Sesebelisoa sa laboratori se le seng sa screw extruder se sebelisa screw e potolohang ho qhibilihisa, ho kopanya le ho etsa lipolymer ka har'a barrel e futhumetseng. Bafuputsi ba itšetlehile kavent single screw extruder, mochini o le mong oa screw, lemochini o se nang metsi oa granulatorho finyella ho kopanya hantle le ts'ebetso e sireletsehileng, e sebetsang hantle. Liphuputso li bontša seolebelo la screw le mochesoama ka ho toba boleng ba sehlahisoa le polokeho.

Likarolo Tse Ka sehloohong tsa Screw Extruder e le 'Ngoe

The Screw

Sekotike pelo ea screw extruder e le 'ngoe. E potoloha ka hare ho barrel mme e tsamaisa polymer pele. Sekurufu sea qhibiliha, se tsoakane, 'me se sutumelletsa thepa ho lebitleng. Moralo oa Screw, ho kenyelletsa bophara, karo-karolelano ea bolelele ho isa ho bophara, le karo-karolelano ea khatello, e ama tsela eo polymer e qhibilihang le ho tsoaka hantle. Sekoti se entsoeng hantle se ntlafatsa maemo a ho qhibiliha le ho sebetsa hantle. Li-grooves holim'a screw kapa barrel li ka eketsa lebelo la ho qhibiliha le ho thusa ho laola ts'ebetso. Lebelo la screw le boetse le fetola palo ea ho kopanya le mocheso o hlahisoang.

Keletso: Ho fetola lebelo la screw ho ka thusa ho laola mocheso oa ho qhibiliha le boleng ba sehlahisoa.

Moqomo

Moqomoe pota-potile screw mme e tšoara polymer ha e ntse e tsamaea. Moqomo o na le libaka tse fapaneng tsa mocheso. Sebaka se seng le se seng se ka beoa mochesong o itseng ho thusa ho qhibilihisa polymer ka ho lekana. Mohlala, sebaka sa pele se ka ba se pholileng ho thusa ho tsamaisa polima e tiileng, ha libaka tsa morao li chesa haholo ho qhibilihisa thepa. Taolo e nepahetseng ea mocheso ka har'a moqomo ke ea bohlokoa bakeng sa phallo e ntle le boleng ba sehlahisoa.Thermocouples e lekanya mocheso ka har'a moqomoho boloka tshebetso e tsitsitse.

- Litlhophiso tsa mocheso oa moqomo li ipapisitse le mofuta oa polymer le moralo oa screw.

- Hangata li-extruder tsa morao-rao li na le libaka tse tharo kapa ho feta tsa mocheso.

- Karolo ea lijo e lokela ho futhumala empa e se chese haholo ho qoba ho khomarela lintho tse bonahalang.

Sistimi ea Heater

Sistimi ea heater e boloka barrel e le mocheso o nepahetseng. Li-heaters li behoa haufi le moqomo 'me li laoloa ke li-sensor. Sistimi e ka fetola sebaka ka seng ho tsamaisana le litlhoko tsa polymer. Taolo e ntle ea heater e thusa ho qoba mathata a joalo ka ho cha kapa ho qhibiliha ho sa tšoaneng. Sistimi ea futhumatsang e sebetsa le sistimi ea taolo ho boloka ts'ebetso e bolokehile ebile e sebetsa hantle.

The Die

The die e bopa polymer e qhibilihisitsoeng ha e siea sekoti se le seng sa extruder. Moralo oa lefu o ama sebopeho sa sehlahisoa sa ho qetela, bokaholimo le boholo ba sehlahisoa. Lefu le letle le fana ka boreleli, esita le ho phalla 'me le thusa ho etsa lihlahisoa tse nang le litekanyo tse nepahetseng. Lefu le tlameha ho sebetsana le mocheso o nepahetseng le khatello ho qoba liphoso. Liphetoho tsa mocheso oa mocheso kapa phallo li ka fetola boleng ba sehlahisoa.

- Lebelo le ts'oanang le ho theoha ha khatello e fokolang sebakeng sa ho tsoa li bohlokoa bakeng sa boleng.

- Die channel geometry le phallo balance ama ho nepahala ha sebopeho sehlahisoa.

