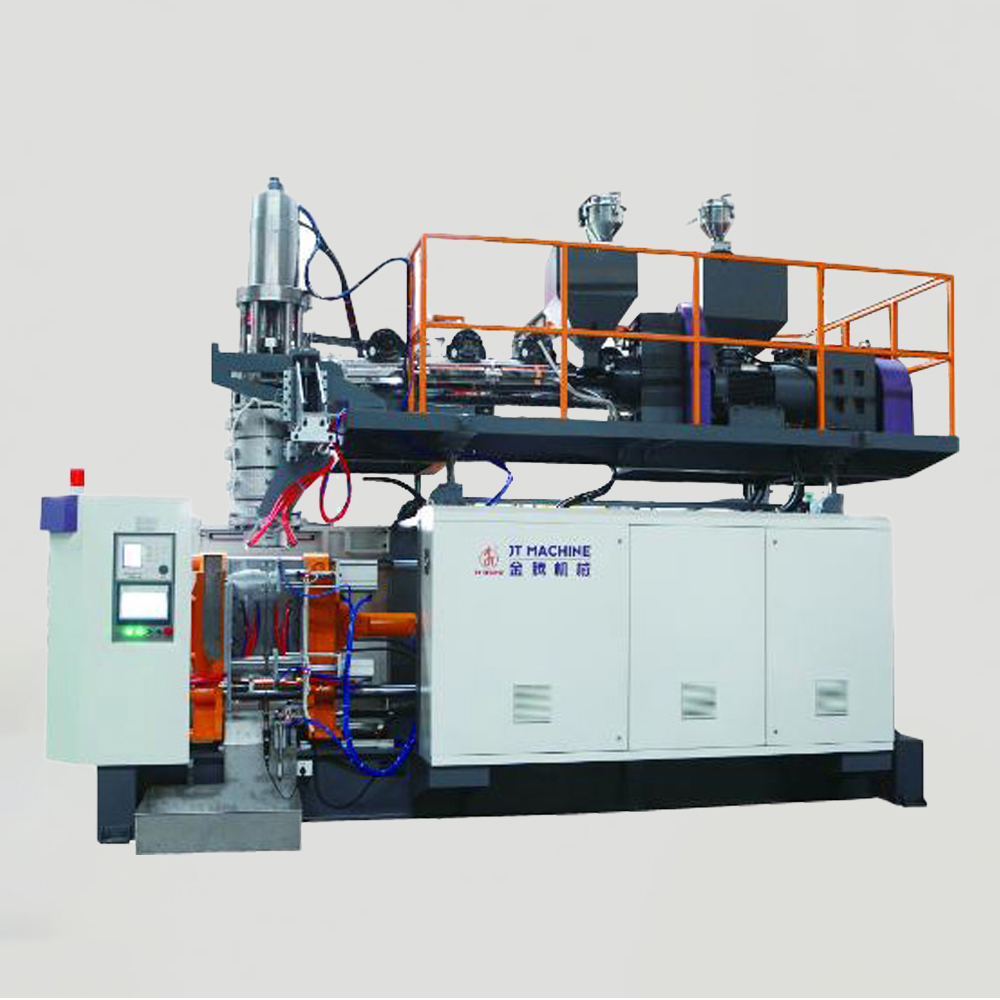

Mechini e tsoetseng pele ea ho fehla libotlolo e fetotse sebopeho sa tlhahiso. Hona joale liindasteri li itšetlehile ka mechine ena ho finyella litlhoko tse ntseng li eketseha tsa tlhahiso ea lebelo le phahameng le e nepahetseng. Likarolo tse kang automation le tlhahlobo ea nako ea nnete li netefatsa boleng bo ts'oanang ha li ntse li fokotsa litšenyehelo. Mefuta ea lebelo le holimo e ka hlahisa pakeng tsa libotlolo tse 500 ho isa ho tse 1,000 ka hora, e sebetsana le tlhoko e ntseng e hola ea indasteri ea lino ea litharollo tse sebetsang hantle. Ho feta moo, phetoho e lebisang ho liphutheloana tse bobebe e lebisitse bahlahisi, ho kenyeletsoaLifeme tsa mochini o fokang botlolo ea PP, ho amohela theknoloji ena bakeng sa ho ikamahanya le maemo. Ho feta moo, ho kopanngoa ha aPVC foam board extrusion linee matlafatsa bokhoni ba tlhahiso, ha asingle screw extruder bakeng sa mokotla oa lithōletlhahiso e tlatsana le lits'ebetso tse fapaneng tsa metjhini ena e tsoetseng pele.

