Ke bona jwangSingle Screw Barrelsfetola polasetiki hape. Ha ke sebelisa Single screw barrel bakeng sa ho tsosolosa granulation, ke hlokomela boleng bo betere ba ho qhibiliha, ho tsoaka ho tsitsitseng, le ho fokotseha ho fokolang. Ea kaPlastic Extruder For Plastic Recyclinge tsamaya hantle. Ka mocheso o nepahetseng le lebelo la screw, myExtruder Bakeng sa Polasetiki Recyclinge finyella tlhahiso e phahameng le boleng ba pellet.

- Ho qhibiliha ha metsi

- Lebelo la screw

- Mocheso oa moqomo

- Taolo ea khatello ea maikutlo

Mekhoa ea Bohlokoa ea ho Khanna ka Katleho

Ntlafatso ea Melt Homogenization

Ha ke sebelisa extruder ea ka ea recycling, ke tsepamisa maikutlo ho fihlelleng ho qhibiliha ha junifomo. Qhibiliha homogenization e bolela ho kopanya polasetiki hantle ha e ntse e qhibiliha, kahoo pellet e 'ngoe le e' ngoe e na le boleng bo tšoanang. Ke ithutile seoho laola mocheso o qhibilihang le ho phallae bohlokoa. Lithuto tsa polasetiki tse kang nylon le polypropylene li bontša hore ha ke boloka junifomo e qhibilihisitsoeng, ke fumana li-pellets tse nchafalitsoeng hantle. Haeba ho qhibiliha ho sa tsitsane, polasetiki e tsosolositsoeng e ka fokola kapa ea senyeha.

Ke bona phapang ea boleng ba pellet ha ke sebelisa sekoti se le seng se etselitsoeng ho kopanya hantle. Mohlala, liphuputso mabapi le melt-state shear homogenization li bonts'a hore ho kopanya ha sekhahla se phahameng ka har'a libarele tse le 'ngoe tsa screw ho ntlafatsa ho ts'oana ha 'mele le mocheso oa lipolasetiki tse tsosolositsoeng. Ts'ebetso ena e fokotsa litšila le ho fetola sebopeho sa polymer ka tsela e thusang ka mehato e meng ea ho e sebelisa hape. Kea hlokomela hore li-pellets tsa ka tse tsosolositsoeng li na le mefokolo e fokolang le ts'ebetso e ntle ha ho qhibiliha ho le homogeneous.

