tlas'a maemo a boima.

Litlhahlobo tse Tloaelehileng bakeng sa Wear and Taar

Litlhahlobo tsa ka mehla ke tsa bohlokoa bakeng sa ho tseba mathata a ka bang teng pele a ka mpefala. Ho hlahloba hore na ha ho na ho senyeha ha likarolo tse kang li-screw le libarele ho ka thibelatokiso e bitsang chelete e ngata le nako ea ho theoha. Litlhahlobo li boetse li thusa ho boloka boleng ba sehlahisoa bo sa fetoheng.

| Molemo | Tlhaloso |

|---|---|

| Tlhokomelo ea Wear and Tear | Ho tsebahatsa ka nako ea maemo a ho apara ho thibela litaba tsa tlhahiso. |

| Phokotso ea Litšenyehelo | E fokotsa tšebeliso ea thepa ea ho hloekisa le litšenyehelo nakong ea liphetoho tsa mebala. |

| Katleho ea Mosebetsi | E nolofatsa tlhokomelo, e khutsufatsa nako ea ho theoha, 'me e fokotsa matla a mosebetsi. |

Ka ho hlophisa tlhahlobo ea khafetsa, basebelisi ba ka sebetsana le litaba tse nyane esale pele, ho netefatsa hore "twin screw extruder" e lula e tšepahala ebile e sebetsa hantle.

Ho beha leihlo le ho fetola Litiiso le Bearings

Litiiso le li-bearings ke likarolo tsa bohlokoa tse hlokang tlhokomelo e haufi. Litiiso tse tsofetseng li ka etsa hore li lutle, athe li-bearings tse senyehileng li ka baka khohlano le ho fokotsa ts'ebetso e sebetsang. Ho beha leihlo likarolo tsena le ho li nkela sebaka ha ho hlokahala ho netefatsa hore extruder e sebetsa ka lebelo le holimo.

- Ho hlahloba khafetsa ho thibela ho roala pele ho nako le likhohlano.

- Ho fetola litiiso tse senyehileng le li-bearings ho boloka katleho le boleng ba sehlahisoa.

- Tlhokomelo e nepahetseng e eketsa nako ea bophelo ea extruder.

Ka ho beha likarolo tsena pele, basebelisi ba ka qoba ho senyeha ho sa lebelloang le ho boloka boleng bo tsitsitseng ba tlhahiso.

Ho Rarolla Mathata a Tloaelehileng ho Twin Screw Extruders

Ho Rarolla Mathata a Ho Fetela ho Fetisisa

Ho futhumala ho feteletseng ho ka sitisa ts'ebetso ea "twin screw extruder" esita le ho senya lisebelisoa tse hlokolosi. Ho laola mocheso oa moqomo le khatello ke senotlolo sa ho thibela taba ena. Basebelisi ba lokela ho lekola boemo ba mocheso khafetsa le ho netefatsa hore sistimi ea ho pholisa e sebetsa hantle.

- Ho na le kamano e tobileng pakeng tsa khatello le ho phahama ha mocheso. Bakeng sa keketseho e 'ngoe le e 'ngoe ea 2-bar ea khatello, mocheso o nyoloha ka 1°C. Ho boloka khatello e tsitsitse ho thusa ho laola mocheso o feteletseng.

- Ho kenya lisebelisoa tse hlahisang khatello, joalo ka lipompo tsa gear, ho ka tsitsisa khatello le ho laola mocheso o qhibilihang ka nepo.

- Nako e khuts'oane ea ho lula ka har'a li-scruder tse peli e fokotsa ho pepesehela mocheso o phahameng, e leng molemo haholo bakeng sa lisebelisoa tse sa utloeng mocheso.

Ka ho sebetsana le mocheso o feteletseng, basebetsi ba ka boloka boleng bo tsitsitseng ba sehlahisoa le ho qoba ho theoha ho sa hlokahaleng.

Ho Thibela Screw Wear le Tšenyo

Sekoahelo sa screwke taba e tloaelehileng e amang katleho ea li-twin screw extruders. Ho hlahlojoa khafetsa le ho sebelisoa ha thepa e sa sebetseng ho ka thusa ho thibela bothata bona. Litlhahiso tse sebetsang ke tsena:

- Hlahloba li-screws le libarele khafetsa ho tseba matšoao a pele a ho khathala.

- Sebelisa lisebelisoa tsa boleng bo holimo, tse sa senyeheng bakeng sa likurufu le libarele ho lelefatsa bophelo ba tsona.

- Netefatsa boholo ba likaroloana nakong ea phepelo ea lintho tse bonahalang ho fokotsa ho roala ha letlalo.

