Moqomo oa sekoti oa ente ea polasetiki o bapala karolo e kholo ho bopeng boleng ba ho qhibiliha le lebelo la tlhahiso. Baenjiniere ba tsepamisa maikutlo hoEnte e Bopa Barrelmoralo ho matlafatsa tshebetso. Ba sebelisa lisebelisoa tse fapaneng bakeng saMochini o le Mong oa Screw Plastic ExtruderleMochini o le Mong oa Screw Extrusion. Khetho e 'ngoe le e' ngoe e thusa mechini hore e sebetsane le polasetiki hantle.

Plastic Ente Molding Screw Barrel Sebopeho le Ts'ebetso

Mefuta ea Barele: Bimetallic vs. Integral

Ho khetha mofuta o nepahetseng oa moqomo ho ka etsa phapang e kholo ea kamoo aPlastiki Ente ea ho bopa moqomoetsa. Li-barrel tsa Bimetallic li sebelisa setsi se matla sa tšepe se nang le lesela le thata la alloy ka hare. Moqapi ona o boloka lisebelisoa tsa bohlokoa 'me o lumella bahlahisi hore ba nke sebaka sa lesela le tsofetseng feela, e leng se etsang hore tlhokomelo e be bonolo le ho boloka chelete e ngata. Ho lekana pakeng tsa lesela le barrel ho tlameha ho nepahala ho boloka mocheso o phalla hantle le ho thibela ho sisinyeha. Li-barrel tsa Bimetallic li sebetsa hantle bakeng sa ho sebetsana le li-plastiki tsa abrasive kapa tse matlafalitsoeng hobane li hanela ho apara le ho nka nako e telele.

Li-barrel tse kenyelletsoeng li entsoe e le sengoathoana se le seng. Sena se ba fa ho nepahala ho phahameng esita le kabo ea mocheso haufi le barrel. Ba etsa hore ho be bonolo ho kenya le ho boloka lisebelisoa tsa ho futhumatsa le ho futhumatsa. Leha ho le joalo, ba hloka taolo e tiileng ea tlhahiso ho boloka boleng bo holimo. Ha ho bapisoa tse peli, libarele tsa bohlokoa li fana ka tlhokomelo e bonolo le ho futhumala ho tšoanang, ha libarele tsa bimetallic li fana ka khanyetso e ntle ea ho apara le ho fetola karolo e bonolo.

| Karolo ea Ts'ebetso | Bokahare ba Barrel | Moqomo oa Bimetallic |

|---|---|---|

| Kaho | Karolo e le 'ngoe, ho nepahala ha tlhahiso e phahameng | Moqomo oa motheo o nang le bushing ea tšepe e ka nkeloang sebaka |

| Kabo ea Mocheso | Kabo e ts'oanang ea mocheso hammoho le axis ea barrel | Ho tsamaisoa ha mocheso ho hlokomeloa haeba ho lekana ha bushing ho nepahetse |

| Apara Resistance | Standard wear resistance | Khanyetso e ntlafalitsoeng ea ho roala ka lebaka la lesela la tšepe ea alloy |

| Tlhokomelo | Ho kenya le ho boloka mekhoa e bonolo ea ho futhumatsa / ho futhumatsa | Replaceable bushing lumella ho be bonolo ho fetola karolo |

| Tšebeliso ea Lintho | E hloka ho nepahala ho holimo le boleng ba thepa | E boloka lisebelisoa tsa bohlokoa ka ho sebelisa tšepe ea alloy feela ka har'a lesela |

Hangata libarele tsa bimetallic li nka nako e telele ho feta libarele tse kenyelletsoeng, haholo-holo ha ho sebetsa thepa e thata. Moqapi oa bona o fokotsa litšenyehelo tsa nako ea ho fokotsa nako le ho nkela sebaka, e leng se thusang ho boloka tlhahiso e sebetsa hantle.