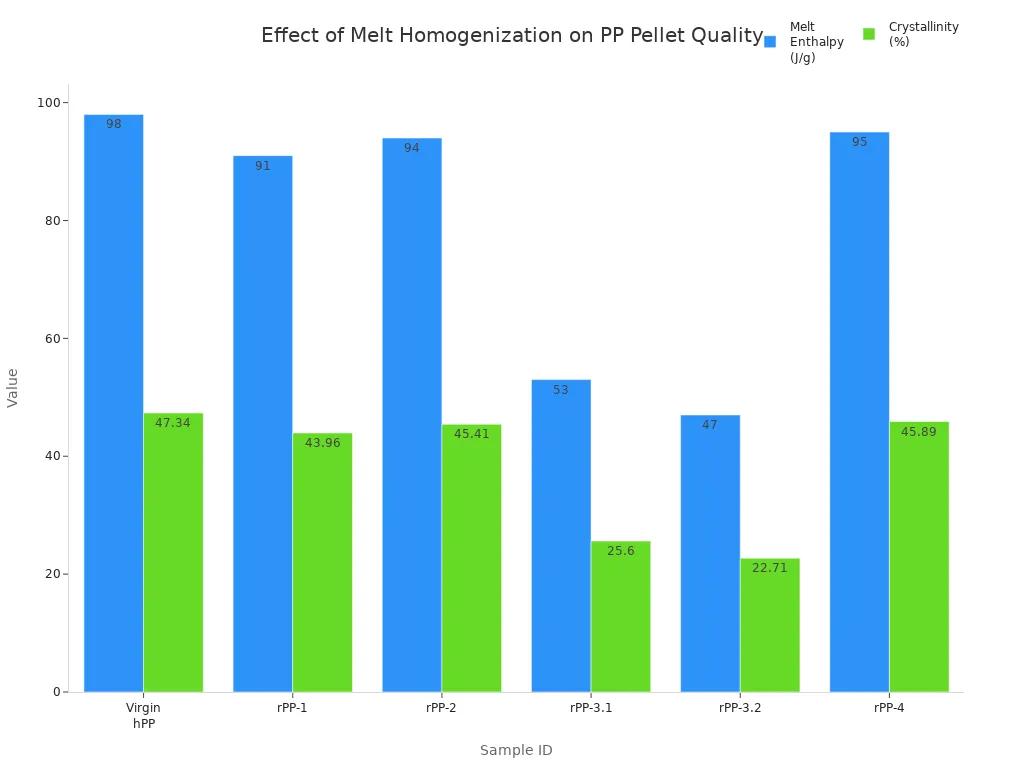

Linomoro li tšehetsa seo ke se bonang lebenkeleng la ka. Ha ke bapisa lisampole tsa polypropylene tse nchafalitsoeng, tse nang le crystallinity e phahameng le e qhibilihisang enthalpy li shebahala joalo ka polasetiki ea moroetsana. Mona ke tafole e bonts'ang hore na maemo a fapaneng a ts'ebetso a ama boleng ba pellet joang:

| ID ea mohlala | Qhibiliha Enthalpy (J/g) | Crystallinity (%) |

|---|---|---|

| Virgin homopolymer PP (hPP) | 98 | 47.34 |

| Recycled PP-1 (rPP-1) | 91 | 43.96 |

| Recycled PP-2 (rPP-2) | 94 | 45.41 |

| Recycled PP-3.1 (rPP-3.1) | 53 | 25.60 |

| Recycled PP-3.2 (rPP-3.2) | 47 | 22.71 |

| Recycled PP-4 (rPP-4) | 95 | 45.89 |

Kamehla ke ikemiselitse ho fumana liphetho tse kang rPP-1, rPP-2, le rPP-4, tse haufi le virgin PP. Litekanyetso tse tlase, joalo ka rPP-3.1 le rPP-3.2, li mpolella hore ho qhibiliha ha hoa tsoakana hantle kapa ho na le tšilafalo.

Ha ke laola ho phalla ha ho qhibiliha le ho kopanya, ke boetse ke bona thepa e ntle ea mochine sehlahisoa sa ho qetela. Li-pellets tsa ka tse nchafalitsoeng li otlolla le ho phahamisa hoo e batlang e le polasetiki e ncha, ho bolelang hore nka li sebelisa lits'ebetsong tse boima haholo.

Optimized Screw Geometry

Sebopeho le moralo oa screw ka hare ho extruder ea ka e etsa phapang e kholo. Ke lekile li-geometri tse fapaneng tsa screw mme ke hlokometse kamoo li amang tšebeliso ea matla, boleng ba ho qhibiliha, le tlhahiso. Ha ke sebelisa sekoti se nang le geometry e nepahetseng, ke fumana motsoako o tsitsitseng le ho feta. Ke boetse ke sebelisa matla a fokolang, a bolokang chelete le ho fokotsa ho senyeha ha thepa ea ka.

- Screw geometry e ama hore na ke hloka matla a makae le hore na mocheso o lula o tsitsitse hakae.

- Ho eketsa lebelo la screw ho ka fokotsa tšebeliso ea matla, empa moralo oa screw o tlameha ho ts'oana le thepa.

- Li-barrier screws le metsoako ea motsoako li thusa ho boloka mocheso o qhibilihang o lekana le ho ntlafatsa ho kopanya.

- Meralo e meng ea li-screw e ntumella hore ke tsamaise extruder kapele ntle le ho lahleheloa ke boleng.