Sistimi ea Taolo

Sistimi ea taolo e laola ts'ebetso ea screw extruder e le 'ngoe. E hlokomela mocheso, khatello, lebelo la screw, le sekhahla sa phepelo. Basebelisi ba sebelisa sistimi ea taolo ho beha le ho lokisa liparamente tsa ts'ebetso. Ho shebella ka nako ea 'nete ho thusa ho boloka ts'ebetso e tsitsitse ebile e bolokehile. Sistimi ea taolo e ka boloka litlolo tsa li-polymer tse fapaneng, ho etsa hore ho be bonolo ho pheta matha a atlehileng.

Mefuta ea Single Screw Extruder bakeng sa Tšebeliso ea Laboratori

Litlhophiso tsa laboratori li hloka mefuta e fapaneng ea li-extruder ho fihlela litlhoko tse ikhethang tsa lipatlisiso. Mofuta o mong le o mong o fana ka likarolo tse ikhethang le melemo ea ho sebetsa ha polymer.

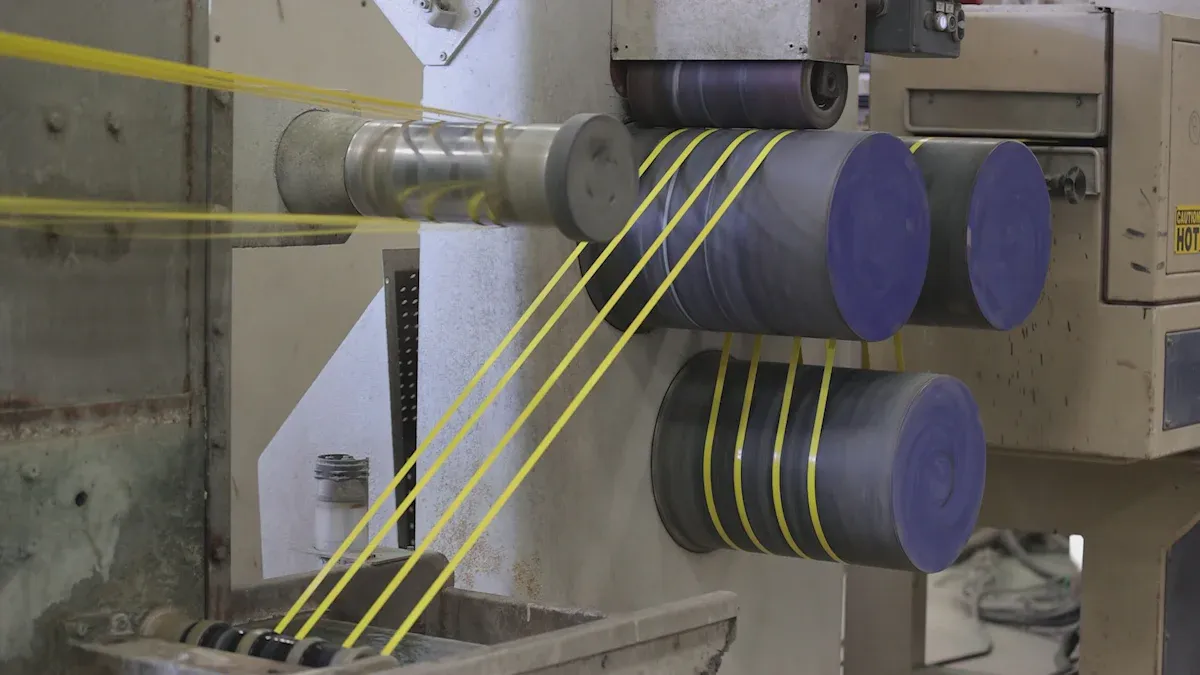

Vented Single Screw Extruder

Sekoahelo se le seng sa screw extruder se sebelisa amoralo oa sekoti sa mekhahlelo e 'meli. Moralo ona o fokotsa litlhoko tsa torque le matla a lipere ha o ntse o boloka tlhahiso le lebelo la screw. Sistimi ea moea e tlosa mongobo le likhase ho tloha polymer e qhibiliha. Mohato ona ke oa bohlokoa bakeng sa ho sebetsa lipolasetiki tse monyang metsi. Ho tlosa li-volatile tsena ho thibela likoli tse kang splay le thepa e fokolang ea mochine. Hangata boema-kepe bo sebetsa tlas'a vacuum, e thusang ho tlosa moea ka ho theola khatello. Sekoti sa mekhahlelo e 'meli se boetse se ntlafatsa ho kopanya ka ho hatella le ho senya polasetiki. Ts'ebetso ena e etsa hore ho be le ho qhibiliha ho tšoanang. Basebelisi ba tlameha ho leka-lekanya tlhahiso lipakeng tsa mekhahlelo ena e 'meli ho qoba likhohola kapa likhohola. Likarolo tsena li etsa hore sekoaelo se le seng sa screw extruder se sebetse hantle ebile se ts'epahala lits'ebetsong tsa laboratori.

Tlhokomeliso: Tlhahiso e tsitsitseng le tšebeliso e tlase ea matla e arola li-extruder tse tsoang libakeng tsa lipatlisiso.

Mochini o le Mong oa Screw

