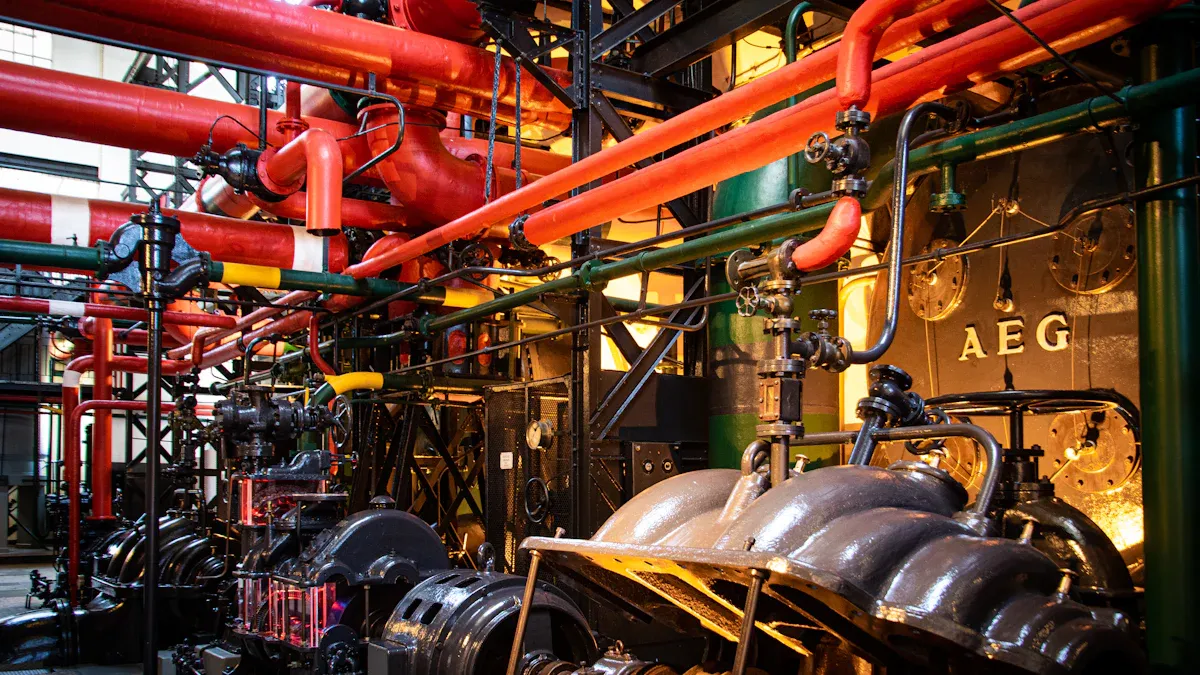

Boenjiniere ba Precision bo fetola indasteri ea Twin Parallel Screw Barrel. Limmaraka tsa lefats'e li rera kholo e matla joalo ka ha bahlahisi ba rataBaetsi ba Li-Barrels tsa Single ScrewleExtruder Twin Screw Barrelbahlahisi ba amohela theknoloji e tsoetseng pele. AFactory ea Twin Parallel Screw Barrelhona joale finyella ho fihlela ho50% tlhahiso e potlakileng, 30% e fokotsehile ka nako, le 90% e fokolang ea lihlahisoa tse fokolang.

Precision Engineering in Twin Parallel Screw Barrel Technology

Ho hlalosa Boenjiniere ba Precision bakeng sa Twin Parallel Screw Barrel Systems

Boenjiniere bo nepahetseng bo bopa bokamoso baLitsamaiso tsa Twin Parallel Screw Barrel. Mokhoa ona o sebelisa mekhoa e tsoetseng pele ea moralo, tlhahiso le taolo ho fihlela mamello e tiileng le boleng bo tsitsitseng. Baenjiniere ba itšetlehile ka thepa ea CNC e nepahetseng haholo, phekolo ea mocheso e laoloang ke k'homphieutha, le lisebelisoa tse tsoetseng pele tsa ho hlahloba. Lisebelisoa tsena li thusa ho theha li-screw shafts le libarele tse nang le litekanyo tse nepahetseng hantle le liphetho tsa bokaholimo.

Sistimi ea sejoale-joale ea Twin Parallel Screw Barrel e na le meralo e ntlafalitsoeng ea shaft. Ka mohlala, karo-karolelano ea OD/ID e eketsehile ho tloha ho 1.25 ho li-key-way shafts ho ea ho 1.66 ka li-asymmetrical splined shafts. Phetoho ena e lumella li-shafts tse nyane ho fetisa torque e phahameng, ho etsa hore mechini e be matla le ho sebetsa hantle. Litlhophiso tsa meqomo le tsona li fetohile. Meetso ea pele e ne e sebelisa libarele tse chitja tse nang le moea o pholileng oa kantle. Kajeno, libarele tse arohaneng tse nang le li-bores tse pholileng ka hare le li-heaters tsa cartridge li fana ka taolo e ntle ea mocheso le botsitso ba ts'ebetso.