- Geometry e nepahetseng ea screw e leka-lekanya ts'ebetso ea matla ka tlhahiso e phahameng le boleng bo botle ba ho qhibiliha.

Ke bone hore li-barrier screws, tse arolang polasetiki e tiileng le e qhibilihisitsoeng, li ntumella ho matha ka lebelo le phahameng le ho fumana tlhahiso e eketsehileng. Leha ho le joalo, ke habohlokoa ho ela hloko mokhoa oa ho sebetsa ho boloka seaparo sa ho qhibiliha. Ho kopanya likarolo tse kang karolo ea Maddock shear ho mpha homogenization e ntle, ho bolelang hore ho na le mefokolo e fokolang ho li-pellets tsa ka.

Mona ke papiso e potlakileng ea mefuta ea screw le litlamorao tsa eona:

| Screw Geometry | Motsoako oa Motsoako (Homogeneity) | Phello | Lintlha |

|---|---|---|---|

| Barrier Screws | Ho sebetsa hantle, ho hloka taolo e hlokolosi | Phahameng | Molemo ka ho fetisisa bakeng sa lihlopha tse kholo, shebella ho kopanya ho sa tšoaneng ka lebelo le phahameng haholo |

| Li-Screws tse nang le likarolo tse tharo | Ts'ebetso e tsitsitseng, empa e tlase | E itekanetseng | E ntle bakeng sa tlhahiso e tsitsitseng, e fokolang haholo |

| Ho Kopanya Lintho | Homogenization e ntle haholo | E fapana | Maddock shear e fana ka motsoako o motle ka ho fetisisa, haholo-holo bakeng sa polasetiki e thata |

Kamehla ke khetha screw geometry e tšoanang le polasetiki eo ke e sebelisang hape. Ka tsela ena, ke fumana tekanyo e ntle ka ho fetisisa ea lebelo, boleng, le tšebeliso ea matla.

Lisebelisoa tse tsoetseng pele tsa Barrel

Thepa ea screw barrel e bohlokoa joalo ka moralo oa eona. Ke itšetlehile ka libarele tse entsoeng ka litšepe tsa boleng bo holimo tse kang 38CrMoAl, tse fanang ka matla le ho tiea. Ha ke sebelisa libarele tse nang le libaka tse nang le nitrided, ke bona ho tlola ho hoholo ka thata. Sena se bolela hore thepa ea ka e nka nako e telele, leha ke sebetsana le li-plastiki tse chefo kapa tse silafetseng.

- Lisebelisoa tsa alloy tse kang 38CrMoAlA le AISI 4140 li mpha nako e telele eo ke e hlokang.

- Litšepe tsa phofo tsa metallurgy li fana ka moaparo o betere le ho hanyetsa kutu.

- Liphekolo tsa nitriding li eketsa boima ba bokaholimo, hangata bo fihlang HV900 kapa ho feta.

- Liaparo tsa bimetallic, joalo ka tungsten carbide, li sireletsa khahlanong le li-fillers tse senyang.

- Chromium plating e eketsa karolo e 'ngoe ea tšireletso khahlanong le mafome le ho roala.

Ke hlokometse hore ha ke sebelisa libarele tse nang le lisebelisoa tsena tse tsoetseng pele le liphahlo, ke qeta nako e fokolang le chelete ho hlokomela. Extruder ea ka e sebetsa nako e telele lipakeng tsa nako ea litšebeletso, 'me ha ke hloke ho tšoenyeha haholo ka ho senyeha. Ho tšepahala hona ho ntumella hore ke tsepamise maikutlo ho hlahiseng li-pellets tsa boleng bo holimo tse nchafalitsoeng.

Keletso:Kamehla bapisa lethepa ea moqomoho mefuta ea li-plastiki le li-additives tseo u li sebetsanang. Lisebelisoa tse thata le liaparo li lefa ha u sebetsana le litšila tsa polasetiki tse hlabang kapa tse tsoakiloeng.