Mochini o le mong oa screw o koahela mefuta e mengata ea li-extruder bakeng sa ho qhibiliha, ho kopanya le ho etsa lipolymers. Mechini ena e fana ka moralo o bonolo le ts'ebetso e bonolo. Bafuputsi ba khona ho laola ho kuta le mocheso hantle, tse thusang ka mekhoa ea motheo ea polymer le mesebetsi ea extrusion. Mechini e le 'ngoe ea li-screw e sebetsa hantle bakeng sa ho etsa li-tubing, filimi, le lihlahisoa tse ling tse bonolo. Li tla ka boholo le litlhophiso tse fapaneng ho lumellana le litlhoko tse fapaneng tsa lipatlisiso.

| Mofuta oa Extruder | Likarolo tsa Bohlokoa le Melemo | Likopo tse Tloaelehileng le ho Tšoanela |

|---|---|---|

| Single Screw Extruders | Moqapi o bonolo, taolo e ntle, ts'ebetso e bonolo | Li-tubing, filimi, libopeho tsa motheo tsa polymer |

| Twin Screw Extruders | Li-screws tse ntlafetseng, tse tenyetsehang, tse intermeshing | Lintho tse kopanyang, tse rarahaneng, meriana ea meriana |

| Li-Extruders tse nyane / tse nyane | E nyenyane, e theko e tlaase, e ka tšeptjoang | R&D, prototyping, disampole tse fokolang tsa thepa |

Mochini oa Granulator o se nang Metsi

Mochini oa granulator o se nang metsi o fetola lisebelisoa tsa polasetiki hore e be li-granules ntle le ho sebelisa metsi. Theknoloji ena e ntlafatsa matla a matla le ho fokotsa tšusumetso ea tikoloho. Ts'ebetso e boloka li-granules li omme li bile li hloekile, e leng se thusang mehato e meng ea ts'ebetso. Mechini ea granulator e se nang metsi e sebetsana le mefuta e mengata ea li-resin tsa polasetiki. Ba thusa bafuputsi ho hlahisa li-granules tsa boleng bo holimo bakeng sa tlhahlobo le nts'etsopele.

Mohato ka Mohato oa Polymer Extrusion process

Ho fepa lintho tse entsoeng ka polymer

Ts'ebetso ea extrusion e qala ka ho fepa thepa e tala ea polymer ka har'a hopper ea phepelo. Hopper e netefatsa ho ajoa le ho thibela li-blockages, tse thusang ho boloka ts'ebetso e tsitsitseng. Sekoti se ka hare ho barrel se qala ho potoloha, se hula li-pellets tsa polymer kapa phofo pele. Moralo oa screw, ho kenyeletsoa karo-karolelano ea bophara le bolelele ho isa ho bophara, e phetha karolo ea bohlokoa mabapi le hore na thepa e tsamaea hantle hakae. Sistimi ea taolo e lumella basebelisi ho fetola lebelo la screw le sekhahla sa phepelo, se thusang ho lokisa ts'ebetso bakeng sa lipolima tse fapaneng.

- Li-feed hoppers li etselitsoe ho thibela li-clog le ho netefatsa phepo e bonolo.