Kamoo Mechini e Bululang Libotlolo e Sebetsang Kateng

Pōpo ea Preform le Ho futhumatsa

Ts'ebetso ea ho phatloha ha botlolo e qala ka ho theha le ho futhumatsa ha preforms. Li-preform tsena, tseo hangata li entsoeng ka thepa e kang PET, li futhumatsoa ho fihlela sebopeho se nepahetseng sa ho bopa. Mechini e tsoetseng pele ea ho fehla libotlolo e sebelisa mahlaseli a infrared kapa moea o chesang ho futhumatsa li-preforms. Sena se tiisa ho tšoana ha mocheso oa thepa, e leng ntho ea bohlokoa bakeng sa ho boloka boleng bo tsitsitseng nakong ea mekhahlelo e latelang.

Mokhoa oa ho futhumatsa mechine ea kajeno o etselitsoe ho nepahala. Basebelisi ba ka laola mocheso ho fokotsa liphoso, ka litlhophiso tse khothaletsoang hangata ho pota 45°C (113°F). Boemo bona ba taolo bo fokotsa litšila tsa thepa mme bo netefatsa hore li-preforms li lokiselitsoe ka ho lekaneng bakeng sa ho otlolla le ho fofa. Ka mor'a ho futhumatsa, li-preforms li fetoha ka mokhoa o tsitsitseng ho ea sethaleng se latelang, moo li bōpehileng ka libotlolo.

Ho Bopa le ho Bopa

Hang ha e futhumetse, li-preforms li kenngoa ka har'a hlobo e hlalosang sebōpeho sa ho qetela le boholo ba libotlolo. Mokhoa oa ho bopa o kenyelletsa likarolo tse 'maloa tsa bohlokoa tse sebetsang ka kutloano ho netefatsa ho nepahala le ho sebetsa hantle.

- Setsi sa ho futhumatsa: E nolofatsa preform bakeng sa pliability.

- Mold Clamping System: E sireletsa hlobo 'me e tsamaisane le preform bakeng sa sebopeho se nepahetseng.

- Ho otlolla le ho FokaMokhoa: E otlolla preform e nolofalitsoeng ha moea o hatelletsoeng o e phetlela ka har'a hlobo, e etsa botlolo.

Mochini oa ho phunya libotlolo tsa JT o ipabola mothating ona ka lebaka la lits'ebetso tsa ona tse tsoetseng pele tsa taolo le moralo o matla. Likarolo tse joalo ka ts'ebetso ea ho phahamisa sethala li amohela libaka tse fapaneng tse phahameng, tse nolofalletsang tlhahiso ea meralo e fapaneng ea libotlolo. Ntle le moo, sistimi e lekanang ea hydraulic ea mochini e netefatsa liketso tse boreleli le tse potlakileng, tse ntlafatsang tlhahiso.

| Karolo | Mosebetsi |

|---|---|

| Setsi sa ho futhumatsa | E nolofatsa preform e sebelisa mahlaseli a infrared bakeng sa pliability nakong ea ho bopa. |

| Mold Clamping System | E sireletsa hlobo sebakeng mme e tsamaisane le preform bakeng sa sebopeho se nepahetseng sa botlolo. |

| Ho otlolla le ho Foka | E otlolla preform e nolofalitsoeng ebe e butsoela moea ho eona ho bopa botlolo ka nepo. |

| Sistimi e phodileng | Ka potlako e pholisa botlolo ho boloka sebopeho le botšepehi ba sebopeho ka mor'a ho bōptjoa. |

| Sistimi ea Ejection | E tlosa botlolo e phethiloeng ka hlobo ho sebelisa matsoho a mochine kapa khatello ea moea ntle le tšenyo. |

Mokhahlelo ona o totobatsa ho tenyetseha ha mechini e butsoelang libotlolo, e ka amohelang boholo le libopeho tse fapaneng ho fihlela litlhoko tse fapaneng tsa mmaraka.

