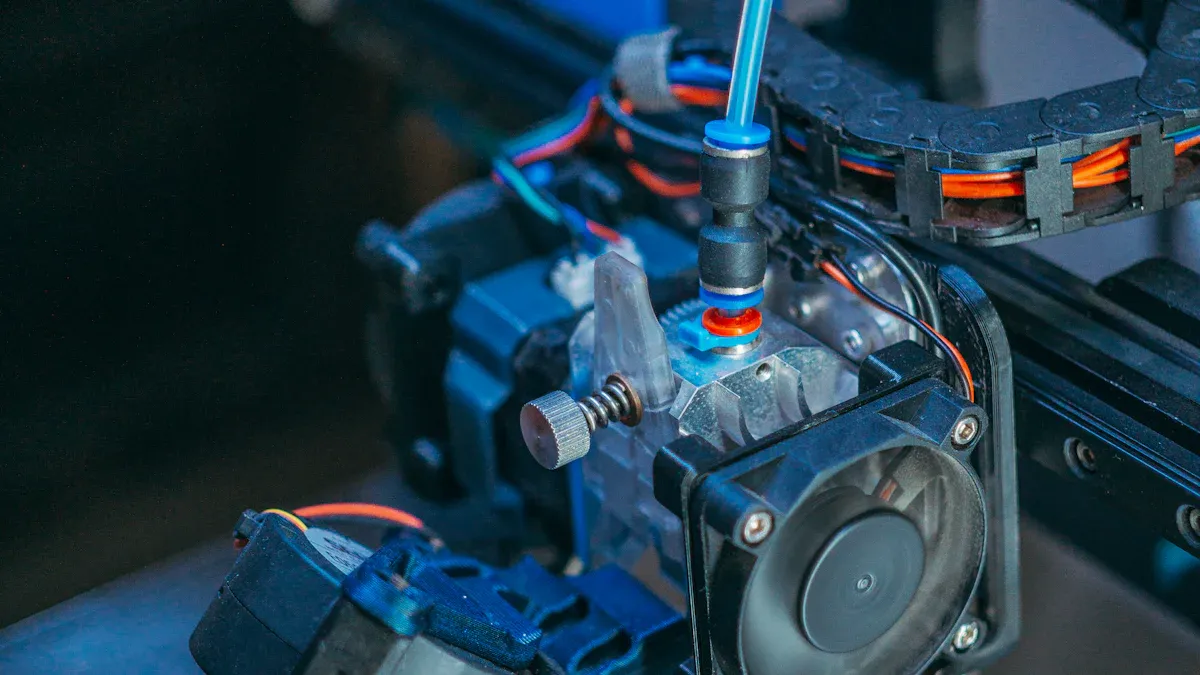

Ho khetha li-extruder tsa polasetiki tse mafahla tse nepahetseng ho netefatsa ts'ebetso le ho nepahala lits'ebetsong tsa ho bopa ente. Mechini ena e ntlafatsa ho kopanya thepa, ho ntlafatsa bokhoni, le ho holisa bokhoni ba ho sebetsa, ho etsa hore e be tsa bohlokoa haholo bakeng sa tlhahiso ea boleng bo holimo.

- Mmaraka oa lefats'e oa "twin screw extruder", o boleng ba $ 1,128.1 milione ka 2022, ho hakanngoa hore o tla fihla ho $ 1,649.5 milione ka 2031.

- Sekhahla sa kholo ea selemo sa 4.5% se totobatsa tlhoko ea bona e ntseng e eketseha ho pholletsa le indasteri.

- Meetso e tsoetseng pele, joalo kalibarele tse sekoere tse mafahla, ntlafatsa tshebetso le ho tšepahala.

Ho lumellana, ho itloaetsa, le ho boloka litšenyehelo li lula e le lintlha tsa bohlokoa ha u khetha adouble screw extruderbakeng sa likopo tse itseng, haholo ha ho nahanoa ka amochini o kopanyang habeli oa screw extrudere etselitsoeng ho fihlela litlhoko tse ikhethang tsa tlhahiso.

Bohlokoa ba Twin Screw Plastic Extruders

Melemo ea ho Bopa ka Ente

Li-extruder tsa polasetiki tse habeli li bapala karolo ea bohlokoaseabo sa ho matlafatsa bokgabanele boleng ba mekhoa ea ho bopa ente. Moralo oa bona o tsoetseng pele o etsa hore ho be le taolo e nepahetseng holim'a motsoako, devolatilization le ho kopanya, tse bohlokoa bakeng sa ho hlahisa likarolo tse bōpiloeng tsa boleng bo holimo. Ka ho laola khatello ka katleho, mechini ena e boloka mocheso o nepahetseng oa ho qhibiliha le viscosity, ho netefatsa ts'ebetso e tsitsitseng ea sehlahisoa.

Melemo ea bohlokoa e kenyelletsa:

- Ho fetola liindasteri ho tloha ho batch ho ea ho ts'ebetso e tsoelang pele, ho ntlafatsa ts'ebetso haholo.

- Ho iketsetsa thepa ka bokhoni bo phahameng ba ho kopanya, bo amang boleng ba sehlahisoa ka kotloloho.