Ka ho kopanya homogenization e ntlafalitsoeng ea ho qhibiliha, jometri e ntlafalitsoeng ea screw, le lisebelisoa tse tsoetseng pele tsa meqomo, ke fihlela katleho e phahameng le liphetho tse betere ts'ebetsong ea ka ea ho sebelisa polasetiki hape. Mekhoa ena e sebetsa 'moho ho fana ka boleng bo tsitsitseng, tlhahiso e phahameng, le litšenyehelo tse tlase.

Ho Rarolla Mathata a Tloaelehileng a ho Recycle

Ho sebetsana le Tšilafalo le Feedstock e feto-fetohang

Ha ke etsa ts'ebetso ea ka ea ho tsosolosa, ke tobana le lijo tse sa lebelloang letsatsi le leng le le leng. Lihlopha tse ling li na le polasetiki e hloekileng, e tšoanang. Ba bang ba fihla ba tsoakane le litšila, tšepe kapa mongobo. Kea tseba hore likaroloana tsa regrind tse nang le sebopeho se sa tloaelehang li na le bongata bo tlase ho feta li-pellets. Sena se fokotsa ts'ebetso mme se etsa hore extruder ea ka e sebetse ka thata. Haeba ke sa rarolle mathata ana, ke bona mocheso o phahameng oa ho qhibiliha le boleng bo tlaase ba pellet.

Ke itšetlehile ka sekoti sa ka se le seng sa screw ho sebetsana le mathata ana. Geometry ea sebaka sa phepelo e ntlafalitsoeng, haholo lipokotho tsa phepelo e atolositsoeng, e ntlafatsa phepelo le phepelo ea lintho tse tiileng. Moqapi ona o thibela ho thella ha lintho le ho boloka phallo e tsitsitse. Kea hlokomela hore extruder ea ka e boloka boleng ba ho qhibiliha leha ke sebetsa li-plastiki tse tsoakiloeng kapa tse silafetseng.

Mona ke liqholotso tsa mantlha tseo ke kopanang le tsona ha ke sebelisa polasetiki hape:

- Libopeho tse sa tloaelehang tsa regrind le bongata bo fokolang

- Phokotso ea ho sebetsa le ho sebetsa hantle

- Mocheso o phahameng oa ho qhibiliha le lifensetere tse tšesaane tsa ho sebetsa

- Tšilafalo le ho senyeha ha lintho tse bonahalang

- Phetoho ea ho sebetsa ka li-plastiki tse tsoakiloeng

Moqomo oa ka o le mong oa screw o nthusa ho hlola mathata ana. Ke bona phepelo e sebetsang hantle, phallo e tsitsitseng ea thepa, le tšebeliso e tlase ea matla. Theknoloji ena e ntumella ho sebetsana le mefuta e mengata e mengata ea polasetiki e sebelisoang hape ntle le ho fana ka boleng.

Hangata ke bapisa li-screw extruder le li-twin screw extruder. Mechini e 'meli ea li-screw e fana ka motsoako o babatsehang le ho senya, empa e loantšana le likhatello tse phahameng le tšilafalo. Li-extruder tsa screw tse le 'ngoe, joalo ka tsa ka, li sebetsana le ts'ebetso e matla ea ho sefa le ho mamella litšila hamolemo. Papiso e potlakileng ke ena:

| Sebopeho | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Ho Kopanya Tšebetso | Ho kopanya ho itekanetseng, homogenization e fokolang | Motsoako o babatsehang, ketso e matla ea ho aba/ea ho qhalakanya |

| Mocheso o tšoanang | E itekanetse, e tjamelang matheba a chesang/ a batang | Kabo e phahameng haholo ea ho qhibiliha mocheso |

| Sephetho sa botsitso | Ho lokile, ho ka ba le pulsation | Tlhahiso e tsitsitseng, e tsitsitseng |

| Lintho Tse Fetohang | Molemo ka ho fetisisa bakeng sa homogeneous, virgin materials | E sebetsana le li-additives, li-blends, li-feedstocks tse silafetseng |

| Degassing Bokhoni | E lekanyelitsoe kapa ha ho letho | E phahameng, e nang le likou tsa vacuum le libaka tsa moea |

| Molemo ka ho Fetisisa Nyeoe | Tekanyo e nyane, e hloekileng ea moroetsana ABS | Indasteri tekanyo, khethehileng, mebala, recycled ABS |