Mokhoa oa ho Pholisa le ho Ejection

Mokhahlelo oa ho qetela o kenyelletsa ho pholile le ho ntša libotlolo. Ho pholisa ka potlako ho tiisa sebopeho sa botlolo, ho etsa bonnete ba hore e boloka sebopeho sa eona mme e kopana le maemo a boleng. Mechini e tsoetseng pele joalo ka letoto la JT e sebelisa motsoako oa lisebelisoa tsa ho pholisa moea le metsi ho potlakisa ts'ebetso ena. Linako tsa ho pholile li ka tloha ho metsotsoana e 1.5 ho isa ho metsotsoana e 20, ho itšetlehile ka boholo ba botlolo le thepa.

Kamora ho pholile, libotlolo li ntšoa ka har'a hlobo ho sebelisoa matsoho a mochini kapa khatello ea moea. Mohato ona ke oa bohlokoa bakeng sa ho boloka lebelo la tlhahiso le ho thibela tšenyo ea lihlahisoa tse felileng. Letoto la JT le kenyelletsa sistimi ea othomathike ea lubrication le sistimi ea cylinder drive bakeng sa ejection e sebetsang, ho fokotsa litlhoko tsa tlhokomelo le nako ea ts'ebetso.

| Tshebetso | Tlhaloso |

|---|---|

| Ho phodisa | Ho pholisa ka potlako ho tiisa sebopeho sa botlolo, ho netefatsa ho boloka sebopeho le potoloho ea tlhahiso e potlakileng. |

| Ejection | Libotlolo lia ntšoa ka mor'a ho pholile 'me li tlas'a taolo ea boleng ho finyella litekanyetso tsa tlhahiso. |

Ka ho kopanya likarolo tsena tse tsoetseng pele, mechini e bululang libotlolo e eketsa lebelo la tlhahiso le ho netefatsa boleng bo ts'oanang, e etsa hore e be tsa bohlokoa haholo tlhahisong ea sejoale-joale.

Melemo ea Bohlokoa ea Mechini ea ho Felisa Libotlolo

Keketseho ea Lebelo la Tlhahiso le Katleho

Mechini ea sejoale-joale e fefolang libotlolo e fetotse lits'ebetso tsa tlhahiso ka ho eketsa lebelo le ts'ebetso haholo. Mechini ena e sebelisa mekhoa e tsoetseng pele, joalo ka lits'ebetso tse tsamaisoang ke servo le theknoloji e lekanang ea hydraulic, ho tsamaisa ts'ebetso. Mochini o fehlang botlolo oa JT o fana ka mohlala oa boqapi bona, o hlahisa lihlahisoa tsa polasetiki tse se nang letho ka nepo le lebelo le makatsang.

Lebelo la tlhahiso le fapana ho latela mokhoa o sebelisitsoeng. Theknoloji ea Blow blow e fihlella libotlolo tse fihlang ho 200 ka motsotso, ha mekhoa ea khatiso ea khatiso e fapana pakeng tsa 50 le 100 libotlolo ka motsotso. Mokhoa ona o fapaneng o lumella bahlahisi ho khetha mokhoa o loketseng ka ho fetisisa bakeng sa litlhoko tsa bona tse khethehileng.

| Mokhoa | Lebelo la Tlhahiso (libotlolo ka motsotso) |

|---|---|

| Phatlala | 200 |

| Tobetsa Blow | 50-100 |

Ho kopanya ha othomathike ho eketsa ts'ebetso. Likarolo tse kang lits'ebetso tsa othomathike tsa lubrication le tlhahlobo ea nako ea nnete li fokotsa nako le litlhoko tsa tlhokomelo. Lintlafatso tsena li thusa bahlahisi ho fihlela litlhoko tsa boleng bo holimo ha ba ntse ba boloka tlhahiso e tsitsitseng.

Keletso: Ho tsetela metjhini e butsoitseng libotlolo ka lebelo le holimo ho ka thusa likhoebo ho lekanya tlhahiso ntle le ho senya boleng.

Boleng bo tsitsitseng le bo ka tšeptjoang

Ho lumellana ka boleng ba sehlahisoa ke letšoao la mechine e tsoetseng pele ea ho phunya libotlolo.Boenjiniere bo nepahetsenge etsa bonnete ba hore botlolo e 'ngoe le e' ngoe e kopana le litekanyetso tse thata, ho fokotsa bofokoli le litšila. Letoto la JT le kenyelletsa theknoloji ea servo stretch blowing, e ntlafatsang boleng ba botlolo ka ho fokotsa liphoso.