- Sekoti se fetisa, se hatella, 'me se qala ho futhumatsa polymer.

- Taolo ea mocheso ka har'a barrel e thusa ho ntlafatsa ts'ebetso ea ho qhibiliha.

Lithuto tsa pele li bonts'itse hore ho laola lebelo la screw le mocheso ho ama ka kotloloho tsela eo polymer e fepang le ho qhibiliha ka eona. Li-extruder tsa morao-rao tsa laboratori li sebelisa litsamaiso tse tsoetseng pele ho boloka phepelo e sebetsa hantle ebile e tsitsitse.

Ho qhibiliha le Plasticizing

Ha polymer e ntse e tsamaea ka har'a moqomo, e kena libakeng tse futhumetseng. Mocheso sebakeng se seng le se seng o eketseha butle-butle, o etsa hore polymer e be bonolo le ho qhibiliha. Ho potoloha ha screw le mocheso oa moqomo li sebetsa 'moho ho etsa polasetiki, ho e fetola boima bo tšoanang ba ho qhibiliha. Li-sensor tse behiloeng haufi le moqomo li lekola mocheso le khatello ho netefatsa hore polymer e qhibiliha ka har'a sebaka sa eona se nepahetseng sa ts'ebetso.

| Paramethara | Tlhaloso |

|---|---|

| Qhibiliha Mocheso | E tlameha ho lula ka har'a sebaka sa ho sebetsa sa polymer bakeng sa liphetho tse ntle. |

| Khatello kaholimo ho Screw | E bontša boleng ba ho qhibiliha le botsitso ba ts'ebetso. |

| Ho Fetoha ha Khatello | E behiloe leihlo ho bona mathata leha e le afe ka ho qhibiliha kapa ho phalla. |

| Ho Fetoha ha Mocheso | E lateloa ho netefatsa hore ho futhumatsa le ho qoba liphoso. |

| Tekanyo ea ho qhibiliha | E hlahlojoa ka pono kapa ka ho lekola filimi e pharalletseng ho hlaka le ho ts'oana. |

| Screw Performance Index | E kopanya lintlha tsena ho lekanya boleng ba ho qhibiliha ho tloha bofutsaneng (0) ho isa ho bo botle (1). |

Taolo e nepahetseng ea mocheso le khatello e thusa ho thibela ho senyeha le ho netefatsa ho qhibiliha ho tsitsitseng. Tlhokomelo ea nako ea 'nete e nang le li-sensor tse tsoetseng pele le mekhoa ea spectroscopy e fana ka data e tsoelang pele, e lumellang bafuputsi ho fetola maemo ha ho hlokahala.

Ho kopanya le ho fetisa

Hang ha e qhibilihisoa, polymer e tlameha ho tsoakoa ka botlalo ho netefatsa hore e tšoana. Moralo oa screw, ho kenyelletsa likarolo tse kang litšitiso kapa libaka tse kopanyang, o thusa ho kopanya thepa le ho tlosa likhechana tse setseng tse tiileng. Ha screw e ntse e potoloha, e sutumelletsa polima e entsoeng ka ho qhibilihisoa ka pele, e e fetisetsa ho dae.

Bafuputsi ba sebelisa li-setups tse tsoetseng pele kalisampole likoung le li-optical detectorsho ithuta kamoo thepa e tsoakanang hantle kateng. Ka ho kenya li-tracers le ho lekanya hore na li ata joang, li khona ho bona hore na lebelo la screw le geometry li ama ho tsoaka joang. Lebelo le phahameng la screw ka linako tse ling le ka siea likhechana tse tiileng, empa meralo e khethehileng ea li-screw e ntlafatsa ho kopanya le ho thibela taba ena.Li-sensor tsa khatello haufi le barrellekanya hore na polymer e tsamaea hantle hakae, ho thusa basebelisi ho ntlafatsa ts'ebetso.