Ke khetha li-screw barrel tse le 'ngoe bakeng sa bokhoni ba tsona ba khatello e phahameng le mamello e ntle ea litšila. Qeto ena e nthusa ho qoba litokiso tse bitsang chelete e ngata le ho boloka mohala oa ka oa ho recycle o sebetsa hantle.

Ho Fokotsa ho Aroha ho Lisebelisoa tsa Abrasive

Lipolasetiki tsa abrasive le li-filler, tse kang fiber fibers, talc, le calcium carbonate, li hlahisa phephetso e kholo semeleng sa ka. Lisebelisoa tsena li senya li-screws le libarele kapele. Ke ne ke tloaetse ho nkela likarolo sebaka hangata, e leng ho eketsang nako le litšenyehelo.

Hona joale, ke sebelisa libarele tsa screw tse le 'ngoe tse nang le kalafo e tsoetseng pele ea holim'a metsi. Moqomo oa ka o na le bokaholimo ba nitrided le likarolo tsa alloy bimetallic. Lintlafatso tsena li matlafatsa boima ba 'mele le ho hanela abrasion. Ke bona phapang e kholo ea nako e telele. Thepa ea ka e nka nako e telele, leha ke sebetsana le li-plastiki tse thata, tse hlabang.

Lintlha tsa bohlokoa tsa moralo tse nthusang ho fokotsa moaparo li kenyelletsa:

- Optimized screw geometry ho thibela li-spikes tsa khatello le ho qhibiliha moferefere

- Ho khethoa ha thepa e sa sebetsaneng le liaparo tse khethehileng

- Moralo o hlophisitsoeng bakeng sa lisebelisoa tse tala le li-filler

- Ho sebetsa ka mokhoa o nepahetseng bakeng sa qetello e boreleli

- Software ea simulation ho utloisisa kabo ea khatello ea qhibiliha

Ke ithutile horeho apara ka holimo ho etsahala haufi le karolo ea phetoho, moo lintho tse tiileng li leng teng le khatello e phahamang. Ka ho khetha lisebelisoa tse nepahetseng le liaparo, Ifokotsa ho ja ka 60%. Ho hlahlojoa le ho hlokomeloa khafetsa ha libaka tse apereng liaparo tse phahameng, joalo ka libaka tsa ho fepa le tsa ho tsoa, ho boloka extruder ea ka e le maemong a holimo.

Keletso:Kamehla ke bapisa moralo oa ka oa screw barrel le li-plastiki le li-filler tseo ke li sebetsanang. Mokhoa ona o eketsa bophelo ba lisebelisoa le ho ntlafatsa katleho ea tlhahiso.

Ho Ntlafatsa Botsitso ba Ts'ebetso le Tšebelisano ea Sephetho

Ho sebetsa ka mokhoa o tsitsitseng ho bohlokoa bakeng sa ho hlahisa li-pellets tsa boleng bo phahameng tse sebelisoang hape. Pele ke sebelisa theknoloji e le 'ngoe ea screw barrel, ke ne ke thatafalloa ke ho phalla ha metsi, ho se tsitse ha ho qhibiliha, le ho felloa ke matla ha lintho tse tiileng. Mathata ana a ile a lebisa ho theoeng ha litheko tsa tlhahiso, ho eketseha ha sekhechana, le litšenyehelo tse phahameng tsa basebetsi.