Lisebelisoa tsa ho futhumatsa tsa infrared li bapala karolo ea bohlokoa ho boloka ho tšoana. Litsamaiso tsena li arola mocheso ka ho lekana ho pholletsa le li-preforms, ho thibela matšoao a khatello ea maikutlo le marako a sa lekaneng. Mokhoa ona o hlokolosi o fella ka libotlolo tse sa khahlehang feela empa hape le sebopeho se setle.

| Sebopeho | Tšusumetso ho Tšebelisano ea Boleng |

|---|---|

| Precision Engineering | E netefatsa libotlolo tsa boleng bo holimo tse nang le litekanyo tse sa fetoheng |

| Servo Otlolla Foka | E ntlafatsa boleng ba botlolo, e fokotsa bofokoli |

| Ho futhumatsa ha infrared | E fokotsa matšoao a khatello ea maikutlo le marako a sa lekaneng |

Baetsi ba liindasteri tse kang ho paka lijo le meriana ba itšetlehile ka mechini ena ho hlahisa libotlolo tse khomarelang litekanyetso tse thata tsa taolo. Letoto la JT le hlahelletse ka bokhoni ba lona ba ho fana ka liphetho tse tšepahalang lits'ebetsong tse fapaneng.

Hlokomela: Boleng bo tsitsitseng bo fokotsa tlhoko ea ho sebetsa bocha, ho boloka nako le lisebelisoa.

Matla a Matla le Ho Boloka Litšenyehelo

Matla a matla ke ntlha ea bohlokoa tlhahisong ea sejoale-joale. Mechini e tsoetseng pele ea ho fehla libotlolo, joalo ka letoto la JT, e kenyelletsa mekhoa ea ho boloka matla e fokotsang litšenyehelo tsa ts'ebetso. Li-mothara tse feto-fetohang le li-hydraulic system tse laoloang ke servo li ntlafatsa tšebeliso ea matla, e leng se etsang hore mechini ena e be 15% ho isa ho 30% e sebetsang hantle ho feta mefuta ea khale.

| Tlhaloso ea Bopaki | Lintlha |

|---|---|

| Tšusumetso ea Tšebeliso ea Matla | Mechini ea setso e sebelisa matla a 25% ho feta mefuta e nyalisitsoeng, e lebisang litšenyehelong tse phahameng tsa ts'ebetso. |

| Litšenyehelo tsa Motlakase | Litšenyehelo tsa motlakase li etsa karolo ea 20% ea litšenyehelo tsa tlhahiso ka kakaretso, li khothaletsa matsete mochining o baballang matla. |

| Phokotso ea Tšebeliso ea Matla | Mechini e mecha e ka fokotsa tšebeliso ea matla ka 15%, e amang litšenyehelo tsa ts'ebetso ka kotloloho. |

Ho feta moo, phetoho e lebisang mekhoeng e tšoarellang e tsamaisa ho amoheloa ha mechini e tšehetsang lipolasetiki tse ka senyehang. Hoo e ka bang 35% ea mefuta e mecha e etselitsoe ho amohela lisebelisoa tse ka sebelisoang hape, tse tsamaellanang le merero ea tikoloho.

- Tšebeliso eamekhoa e sebetsang hantle ea matlae fokotsa litšenyehelo tsa motlakase, tse ikarabellang bakeng sa karolo e kholo ea litšenyehelo tsa tlhahiso.

- Bahlahisi ba amohelang tlhahiso e tsitsitseng ea libotlolo ba rua molemo ka tšebeliso e tlase ea matla le ho fokotsa tšusumetso ea tikoloho.

Ka ho etelletsa pele ts'ebeliso ea matla a matla, likhoebo li ka fumana poloko ea nako e telele ha li ntse li kenya letsoho boitekong ba ts'ebetso ea lefats'e.

Hoelehetsa: Mechini e fefolang libotlolo e baballang matla ha e fokotse litšenyehelo feela empa hape e ts'ehetsa mekhoa ea ho etsa eco-friendly.

