Ho khetha boleng bo holimoli-screw tse nang le nitrided le libarelee bohlokoa bakeng sa ho netefatsa ts'ebetso e nepahetseng mochining. Lintlha tse kang mofuta oa thepa, tšebelisano ea moralo, le litlhoko tsa ts'ebeliso li susumetsa khetho ena haholo. Liqeto tse nang le tsebo ha li ntlafatse bophelo ba ts'ebetso ea likarolo tse kangMochini oa Extrusion Single Screw Barrelle eaPvc Pipe Single Screw Barrelempa hape ho ntlafatsa katleho le tlhahiso ka kakaretso.

Khetho ea Boitsebiso bakeng sa Li-Screw tse Nitrided le Libarele

Ho khetha thepa e nepahetseng bakeng sali-screw tse nang le nitrided le libarelee bohlokoa bakeng sa ho fihlela ts'ebetso e nepahetseng lits'ebetsong tse fapaneng. Lisebelisoa tse sebelisoang li susumetsa haholo ho tšoarella, ho sebetsa hantle, le katleho e akaretsang ea likarolo tsena.

Mefuta ea Lisebelisoa

Lisebelisoa tse 'maloa li sebelisoa hangata ha ho etsoa li-screws le libarele tsa nitrided. Ntho e 'ngoe le e' ngoe e na le litšobotsi tse ikhethang tse amang ho tšoaneleha ha eona bakeng sa lisebelisoa tse khethehileng. Mona ke tse ling tsa lisebelisoa tse atileng haholo:

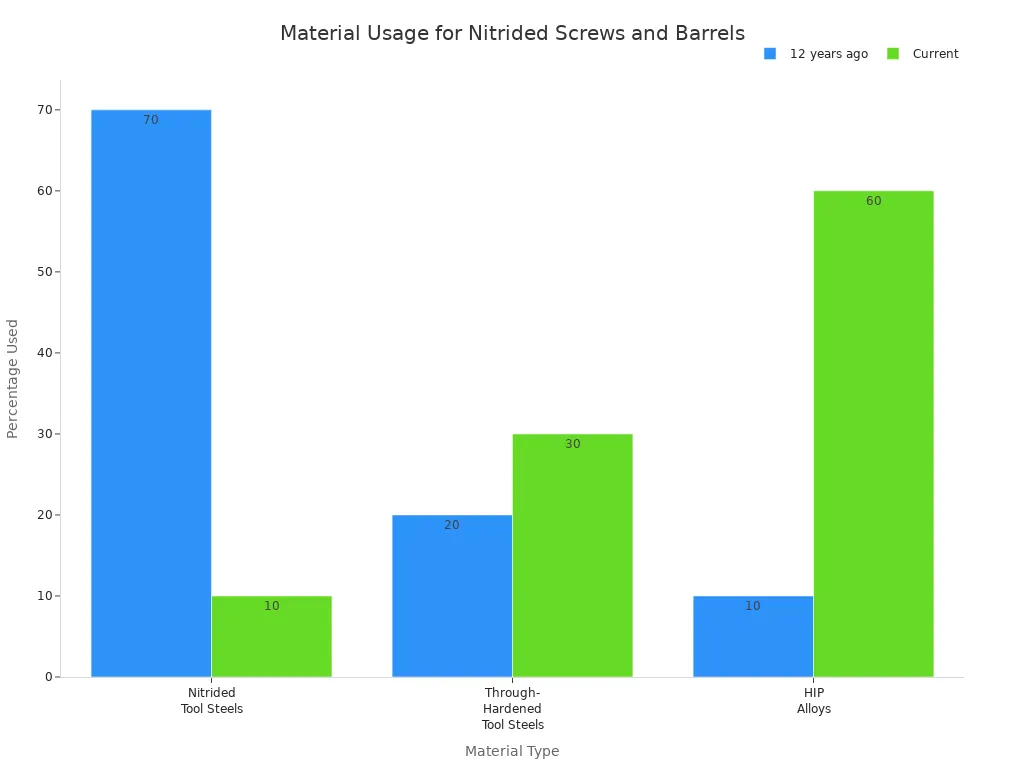

- Lisebelisoa tsa Nitrided Tool: Ho latela nalane, litšepe tsena li ne li nka karolo ea 70% ea 'maraka lilemong tse leshome le metso e' meli tse fetileng. Leha ho le joalo, ts'ebeliso ea bona e fokotsehile ho isa ho 10% hajoale.