Taolo ea ts'ebetso e phetha karolo ea bohlokoa ho boenjiniere bo nepahetseng. Li-sensor li hlokomela lebelo la screw, sekhahla sa phepelo, mocheso le maemo a vacuum. Li-algorithms tsa PID li sebelisa data ena ho boloka ts'ebetso e tsitsitse. Baenjiniere ba ka fetola liparamente tsena ka nako ea nnete, ba netefatsa ts'ebetso e nepahetseng le boleng ba sehlahisoa.

Hlokomela:Boenjineri bo nepahetseng ho lits'ebetso tsa Twin Parallel Screw Barrel bo bolela hore karolo e 'ngoe le e 'ngoe, ho tloha ntlheng ea screw ho ea leboteng la moqomo, e kopana le litekanyetso tse thata. Boemo bona ba lintlha bo lebisa ho kopantseng hantle, phallo e ntlafalitsoeng ea thepa, le ho tsitsa ha lihlahisoa tse phahameng.

Melemo ea Ts'ebetso ea Bohlokoa e Ntlafalitsoeng ke Boenjiniere ba Precision

Boenjiniere bo nepahetseng bo fana ka lintlafatso tse lekantsoeng ts'ebetsong ea Twin Parallel Screw Barrel. Baenjineri ba sebelisa mefuta e tsoetseng pele ea likhomphutha, joalo ka Discrete Element Method (DEM) le Population Balance Modeling (PBM), ho sekaseka phallo ea thepa, katleho ea ho kopanya, le kabo ea nako ea bolulo. Mefuta ena e senola hore na liphetoho tsa tlhophiso ea screw, sekontiri se phahameng le boemo ba ho tlatsoa ha meqomo li ama boholo ba granule le boleng ba sehlahisoa joang.

Li-metrics tse 'maloa tsa bohlokoa li hlalosa ts'ebetso ea sistimi ena:

| Metric | Tlhaloso | Tšusumetso ho Ts'ebetso |

|---|---|---|

| OD/ID Karolelano | Karolelano ea bophara ba ka ntle ho ea kahare ea "screw shaft". | Phetiso e phahameng ea torque |

| Karolelano ea L/D | Karolelano ea bolelele ho isa ho bophara ba moqomo | Ts'ebetso e eketsehileng ea yuniti, ho kopanya hantle |

| Specific Energy (SE) | Kenyeletso ya matla ho ya ka boima ba yuniti (kW ka kg/h) | Tšebeliso e tlase ea matla, ts'ebetso e phahameng |

| Nako ea Bolulo (Φ) | Lisebelisoa tsa nako li sebelisoa karolong ea extruder | Taolo ea ts'ebetso e betere |

| Peak Shear Stress | Matla a mangata a sebelisoang ho lintho tse bonahalang nakong ea ho kopanya | Ho ntlafala ho kopanya, botšepehi ba lintho tse bonahalang |

Mohlala, lipapiso tsa DEM li bonts'a mekhoa e felletseng ea phallo le boits'oaro bo tsoakaneng ka har'a moqomo. Mefuta ea DEM e ntlafalitsoeng ea GPU e bolela esale pele hore na sebopeho sa likaroloana se ama thepa ea phetisetso joang. Ho kopanngoa ha theknoloji ea ho hlahloba ts'ebetso (PAT), joalo ka haufi le infrared le Raman spectroscopy, e lumella ho shebella nako ea sebele le ho laola ho ikamahanya le maemo. Lisebelisoa tsena li thusa lienjineri ho etsa litokiso kapele, tse lebisang mefokolong e fokolang le tlhahiso e tsitsitseng haholoanyane.

Boenjiniere bo nepahetseng bo boetse bo ntlafatsa taolo ea mocheso. Libarele tse arohaneng tse nang le pholileng ea ka hare le li-heaters tsa cartridge li boloka ts'ebetso e tsitsitse. Botsitso bona bo fokotsa nako ea ho theoha le ho eketsa tlhahiso.

- Baenjiniere ba beha leihlo le ho laola:

- Lebelo la screw(rpm)

- Sekhahla sa lijo (kg/h)

- Mocheso

- Maemo a vacuum

Lintlafatso tsena li behile litekanyetso tse ncha tsa ho sebetsa hantle, ho ts'epahala, le boleng ba sehlahisoa ho theknoloji ea Twin Parallel Screw Barrel.