Tsoelo-pele ea Theknoloji Mechineng e Fellang Libotlolo

Automation le Smart Control Systems

Automation e se e le lejoe la sekhutlo la mechini ea sejoale-joale e butsoelang libotlolo, e fetolang lits'ebetso tsa tlhahiso ka nepo le ts'ebetso e ke keng ea bapisoa. Sistimi ea taolo e bohlale, e tsamaisoang ke bohlale ba maiketsetso le li-sensor tse tsoetseng pele, li thusa ho beha leihlo ka nako ea nnete le litokiso tsa othomathike. Lintlha tsena li netefatsa boleng bo tsitsitseng le ho fokotsa litšila tsa thepa. Mohlala, tlhahlobo e tsoelang pele e ntlafatsa ts'ebetso ea data, e lumellang baetsi ho tseba le ho rarolla mathata kapele.

Litsamaiso tse ikemetseng li boetse li ntlafatsa lebelo la tlhahiso le ts'ebetso ea mosebetsi. Mechini e nang le liroboto e ka ikamahanya le mefuta e fapaneng ea libotlolo, e felisa tlhoko ea li-setups tse ngata. Ho feto-fetoha ha maemo ho fokotsa nako ea ho theoha le ho eketsa tlhahiso. Ho feta moo, likhokahano tse bonolo tsa basebelisi li nolofatsa ts'ebetso, li fokotsa litlhoko tsa koetliso le ho ntlafatsa tlhahiso ka kakaretso.

| Karolo | Tlhaloso |

|---|---|

| Nepahetseng le ho tsitsisa | Automation e etsa bonnete ba hore botlolo e 'ngoe le e' ngoe e kopana le litlhaloso tse nepahetseng, e fokotsa bofokoli le litšila. |

| Lebelo | Lisebelisoa tse ikemetseng li ntlafatsa haholo lebelo la tlhahiso le ho fokotsa tieho. |

| Smart Manufacturing | Ho kopanya le lits'ebetso tsa data ho lumella ho lokisoa esale pele le ho ntlafatsa ts'ebetso. |

Lintlafatso tsena li etsa hore boiketsetso e be tšobotsi ea bohlokoa bakeng sa bahlahisi ba ikemiselitseng ho lula ba le tlholisano 'marakeng o potlakileng.

Ho feto-fetoha ha Meralo le Boholo ba Botlolo

Mechini ea sejoale-joale ea ho fehla libotlolo e fana ka mefuta e mengata e fapaneng, e amohelang amefuta e mengata ea meralo ea libotlolole boholo. Mechini e kang letoto la JT e sebetsa hantle haholo ho hlahiseng libotlolo tsa libopeho tse fapaneng le meqolo, ho tloha lijaneng tse nyane tsa 100 ml ho isa lihlahisoa tse kholo tsa 50-litre. Litsamaiso tse tsoetseng pele tsa taolo le li-sensor li netefatsa ho nepahala, ho boloka botsitso ba sebopeho ho meralo eohle.

Baetsi ba rua molemo ka ho ikamahanya le maemo, kaha e felisa tlhokahalo ea mechine e mengata ea ho sebetsana le mefuta e sa tšoaneng ea libotlolo. Mohlala, mechini ea PET Technologies ea ho bopa e ka hlahisa libotlolo bakeng sa lits'ebetso tse khutlisoang ha e ntse e ts'ehetsa lisebelisoa tsa PET tse 100%. Bokhoni bona bo tsamaellana le mekhoa ea indasteri ho isa litharollong tse bobebe le tse tšoarellang tsa ho paka.

- Mechini e khona ho sebetsana le libopeho le boholo bo fapaneng ba libotlolo, e netefatsa ho nepahala le ho sebetsa hantle haholo.

- Li-sensor tse tsoetseng pele li ntlafatsa maemo a tlhahiso, li ntlafatsa maemo a tlhahiso.

Mokhoa ona oa ho feto-fetoha o lumella bahlahisi ho fihlela litlhoko tsa liindasteri tse fapaneng, ho tloha ho lino tse tahang ho ea ho tsa meriana, ka boiketlo.

Kopanyo le Mekhoa e Tsoelang Pele

Ho tšoarella ho fetohile ntlha ea bohlokoa tlhahisong ea libotlolo. Mechini e tsoetseng pele ea ho fehla libotlolo hona joale e kenyelletsa litsamaiso tse baballang matla le ho ts'ehetsa ts'ebeliso ea lisebelisoa tse nchafalitsoeng. Li-motor tse feto-fetohang le li-hydraulic tse laoloang ke servo li fokotsa tšebeliso ea matla ka 30%, li theola litšenyehelo tsa ts'ebetso le phello ea tikoloho.