Ka JT single screw barrel, ke fumana phallo e tsitsitseng ea ho qhibiliha le tlhahiso e tsitsitseng. Lisebelisoa tse tsoetseng pele tsa taolo, ho kenyelletsa le li-sensor le li-logic controller, li nthusa ho boloka mocheso o tsitsitseng le khatello. Ke beha leihlo maemo a ts'ebetso ka hloko ho thibela ho feto-fetoha ho ka senyang ts'ebetso.

Ke sebelisali-alloys tsa bimetallic le liaparo tse tsoetseng peleho matlafatsa ts'ebetso ea ho ruruha le ho thibela ho bola. Likarolo tsena li bohlokoa bakeng sa ho sebetsana le lipolasetiki tsa abrasive kapa tse tsosolositsoeng. Maemo a tsitsitseng a ts'ebetso a thibela ho fapana ha thepa ea lihlahisoa le ho fokotsa litšila.

Mehato eo ke e nkang ho boloka botsitso ba ts'ebetso ke ena:

- Tlhokomelo ea kamehla le phetisetso e nakong ea li-screws le libarele tse tsofetseng

- Ho beha leihlo mocheso le khatello ka litsamaiso tse tsoetseng pele tsa taolo

- Ho sebelisa li-screw profiles bakeng sa ho qhibilihisa homogeneity hantle le ho kopanya

- Ho hlahloba libaka tse apereng liaparo tse phahameng ho fokotsa nako e sa lebelloang

Boithuto bo bonts'a hore ho ntlafatsa lebelo la screw le libaka tsa mocheso ho eketsa ts'ebetso le ho ntlafatsa ho sebelisoa hape. Mabelo a tlase a screw a eketsa torque le ho fokotsa matla a mochini, a lebisang katlehong e ntle le tlhahiso e tsitsitseng. Ke tlalehile keketseho ea sekhahla sa tlhahiso ea 18% ho isa ho 36% kamora ho ntlafatsa moralo oa ka oa screw barrel.

Hlokomela:Tlhahlobo e sa fetoheng le tlhokomelo e boletsoeng esale pele e lelefatsa bophelo ba lisebelisoa le ho ntlafatsa botsitso ba ts'ebetso ts'ebetsong ea ka ea ho e sebelisa hape.

Ka ho sebetsana le tšilafalo, ho roala, le botsitso ba ts'ebetso, moqomo oa ka o le mong oa screw o nthusa ho fana ka li-pellets tsa boleng bo holimo tse nchafalitsoeng. Ke kopana le litlhoko tsa morao-rao tsa morao-rao ka kholiseho le katleho.