Lisebelisuoa tse Tsoetseng Pele le Liaparo ka Moralo oa Twin Parallel Screw Barrel

Li-alloys tse sebetsang hantle haholo le lisebelisoa tse kopaneng

Baenjiniere ba khetha li-alloys tse sebetsang hantle le lisebelisoa tse kopaneng ho matlafatsa ts'ebetso le ts'ebetso eascrew barrel. Metal matrix composite (MMCs) e kopanya tšepe e kang aluminium kapa magnesium le ceramic kapa fiber matrices. Lisebelisoa tsena li fana ka khanyetso e ntlafetseng ea ho apara, litekanyetso tse phahameng tsa matla-to-weight, le mamello e ntle ea mocheso. Libarele tse kopantsoeng li na le boima bo fokolang, bo lumellang libarele tse telele le sebaka se seholoanyane se monate. Libarele tsa alloy li fana ka nako e telele le ho sebetsa hantle libakeng tse batang. Mefuta ena ka bobeli e fana ka ts'ebetso e matla, haholo-holo ha thepa e tobane le khatello e phahameng kapa mocheso o fetoha.

Liaparo tse sa Apareng le tse sa Ruleng

Baetsi ba sebelisa litlolo tse tsoetseng pele ho sireletsaTwin Parallel Screw Barrelho tloha ho tsofala le ho bola. Mekhoa e kang PVD, CVD, le spray spray e etsa libaka tse thata, tse tšoarellang. Liaparo tsa Nanostructured li boloka boima bo phahameng esita le ka mor'a ho pepesehela mocheso. Laser cladding e hlahisa maqhama a matla le microstructure e hloekisitsoeng, e eketsang ho hanyetsa ho bola. Khetho ea mokhoa oa ho roala e ama nako ea bophelo le ho tšepahala ha moqomo. Mohlala, tšepe e sa hloekang le titanium li bonts'a khanyetso e ntle ea kutu, athe li-polymer tse matlafalitsoeng ka fiber le tsona li sebetsa hantle maemong a thata.

| Lintho tse bonahalang | Khanyetso ea Corrosion |

|---|---|

| Tšepe ea Carbon | Mafutsana |

| Ts'epe e sa beng le mabali | E kgabane |

| Aluminium | E ntle |

| Koporo | E ntle |

| Titanium | E kgabane |

| Fiber-Reinforced Polymers (FRP) | E kgabane |

Liaparo tse sa tsoeng li fokotsa litšenyehelo tsa tlhokomelo le nako ea ho theoha. Li thusa libarele hore li sebetse ka katleho maemong a boima.

Tšusumetso ho Bophelo ba Tšebeletso le Litlhoko tsa Tlhokomelo

Lisebelisoa tse tsoetseng pele le liphahlo li eketsa bophelo ba ts'ebeletso ea libarele tsa screw. Liaparo tsa nitride le li-tungsten linings li fana ka tšireletso e phahameng ea ho apara. Lintlafatso tsena li fokotsa litšenyehelo tsa potoloho ea bophelo le ho ntlafatsa ts'epo.Li-indices tsa bokhoni tse kang Cp le Cpkbonts'a mefokolo e fokolang le botsitso bo betere ba ts'ebetso. Lipalopalo tsa Taolo ea Ts'ebetso (SPC) li lekola boleng le ho fokotsa litefiso tsa maqheku. Ka lebaka leo, bahlahisi ba na le nako e fokolang ea ho theoha le ho feta ho feta.

Smart Sensors le Taolo ea Ts'ebetso bakeng sa Ts'ebetso ea Twin Parallel Screw Barrel Systems

IoT Integration le Tlhokomelo ea Nako ea 'Nete

Li-sensor tse bohlale le theknoloji ea IoT joale li bapala karolo ea bohlokoa tlhahisong ea sejoale-joale. Likhamphani li sebelisa li-sensor tsa IoT ho lekola mocheso, khatello le lebelo la screw ka nako ea nnete. Li-sensor tsena li romella data ho litsamaiso tsa taolo, tse thusang basebelisi ho bona mathata kapele. Ka mohlala, General Electric e sebelisa li-sensor tsa IoT le ho ithuta ka mochine ho shebella lisebelisoa, ho lumella tlhokomelo e boletsoeng esale pele e fokotsang nako ea ho theoha le ho matlafatsa bokhoni ba tlhahiso. Lintlha tsa nako ea sebele li boetse li lumella lik'hamphani ho fetola linako tsa tlhahiso hang-hang, ho ntlafatsa ts'ebetso le ho fokotsa litšila. Litsamaisong tsa Twin Parallel Screw Barrel, sena se bolela taolo e betere ea ts'ebetso le liphoso tse fokolang tsa sehlahisoa.