- Ka Tool-Hardened Tool Steels: Mofuta ona o bone ho eketseha ha botumo, ho tloha ho 20% ho ea ho 30% ka nako e tšoanang.

- Lisebelisoa tsa HIP: Li-alloys tsena li fumane ts'ebetso e kholo, li tloha ho 10% ho ea ho 60% ts'ebelisong ea hajoale.

Tafole e latelang e akaretsa liphetoho tsa tšebeliso ea thepa ho theosa le lilemo:

| Mofuta oa Boitsebiso | Peresente (lilemo tse 12 tse fetileng) | Peresente (Hona joale) |

|---|---|---|

| Lisebelisoa tsa Nitrided Tool | 70% | 10% |

| Ka Tool-Hardened Tool Steels | 20% | 30% |

| Lisebelisoa tsa HIP | 10% | 60% |

Thepa ea Lisebelisoa tsa Nitrided

Lisebelisoa tsa nitrided li bonts'a lisebelisoa tse 'maloa tse molemo tse ntlafatsang ts'ebetso ea tsona lits'ebetsong tsa indasteri. Ts'ebetso ea naetrojene e kenya naetrojene ka holim'a thepa, e etsa lera le thata la nitride. Lera lena le ntlafatsa haholo lisebelisoa tse fapaneng tsa mochini, ho etsa hore lisebelisoa tsa nitrided li lakatsehe haholo.

- Apara Resistance: Lisebelisoa tsa nitrided li bonts'a khanyetso e ntle ea ho roala ka lebaka la lera le thata le entsoeng nakong ea nitriding. Thepa ena e bohlokoa bakeng sa likarolo tse tlas'a maemo a abrasive, joalo ka lits'ebetsong tsa extrusion.

- Khanyetso ea Corrosion: Lera la nitride le boetse le fana ka khanyetso e ntlafetseng ea ho senya, e leng ea bohlokoa ha ho sebetsanoa le li-polymer tse qhibilihisitsoeng le lintho tse ling tse senyang.

- Ho thatafala: Kamora ho kenya nitriding, lisebelisoa li ka fihlela maemo a thata a fetang 65 HRC. Ho thatafala hona ho tlatsetsa ho matla le ho tšoarella ha li-screws le libarele ka kakaretso.

- Comprehensive Properties: Litšepe tse nang le nitrided le li-alloys tse khethehileng tse kang 38CrMoAl li tsebahala ka thepa ea tsona e ntle ka kakaretso, e leng se etsang hore li tšoanelehe bakeng sa lisebelisoa tse fapaneng.

Tafole e latelang e bonts'a likarolo tsa bohlokoa tsa mochini oa lisebelisoa tsa nitrided tse sebelisoang ho li-screw le libarele:

| Thepa | Tlhaloso |

|---|---|

| Apara Resistance | Lisebelisoa tsa nitrided li bonts'a khanyetso e ntle ea ho apara ka lebaka la ts'ebetso ea nitriding. |

| Khanyetso ea Corrosion | Ba na le khanyetso e ntle ea kutu, leha limaraka tse ling li ka ba le mefokolo. |

| Ho thatafala | Ho thatafala ka mor'a nitriding ho ka feta 65 HRC, ho matlafatsa matla ka kakaretso. |

| Comprehensive Properties | Nitrided steel le 38CrMoAl li tsebahala ka thepa ea tsona e ntle ka kakaretso. |

| Botebo ba Lera la Nitriding | Ka tloaelo, lera la nitriding le fihla ho 0.4-0.6 mm. |

Lintlha Tseo U Lokelang ho li Nahana ha U Khetha Likarolo Tsa Nitrided

Nengkhetha li-screws le libarele tse nang le nitrided, ho na le lintlha tse peli tsa bohlokoa: ho lumellana le moralo le litlhoko tsa kopo. Ho utloisisa lintlha tsena ho netefatsa hore likarolo tse khethiloeng li sebetsa hantle maemong a tsona a reriloeng.