Screw Geometry: Karolelano ea L/D, Karolelano ea Khatello, le Moralo oa Sefofane

Sebopeho sa geometry eascrew ka hare ho Plastic Ente molding barrellibopeho kamoo lipolasetiki li qhibilihang le ho tsoakana kateng. Karo-karolelano ea L / D, e bapisang bolelele ba screw ho bophara ba eona, e ama ho tšoana ho qhibilihang le ho kopanya. Sekurufu se selelele (karolelano e phahameng ea L/D) se fa polasetiki nako e eketsehileng ea ho qhibiliha le ho tsoakana, e leng ho ntlafatsang boleng ba sehlahisoa. Leha ho le joalo, haeba screw e le telele haholo, e ka baka ho senyeha ha mocheso, haholo-holo ka li-plastiki tse sa utloeng mocheso. Lisebelisoa tse kang PVC le POM li hloka li-screw tse khutšoane ho qoba tšenyo, ha lipolasetiki tse tletseng likhalase kapa tse nang le viscosity e phahameng li rua molemo ho tsoa ho li-screw tse telele le libaka tsa ho kopanya tse matlafalitsoeng.

- Lisebelisoa tse nang le botsitso bo botle ba mocheso li sebelisa li-screw tse telele bakeng sa ho kopanya hantle.

- Li-plastiki tse sa utloeng mocheso li hloka li-screw tse khutšoane kapa liqapi tse khethehileng tsa likhoele.

- Likurufu tsa morero ka kakaretso (L/D ~20:1) li lumellana le lipolasetiki tse tloaelehileng empa li ka bontša ho fapana ha mebala.

- Li-barrier screws (L / D ~ 24: 1) li ntlafatsa ho kopanya bakeng sa li-plastiki tse matlafalitsoeng.

- Li-screws tsa karohano (L/D ~18:1) li thusa lisebelisoa tse sa utloeng mocheso le mocheso ho qoba ho senyeha.

- Li-screws tse kopanyang (L / D ~ 22: 1) li fana ka ho qhibiliha ho tšoanang bakeng sa li-plastiki tse khethehileng.

Karo-karolelano ea khatello e lekanya hore na screw e hatella polasetiki hakae. Li-plastiki tse nang le viscosity e phahameng li hloka tekanyo e phahameng ea compression ho qhibiliha le ho kopanya hantle. Ho fetola karo-karolelano ea khatello ho thusa ho leka-lekanya tšebetso le boleng ba sehlahisoa. Hangata bahlahisi ba beha leihlo le ho ntlafatsa sebopeho sa screw ho tsamaisana le litlhoko tsa thepa.

Moralo oa sefofane oa Screw le ona oa bohlokoa. Li-screw tse ntlafalitsoeng ka mokhoa oa "rheologically optimized" li ntlafatsa boleng ba ho qhibiliha ka ho tsamaisana le boits'oaro ba polima. Lisebelisoa tse laoloang tsa Melt Delivery li thusa ho laola mocheso o qhibilihisang le viscosity, ho fokotsa kotsi ea ho senyeha. Li-screws tse kopanyang le li-barrier barrier screws li fana ka mokhoa o ts'oanang oa ho qhibiliha le ho thibela matheba a shoeleng, e leng ho thibelang polasetiki hore e se ke ea chesa haholo kapa ea fetoha mebala.