Tlhokomelo e lebeletsoeng pele le Ntlafatso e tsamaisoang ke data

Tlhokomelo ea esale pele e sebelisa li-sensor tse bohlale ho lekola bophelo ba lisebelisoa. Lisensara tsena li lekola mocheso, ho thothomela le khatello, ho thusa lihlopha ho fumana liphoso kapele. Ho ithuta ka mochini ho sekaseka lintlha tsena ho bolela esale pele hore na tlhokomelo e hlokahala neng. Mokhoa ona o fokotsa litokiso tse sa hlokahaleng 'me o shebane le litlhoko tsa sebele tsa lisebelisoa. Likhamphani tse kang General Motors li bone15% nako e tlase ea ho theohale ho boloka limilione ka ho sebelisa tlhokomelo e boletsoeng esale pele. Tlhokomelo le tlhahlobo ea remoutu e boetse e ntlafatsa linako tsa ho arabela le polokeho. Phello e ba nako e telele ea lisebelisoa, ho senyeha ho fokolang, le litšenyehelo tse tlaase tsa tlhokomelo.

| Molemo | Tlhaloso |

|---|---|

| Ho Fumana Phoso ea Pele | Li-sensor li bona mathata pele li hloleha |

| Maintenance Optimized | Mananeo a tsamaisoang ke data a fokotsa litokiso tse sa hlokahaleng |

| Nako ea Bophelo ea Thepa e Ekelitsoeng | Tlhokomelo e nakong e eketsa bophelo ba tšebeletso |

| Nako ea ho phomola e fokotsehile | Ho koala ho sa lebelloa ho fokolang |

Thuto-pale: Ho Matlafatsoa ha Ts'ebetso le Boleng ba Sephetho

Bahlahisi ba likete joale ba sebelisa li-sensor tse bohlale lits'ebetsong tsa bona tsa Twin Parallel Screw Barrel. Tlhokomelo ea nako ea 'nete ea mocheso le lebelo la screw e thusa basebelisi ho boloka ts'ebetso e tsitsitse. Mekhoa e tsoetseng pele ea taolo ea mocheso e thibela ho senyeha ha thepa le ho netefatsa boleng bo tsitsitseng ba sehlahisoa. Lik'hemik'hale tse sebelisang litsamaiso tsena li tlaleha ho koaloa ho sa lebelloang ho fokolang ka 30%. General Motors e fihletse lidolara tse limilione tse 20 ho boloka selemo le selemo le ho ntlafatsa botsitso ba ts'ebetso. Liphetho tsena li bonts'a hore li-sensor tse bohlale le taolo ea ts'ebetso li fana ka ts'ebetso e phahameng, boleng bo betere ba sehlahisoa, le litšila tse fokotsehileng.

Modular le Customizable Twin Parallel Screw Barrel Designs

Litlhophiso tse Fetohang bakeng sa Litlhoko tse fapaneng tsa Tlhahiso

Kajeno bahlahisi ba batla lisebelisoa tse ikamahanyang le mefuta e mengata ea lisebelisoa le lits'ebetso. Moralo oa "screw" oa modular o lumella lienjineri hore li iketsetse libaka tsa ts'ebetso bakeng sa litlhoko tse ikhethang tsa thepa. Ba ka khetha likarolo tse fapaneng tsa screw le li-module tse sebetsang ho tsamaisana le sesebelisoa ka seng. Ho feto-fetoha ha maemo ho tšehetsa liphello tse nepahetseng ka mekhoa e rarahaneng, ho kenyelletsa le li-polymers tse tsitsitseng le tse thehiloeng ho bio. Likhamphani tse kang Thermo Fisher Scientific le Leistritz li fana ka li-extruder tse nang le meralo ea modular, tse nolofalletsang mocheso o nepahetseng le taolo ea lebelo. Litheknoloji tse tsoetseng pele tsa ho beha leihlo le taolo li eketsa ho fetoha habonolo ha ts'ebetso le ho ntlafatsa ts'ebetso.

Sistimi ea Modular Twin Parallel Screw Barrel e ntlafatsa bokhoni ba ho kopanya, e eketsa phallo, le ho sebetsana le lisebelisoa tse fapaneng habonolo.

Phetoho e potlakileng le Phokotso ea Nako ea ho Phokotsa

Maano a moralo oa modular a thusa ho lokisoa ka potlako ha li-screw modules le likarolo tsa barrel. Basebelisi ba ka fetoha kapele lipakeng tsa lihlahisoa, ba fokotsa nako ea ho theoha nakong ea liphetoho. Digitalization le lisebelisoa tsa ho laola maru li fana ka li-analytics tse bohareng. Tlhokomelo e boletsoeng esale pele e tsamaisoang ke ho ithuta ka mochini e lebelletse ho khathala ha likaroloana, ho fokotsa ho emisa ho sa lebelloang. Likarolo tsena li thusa bahlahisi ho boloka tlhahiso e phahameng le boleng bo tsitsitseng.