Liphuputso li totobatsa katleho ea matsapa ana. K'hamphani ea lino tse nooang ea Amerika Leboea e fihletse phokotso ea 30% ea tšebeliso ea matla le keketseho ea 20% ea lebelo la tlhahiso ka ho amohela mekhoa e tšoarellang. Ka mokhoa o ts'oanang, moetsi oa lihlahisoa tsa tlhokomelo ea motho oa Europe o fokolitse litšila haholo ha a ntse a ntlafatsa khotsofalo ea bareki.

| Lebitso la K'hamphani | Phokotso ea Matla | Ho eketseha ha lebelo la tlhahiso | Phokotso ea litšila | Khotsofalo ea Bareki |

|---|---|---|---|---|

| Khamphani ea Lijo tsa Amerika Leboea | 30% | 20% | N/A | N/A |

| Moetsi oa Lihlahisoa tsa Tlhokomelo ea Motho oa Europe | 25% | N/A | Bohlokoa | E ntlafalitsoe |

Ka ho kopanya mekhoa e tsitsitseng, bahlahisi ha ba fokotse litšenyehelo feela empa hape ba lumellana le lipakane tsa lefatše tsa tikoloho, ho ntlafatsa botumo ba bona ba 'maraka.

Lits'ebetso tsa 'Nete tsa Lefatše tsa Mechini e Hlakolang Libotlolo

Liindasteri tsa ho paka lino le Lijo

Liindasteri tsa lino le lijo tse pakang lijo li itšetlehile haholo kamechine e butsoelang libotloloho fihlela tlhoko e ntseng e hola ea litharollo tsa ho paka tse sebetsang hantle le tsa boleng bo holimo. Mechini ena e hlahisa libotlolo tsa lihlahisoa tse fapaneng, ho kenyeletsoa metsi, lero, lino-mapholi, lisoso le oli e jeoang. Tšebeliso ea lefats'e ea metsi a libotlolo feela e ntse e eketseha ka 7.0% selemo le selemo, ka likhakanyo tse bontšang ho phahama ho tloha ho lilithara tse limilione tse likete tse 232 ka 2011 ho ea ho lilithara tse limilione tse likete tse 513 ka 2025. Keketseho ena e totobatsa tlhokahalo ea mahlale a tsoetseng pele a ho paka a ka tsamaisanang le litlhoko tsa 'maraka.

Melemo ea bohlokoa bakeng sa liindasteri tsena e kenyelletsa lebelo la tlhahiso e potlakileng, litšila tse fokolitsoeng tsa thepa, le bokhoni ba ho etsa libotlolo tse bobebe empa tse tšoarellang. Tlhokahalo ea litharollo tse sebetsang tsa ho paka e ntse e hola ha bahlahisi ba ntse ba leka ho fihlela litebello tsa bareki bakeng sa botsitso le boiketlo.

Makala a Meriana le Litlolo

Mechini e butsoang ka libotlolo e bapala karolo ea bohlokoa makaleng a meriana le a litlolo, moo ho nepahala le boleng li leng bohlokoa haholo. Indastering ea meriana, mechini ena e hlahisa libotlolo tse etselitsoeng ho boloka le ho tsamaisa lisyrups, matlapa, li-capsules le meriana ea metsi ka mokhoa o sireletsehileng. Bakeng sa litlolo, ba etsa lijana tse khahlang pono tsa litlolo, litlolo, li-shampoo le litlolo tse nkhang hamonate, tse ntlafatsang tlhahiso ea lihlahisoa le ho rekisoa.

| Lekala | Tlhaloso ea Kopo |

|---|---|

| Pharmaceutical | Ho hlahisa libotlolo tsa ho paka tsa meriana ho netefatsa polokelo e bolokehileng le ho tsamaisoa ha meriana. |

| Cosmetic | Ho theha libotlolo tse ntle tsa litlolo ho ntlafatsa boemo le botle ba lihlahisoa 'marakeng. |

Ho feto-fetoha ha mechini ea ho bululela libotlolo ho lumella bahlahisi ho ikamahanya le litlhoko tse ikhethang tsa liindasteri tsena, ho etsa bonnete ba hore ba latela litekanyetso tse thata tsa taolo ha ba ntse ba boloka boipiletso ba botle.