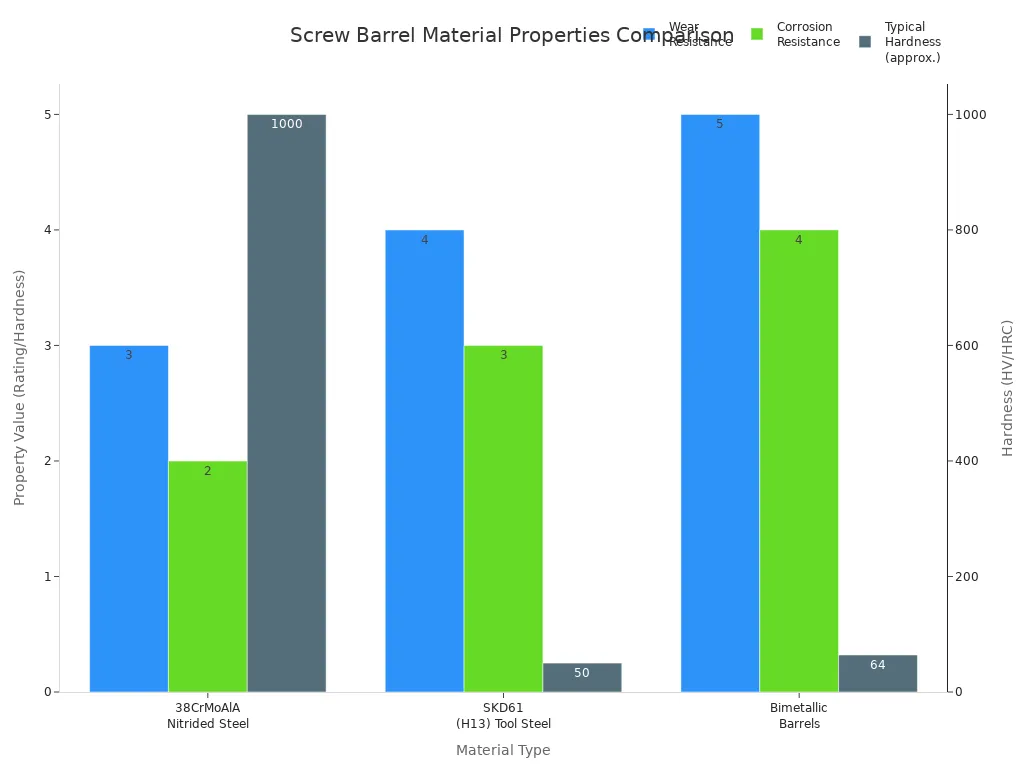

Sebopeho sa Lintho le Liphekolo tsa Bokaholimo

Thepa e sebelisoang ho etsa sekoti sa polasetiki ea Injection molding e ama ho tšoarella ha eona le ts'ebetso ea eona. Nitrided steel e fana ka boima bo botle le ho hanyetsa ho roala bakeng sa polasetiki e tloaelehileng. Li-barrel tsa Bimetallic li kopanya setsi sa tšepe se nang le liner tsa alloy, tse fanang ka moaparo o motle haholo le ho hanyetsa ha kutu bakeng sa li-plastiki tse thata kapa tse tletseng. Lisebelisoa tsa tšepe li fana ka matla a phahameng le ho roala ho hanyetsa bakeng sa libaka tse feteletseng.

| Mofuta oa Boitsebiso | Lintho tsa Bohlokoa le Melemo | Mathata le Mefokolo | Molemo ka ho Fetisisa Likopo |

|---|---|---|---|

| Nitrided Steel | Ho thatafala holimo holimo; ho hanyetsa ho apara hantle bakeng sa li-resin tse sa tlatsoang; theko e tlaase | Khanyetso e mpe ea kutu; e sa lokang bakeng sa li-resin tsa abrasive/chemical | Li-resin tsa thepa tse kang polyethylene, polypropylene |

| Libarele tsa Bimetallic | Tšehetso ea tšepe e nang le alloy liner; ho apara hantle le ho hanyetsa kutu; nako e telele ea bophelo | Ho bitsa chelete e ngata; e ka ba overkill bakeng sa tšebeliso e akaretsang | Li-nylon tse tlatsitsoeng ka khalase, ABS e thibelang malakabe, PVC, lipolima tse mabifi |

| Li-alloys tse thehiloeng ho Nickel | Khanyetso e ikhethang ea kutu; e ntle bakeng sa li-resin tse thibelang malakabe le halogenated | Ka tlaase ho thata ho feta li-alloys tse thehiloeng ka tšepe; ho hanyetsa ho apara ka tlase | Li-polymer tse nang le lik'hemik'hale tse mabifi |

| Li-alloys tse thehiloeng ho tšepe | Boima bo phahameng le ho hanyetsa ho apara | Khanyetso ea kutu e tlase ho feta li-alloys tse thehiloeng ho nickel | Li-resin tse nang le abrasive, tse tletseng haholo |

| Tool Steel | boima le matla a ikhethang; khanyetso e phahameng ea ho apara | Litšenyehelo tse phahameng; e futsanehileng ke ho bola ntle le ho koaela | Libaka tsa ho apara ka mokhoa o feteletseng, lisebelisoa tse phahameng haholo |

| Li-Barrels tse koahetsoeng tse khethehileng | Liaparo tse kang tungsten carbide kapa chrome plating li ntlafatsa ho apara le ho thibela kutu | E eketsa litšenyehelo le ho rarahana; barbotage adhesion fapana | Lisebelisoa tse tloaelehileng kapa tse mabifi tsa resin |