Boenjiniere ba Tloaelo bakeng sa Likopo tse Khethehileng

Litharollo tsa boenjiniere tse ikhethileng li rarolla mathata a ikhethang a ts'ebetso.Li-extruder tsa mafahla tse bapileng tse potolohang, mohlala, fana ka bolelele bo bolelele ba screw le ho hanyetsa ho hoholo ha kutu. Likarolo tsena li ntlafatsa boleng ba sehlahisoa le ho lelefatsa bophelo ba moqomo, haholo ha o sebetsana le PVC e nang le filler e phahameng ea calcium carbonate. Tafole e ka tlase e bapisa likarolo tsa bohlokoa tsa parallel le conical twin screw extruder:

| Karolo | Parallel Counter-Rotating Twin Screw Extruder | Conical Twin Screw Extruder |

|---|---|---|

| Screw Length (L/D ratio) | Nako e telele (1/30) | Khutšoane |

| Ho loketse bakeng sa PVC + High CaCO3 Filler | E kgabane | E sa sebetseng hantle |

| Khanyetso ea Corrosion | E phahameng | Tlase |

| Boleng ba Sehlahiswa | Homogeneity e ntlafalitsoeng | Kotsi e kholo ea liphoso |

| Matla a Matla | Ho fihlela ho 35% phokotso ea tšebeliso ea matla | Ha ea hlalosoa |

Meralo e tloahelehileng e netefatsa hore sistimi e 'ngoe le e' ngoe ea Twin Parallel Screw Barrel e fihlela litlhoko tse hlakileng tsa lits'ebetso tse ikhethileng, e fana ka ts'ebetso e phahameng le ho tšoarella.

Matla a Matla le Moshoelella ho Twin Parallel Screw Barrel Technology

Precision Machining bakeng sa Khohlano e Tlaase le Tšebeliso ea Matla

Ho sebetsa ka mokhoa o nepahetseng ho etsa libaka tse boreleli holim'a lisekere le libarele. Ts'ebetso ena e fokotsa likhohlano lipakeng tsa likarolo tse tsamaeang. Khohlano e tlase e bolela hore mochini o sebelisa matla a fokolang nakong ea ts'ebetso. Baenjiniere ba lik'hamphani tse etellang pele ba sebelisa lisebelisoa tsa CNC ho fumana mamello e nepahetseng. Mamello ana a thata a thusa sistimi ea screw barrel hore e sebetse hantle haholoanyane. Ka lebaka leo, bahlahisi ba bona likoloto tse fokolang tsa motlakase le ho fokotsa mocheso o fokolang. Ho sebetsa ka mokhoa o nepahetseng ho boetse ho lelefatsa bophelo ba karolo ka 'ngoe.

Keletso:Libaka tse boreleli ha li boloke matla feela empa li boetse li ntlafatsa boleng ba sehlahisoa ka ho fokotsa lintho tse khomarelang le ho apara.

Merero ea Tlhahiso e Sebeletsang Eco le Moruo oa Circle

Baetsi ba bangata hona joale ba tsepamisa maikutlo hotlhahiso ea eco-friendly. Ba khetha lisebelisoa tse ka sebelisoang hape 'me ba fokotsa litšila nakong ea mochini. Lik'hamphani tse ling li sebelisa lipeo tsa tšepe hape 'me li sebelisa metsi a sebetsang hape. Ba bang ba sebelisa mehloli ea matla a ka nchafatsoang lifemeng tsa bona. Mehato ena e tšehetsa moruo oa selikalikoe, moo lisebelisoa li lulang li sebelisoa nako e telele kamoo ho ka khonehang.

Mekhoa ea bohlokoa ea ho boloka tikoloho:

- Tšebeliso ea li-alloys tse tsosolositsoeng

- Mekhoa ea ho hloekisa e thehiloeng metsing

- Mabone le lisebelisoa tse baballang matla

Ho Fokotsa Tšusumetso ea Tikoloho Ts'ebetsong ea Liindasteri

Theknoloji ea Twin parallel screw barrel e thusafokotsa boemo ba tikolohotsa lifeme. Mechini e nang le matla a phahameng a matla e hlahisa likhase tse fokolang tsa khabone. Liaparo tse tsoetseng pele le lisebelisoa li fokotsa tlhokahalo ea ho fetola khafetsa. Sena se bolela hore litšila tse fokolang tse eang litsing tsa lithōle. Likhamphani tse sebelisang mahlale ana li kopana le maemo a thata a tikoloho le ho ntlafatsa botumo ba tsona 'marakeng.

Baetsi ba tsetelang theknoloji e tsitsitseng ba etella pele bokamoso bo botala.