Single Screw Barrel for Recycling Granulation: Real-World Results

Keketseho ea Phallo le Boleng

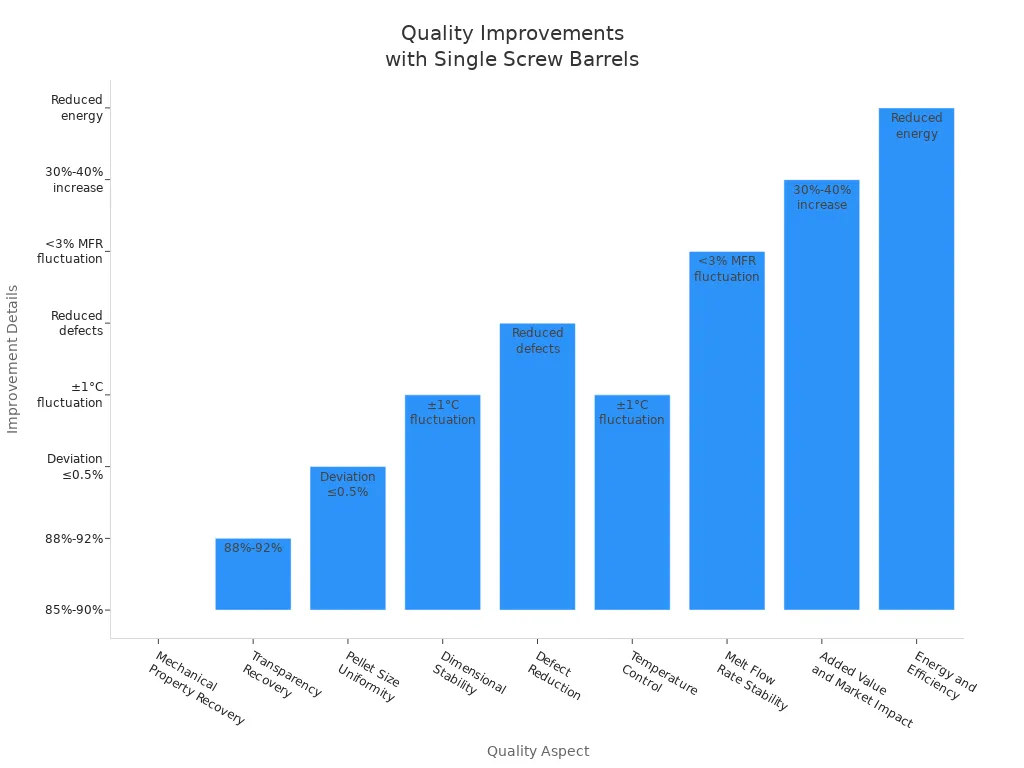

Ha ke fetohela ho moqomo o le mong oa screw bakeng sa ho tsosolosa granulation, ke ile ka bona matlafatso e hlakileng ho boleng ba lisebelisoa le pellet. Li-pellets tsa ka tse nchafalitsoeng joale li bonts'a matla a ntlafetseng a mochini le pepeneneng e ntlafalitsoeng. Ke khona ho laola boholo ba pellet ka nepo, e nthusang ho fihlela litlhoko tse thata tsa bareki. Taolo e tsoetseng pele ea mocheso e boloka ho phalla ho tsitsitseng, kahoo ke fumana likoli tse fokolang le li-pellets tse ngata tse tšoanang.

| Boemo ba Boleng | Lintlha tsa Ntlafatso |

|---|---|

| Pholiso ea Thepa ea Mechini | 85% -90% sekhahla sa ho hlaphoheloa, se phahame haholo ho feta ka lisebelisoa tse tloaelehileng |

| Pholiso ea Pontšo | 88% -92% sekhahla sa ho hlaphoheloa |

| Pellet Size Uniformity | Ho kheloha ka boholo ka har'a 0.5% |

| Botsitso ba Dimensional | Thempereichara e ts'oanang (± 1 ° C feto-fetoha) e netefatsa botsitso |

| Phokotso ea Sekoli | Litšila le mefokolo e fokolang |

| Taolo ea Mocheso | Taolo ea mekhahlelo e mehlano, ho feto-fetoha ha ± 1°C |

| Melt Flow Rate Stability | Phetoho ea MFR e ka tlase ho 3% |

| Boleng bo Ekelitsoeng le Kameho ea Mmaraka | 30% -40% keketseho ea boleng bo eketsehileng |

| Matla le Sebetsa | Tšebeliso e tlase ea matla, ts'ebetso e phahameng |

Tlhokomelo e Tlaase le Nako ea Phomolo

Ke ithutile hore tlhokomelo ea kamehla e boloka sekoti sa ka se le seng bakeng sa ho tsosolosa granulation e sebetsa hantle. Ke latela kemiso e tiileng ea ho lokisa le ho hlahloba moqomo beke le beke. Ke lula ke boloka mocheso le lebelo la screw li tsitsitse ho qoba khatello ea maikutlo mochining. Lijo tsa polasetiki tse hloekileng, tse hlophiloeng li thusa ho thibela tšenyo e bakoang ke litšila. Ke hloekisa le ho tlotsa likarolo tse tsamaeang ho thibela mafome le khohlano. Ha ke bona likarolo tse tsofetseng, ke li nkela sebaka hang-hang. Ke khetha libarele tse entsoeng ka li-alloys tse thata tse nang le liaparo tse khethehileng, tse kang nitriding, ho lelefatsa bophelo ba tsona.