Liphekolo tsa holim'a metsi joalo ka nitriding le chrome plating li matlafatsa khanyetso le nako ea bophelo. Nitriding e ka imena habeli kapa habeli bophelo ba ts'ebeletso ea li-screws le libarele. Chrome plating e eketsa ho ba thata le ho hanyetsa kutu, empa nitriding hangata e sebetsa betere tlas'a maemo a hlabang. Ho fafatsa ka molybdenum ho kopantsoe le nitriding ho fana ka tšireletso le ho feta. Ts'ebetso e nepahetseng le tlhokomelo li thusa ho eketsa melemo ena.

Moralo oa Fepa Port le Venting

Moralo oa kou ea phepelo o laola hore na polasetiki e kena joang ka har'a moqomo. Taolo e ntle ea mocheso boema-kepeng ba phepelo e boloka viscosity ea lintho tse bonahalang e tsitsitse, e thusang ho boloka phallo e tsitsitseng le phepo. Li-vacuum loaders le li-hopper li etsa bonnete ba hore thepa e tsamaea hantle ka har'a mochine, e fokotsa tšilafalo le ho qhalla. Seta sena se boloka boleng ba tlhahiso bo le holimo 'me phepo e sa fetohe.

- Li-vacuum loaders li nyoloha ka ho toba 'metsong oa mochine, li fokotsa tšilafalo.

- Ba amohelang Hopper ba sebelisa matla a khoheli ho fepa lintho tse bonahalang, ho nolofatsa mokhoa ona.

Moralo oa ho kenya moea le oona o phetha karolo ea bohlokoa. Li-screws tsa Vent li na le libaka tse khethehileng tse tlosang mongobo le li-volatile nakong ea ts'ebetso. Sena se bohlokoa bakeng sa thepa ea hygroscopic le li-plastiki tse recycled. Boema-kepe ba moea bo lumella likhase le mongobo ho tsoa, ho thibela bofokoli le ho boloka boleng ba extrusion bo le holimo.

Keletso: Moetso o nepahetseng oa boemakepe le oa ho kenya moea o thusa ho boloka tlhahiso e tsitsitseng le ho ntlafatsa boleng ba sehlahisoa, haholo-holo ha o sebetsa ka lipolasetiki tse nchafalitsoeng kapa tse bobebe.

Liphello tsa Ts'ebetso ea Moralo oa Ente ea Plastiki Molding Screw Barrel

Qhibiliha Boleng le Homogeneity

Moqomo o entsoeng hantle oa Plastic Injection molding screw barrel o thusa ho etsa hore e be boreleli le ho qhibiliha. Geometry ea screw, ho kenyelletsa le eonakaro-karolelano ea khatellole sebōpeho sa libaka tsa eona, e laola hore na li-pellets tsa polasetiki li qhibiliha joang le ho tsoakana. Ha tekanyo ea compression e lumellana le thepa, ho qhibiliha ho phalla ka tsela e tšoanang. Sena se fokotsa mathata a kang splay marks kapa ho qhibiliha ho sa fellang. Thesebaka sa phepeloe tsamaisa le ho futhumatsa li-pellets, sebaka sa compression se qhibiliha ebe se hatella thepa, 'me sebaka sa metering se etsa bonnete ba hore ho qhibiliha ho lekana. Likarolo tse kang botebo ba kanale le likarolo tse kopanyang li thusa mocheso oa screw le ho kopanya polasetiki. Li-barrier screws li ka arola polasetiki e tiileng le e qhibilihisitsoeng, tsa etsa hore ho qhibiliha ho be le matla le ho boloka matla.