Ho Bopa ka Lefu

Polima e entsoeng ka ho qhibilihisoa e fihla lefung, e e bopang ka mokhoa o lakatsehang. Moetso oa lefu lena o etsa qeto ea boholo ba sehlahisoa sa ho qetela le boleng ba bokaholimo. Baenjineri ba sebelisa lipapiso tsa komporo le tlhahlobo ea likarolo tse lekanyelitsoeng ho rala liforomo tse hlahisang libopeho tse nepahetseng le ho fokotsa liphoso. Ba boetse ba ntlafatsa geometry ea mocha oa phallo ho leka-lekanya lebelo le ho fokotsa liphapang tsa limolek'hule, tse ka amang boholo ba sehlahisoa.

| Karolo ea Bopaki | Tlhaloso |

|---|---|

| Finite Element Analysis | E sebelisoa ho ithuta phallo le ho bopa ho nepahala ha lefu. |

| Moqapi oa Ntlafatso | E fokotsa liphoso le ho ntlafatsa ho nepahala ha geometri. |

| Netefatso ya Teko | E tiisa taolo e tiileng ea boholo ba sehlahisoa. |

| Ketsiso ya Palo | Ho bolela esale pele ho ruruha le ho sisinyeha ha sebopeho bakeng sa liphetho tse ntle. |

| Taolo ea Boithuto ba Limolek'hule | Litekanyo li phalla ho thibela ho otlolla ho sa tšoaneng le liphetoho tsa sebopeho. |

Taolo e nepahetseng ea lisebelisoa tsa die le tse tlase ho netefatsa hore sehlahisoa se tlohaSingle Screw Extrudere nang le sebopeho le boholo bo nepahetseng.

Ho pholisa le ho tiisa

Ka mor'a ho bopa, polima e chesang e tsoa lefung ebe e kena karolong ea ho pholile. Ho pholile ho tiisa polymer, ho koala sebopeho sa eona sa ho qetela le thepa. Sekhahla sa ho pholisa se itšetlehile ka mocheso oa extrusion, maemo a tikoloho, le lebelo leo sehlahisoa se tsamaeang ka lona sebakeng sa pholileng.

| Paramethara/Aspect | Tebello/ Sephetho |

|---|---|

| Mocheso oa Extrusion | Polymer e fetisitsoe ka mocheso oa 100 ° C |

| Mocheso oa tikoloho | E bolokiloe hoo e ka bang 20 °C nakong ea liteko |

| Cooling sekhahla tlhōrō mocheso | Hoo e ka bang 72 °C |

| Phello ea lebelo | Mabelo a tlase a liehisa ho pholile 'me a eketsa nako ea ho tiisa |

| Boitšoaro ba sekhahla sa ho pholisa | Sekhahla se phahameng se theoha ha lebelo le fokotseha; maemo a phahameng a fetoha ka nako e telele |

| Phello ea mekhahlelo e mengata | Likarolo tsa morao-rao li ka futhumatsa tse pejana, tsa ntlafatsa ho khomarela |

Ho boloka libaka tse batang ka har'a mocheso o patisaneng, hangata ka har'a ±2°C, ho thusa ho netefatsa boleng bo tsitsitseng ba sehlahisoa. Pholiso e nepahetseng e thibela ho soahlamana le ho tiisa hore polymer e tiisa ka ho lekana.

Lisebelisoa tsa Single Screw Extruder ho Polymer Research

Tlhahiso ea Boitsebiso le Teko

Bafuputsi ba sebelisa li-extruder tsa laboratori ho nts'etsapele le ho leka mefuta e mecha ea polymer. Lithuto tsa motheo le litokelo tsa molao li hlalosa kamoomoralo oa sekotile taolo ea mocheso e ntlafatsa ho qhibiliha le ho kopanya. Lintlafatso tsena li thusa bo-ramahlale ho theha lisebelisoa tse ncha tse nang le thepa e ikhethang. Ka mohlala, extruder ea boemo bo tlaase e hahiloeng ka thepa ea lehae e bontšitse ts'ebetso e matla tlhahisong ea lab-scale. E ile ea sebetsa ho fihlela ho 13 kg ka hora le ho fokotsa metsoako e sa batleheng sehlahisoa sa ho qetela. Liphetho tsena li tiisa hore li-extruder tsa laboratori li tšehetsa popontšuoa le taolo ea boleng ha ho etsoa thepa.