Melemo ea 'Nete ea Lefatše bakeng sa Baetsi le Basebelisi ba Bofelo

Boleng bo ntlafetseng ba Sehlahisoa le ho tsitsisa

Baetsi ba bona melemo e hlakilengboleng ba sehlahisoa le botsitsoe nang le lisebelisoa tse tsoetseng pele tsa Twin Parallel Screw Barrel. Basebelisi ba latela metrics ea bohlokoa ho netefatsa hore sehlahisoa se seng le se seng se fihlella maemo a thata. Tafole e ka tlase e bontša kamoo metrics ena e tšehetsang liphetho tse betere:

| Metric | Tlhaloso | Kamoo e Tšehetsang Boleng bo Ntlafetseng le ho tsitsisa |

|---|---|---|

| Lihlahisoa (ho kenyeletsoa le Tlhahiso ea Pele-Pass) | Mehato ea katleho ea ts'ebetso; FPY ke liperesente tsa lihlahisoa tse entsoeng ka nepo khetlo la pele ntle le ho sebetsa hape. | E thusa ho ntlafatsa katleho ea tlhahiso ka ho tseba ho se sebetse hantle, ho lekanya ts'epahalo ea ts'ebetso, le ho senola litšenyehelo tse patiloeng ho tsoa ho rework. |

| Kakaretso ea Kakaretso ea Thepa (OEE) | E kopanya ho fumaneha, ts'ebetso, le boleng ho lekanya tlhahiso ea mochini le katleho. | E matlafatsa ts'ebeliso ea mochini, e ntlafatsa kemiso ho fokotsa nako, 'me e latela mekhoa ea ts'ebetso ho lebella ho hloleha. |

| Phello | Palo ea thepa e hlahisoang ha nako e ntse e ea, e lekantsoeng ka mochini, mohala oa sehlahisoa, kapa semela. | E supa mathata, e beha lipheo tsa sebele tsa tlhahiso, le ho lekanya ROI ea lisebelisoa kapa ntlafatso ea ts'ebetso. |

| Supplier Quality Metrics | E kenyelletsa sekhahla sa bofokoli ba barekisi, litefiso tsa morao-rao, le liperesente tse kenang tsa boleng. | E fokotsa litšenyehelo tsa boleng ka ho beha leihlo boleng ba thepa ea mofani oa thepa, e lumellang mehato ea tokiso ho thibela mefokolo ho ea tlase. |

| Delivery Metrics | Ho tsamaisoa ka nako (OTD) le Perfect Order Metric (POM) li lekanya nako ea ho fihla le ho nepahala. | E ntlafatsa khotsofalo ea bareki ka ho etsa bonnete ba hore ho tsamaisoa ka nako, ka botlalo, le ho se na liphoso, ho bonts'a boleng ba sehlahisoa bo sa fetoheng. |

| Tšebeliso ea Nako ea ka hare | Metrics joalo ka nako ea potoloho ea tlhahiso, nako ea phetoho, le sekhahla sa tlhahiso e ncha ea sehlahisoa. | E matlafatsa ts'ebetso ea ts'ebetso ka ho fokotsa tieho le ho potlakisa liphetoho tsa tlhahiso, ho tšehetsa tlhahiso e tsitsitseng. |

| Theko ea boleng (CoQ) | E latela litjeo tse amanang le boleng bo tlase (sekhechana, rework) le matsete a netefatso ea boleng. | E totobatsa tšusumetso ea lichelete ea litaba tsa boleng, e tataisang matsete ho fokotsa liphoso le ho ntlafatsa ts'epahalo ea sehlahisoa. |

Basebelisi ba boetse ba shebana le ho nepahala ha data, botlalo, le nako. Mekhoa ena e thusa ho boloka litekanyetso tse phahameng le ho fokotsa liphoso.

Litsenyehelo tse tlase tsa ts'ebetso le nako e eketsehileng ea ho sebetsa

Likhamphani li rua molemo ka litšenyehelo tse tlase tsa ts'ebetso le nako e eketsehileng. Boenjiniere bo nepahetseng le ho beha leihlo ka bohlale ho fokotsa tlhoko ea ho lokisoa. Mechini e sebetsa nako e telele ntle le ho emisa. Lihlopha li sebelisa chelete e nyane ho lokisa le ho kenya likarolo tse ling. Lisebelisoa tsa ho lokisa esale pele li thusa ho bona mathata esale pele, kahoo basebelisi ba li lokise pele li baka nako. Mokhoa ona o boloka mela ea tlhahiso e ntse e tsamaea le ho boloka chelete.

Likhamphani tse sebelisang maano a tsoetseng pele a ho beha leihlo le tlhokomelo li bona ho putlama ho fokolang le phaello e phahameng.

Melemo ea Litlholisano 'Marakeng oa Lefatše

Baetsi ba theknoloji e tsoetseng pele ea Twin Parallel Screw Barrel ba fumana boemo bo matla mebarakeng ea lefatše. Kabelo ea 'maraka e sebetsa e le sesupo sa bohlokoa sa katleho. Kabelo e phahameng ea mmaraka e bonts'a tlholisano e matla le setsi se seholo sa bareki. Likhamphani tse nang le karohano e ntseng e hola ea 'maraka li natefeloa ke melemo e joalo ka moruo oa maemo a holimo, matla a betere a therisano, le ho eketseha ha botumo ba lebitso. Melemo ena e ba thusa ho etella pele indasteri le ho hohela bareki ba bangata. Tlhahlobo ea karolo ea 'maraka e boetse e thusa lik'hamphani ho utloisisa sebaka sa tsona' marakeng le ho rera kholo ea nako e tlang.