Ho thibela ho roala li-screw ha ho boloke ts'ebetso feela empa hape ho netefatsa boleng bo tsitsitseng ba sehlahisoa ha nako e ntse e ea.

Tharollo ea Mathata a Material Build-up

Ho bokella lintho ka hare ho extruder ho ka lebisa tlhahiso e sa tsitsang le ho fokotsa katleho. Ho rarolla mathata ka katleho ho ka ntlafatsa haholo liphetho tsa ts'ebetso.

Ho laola boemo ba mocheso ho bohlokoa. Ho fetola maemo a mocheso ho nolofatsa resin, ho ntlafatsa ho kopanya ho qhalakaneng le ho thibela ho senyeha ha thepa. Ntle le moo, ho ntlafatsa sebopeho sa screw ho lumella taolo e betere holim'a viscosity e qhibilihisitsoeng, e ntlafatsang katleho ea ho kopanya.

Basebelisi ba boetse ba lokela ho hloekisa extruder khafetsa ho tlosa lisebelisoa tse setseng. Mokhoa ona o fokotsa tšilafalo mme o netefatsa ts'ebetso e bonolo.

Ho Rarolla Boleng ba Sephetho bo sa Tletseng

Boleng bo sa tsitsang ba tlhahiso bo ka fella ka thepa e senyehileng le litšenyehelo tse eketsehileng. Ho sebetsana le taba ena ho hloka ho tsepamisa maikutlo taolong ea boleng le tlhahlobo ea nako ea nnete.

- Moetsi ea kopantseng tsamaiso ea Model Predictive Control (MPC) le "twin screw extruder" o bone keketseho ea 15% ea tlhahiso le phokotso ea 10% ea thepa e sa tloaelehang.

- Khamphani e 'ngoe e kentse rheometer ea in-line ho lekola ho fetoha ha viscosity. Ka ho fetola lebelo la screw le boemo ba mocheso ho ipapisitsoe le data ea nako ea nnete, ba fokolitse sekhahla sa ho hana ka 25%.

Mehlala ena e totobatsa kamoo ho rarolla ho se lumellane ha lihlahisoa ho ka ntlafatsang ts'ebetso ea sehlahisoa le ho fokotsa litšila.

Malebela a Ntlafatso bakeng sa Twin Screw Extruders

Tlhophiso e Ntle Taolo ea Mocheso

Taolo ea mocheso ke phetoho ea papali bakeng sa ho ntlafatsa ts'ebetso ea "twin screw extruder". Ho fetola mocheso libakeng tse itseng ho ka ntlafatsa ho qhibiliha ha thepa le ho fokotsa ho senyeha ha likaroloana. Mohlala:

- Ho beha libaka tsa 1 le 2 ho ea ho mocheso o phahameng ho fokotsa ho apara linthong tsa polasetiki. Phetoho ena e lumella lisebelisoa hore li qhibilihe ka mokhoa o atlehileng haholoanyane, ho fokotsa tlhokahalo ea matla a mechine.

- Lithuto tsa Maridass le Gupta, hammoho le Ulitzsch et al., li totobatsa kamooho ntlafatsa mocheso oa moqomoe ntlafatsa boleng ba ts'ebetso le ho ntlafatsa ts'ebetso.

Ho feta moo, ho boloka likhatello tse tlase tsa ho tsoa ho ka tsitsisa mocheso oa ho qhibiliha. Mokhoa ona o fokotsa ho roala ha li-screws le ho matlafatsa botsitso ba mocheso, ho netefatsa ts'ebetso e tsitsitseng.

Ho Ntlafatsa Phepelo le Tšoaro ea Lintho Tse Bonahalang

Ho fepa le ho sebetsana ka katleho le thepa ho ama ka kotloloho tšebetso ea extruder le tšebeliso ea matla. Likhamphani li fumane litholoana tse ntle ka ho ntlafatsa lits'ebetso tsena:

- Mochine oa li-polymers tse matlafalitsoeng ka khalase o ile oa eketsa tlhahiso ka 18% ka ho kopanya sefepi se ka thōko le ho fetola moralo oa screw.

- Phallo e ile ea phahama ho tloha ho 2000 kg / hr ho ea ho 2300 kg / hr, e hlahisang $ 180,000 e eketsehileng phaellong ea selemo.

- Ho boloka matla a 5% (kapa 138 MWh/yr) ho fihletsoe ka lebaka la tekanyo e phahameng ea ho tlatsa extruder.

Lintlafatso tsena ha li ntlafatse ts'ebetso ea ts'ebetso feela empa hape li fokotsa litšenyehelo, li etsa hore e be katleho e kholo ho bahlahisi.