Mehlala ea Likhamphani Tse Sebelisang Mechini e Tsoetseng Pele

Likhamphani tse 'maloa li atlehile ho amohela mechini e tsoetseng pele ea ho bululela libotlolo ho ntlafatsa bokhoni ba tsona ba tlhahiso. Beermaster, k'hamphani ea lino-mapholi ea Moldova, e sebelisitse mochini oa ho etsa mochini oa APF-Max ho fihlela lintlafatso tse kholo. Mochini o ile oa eketsa tlhahiso ea tlhahiso ho libotlolo tse 8,000 ka hora bakeng sa libotlolo tsa 500 ml, ho feta bokhoni ba pele. Liphetoho tse potlakileng tsa hlobo, tse phethiloeng ka metsotso e 20 feela, li fane ka monyetla oa ho hlahisa mefuta e mehlano ea libotlolo tse fapaneng. Ho feta moo, ntlafatso ea ts'ebeliso ea matla e tsamaellana le mekhoa e tsitsitseng, e fokotsang tšebeliso ea matla ka kakaretso. Likhetho tsa ho itlhophisa bakeng sa meralo ea libotlolo li ile tsa matlafatsa kananelo ea lebitso le boipiletso ba pono.

Mehlala ena e bonts'a kamoo metjhini e tsoetseng pele ea ho fehla libotlolo e thusang likhoebo ho lula li le tlholisano ka ho ntlafatsa ts'ebetso, ho fokotsa litšenyehelo, le ho fihlela litlhoko tse fapaneng tsa mmaraka.

Mechini e tsoetseng pele ea ho fehla libotlolo, joalo ka letoto la JT, hlalosa bocha tlhahiso ka ho matlafatsa lebelo la tlhahiso, ho netefatsa boleng bo tsitsitseng, le ho fokotsa tšebeliso ea matla. Meralo ea bona e kopaneng, ea modular e tsamaisa potoloho ea tlhahiso, athe thepa e tšoarellang e matlafatsa ts'epahalo. Mekhoa e sebetsang hantle ea matla e theola litšenyehelo le phello ea tikoloho, e leng se etsang hore mechini ena e be ea bohlokoa haholo bakeng sa lik'hamphani tse loanelang ho lula li le tlholisano mebarakeng e matla.

| Karolo | Tlhaloso |

|---|---|

| Lebelo la Tlhahiso | Meralo e kopaneng, ea modular e hokahana ka mokhoa o sa reroang mecheng ea tlhahiso, e potlakisang potoloho. |

| Boleng | Thepa e tšoarellang le mekhoa e tsoetseng pele e netefatsa tlhahiso e tšepahalang, ea boleng bo holimo. |

| Matla a Matla | Meralo ea ho boloka matla e fokotsa litšenyehelo tsa ts'ebetso le ho ts'ehetsa mekhoa e tsitsitseng ea tlhahiso. |

LBH

Ke lisebelisoa life tse ka etsang mochini oa mochini oa JT Series?

Letoto la JT le sebetsanalisebelisoa tse kang PE, PP, le K, e etsa hore e sebetse ka mokhoa o fapaneng bakeng sa ho hlahisa lihlahisoa tsa polasetiki tse se nang letho liindastering tse fapaneng.

Letoto la JT le netefatsa ts'ebetso ea matla joang?

Mochine o sebelisa li-motor tse feto-fetohang le li-hydraulic tse laoloang ke servo, ho fokotsa tšebeliso ea matla ka 15% ho isa ho 30% ha e bapisoa le mefuta ea setso.

Na letoto la JT le ka amohela boholo bo fapaneng ba botlolo?

E, ts'ebetso ea ho phahamisa sethala le litsamaiso tse tsoetseng pele tsa taolo li lumella letoto la JT ho hlahisa libotlolo ho tloha ho lilithara tse 20 ho isa ho tse 50 ka nepo.

Keletso: Bakeng sa liphetho tse nepahetseng, lokisa litlhophiso tsa mochini ho latela litlhoko tsa thepa le boholo ba botlolo.

Nako ea poso: May-23-2025