Ho Hlōla Liqholotso ho Boenjiniere ba Twin Parallel Screw Barrel

Ho sebetsana le li-geometri tse rarahaneng le ho mamellana ka thata

Baenjiniere ba tobana le mathata a bohlokoa ha ba etsa li-screw tse nang le libopeho tse rarahaneng le ho boloka mamello e tiileng. Thuto ea "Evolutionary Multi-Objective Optimization of Extrusion Barrier Screws: Data Mining and Decision Dong" e totobatsa hore mekhoa ea setso hangata e haelloa ke li-barrier screws ka lebaka la lijeometri tsa tsona tse rarahaneng. Mokhoa oa lipalo le ntlafatso e thehiloeng ho AI joale li thusa baenjiniere ho utloisisa ho qhibiliha le ho phalla ka har'a screw. Lisebelisoa tsena li lumella taolo e nepahetseng holim'a likarolo tse kang lifilimi tse ngata tse qhibilihisang le libaka tse thata tsa libethe. Li-extruder tsa twin screw, haholo-holo tse nang le li-intermeshing screws, li hlokataolo e nepahetseng ya mahlakoreho netefatsa ts'ebetso e nepahetseng. Liphapang tsa boits'oaro ba mochini le mocheso lipakeng tsa sistimi e le 'ngoe le tse peli tsa screw li eketsa ho rarahana. Baenjiniere ba tlameha ho sebelisa mekhoa e tsoetseng pele ea ho etsa mohlala le ho metha ho fihlela litlhoko tsena tse thata.

Litharollo bakeng sa Likopo tse Phahameng ka ho Fetisisa le tse Batlang

Ho etsoa ha sejoale-joale ho hloka lebelo le ts'epo. Li-platform tsa tlhahiso ea li-No-code li fa baenjiniere bokhoni ba ho haha likopo tsa nako ea sebele tse hokahanyang le lisebelisoa tsa IoT. Li-platform tsena li tšehetsa litaelo tsa mosebetsi oa pono le lisebelisoa tsa tlhahlobo ea boleng, tse thusang basebetsi ho latela mehato e rarahaneng ea kopano le ho tšoara litaba esale pele. Litlhahiso tse kang li-line arrays tsa li-point actuators le lisebelisoa tse tšoanang li sutumelletsa lebelo la tlhahiso maemong a macha. Litsamaiso tsena li hokahanya lisebelisoa ka nepo 'me li sebetsa haufi le meeli ea bokhoni ba motho. HoTwin Parallel Screw Barreltlhahiso, litharollo tsena li nolofalletsa ho itlhophisa ka potlako le ho boloka boleng bo phahameng ba tlhahiso, esita le libakeng tse boima.

Ho leka-lekanya Litšenyehelo le Ts'ebetso ho Tlhahiso e nepahetseng

Baetsi ba tlameha ho fumana tekanyo e nepahetseng pakeng tsa litšenyehelo le ts'ebetso. Taolo ea litjeo ea maano e sebelisa lisebelisoa tse joalo ka litheko tse ipapisitseng le ts'ebetso, benchmarking, le boenjiniere ba boleng. Mekhoa ena e itšetlehile ka lintlha tsa lipalo-palo ho tataisa liqeto tse ntlafatsang phaello le boleng ba sehlahisoa. Matsete a taolo ea boleng, joalo ka lisebelisoa tse betere le koetliso, a fokotsa likopo tsa maqheku le tiisetso. Lipalo tsa ho khutlisa lichelete li thusa ho lokafatsa litšenyehelo tsena. Liphuputso tsa morao-rao tsa indasteri li bonts'a hore bahlahisi ba bangata hona joale ba hlophisa bocha liketane tsa phepelo ho laola litšenyehelo le ho ntlafatsa boitelo. Ka ts'ebetso ea ho ts'oara kapa e haufi, lik'hamphani li boloka liketane tsa phepelo li le matla ha li ntse li boloka maemo a holimo bakeng saLitsamaiso tsa Twin Parallel Screw Barrel.

Mekhoa ea Bokamoso ho Twin Parallel Screw Barrel Innovation

Theknoloji e Hlahang le Maemo a Indasteri

Mahlale a macha a ntse a tsoela pele ho theha bokamoso ba litsamaiso tsa Twin Parallel Screw Barrel. Litsebi tsa indasteri li totobatsa tsoelo-pele e 'maloa ea bohlokoa:

- Theknoloji e ntlafalitsoeng ea ho kopanyae theha kabo ea tlatsetso e tšoanang, e lebisang ho boleng bo phahameng ba sehlahisoa.