Ho Lokisa Screw Configuration bakeng sa Lits'ebetso tse Ipehileng

Ho iketsetsa tlhophiso ea screw ho ka ntlafatsa haholo ts'ebetso ea lisebelisoa le lits'ebetso tse fapaneng. Litokiso tsa bohlokoa li kenyelletsa:

- Ho fetola botebo ba seteishene ho ntlafatsa tekanyo ea compression bakeng sa thermoplastics.

- Ho eketsa karo-karolelano ea "screw-to-diameter" (L/D) ho matlafatsa ho kopanya le ho qhibilihisa.

- Ho kenyelletsa likarolo tsa spiral kapa li-mixer tsa Maddock bakeng sa ho kopanya hantle le taolo ea mocheso.

- Ho lokisa angle ea helix le sekontiri ho netefatsa phallo e nepahetseng ea thepa.

- Ho sebelisa li-barrier screws ho arola lisebelisoa tse qhibilihisitsoeng le tse sa qhibilihang, ho ntlafatsa botsitso.

Litokiso tsena li lumella li-operators ho etsa extruder hore e lumellane le litlhoko tse itseng, ho etsa bonnete ba hore liphetho li nepahetse.

Ntlafatso ea Ts'ebetso ea Ts'ebetso ka Boiketsetso

Automation e fetotse tsela eo li-twin screw extruder li sebetsang ka eona. Litsamaiso tse tsoetseng pele tse nang le li-sensor le tlhahlobo ea nako ea nnete li fokotsa tlhoko ea ho kenella ka letsoho. Likarolo tsa ho lokisa esale pele li fokotsa nako le ho ntlafatsa ts'epahalo.

Artificial Intelligence (AI) e nka boiketsetso mohato o mong hape ka ho ntlafatsa liparamente tsa extrusion le phallo ea thepa. Sena se lebisa ho fokotseheng ha litšila, taolo ea boleng bo betere, le ts'ebetso e matlafalitsoeng ka kakaretso. Baetsi ba sebelisang li-automation ba bona ntlafatso e kholo tlhahisong le ho boloka litšenyehelo, e leng ho etsang hore e be letsete la bohlokoa.

Mehato ea Thibelo bakeng sa Twin Screw Extruders

Ho phethahatsa Lits'ebetso tsa Ka mehla tsa Tlhokomelo

Litokisetso tsa kamehla tsa tlhokomelo ke mokokotlo oa tlhokomelo ea thibelo bakeng sali-fin screw extruders. Tlhokomelo ea kamehla e tiisa hore mechini e sebetsa hantle 'me e qoba ho senyeha ho sa lebelloang. Basebelisi ba ka rera nako ea ho lokisa ho ipapisitse le data ea nalane, ho khutlisa kapa ho nchafatsa likarolo pele li hloleha.

Keletso: Lenaneo la tlhokomelo e hlophisitsoeng ha le thibele nako ea ho theoha feela empa hape le eketsa nako ea bophelo ea lisebelisoa.

Mona ke seo liphuputso tsa indasteri li se senolang ka melemo ea tlhokomelo e tloaelehileng:

| Molemo | Tlhaloso |

|---|---|

| Ntlafatso ea Ts'ebetso | Tlhokomelo ea kamehla e netefatsa ts'ebetso ea tlhōrō ka ho lumellana hantle le ho tlotsa likarolo. |

| Ho Thibela Nako ea ho Pholosa | Tlhokomelo e reriloeng e fokotsa tšenyo e sa lebelloang, e lumellang hore ho be le litšitiso tse reriloeng tsa tlhahiso. |

| Ho Boloka Litšenyehelo | Licheke tse tloaelehileng li ka thibela mathata a manyenyane hore e se ke ea e-ba mathata a maholo, ho boloka litšenyehelo tsa ho lokisa. |

| Polokeho | Tlhokomelo e nakong e fokotsa likotsi tsa polokeho bakeng sa basebelisi ba mochini ka ho sebetsana le likarolo tse tsofetseng kapa tse senyehileng. |

| Katoloso ea Bophelo | Tlhokomelo e tsitsitseng e ka eketsa haholo bophelo ba ts'ebetso ea extruder, ho sireletsa matsete. |

| Boleng ba Sehlahiswa | Mechini e hlokometsoeng hantle e hlahisa lihlahisoa tsa boleng bo holimo ka ho thibela litšila tse entsoeng ka thepa. |

| Matla a Matla | Licheke tsa khafetsa li ntlafatsa lisebelisoa bakeng sa tšebeliso e ntle ea matla, ho fokotsa litšenyehelo tsa ts'ebetso. |

Ka ho khomarela kemiso ea tlhokomelo, basebetsi ba ka qoba litokiso tse bitsang chelete e ngata ’me ba boloka tlhahiso e sebetsa ka katleho.