Ho lumellana ha Moqapi

Khokahano ea moralo e bohlokoa bakeng sa kopanyo e atlehileng ea li-screw tse nang le nitrided le libarele mochining o teng. Likarolo tse 'maloa tsa moralo li tlameha ho nahanoa ho netefatsa tšebelisano ena:

| Sebopeho sa Moralo | Tlhaloso |

|---|---|

| Khetho ea Lintho | Nitrided steel e ratoa bakeng sa bokaholimo ba eona bo thata le ho hanyetsa kutu. |

| Ho roala ka Barrel | Li-barrel tsa Bimetallic tse nang le liaparo tse thibelang ho roala lia hlokahala bakeng sa likopo tse phahameng tsa ts'ebetso. |

| Screw Geometry | Li-geometri tsa screw tse entsoeng ka mokhoa o ikhethileng li ntlafatsa plastification le tlhahiso. |

| Karolelano ea L/D | Karo-karolelano ea bolelele ba screw ho bophara e ama mekhoa ea ho qhibiliha le ho kopanya. |

| Compression ratio | Likarolo tse phahameng tsa compression li ntlafatsa ts'ebetso ea ho kopanya le tlhahiso ea khatello. |

| Tekanyo ea Botebo ba Sefofane | E laola molumo oa lipalangoang tsa thepa le ts'ebetso ea phallo ea moqomo. |

Nitrided steel e fana ka nako e telele le ho hanyetsa ho apara, ho etsa hore e be khetho e ratoang. Libarele tsa Bimetallic li ntlafatsa ts'ebetso libakeng tse hlabang, ha li-screws tse telele li ntlafatsa ts'ebetso ea ts'ebetso ea thepa. Ho eketseha ha likhatello tsa khatello ho lebisa ho motsoako o betere le tlhahiso ea khatello, e leng tsa bohlokoa bakeng sa ho finyella litekanyetso tse nepahetseng tsa tlhahiso.

HMG Extrusions e totobatsa bohlokoa ba ho sebelisa tšepe ea nitriding e sa sebetseng haholo bakeng sa likurufu. Tlhokomelo ena ea lintlha e thusa ho boloka lintlha tse thata tsa mamello, ho netefatsa ho lumellana le mechini e teng.

Litlhoko tsa Kopo

Litlhoko tsa kopo li bapala karolo ea bohlokoa ho lekanyeng ho nepahala ha li-screw le libarele tsa nitrided. Lintlha tsa bohlokoa li kenyelletsa:

- Mehopolo ea Moralo: Moqapi o tlameha ho ikarabella bakeng sa litšobotsi tse bonahalang tse kang viscosity, sebaka se qhibilihang, le sekhahla sa phallo.

- Ho qhibiliha ha Uniform le ho Kopanya: Moqapi o nepahetseng o tiisa hore lisebelisoa tsa polasetiki li qhibiliha ka mokhoa o ts'oanang 'me li kopantsoe, ho thibela ho chesa le ho chesa.

- Boreleli ba Sefahleho: Ho ntlafatsa boreleli ba bokaholimo ho bohlokoa bakeng sa ho leka-lekanya ho kopanya, ho kuta le ho tsamaisa thepa. Sena se ama ka kotloloho katleho ea tlhahiso le boleng ba sehlahisoa.

Mamello ea li-Dimensional e boetse e ama ts'ebetso. Ho roala holim'a li-screws le libarele ho ka ama ts'ebetso ea polasetiki haholo, khatello ea mokokotlo, molumo oa ho thunya, linako tsa potoloho le ho tsitsa ha karolo. Likarolo tse tsofetseng li ka fokotsa ts'ebetso ea ts'ebetso ho fihla ho 25%, tsa eketsa ts'ebeliso ea matla, 'me tsa baka bofokoli likarolong tse bōpiloeng. Ho feta tumello pakeng tsa screw le barrel ho ka fella ka ho lutla ha resin, boleng bo fokolang ba ho qhibiliha, le khatello e sa tsitsang ea ente.

Malebela a Tlhokomelo bakeng sa Bophelo bo Bolelele

Tlhokomelo e nepahetseng ea li-screws le libarele tse nang le nitrided li bohlokoa bakeng sa ho holisa bophelo ba tsona le ho netefatsa ts'ebetso e nepahetseng. Ho kenya ts'ebetsong lenaneo le matla la tlhokomelo ea thibelo (PM) ho ka fokotsa haholo ho apara le ho lelefatsa bophelo ba likarolo tsena.