Ha ho qhibiliha ho tšoana, sehlahisoa sa ho qetela se shebahala se le betere ebile se sebetsa hantle. Ho kopanya ho fokolang ho ka baka li-streaks tsa mebala, matheba a fokolang, kapa liphetoho tsa boholo ba karolo. Homogeneity e ntle ea ho qhibiliha e bolela mefokolo e fokolang le likarolo tse tšepahalang haholoanyane. Basebelisi ba ka sebelisa li-sensor ho shebella boleng ba ho qhibiliha le ho fetola litlhophiso bakeng sa liphetho tse ntle.

- Motsoako o mobe oa ho qhibiliha o baka li-streaks tsa mebala le matheba a fokolang.

- Boleng bo botle ba ho qhibiliha bo lebisa ho boholo bo sa fetoheng ba karolo le matla.

- Boleng ba ho qhibiliha bo ipapisitse le mocheso oa barrel, lebelo la screw, le backpressure.

Tlhokomeliso: Ho boloka mocheso oa mocheso o tsitsitse le moralo o ts'oanang oa screw ho mofuta oa polasetiki ho thusa ho qoba liphoso le ho boloka boleng ba sehlahisoa bo le holimo.

Ho Kopanya ka Katleho le Nako ea Potoloho

Ho kopanya hantle ho itšetlehile ka sebopeho sa screw le likarolo tse khethehileng. Ha screw e ntse e phethoha, e sututsa le ho mena polasetiki, e etsa hore e be matlamatla a ho kuta. Ho kopanya likarolo tse haufi le ntlha, joalo ka li-pin kapa lifofane tse thibelang metsi, ho thusa ho kopanya ho qhibiliha. Ketso ena e jala mmala le li-additives ka mokhoa o ts'oanang, kahoo karolo ea ho qetela e shebahala e boreleli ebile e tšoana. Li-barrier screws li sebelisa sefofane sa bobeli ho arola polasetiki e qhibilihisitsoeng ho likotoana tse tiileng, ho potlakisa ho qhibiliha le ho thibela likotoana tse sa qhibilihang.

- Screw geometry e laola hore na li-pellets li sisinyeha joang, li qhibiliha, 'me li tsoakana.

- Likarolo tse kopanyang li etsa motsamao oa looping,ho kopanya ho feta 95%ea boitsebiso kapele.

- Li-barrier screws le meralo e khethehileng li thusa ho qhala mebala le li-additives.

Ho kopanya hantle ho boetse ho ama nako ea potoloho. Ho qhibiliha ka potlako le ho feta ho bolela hore mochini o ka tsamaisa lipotoloho tse ngata ka nako e nyane. Ho sebelisa li-barrier screws, li-screws tse kholoanyane tsa bophara, kapa li-grooves tse tebileng li eketsa lebelo la polasetiki. Ho phahamisa lebelo la screw (ha ho bolokehile bakeng sa thepa) le ho fokotsa khatello ea morao le hona ho ka khutsufatsa linako tsa potoloho. Mekhoa e tsoetseng pele ea ho futhumatsa le ea ho pholisa e boloka barrel e le mochesong o nepahetseng, e thusa likaroloana ho fola ka potlako le ho boloka tlhahiso e ntse e tsamaea.

- Moralo o ntlafalitsoeng oa screw barrel o thibela ho koala le tieho.

- Lisebelisoa tse nepahetseng tsa ho futhumatsa le tse futhumatsang li thusa likarolo tsa eona ho tiea kapele.

- Lisebelisoa tse tšoarellang le liaparo li fokotsa nako ea ho lokisoa.

Apara Khanyetso le Tlhokomelo

Wear ke bothata bo boholo bakeng sa sekoti sefe kapa sefe sa Plastic Injection molding. Li-filler tse senyang, li-plastiki tse senyang, le lihlahisoa tse telele tsa tlhahiso li ka senya screw le barrel. Mefuta e tloaelehileng ea ho apara e kenyelletsa li-abrasive wear, li-abrasive wear le corrosion. Ho etsa mohlala, ho roala ho etsahala ha li-filler tse thata joalo ka faeba ea khalase e hohla tšepe. Liaparo tse senyang li tsoa lik'hemik'hale tsa polasetiki tse kang PVC.