Basebelisi ba Koetliso ka Mekhoa e Metle ka ho Fetisisa

Li-operators li phetha karolo ea bohlokoa ho boloka li-twin screw extruder. Ho ba koetlisa ka mekhoa e metle ho netefatsa hore ba utloisisa mokhoa oa ho sebetsana le lisebelisoa hantle. Basebelisi ba rutehileng ba ka tseba matšoao a pele a ho khathala le ho rarolla mathata a manyane pele a ka mpefala.

Hlokomela: Mananeo a koetliso a tlameha ho akaretsa tlhahlobo ea kamehla, mekhoa ea ho tlotsa, le ho rarolla mathata a tloaelehileng.

Ha basebetsi ba tseba ho kena le ho tsoa ha mochine, ba ka khona ho lokisa le ho fetola ka nako, ho fokotsa nako le ho ntlafatsa tlhahiso.

Ho boloka Likarolo tsa Spare Inventory li Lokisitsoe

Ho ba le likarolo tse ling ka letsoho ho pholosa bophelo maemong a sa lebelloang. Litiiso tse tsofetseng, li-bearing, kapa likurufu li ka emisa tlhahiso haeba tse ling li sa fumanehe habonolo. Ho boloka lethathamo la likarolo tsa bohlokoa ho netefatsa litokiso tse potlakileng le ho fokotsa nako ea ho theoha.

- Likarolo tsa bohlokoa tsa thepa joalo ka li-screws, barrel le liqibi.

- Lekola maemo a moaparo ho bona esale pele litlhoko tse ncha.

- Selekane le bafani ba thepa ba tšepahalang ho netefatsa boleng le ho fumaneha.

Setoko se nang le thepa e ngata se boloka ts'ebetso e sebetsa hantle 'me e thibela tieho e theko e boima.

Ho Sebelisa Lisebelisoa le Likarolo tsa Boemo bo Phahameng

Lisebelisoa tsa boleng bo holimo ke motheo oa li-extruder tse ka tšeptjoang tsa mafahla. Likarolo tse entsoeng ka thepa e tšoarellang joalo ka tšepe ea nitriding li ntlafatsa ts'ebetso le ho fokotsa litlhoko tsa tlhokomelo. Mekhoa e tsoetseng pele ea tlhahiso, joalo ka quenching le nitriding, e ntlafatsa bophelo bo bolelele ba likarolo.

Ho tsetela ka thepa ea premium ho lefa ka nako e telele. Baetsi ba na le mathata a fokolang, litšenyehelo tse tlase tsa tlhokomelo, le ts'ebetso e tsitsitseng.

Ka ho beha boleng pele, basebetsi ba sireletsa matsete a bona mme ba natefeloa ke ROI e ntle ka ho fokotsa litšenyehelo tsa ts'ebetso le nako ea ho theoha.

Tlhokomelo ea kamehla e boloka li-scruder tse mafahla li sebetsa hantle. Tlhokomelo e sebetsang e fokotsa nako ea ho theoha, e lelefatsa bophelo ba lisebelisoa, 'me e netefatsa boleng bo tsitsitseng ba sehlahisoa. Basebelisi ba latelang malebela ana ba ka eketsa ts'ebetso mme ba qoba litokiso tse bitsang chelete e ngata.

Keletso: Qala hanyane. Theha kemiso ea tlhokomelo 'me u koetlise sehlopha sa hau. Mehato ena e etsa phapang e kholo ka nako e telele!

LBH

Mokhoa o motle oa ho hloekisa "twin screw extruder" ke ofe?

Ho hloekisa ka resin e loketseng kapa thepa ea ho hloekisa ho sebetsa hantle. E tlosa masalla mme e thibela tšilafalo, e netefatsa ts'ebetso e tsitsitseng le boleng ba sehlahisoa.

Tlhokomelo e tloaelehileng e lokela ho etsoa hangata hakae?

Basebelisi ba lokela ho latela litlhahiso tsa moetsi. Ka tloaelo, tlhokomelo e tloaelehileng ea "twin screw extruder" e lokela ho etsahala lihora tse ling le tse ling tse 500-1,000 tsa ts'ebetso.

Ke eng e bakang ho roala ha screw ka har'a "twin screw extruder"?

Hangata li-screw li hlaha ka lebaka la lisebelisoa tse chefo, mocheso o phahameng oa ho sebetsa, kapa ho tlotsa ka mokhoa o sa lokelang. Ho hlahlojoa khafetsa le ho sebelisa lisebelisoa tse sa tsitsang ho ka thusa ho fokotsa taba ena.

Nako ea poso: May-29-2025