Li-granulator tse nyane tsa tikoloho tsa PE ka 2025 li sebelisa li-motor tse sebetsang hantle haholo, ts'ebetso ea ts'ebetso, le li-automation tsa nako ea nnete ho fokotsa tšebeliso ea matla. Basebelisi ba bona liphetho hanghang, joalo ka aHo theoha ha 40% ea tšebeliso ea matla ka tonnebapisoa le setsomochini o le mong oa screw or vent single screw extruderlitsamaiso. Ho hlaphoheloa ha mocheso oa litšila ho boetse ho tšehetsamochini o se nang metsi oa granulatorts'ebetso.

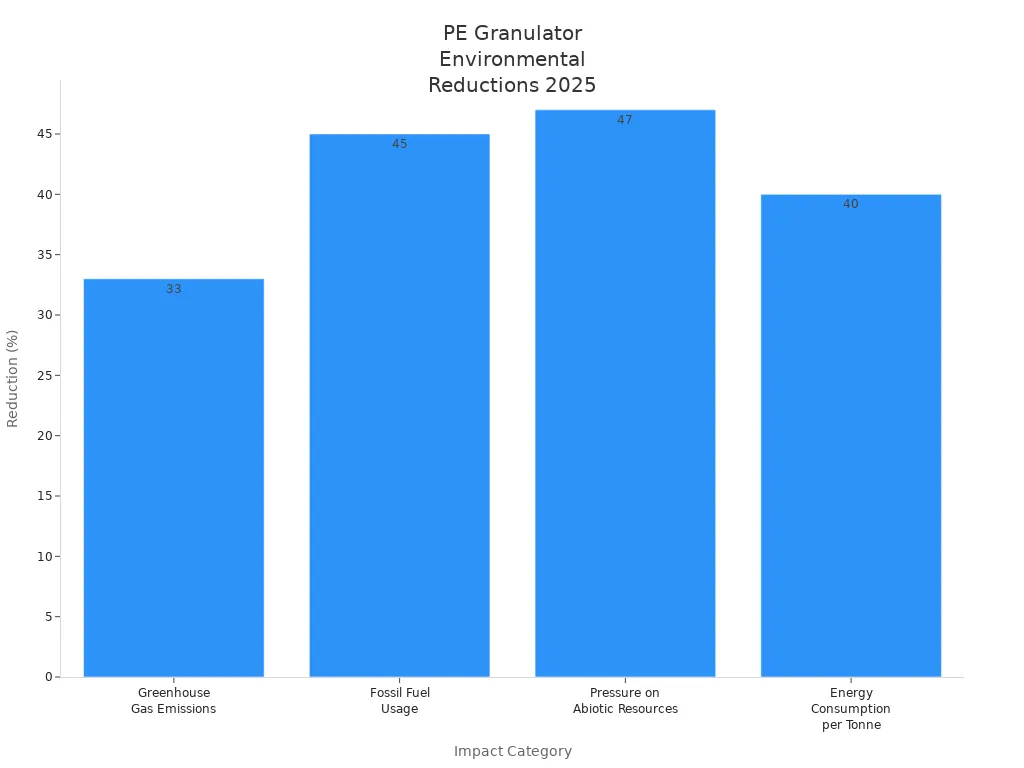

| Metric | Phokotso e Fumanehileng ka 2025 Ha e Bapisoa le Lilemo Tse Fetileng |

|---|---|

| Phokotso ea Khase ea Greenhouse | 33% ea fokotseha |

| Phokotso ea Tšebeliso ea Mafura a Fossil | 45% ea fokotseha |

| Khatello ho Lisebelisoa tsa Abiotic | 47% ea fokotseha |

| Tšebeliso ea Matla ka Tonne | Ka tlase ho 10 kW-h/tonne, 40% e ka tlase ho lisebelisoa tsa setso |