| Paramethara | Boleng/Sephetho |

|---|---|

| Phello | 13.0 kg/h |

| Screw Speed | 200 rpm |

| Diameter ea moqomo | 40 limilimithara |

| Karolelano ea Katoloso | 1.82–2,98 |

| Ho fokotseha ha trypsin inhibitor | 61.07%–87.93% |

Ntlafatso ea Ts'ebetso

Li-extruder tsa laboratori li thusa bo-ramahlale ho fumana litlhophiso tse ntle ka ho fetisisa tsa li-polymer tse fapaneng. Lintlha tsa liteko li bontša seotšebeliso ea matla e itšetlehile ka lebelo la screw le thepa ea thepa. Ka ho rekota matla a motlakase le ho lokisa litlhophiso, bafuputsi ba ka ntlafatsa ts'ebetso ea matla le boleng ba sehlahisoa. Liphuputso li boetse li bontša hore ho fetohalebelo la sekotile ho eketsa metsoako e itseng ho ka ntlafatsa tsela eo lipolymer li kopanyang le ho phalla ka eona. Liphuputso tsena li thusa lihlopha ho theha mekhoa e bolokehileng, e sebetsang hantle, le e phetoang bakeng sa lipatlisiso le tlhahiso.

Keletso: Ho fetola lebelo la screw le thempereichara ho ka leka-lekanya tšebeliso ea matla le ho ntlafatsa boleng ba sehlahisoa.

Tlhahiso ea Lihlahisoa tse Nyenyane

Li-extruder tsa Lab li etsa hore ho be bonolo ho theha lihlopha tse nyane tsa lihlahisoa tse ncha. Lihlopha li ka laola mocheso, khatello le lebelo la screw bakeng sa liphetho tse tšepahalang. Mokhoa ona o boloka chelete ebile o potlakisa nts'etsopele. Bafuputsi ba ka lekola mehopolo e mecha kapele le ho nyolla e atlehileng. Li-extruder tsa Compact li boetse li lumella liphetoho tse feto-fetohang tsa thepa kapa moralo. Tsoelo-pele ea li-automation le tlhahlobo ea nako ea nnete e ntlafatsa taolo ea ts'ebetso le ho fokotsa litšila.

- Taolo e nepahetseng holim'a mekhahlelo ea ts'ebetso

- Litšenyehelo tse sebetsang hantle le tse potlakileng tsa prototyping

- Ho ikamahanya habonolo bakeng sa lisebelisoa tse fapaneng

- Boleng bo ntlafalitsoeng ba sehlahisoa le ho tšoana

Malebela a Tšebetso le Tharollo ea Mathata bakeng sa Single Screw Extruder

Ho theha Extruder

Ho seta ka nepo ho netefatsa ts'ebetso e tšepahalang le ho lelefatsa bophelo ba lisebelisoa. Litheknishiene li latela tsenamehato bakeng sa tshebetso e ntlafetseng:

- Kenya li-screwmaemong a bona a mantlha mme o leke likurufu tse ncha ka lebelo le tlase pele o sebetsa ka botlalo.

- Lekanyataolo ea mochesolisebelisoa kamehla bakeng sa liphetoho tse nepahetseng.

- Sebelisa metsi a hloekisitsoeng ka tanka ea ho pholisa ho thibela ho phahama le ho hlahloba maemo a metsi khafetsa.

- Hlahloba li-valve tsa solenoid le likhoele, u nkele likarolo leha e le life tse fosahetseng.

- Sireletsa li-couplers letsatsi le letsatsi 'me u netefatse hore li-relay tsa sebaka sa ho futhumatsa le li-valve tsa solenoid li sebetsa ka nepo.

- Hloekisa litanka tsa vacuum le likamore tsa ho ntša metsi; fetola mehele e tiisitsoeng e tsofetseng ha ho hlokahala.

- Sheba borashe ba likoloi tsa DC 'me u sireletse khahlanong le mafome.

- Preheat butle butle nakong ea ho qala 'me u eketse lebelo la screw butle.

- Lubricate likarolo tse tsamaeang le ho tiisa li-fasteners kamehla.

- Bakeng sa polokelo ea nako e telele, tlotsa mafura a thibelang mafome 'me u boloke likurufu hantle.

Keletso: Ho latela mehato ena ho thusa ho boloka boleng ba sehlahisoa le nako e telele ea lisebelisoa.