Ho Hloekisa le Tlhokomelo

Ho hloekisa kamehla le ho tlotsa mafura ho bohlokoa ho thibela ho roala pele ho nako. Mekhoa e meng e khothalelitsoeng ke ena:

- Sebelisa Metsoako ea ho Hlatsoa Khoebo (CPCs): Metsoako ena e ntlafatsa ts'ebetso ea ho hloekisa 'me e thusa ho tlosa masalla ho screw le barrel.

- Latela Litlhahiso tsa Moetsi: Khomarela litataiso tse fanoeng ke baetsi ba screw le barrel bakeng sa tlhokomelo ea kamehla.

Ho boloka likaroloana ka katleho, nahana ka makhetlo a latelang a tlhokomelo:

| Maintenance Frequency | Tlhaloso ea Mosebetsi |

|---|---|

| Beke le beke | Fetola filthara ea oli e tlotsang ea mochini o fokotsang 'me u hlahlobe hore na ha ho na litšila. |

| Khoeli le khoeli | Lekola coaxiality ea khokahanyo ea enjene ebe u e lekanya. |

| Kotara | Tlhahlobo e felletseng ea disassembly ea screw, barrel le hlobo. |

Tlhahlobo le Phetoho

Litlhahlobo tsa ka mehla li bohlokoa bakeng sa ho bona hore na ho senyehile kapa ho senyeha ha li-screw tse nang le nitrided le barrel. Litsebi li lokela ho kenyelletsa mekhoa e latelang mananeong a bona a tlhokomelo:

- Etsa tlhahlobo e tloaelehileng ea likarolo tsa polasetiki.

- Lekanya moaparo nakong ea tlhahlobo e reriloeng ho theha profaele ea moaparo.

- Hlalosa nako e lebelletsoeng ea bophelo ea likarolo bakeng sa ho nchafatsa le ho lokisoa ho reriloeng.

Ho hlahloba li-screw le libarele khafetsa ho u fa monyetla oa ho lemoha mathata a ka bang teng kapele, e leng se nolofalletsang ho kenella ka potlako. Tafole e latelang e bontša nako ea bophelo ea likarolo tse fapaneng:

| Mofuta oa Karolo | Nako ea bophelo (Lilemo) | Lintlha |

|---|---|---|

| Li-screws tse tloaelehileng | 1 - 1.5 | Bakeng sa lipolasetiki tsa morero o akaretsang (mohlala, PP/PE) |

| Li-screws tse tloaelehileng | 0.5 - 0,67 | Bakeng sa li-filler (mohlala, fiberglass) |

| Nako ea bophelo ba moqomo | 1.5 - 2 linako tse ling | Ka tloaelo nako e telele ho feta nako ea bophelo ea screw; nka sebaka haeba ho feta lilemo tse 3. |

| Leano la ho Fetola | N/A | Kenya sebaka sa screw le barrel e le sete bakeng sa melemo ea moruo. |

Ka ho latela tsenamalebela a tlhokomelo, li-operators li ka netefatsa nako e telele le ho tšepahala ha li-screws le libarele tsa boleng bo phahameng ba nitrided.

Lits'enyehelo tsa Litšenyehelo tsa Boleng bo Phahameng ba Nitrided Screw le Barrel

Ha u tsetela ka li-screws le libarele tsa boleng bo holimo, ho utloisisalitlamorao tsa litšenyeheloe bohlokoa. Likhamphani li tlameha ho leka-lekanya litšenyehelo tsa pele le melemo ea nako e telele ho etsa liqeto tse nang le tsebo.

Budgeting for Quality

Ho etsa moralo oa lichelete bakeng sa likarolo tsa nitrided ho hloka hore ho nahanoe ka hloko lintlha tse fapaneng. Likhamphani li tlameha ho lekola lintlha tse latelang:

- Mofuta oa polasetiki o entsoeng: Etsa qeto ea hore na kopo e kenyelletsa polasetiki e tloaelehileng kapa e matlafalitsoeng. Khetho ena e ama khetho ea thepa le litšenyehelo tse amanang le tsona.

- Lisebelisoa tse sebelisoang: Lekola hore na li-additives li ama joang ho apara le ho phela nako e telele. Lintlha tsena li ka ama litšenyehelo ka kakaretso haholo.

- Sekala sa tlhahiso: Ts'ebetso e phahameng haholo e lokela ho etelletsa pele li-alloys tse matla. Ho tsetela ka thepa e tšoarellang ho lefa ka nako e telele.