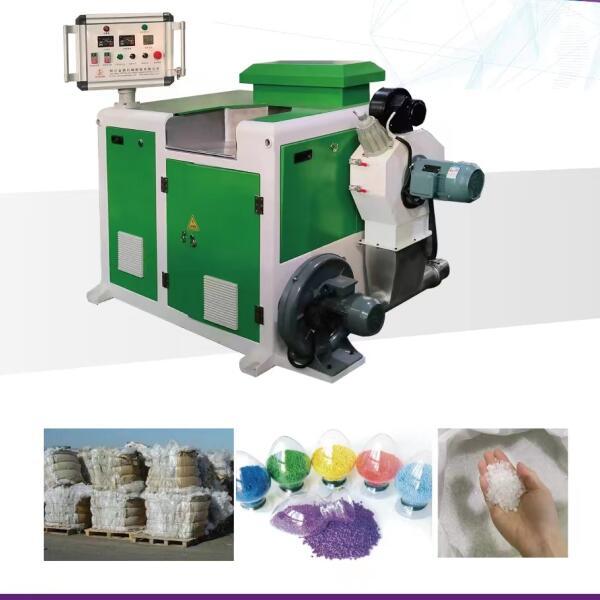

PE Small Environmental Granulators: Energy-Saving Technologies

Li-Motor le Lisebelisoa tsa Phetiso e Phahameng ka ho Fetisisa

Li-granulator tse nyane tsa tikoloho tsa PE ka 2025 li itšetlehile kali-motor tse sebetsang hantle haholo le lisebelisoa tse tsoetseng pele tsa phetisetsoho fumana chelete ea bohlokoa ea ho boloka matla. Li-motor tsena li fetola matla a motlakase hore e be matla a mochini ka tahlehelo e nyane, ho netefatsa hore boholo ba matla a kenyelletsoang a tsamaisa tšebetso ea granulation. Lisebelisoa tse tsoetseng pele tsa phetisetso li ntlafatsa ts'ebetso ena ka ho ntlafatsa tsela eo matla a tsamaeang ho tloha ho enjene ho ea ho likarolo tsa ho itšeha le tsa extrusion. Ha li kopantsoe, mahlale ana a fokotsa tšebeliso ea matla ka kakaretso nakong ea ts'ebetso. Kopanyo ena e theha leano le felletseng la ho baballa eneji le tshehetsang tshebediso e tlase ya eneji le bokgoni bo phahameng ba tlhahiso. Baetsi ba rua molemo likolotong tse tlase tsa motlakase le ts'ebetso e ntlafetseng ea lisebelisoa. Tšebeliso ea li-motor tse sebetsang hantle haholo le lisebelisoa tsa phetisetso le tsona li eketsa nako ea bophelo ea granulator, ho fokotsa litlhoko tsa tlhokomelo le nako ea ho theoha.

Keletso:Ho ntlafatsa ho lienjini tse sebetsang hantle haholo le lits'ebetso tsa phetiso ho ka fokotsa tšebeliso ea matla ka 30% ha e bapisoa le mefuta ea khale.

Intelligent Automation le Ts'ebetso ea Ts'ebetso

Intelligent automation e eme mokokotlong oa li-granulator tse nyane tsa tikoloho tsa PE. Sistimi ena e sebelisa li-control tse bohlale ho beha leihlo le ho lokisa matšoao a bohlokoa a ts'ebetso joalo ka mocheso, lebelo la koloi le ho thothomela. Basebelisi ba ka itšetleha ka likarolo tse kang PLC touch screens, tse lumellang liphetoho tse matla ho mocheso le boholo ba pellet. Li-sensor li lemoha litaba tse kang ho koala ha lefu kapa ho tlala ka koloi, ho fokotsa kotsi ea nako e sa lebelloang.

- Smart granulator e laola matšoao a ts'ebetso bakeng sa tlhokomelo e boletsoeng esale pele.

- Litsamaiso tse thehiloeng ho AI li tsebisa moralo oa tlhokomelo, joalo ka nako ea ho fetola lithipa kapa libere tsa mafura.

- Li-platform tse thehiloeng marung li thusa ho beha leihlo hole le ho romella likhopotso tsa tlhokomelo.

- Wiring ea khabinete ea matla e ts'ehetsa ho kopanya habonolo le lisebelisoa tse ling.

- Automation e fokotsa ho kenella ka letsoho, ho ntlafatsa polokeho le ho tšepahala.

- Ntlafatso ea ts'ebetso e lokisa liparamente tsa ts'ebetso, ho ntlafatsa granulation le ho fokotsa tšenyo ea matla.

- Moralo oa modular o lumella ho itlhophisa bakeng sa lisebelisoa tse fapaneng le litlhoko tsa tlhahiso.

Mekhoa ea ho ntlafatsa ts'ebetso e eketsa ts'ebetso ea matla le ho feta. Meralo ea mochini e kopantsoeng e kopanya shredding, seha, extrusion le pelletizing ts'ebetsong e le 'ngoe e tsoelang pele. Mokhoa ona o fokotsa tšebeliso ea matla, nako le mosebetsi. Mekhoa ea ho fepa e tsitsitseng e tsitsisa phallo ea lintho tse bonahalang, e thibela ho theoha le ho ntlafatsa boleng ba tlhahiso. Likarolo tsa othomathike joalo ka taolo ea phepelo ea koloi, lisefe tsa liteishene tse peli, le lebelo la thipa le itokisang li netefatsa tlhahiso e ntle le e sebetsang hantle. Li-motor tse sebetsang hantle ka matla, li-drive tse lebelo tse fapaneng, le litsamaiso tse pholileng tse tsoetseng pele le tsona li kenya letsoho ho theoleng tšebeliso ea matla.