| Apara Mechanism | Tlhaloso | Merero ea ho Fokotsa Moralo |

|---|---|---|

| Sekgomaretsi | Metal surfaces kopana le phetiso thepa. | Sebelisa li-alloys tse thata, hlahloba lintlha, etsa bonnete ba ho lumellana ha lintho. |

| Abrasive Wear | Ketso ea ho kuta ho tsoa ho li-pellets kapa li-filler. | Sebelisa li-alloys tse thata, qoba li-fillers, boloka li-feedstock li hloekile. |

| Seaparo se Senyang | Tlhaselo ea lik'hemik'hale ho tloha lipolasetiki tse itseng. | Sebelisa thepa e sa jeng, qoba lik'hemik'hale tse bohale. |

| Mathata a ho Ikamahanya | Ho se tsamaisane hantle ho baka ho hohla le ho apara ka tsela e sa lekanang. | Etsa bonnete ba ho otloloha le ho tsamaisana hantle. |

Khetho ea thepa le kalafo ea bokaholimo li etsa phapang e kholo. Nitriding ea mokelikeli e eketsa ho tiea ha bokaholimo le ho se mamelle. Li-barrel tsa Bimetallic tse nang le li-liner tse khethehileng li tšoarella nako e telele, haholo-holo ka li-plastiki tse thata. Litlhahlobo tsa khafetsa le tlhokomelo e thibelang, joalo ka ho hloekisa le ho lekola boemo, li thusa ho rarolla mathata esale pele. Liaparo tse tsoetseng pele le lisebelisoa tse ncha li ka lelefatsa bophelo ba moqomo ho fihlela ho 40%, tsa fokotsa litšenyehelo tsa tlhokomelo le ho fokotsa nako ea ho theoha.

- Khafetsa ea tlhokomelo e itšetlehile ka thepa ea barrel le liphahlo.

- Tlhokomelo e thibelang le ho hlahlojoa khafetsa ho eketsa bophelo ba moqomo.

- Litlhare tse tsoetseng pele tsa holim'a metsi li fokotsa ho lokisoa le ho nkeloa sebaka.

Ho Ikamahanya le Lintho tse Fapaneng le Lisebelisoa

Moralo o bonolo oa screw barrel o lumella bahlahisi ho sebetsana le mefuta e mengata ea polasetiki. Screw geometry, joalo ka bolelele, sekontiri, le botebo ba mocha, li ka fetoloa hore li lumellane le lisebelisoa tse fapaneng. Morero o akaretsang, litšitiso, le likurufu tse kopanyang se seng le se seng se sebetsa hantle ka lipolasetiki tse itseng. Lisebelisoa tsa ho pholisa, joalo ka likanale tsa metsi, li boloka moqomo ka mocheso o nepahetseng bakeng sa thepa ka 'ngoe.

- Moralo oa Screw le geometrykopanya lipolasetiki tse fapaneng.

- Mekhoa e pholileng e thibela ho chesa haholo.

- Li-alloys tse matla le liphahlo li sebetsana le maemo a thata.

Meralo e feto-fetohang e boetse e etsa hore ho be bonolo ho fetola lipakeng tsa mesebetsi. Likarolo tse kang liadapter tsa ho hakolla kapele le li-screw pushers li thusa basebelisi ho fetola likurufu kapele. Litaolo tsa ts'ebetso ea Adaptive li sebelisa li-sensor le ho ithuta ka mochini ho lokisa maemo ka nako ea nnete. Sena se fokotsa liphetoho tsa matsoho le ho potlakisa liphetoho, kahoo tlhahiso e ka fetoha ho tloha ho thepa kapa sehlahisoa ho ea ho se seng ka nako e fokolang.

Keletso: Meetso ea li-screw barrel e feto-fetohang e thusa lifeme ho sebetsana le mefuta e mengata ea lipolasetiki le ho fetola mesebetsi kapele, ho boloka tlhahiso e tenyetseha ebile e sebetsa hantle.