- Ho hlahlojoa ha moqomo oa beke le bekeboloka lisebelisoa tsa ka li le maemong a holimo.

- Mocheso o nepahetseng le litlhophiso tsa khatello li thibela ho senyeha.

- Lijo tse hloekileng li fokotsa tšenyo ea ka hare.

- Ho hloekisa khafetsa le ho tlotsa ho emisa ho senyeha.

- Phetoho ea karolo e sebetsang e qoba nako e sa lebelloang.

- Li-alloys tse thata le liaparo li etsa hore moqomo o tšoarelle nako e telele.

Limela tse latelang mehato ena li tlaleha nako e fokolang le litšenyehelo tse tlaase tsa ho lokisa. Mohala oa ka oa ho sebelisa hape o sebetsa hantle le ka ts'epo.

Thuto-pale: JT Single Screw Barrel in Multi-Plastic Recycling

Ke kentse moqomo oa JT single screw bakeng sa ho nchafatsa granulation setsing sa ka ho sebetsana le lipolasetiki tse fapaneng joalo ka PE, PP, le PVC. Thepa e manganga, joalo ka38CrMoAl le tungsten carbide, ba lelefalitse bophelo ba moqomo. Hona joale ke sebelisa chelete e nyenyane ho lokisoa le ho reka tse ling. Mohala oaka oa tlhahiso ha o eme ka seoelo, kahoo ke kopana le linako tsa ka tsa ho tlisa. Tshebetso e tsitsitseng ea JT single screw barrel bakeng sa ho tsosolosa granulation e ntlafalitse tlhahiso ea ka le ho fokotsa litšenyehelo tsa ka. Ke bona litšitiso tse fokolang le betereboleng ba pellet, e nthusang hore ke lule ke le tlhōlisano 'marakeng.

Ke bona kamoo libarele tsa screw tse le 'ngoe li rarollang mathata a bohlokoa a ho sebelisoa hape. Phihlelo ea ka e bonts'a boleng bo betere ba ho qhibiliha, ho kopanya, le botsitso ba ts'ebetso. Ka "screw barrel" e le 'ngoe bakeng sa ho tsosolosa granulation, ke finyella katleho e phahameng le ho tšepahala. Lintlafatso tsena li ts'ehetsa ts'ebetso ea bohloeki, litšenyehelo tse tlase, 'me li nthusa ho fihlela litlhoko tse ntseng li hola tsa indasteri bakeng sa phepelo e tsitsitseng ea polasetiki.

LBH

Ke lipolasitiki life tseo nka li sebetsanang le barrel ea JT single screw?

Ke khona ho sebetsana le lipolasetiki tse ngata, ho kenyeletsoa PE, PP, PS,PVC, PET, PC, le PA. Moqomo o ikamahanya le lisebelisoa tse fapaneng bakeng sa ho sebelisoa hape hantle.

Nka fokotsa joang moqomo oa screw barrel?

Ke sebelisa libarele tse entsoeng ka li-alloys tse thata tse nang le li-nitrided kapa bimetallic coatings. Ho hloekisa khafetsa le litlhophiso tse nepahetseng li nthusa ho lelefatsa bophelo ba barrel le ho boloka ts'ebetso e le holimo.

Ke hobane'ng ha ho qhibilihisa homogenization ho bohlokoa ha ho sebelisoa hape?

Qhibiliha homogenization e mpha li-pellets tse tšoanang. Ke bona mefokolo e fokolang le matla a sehlahisoa a betere. Ho kopanya kamehla ho nthusa ho fihlela litekanyetso tsa boleng le litlhoko tsa bareki.

Nako ea poso: Aug-21-2025