Pheliso ea Mocheso oa Litšila le Tšebeliso

Ho khutlisa mocheso oa litšila ho emela tsoelopele e kholo ho li-granulator tse nyane tsa tikoloho tsa PE. Nakong ea ts'ebetso ea granulation, mechini e hlahisa mocheso joalo ka sehlahisoa. Ho e-na le ho tlohella mocheso ona hore o tsoe, litsamaiso tsa morao-rao lia o hapa le ho o sebelisa hape. Theknoloji e kang lipompo tsa mocheso o phahameng oa mocheso le lisebelisoa tsa polokelo ea mocheso o patehileng o sebelisa lisebelisoa tsa phetoho ea mekhahlelo (PCMs) li khutlisa mocheso o tlaase oa mocheso le ho o ntlafatsa hore o sebelisoe ho hlahisa mouoane kapa ho futhumatsa sebaka. Lifekthering tsa lipontšo, lisebelisoa tsa pompo ea mocheso oa lebasetere li fumane mocheso o fetang 80% oa litšila, ho fokotsa ho itšetleha ka mocheso oa motlakase ho ea ho 20%. Sena ha se ntlafatse feela katleho ea matla ka kakaretso empa hape se fana ka phaello e matla ea moruo, hangata e itefella ka nako e ka tlase ho lilemo tse tharo. Motsoako oa polokelo ea mocheso le lipompo tsa mocheso o nolofalletsa ts'ebetso e tsoelang pele le ho falla ha mojaro, ho fokotsa litšenyehelo tsa matla le ho theola likhase tsa CO2.

| Thekenoloji | Mosebetsi | Tšusumetso ho Tšebeliso ea Matla |

|---|---|---|

| Pompo ea Mocheso o Phahameng oa Mocheso | E ntlafatsa mocheso oa litšila bakeng sa mouoane | E fokotsa mocheso oa motlakase |

| Latent Heat Storage (PCM) | E boloka le ho ntša mocheso ha ho hlokahala | E nolofalletsa phetisetso ea mojaro |

| Sistimi ea Hybrid | E kopanya ka bobeli bakeng sa katleho e kholo | E fumana 81.1% ea mocheso o litšila |

Li-granulator tse nyane tsa tikoloho tsa PE li behile maemo a macha a ho sebetsa hantle ha matla a polasetiki. Theknoloji ea bona e tsoetseng pele ea ho boloka matla e thusa bahlahisi ho fokotsa litšenyehelo, ho ntlafatsa tlhahiso le ho tšehetsa lipakane tsa tikoloho.

Melemo ea PE Small Environmental Granulators ka 2025

Litšenyehelo tse Fokotsoeng tsa Ts'ebetso le Tšebeliso ea Matla

Baetsi ba bona ho boloka litšenyehelo tse hlakileng ha ba sebelisa li-granulator tse nyane tsa tikoloho tsa PE. Mehlala e pholileng ka moea e tlosa tlhokahalo ea metsi, e bolokang chelete ho hloekisa metsi le ho boloka lisebelisoa. Li-granulator tsena li sebelisa matla a fokolang ho feta litsamaiso tse pholileng ka metsi ka lebaka la moralo oa tsona o bonolo le ts'ebetso e ntlafetseng. Tlhokomelo e ba bonolo, 'me kotsi ea ho senyeha ho tloha mathateng a tsamaiso ea metsi ea theoha. Basebelisi ba ka tsamaisa mechine ena libakeng tse nang le metsi a fokolang kapa moea o fokolang, ho boloka tlhahiso e tsitsitse. Pholiso e tšoanang e boetse e ntlafatsa boleng ba sehlahisoa le ho fokotsa litšila.

- Ho sebetsa ka moea o pholileng ho felisa litšenyehelo tsa metsi le tlhokomelo e amanang le eona.

- Tšebeliso e tlase ea matla e bolela likoloto tse nyane tsa motlakase.

- Sebopeho se bonolo se fokotsa litlhoko tsa ho lokisa le ho fokotsa nako.

- Ts'ebetso e tsitsitseng libakeng tse thata e tiisa tlhahiso e ka tšeptjoang.

- Boleng bo betere ba sehlahiswa bo lebisa tshenyehong e nyane le ho sebetsa hantle haholo.