Mathata a Tloaelehileng le Litharollo

Basebetsi ba ka 'na ba tobana le mathata a mangata nakong ea ts'ebetso. Tafole e ka tlase e bontša mathata le tharollo e tloaelehileng:

| Sehlopha sa Litaba | Mathata a Tloaelehileng | Lisosa | Matšoao | Litharollo |

|---|---|---|---|---|

| Ho hloleha ha Mechine | Screw e khomaretsoe | Keketseho ea lintho tse bonahalang, mafura a fokolang | Motlakase oa motlakase, lerata | Hloekisa, tlotsa, hlahloba |

| Ho Hloka Motlakase | Ho hloleha ha makoloi | Overheating, potoloho e khutšoanyane | Ha ho na qalo, ho chesa haholo | Hlahloba tsamaiso, qoba ho tlala |

| Ho hloleha ha Tshebetso | Plastiki e mpe | Lebelo le tlase, mocheso o fosahetseng | Sebaka se makukuno, li-bubble | Fetola lebelo, mocheso, thepa |

| Mehato ea Thibelo | Tlhokomelo | Ho hloka tlhoekiso, tlhahlobo | N/A | Kemiso ea ho hloekisa, ho hlahloba |

Ho hlahlojoa le ho hlokomeloa khafetsa ho thibela mathata a mangata. Basebelisi ba lokela ho latela litaelo tsa matsoho ha ba lokisa mochini oa extrusion ho qoba liphoso.

Mehopolo ea Tšireletseho

Ts'ebetso ea extruder ea laboratori e kenyelletsa likotsi tse 'maloa. Mehato ea polokeho e kenyelletsa:

- Ho roala lisebelisoa tsa ho itšireletsa tse kang lieta tsa tšireletso le likhalase.

- Ho qoba liaparo tse hlephileng haufi le likarolo tse tsamaeang.

- Ho theola lisebelisoa tsohle tsa motlakase ka basebetsi ba tšoanelehang.

- Ho boloka mekato e omme le ho sebelisa sethala kapa li-drain ho thibela ho thella.

- Ho kenya balebeli likarolong tse tsamaeang ho sireletsa matsoho.

- Ho sebelisa mela e qalang bakeng sa ho khoaela sebakeng sa ho fepa ka letsoho.

Tlhokomeliso: Taeo e tiileng ea polokeho e fokotsa kotsi ea ho cha, ho tsukutloa ha motlakase le likotsi tsa mochini.

Li-extruder tsa laboratori li ts'ehetsa ts'ebetso e bolokehileng, e sebetsang ea polymer kataolo e nepahetseng ea mocheso, khatello, le lebelo la sekurufu. Bafuputsi ba rua molemo tlhahisong ea li-batch tse nyane, litšila tse fokotsehileng, le prototyping e potlakileng. Meetso ea modular e thusa ho fetoha kapele le ho e etsa. Tloaelo e tsitsitseng le ho ela hloko lintlha li thusa ho fihlela liphetho tse tšepahalang le ho khothaletsa boqapi lipatlisisong tsa polymer.

LBH

Ke li-polymer life tse ka etsang laboratoring single screw extruder process?

A laboratori e le 'ngoe ea screw extrudere ka sebetsana le boholo ba thermoplastics, ho kenyelletsa polyethylene, polypropylene, polystyrene, le PVC. Hangata bafuputsi ba khetha lisebelisoa ho latela litlhoko tsa morero.

Ho kenya moea ho ntlafatsa boleng ba polymer joang?

Ho ntša moea ho tlosa mongobole likhase tse tsoang polimang ea qhibiliha. Mohato ona o thibela mefokolo, joalo ka lipudula kapa matheba a fokolang, mme o ntlafatsa boleng ba sehlahiswa sa ho qetela.

Basebelisi ba laola mocheso oa extrusion joang?

Basebelisi ba beha le ho hlokomela mocheso oa moqomo ba sebelisa sistimi ea taolo. Li-sensor li fana ka maikutlo a nako ea 'nete, tse lumellang litokiso tse nepahetseng bakeng sa ho qhibiliha le ho bōptjoa ha polymer.

Nako ea poso: Jul-01-2025