Ho rarolla Mathata a Tloaelehileng a Ts'ebetso

Esita le ka moralo o motle ka ho fetisisa, mathata a ka etsahala. Litaba tse tloaelehileng li kenyelletsaho apara hofeta tekanyo, mathata a mocheso, thibane, lerata, le liphoso tsa ho kopanya mebala. Bothata bo bong le bo bong bo na le lisosa le tharollo ea bona.

| Taba ea Ts'ebetso | Tlhaloso le Matšoao | Mabaka le Litharollo |

|---|---|---|

| Ho Apara ho Feteletseng | Ho lutla ha lintho, boleng bo bobe, mocheso o phahameng, lerata | Sebelisa libarele tsa bimetallic, li-alloys tse thata, ho hloekisa kamehla, ho tsamaisana hantle |

| Molao oa Mocheso | Ho fifala ha 'mala, ho chesoa, ho putlama, ho soahlamana | Arola moqomo ka libaka, sebelisa li-sensor, preheating butle-butle, lijakete tsa ho kenya letsoho |

| Blockage le Build-up | Khatello e phahameng, phallo e mpe, matheba a matšo | Hloekisa ka metsoako ea ho hloekisa, lebelo le nepahetseng la screw, seal barrel nakong ea ho phomola |

| Lerata kapa Vibration | Lerata le leholo, ho thothomela, ho ferekana | Lekola ho tsamaisana, li-bearings, sebelisa damping ea vibrate, likarolo tse ikhethileng |

| Ho Kopanya Mebala/Tshireletso | Mebala ea mebala, li-shades tse sa tsitsang, tšilafalo | Sebelisa metsoako ea ho hloekisa, ho hloekisa khafetsa, ho ntlafatsa moralo oa screw, mechini ea tiiso nakong ea ho koala |

Basebelisi ba ka rarolla mathata a mangata ka ho latela mehato e seng mekae ea bohlokoa:

- Ntlafatsa sebopeho sa screw le libaka tsa mocheso oa barrel.

- Lekola le ho lokisa mocheso le lebelo la screw.

- Lekanya li-feeders le ho thibela ho kopana ha lintho.

- Lekola li-screws le libarele hore na ha li senyehile, haholo-holo libakeng tse nang le khatello e matla.

- Sebelisa tlhokomelo e boletsoeng esale pele ho rera tokiso le ho fokotsa nako.

- Boloka sekurufu se sengle ho nchafatsa ka makhetlo a 'maloa feela.

- Koetlisa basebetsi ho bona matšoao a lemosang esale pele.

Hlokomela:Ho hloekisa kamehla, ho tlotsa ka mokhoa o nepahetseng, le ho beha leihlo ka hlokothusa ho boloka sekoahelo sa polasetiki sa Ente ea ho bopa se sebetsa hantle le ho lelefatsa bophelo ba sona.

Ho ntlafatsa sebopeho sa moqomo oa sekoti oa polasetiki oa ente ho matlafatsa boleng ba ho qhibiliha le bophelo ba lisebelisoa. Ha bahlahisi ba khetha eamofuta oa moqomo o nepahetseng, geometry ea screw, le lisebelisoa, ba bona phallo e thellang, ho tsoakana hamolemonyana, le mefokolo e fokolang. Ho hlokomeloa kamehla, ho akarelletsa ho hloekisa le ho hlahloba, ho boloka mechine e sebetsa hantle le ho fokotsa litšenyehelo.

LBH

Molemo o ka sehloohong oa bimetallic screw barrel ke ofe?

Li-barrel tsa Bimetallic li hanela ho apara ho tloha li-plastiki tse thata. Li tšoarella nako e telele 'me li fokotsa nako ea ho phomola bakeng sa tlhokomelo.

Basebelisi ba lokela ho hlahloba sekoere barrel hangata hakae?

Basebelisi ba lokela ho hlahloba barrel ea screw khoeli le khoeli. Ho hlahlojoa khafetsa ho thusa ho ts'oara nako esale pele le ho boloka mochini o sebetsa hantle.

Na sekoti se le seng se ka sebetsa ka mefuta e mengata ea polasetiki?

| Mofuta oa Moqomo | Ho ikamahanya le maemo |

|---|---|

| Sepheo se Akaretsang | E ntle |

| Tšitiso | E kgabane |

| Ho kopanya | Hantle haholo |

Moqomo o entsoeng hantle o ka sebetsana le li-plastiki tse ngata, empa lisebelisoa tse ling li hloka likarolo tse khethehileng.

Nako ea poso: Aug-25-2025