Tšusumetso ea Tikoloho le Phokotso ea Mehato ea Carbon

Li-granulator tse nyane tsa tikoloho tsa PE li thusa lik'hamphani ho theola tšusumetso ea tsona ea tikoloho. Ba khaola khabone letshebediso ya matla, ho etsa hore tšebetso ea polasetiki e be tala.

| Molemo oa Tikoloho | Lintlha |

|---|---|

| Phokotso ea tlhahiso ea CO2 | Lithane tse 1.5 tsa CO2 li fokotsehile ka tonne e le 'ngoe ea li-pellets tse tsosolositsoeng |

| Phokotso ea Tšebeliso ea Matla | 30% matla a tlase a sebelisoang ke li-granulator tse ncha tsa lebelo le tlase |

| Phokotso ea Lerata | 20dB maemo a tlase a lerata |

| Ntlafatso ea Recycling Rate | Koala-loop recycling e fokotsa tšebeliso ea thepa e tala |

| Mohlala oa nyeoe - Koloi | Lithane tse 300 tsa polasetiki e ncha e bolokiloe selemo le selemo ka ho sebelisa litšila tse ngata |

| Mohlala oa Mohlala - Temo | 85% sekhahla sa phetoho se fihlelletsoeng ke lihoai tsa India tse sebelisang li-pellets tse nyane |

Mechini ena e boetse e tšehetsa moruo oa selikalikoe ka ho fetola litšila tsa polasetiki hore e be li-granules tse ka sebelisoang hape. Ts'ebetso ena e fokotsa litšila tsa litšila le ho boloka mehloli ea tlhaho.

Ho Ikamahanya le maemo le ho Ikamahanya le Maemo a Indasteri

Li-granulator tse nyane tsa tikoloho tsa PE li thusa lik'hamphani ho fihlela melao e thata ea tikoloho libakeng tse ngata. Mechini e ts'ehetsa ho sebelisoa hape le ho fokotsa ts'ebeliso ea lithōle, e tsamaellanang le mananeo a mmuso bakeng sa litšila tse se nang letho. Mefuta e mengata e kopana le litekanyetso tsa machabeng joalo ka ISCC PLUS, e latellang tšebeliso e tsitsitseng ea phepelo ea lijo le ho netefatsa ho latela lipheo tsa sechaba le tsa tikoloho. Moralo oa bona o feto-fetohang o lumellana le lits'ebetso tse kholo le tse nyane, ho thusa likhoebo ho ikamahanya le maemo a fetohang. Advanced automation lelikarolo tsa ho boloka matlaetsa hore ho be bonolo ho latela melao e mecha mabapi le mesi le lerata. Likhamphani tsa Amerika Leboea le Europe li sebelisa li-granulator tsena ho ts'ehetsa lipheo tsa moruo o potolohang le ho fihlela maemo a lehae le a lefats'e.

Li-granulator tse nyane tsa tikoloho tsa PE li fumana matla a holimo ka ho sebelisa meralo ea lebelo le tlase, likarolo tse ka khonehang, le theknoloji e tsoetseng pele ea ho e sebelisa hape. Mechini ena e thusa liindasteri ho theola litšenyehelo, ho fokotsa litšila, le ho tšehetsa moruo o potolohang. Likhamphani tse khethang li-granulator tsena li ntlafatsa ts'ebetso, li kopana le melaoana le ho theha bokamoso bo hloekileng.

LBH

Granulator e nyane ea tikoloho ea PE e boloka matla joang?

Granulator e sebelisa li-motor tse sebetsang hantle haholo le li-automation tse tsoetseng pele. Likarolo tsena li fokotsa tšebeliso ea motlakase le ho fokotsa litšila nakong ea tlhahiso ea granule ea polasetiki.

Keletso:Tlhokomelo ea kamehla e thusa ho boloka chelete ea motlakase e phahame.

Na granulator e ka sebetsana le mefuta e fapaneng ea litšila tsa polasetiki?

Ee. Mochine o tšehetsa lisebelisoa tse fapaneng tsa polasetiki. Basebelisi ba ka fetola litlhophiso bakeng sa mofuta o mong le o mong, ho netefatsa granulation e tsitsitseng le tlhahiso ea boleng.

Ke tlhokomelo efe eo granulator e e hlokang?

Basebelisi ba lokela ho hlahloba li-motor, lihloela tse hloekileng, 'me ba hlahlobe li-blade tse sehang khafetsa. Litaolo tse bonolo le likarolo tsa modular li etsa hore tlhokomelo ea kamehla e potlake hape e be bonolo.

Nako ea poso: Jul-17-2025