- Phallo e ntseng e eketseha e lumella ho potlakisa lebelo la ts'ebetso le linako tse khuts'oane tsa potoloho.

- Tšebeliso e matla ea matla e thusa lik'hamphani ho boloka litšenyehelo tsa ts'ebetso.

- Ho feto-fetoha ho hoholo ho thusa ho sebetsana le lisebelisoa tse ngata tse fapaneng ntle le liphetoho tse kholo.

- Taolo e phahameng holim'a mocheso le khatello e tiisa liphello tse tsitsitseng le mefokolo e fokolang.

- Scalability le tlhokomelo e bonolo li lumella bahlahisi ho ikamahanya le maemo a fetohang ka potlako.

Litloaelo tsena li bonts'a hore lits'ebollo tsa nako e tlang li tla shebana le ts'ebetso, ho ikamahanya le maemo, le kopanyo e bohlale ea tlhahiso. Likhamphani joale li batla lits'ebetso tse ka hokahanang le sethala sa indasteri ea 4.0, se fanang ka tlhahlobo ea nako ea nnete le taolo e nepahetseng ea ts'ebetso.

Litaelo tse Tsoelang Pele tsa Lipatlisiso le Nts'etsopele

Lihlopha tsa lipatlisiso le bahlahisi ba tsetela haholo litharollong tse ncha tsaTheknoloji ea Twin Parallel Screw Barrel. Likhakanyo tsa 'maraka li bolela esale pele kholo e matla,' maraka oa US o lebelletsoe ho fihla ho $ 1.8 bilione ka 2033. Keketseho ena e tsoa tlhokahalong e phahameng ea lihlahisoa tsa polasetiki tsa boleng bo holimo le ho fetohela ho lisebelisoa tse tšoarellang, tse senyehang. Automation le digitalization li khanna tlhokahalo ea lisebelisoa tse tsoetseng pele tsa screw le barrel. Litsamaiso tsena li tlameha ho fana ka motsoako o betere, phallo e phahameng, le ho ntlafatsa ts'ebetso ea matla. Liphetoho tsa taolo le likhetho tsa bareki bakeng sa lihlahisoa tse bonolo tsa tikoloho le tsona li sutumelletsa lik'hamphani ho theha mekhoa e mecha ea ho sebetsana le lisebelisoa. Ka lebaka leo, lipatlisiso tse tsoelang pele li shebane le litharollo tsa tlhahiso tse bohlale, tse tala, le tse bonolo haholoanyane.

Boenjiniere bo nepahetsenge phahamisa lebelo bakeng sa ts'ebetso ea Twin Parallel Screw Barrel, ts'ebetso, le ts'ebetso e tsitsitseng. Liphuputso tsa morao-rao li totobatsa tsoelo-pele ea torque e phahameng, meralo ea modular, le tlhokomelo e boletsoeng esale pele. Hona joale bahlahisi ba rua molemo ho tsoa ho boleng bo ntlafetseng, litšenyehelo tse fokotsehileng, le ho tšepahala ho hoholo. Boqapi bo tsoelang pele bo tla tsoela pele ho bopa lipolasetiki le metjhini ea rabara.

- Lithuto li shebane le:

- Ho fokotsa ho roala ho tloha ho li-fillers le tšilafalo

- Ho ntlafatsa ho feto-fetoha ha maemo le ho kopanya

- Ho kopanya AI le IoT bakeng sa ts'ebetso e bohlale

LBH

Ke melemo efe eo libarele tsa screw-engineered twin parallel screw li fanang ka tsona?

Libarele tse entsoeng ka mokhoa o nepahetsenge fana ka ts'ebetso e phahameng, bophelo bo bolelele ba ts'ebeletso, le ts'ebetso e ntlafalitsoeng ea sehlahisoa. Baetsi ba bona litšenyehelo tse fokotsehileng tsa nako le tlhokomelo.

Li-sensor tse bohlale li ntlafatsa ts'ebetso ea screw barrel joang?

Li-sensor tse bohlale li fana ka data ea nako ea nnete. Basebelisi ba sebelisa tlhahisoleseding ena ho beha maemo leihlo, ho bolela esale pele litlhoko tsa tlhokomelo, le ho ntlafatsa tlhahiso bakeng sa boleng bo botle le ho tšepahala.

Na bahlahisi ba ka khona ho etsa li-twin parallel screw barrel sistimi bakeng sa lits'ebetso tse ikhethang?

Ee. Baenjiniere ba theha litsamaiso tsa modular ho fihlela litlhoko tse ikhethileng tsa ts'ebetso. Litlhophiso tsa tloaelo li tšehetsa lisebelisoa tse fapaneng le litlhoko tse ikhethang tsa tlhahiso.

bahlahisi ba tsetelang theknoloji e tsitsitseng ba etella pele bokamoso bo botala.

Nako ea poso: Jul-07-2025