- Lintlha tsa tekanyetso: Ho khetha likhetho tsa bimetallic kapa tse koahetsoeng ho ka lebisa ho boloka nako e telele. Likhetho tsena hangata li fokotsa litšenyehelo tsa tlhokomelo le tse ncha.

Litšenyehelo tse phahameng tsa qalong tsa likaroloana tsa bimetallic, tse kang li-screw tse nang le nitrided le libarele, li hlaha ka mekhoa e rarahaneng ea tlhahiso le lisebelisoa tse khethehileng. Ho rarahana hona ho lebisa litšenyehelong tse eketsehileng tsa tlhahiso, tse susumetsang haholo theko ea ho qetela ea likarolo tsena. Likarolong tse kang tsa likoloi, tlhokahalo ea libarele tsa "nitriding steel feed screw" li bakoa ke ho thatafala ha tsona le ho se mamelle. Thepa ena e lokafatsa litšenyehelo tse phahameng tsa thepa le tlhahiso.

Boleng ba Nako e Telele khahlano le Litšenyehelo tsa Pele

Ho tsetela ka lisebelisoa tsa boleng bo holimo tse nang le nitrided ho ka fana ka chelete e ngata ea nako e telele. Likaroloana tsena hangata li nka nako e telele ho 2 ho isa ho 5 ho feta mefuta e meng e se nang nitrided. Nako ena ea nako e telele e fokotsa khafetsa ea ho nkela sebaka le tlhokomelo, e leng se bakang litšenyehelo tse tlase tsa beng ba mochini le lits'ebetso tse sebelisang likarolo tsa nitrided.

Lethathamo le latelang le bontša kamoo lintlha tse fapaneng li amang litšenyehelo tsa beng:

| Ntlha | Tšusumetso ho Litšenyehelo tsa ho ba Beng |

|---|---|

| Apara Resistance | Litšenyehelo tse fokolang, litšenyehelo tse tlase |

| Maintenance Frequency | Ho fokotsa nako ea ho phomola, ho fokotsa litšenyehelo tsa basebetsi |

| Matla a Matla | Likoloto tse tlase tsa lisebelisoa |

| Predictive Monitoring | Ho lemoha kapele, ho fokotsa litokiso |

Ka ho nahana ka litšenyehelo tsa pele le boleng ba nako e telele, lik'hamphani li ka etsa liqeto tsa maano tse ntlafatsang katleho ea ts'ebetso le ho fokotsa litšenyehelo ka kakaretso. Ho tsetela ho li-screws le libarele tsa boleng bo holimo ha ho ntlafatse ts'ebetso feela empa hape ho kenya letsoho ponong e tsitsitseng ea lichelete.

Ho khetha li-screw tse nepahetseng tsa nitrided le libarele ho kenyelletsa ho nahanoa ka hloko eaho lumellana ha linthole mekhoa ea tlhokomelo. Lintlha tsa bohlokoa li kenyelletsa ho khetha lisebelisoa tse sa senyeheng tse kang tšepe ea nitrided le ho etsa tlhahlobo ea kamehla. Ka ho etsa liqeto tse nang le tsebo, basebelisi ba ka ntlafatsa ts'ebetso le ho lelefatsa nako ea bophelo ea likarolo tsa mochini oa bona.

Lintlha tsa bohlokoa:

- Ho lumellana ha thepa ho ama ho apara le ho hanyetsa ho bola.

- Tlhokomelo ea kamehla e fokotsa nako ea ho theoha 'me e ntlafatsa katleho.

LBH

Mokhoa oa nitriding ke eng?

Nitriding ke kalafo e thatafatsang holim'a metsi e jalang naetrojene ka har'a thepa, ho etsa lera le thata la nitride.

Nitriding e ntlafatsa ts'ebetso ea screw le barrel joang?

Nitriding e ntlafatsa ho hanyetsa ho senyeha, ho hanyetsa kutu, le ho fokotsa khohlano, e lebisang bophelong bo bolelele ba ts'ebeletso le ts'ebetso e ntlafetseng.

Ke mekhoa efe ea tlhokomelo e eketsang bophelo ba likarolo tsa nitrided?

Ho hloekisa khafetsa, ho tlotsa le ho hlahloba ho thusa ho lemoha ho khathala pele ho nako, ho netefatsa ts'ebetso e nepahetseng le ho phela halelele ha li-screws le libarele tsa nitrided.

Nako ea poso: Sep-16-2025