- Ho thusa ho senya ka likhahla tse behiloeng ka mokhoa o hlophisitsoeng, ho thibela likhohola le ho netefatsa ho tlosoa ha lintho tse fokang.

- Ho lumella taolo e ikemetseng ea litefiso tsa phepelo le li-screw RPMs, ho ntlafatsa mekhoa ea ho kopanya le ea devolatilization.

Moralo o potolohang, o kopanyang oa li-extruder tsa polasetiki tse mafahla o nkoa e le tharollo e sebetsang ka ho fetesisa indastering ea polasetiki. Sena se etsa hore e be tsa bohlokoa haholo ho bahlahisi ba batlang ho fumana ho nepahala le ho ts'epahala ho bopeng ente.

Melemo Holim'a Single Screw Extruders

Li-extruder tsa polasetiki tse habeli li fana ka melemo e mengata ho feta li-screw tsa tsona tse le 'ngoe, haholo-holo mabapi le bokhoni ba ho sebetsa, ho tenyetseha le ho sebetsa hantle. Tafole e latelang e totobatsa liphapang tsa bohlokoa:

| Sebopeho | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Matla a Ts'ebetso | Extrusion ea motheo le ho kopanya ho bonolo. | E sebetsana le lisebelisoa tse rarahaneng le ho kopanya ho rarahaneng. |

| Tšebeliso le Sebetsa | Phaello e tlase, e loketseng tlhahiso e nyane. | Phello e phahameng, ho netefatsa boleng ba sehlahisoa se betere. |

| Ho feto-fetoha ha maemo le ho feto-fetoha ha maemo | Ho feto-fetoha ha maemo, ts'ebetso e bonolo. | E feto-fetoha haholo le li-parameter tse feto-fetohang. |

| Lintho tse Fetohang | E loketse li-thermoplastics tsa mantlha le li-fillers. | E ntle bakeng sa libopeho tse rarahaneng le lisebelisoa tse phahameng tsa viscosity. |

| Ho Kopanya Bokgoni | E lekane bakeng sa metsoako e bonolo. | Motsoako o holimo, o loketseng ho kenyelletsoa ha tlatsetso. |

| Ho senya le ho senya | Bokhoni bo fokolang. | Bokhoni bo botle, bo kopanang le litekanyetso tse thata tsa boleng. |

Melemo ena e etsa li-extruder tsa polasetiki tse mafahla e le khetho e ratoang bakeng sa bahlahisi ba ikemiselitseng ho ntlafatsa katleho ea tlhahiso le boleng ba sehlahisoa. Bokhoni ba bona ba ho sebetsana le lisebelisoa tse sa tšoaneng le mekhoa e rarahaneng e tiisa hore e lula e le motheo oa mekhoa ea morao-rao ea ho bopa ente.

Lintlha tsa Bohlokoa Tseo U Lokelang ho li Nahana ha U Khetha Li-extruder tsa Plastiki tsa Twin Screw

Ho tsamaellana le Mechini ea Ente ea ho Bopa

Ho bohlokoa ho khetha "scruder" ea polasetiki ea mafahla e tsamaellanang le lintlha tsa mochini oa hau oa ente ho bohlokoa. Ho lumellana ho tiisa ho kopanya ho se nang moeli, ho fokotsa nako ea ho theoha le ho ntlafatsa katleho ka kakaretso. Baetsi ba tlameha ho lekola bokhoni ba tlhahiso ea extruder, moralo oa screw, le bokhoni ba ho sebetsana le thepa ho tsamaisana le litlhoko tsa mochini oa bona oa ho bopa. Mohlala, extruder e nang le tekano e phahameng ea torque le lebelo la screw e khona ho sebetsana le lisebelisoa tse rarahaneng, ho netefatsa hore ho fepa le ho qhibiliha ho sa fetohe.

Extruder e tsamaellanang hantle e boetse e fokotsa tšebeliso ea matla le ho roala likarolo. Tafole e latelang e totobatsa kamoo lintlha tsa bohlokoa joalo ka lebelo la screw le thepa e amang ts'ebetso:

| Ntlha ea Bohlokoa | Tšusumetso ho Tšebeliso ea Matla | Tšusumetso ho Khatello | Tšusumetso ho Torque |

|---|---|---|---|

| Screw Rotational Speed (n) | Phokotso e kholo ea tšebeliso e khethehileng ea matla (45% e fokotseha) ka lebelo le eketsehileng | Khatello e eketsehileng ka 3.1 MPa (65%) ka lebelo le phahameng | Torque e eketsehileng ka lebelo le holimo |

| Litaba tsa Lekala (u) | Ha ho na tšusumetso e kholo tšebelisong ea matla | Khatello e eketsehileng ea 3.8 MPa (75%) e nang le lihlahisoa tse fokotsehileng tsa bran | Torque e fokotsehile ka 34% ka litaba tsa bran tse eketsehileng |

Ho utloisisa metrics ena ho thusa bahlahisi ho khetha extruder e tlatselletsang setupo sa bona sa ho bopa ente.

Likhetho tsa ho Itlhophisa bakeng sa Lits'ebetso tse Khethehileng

Li-extruder tsa polasetiki tse habeli li fana ka likhetho tse ke keng tsa bapisoa tsa ho li etsa, li li etsa tse loketseng lits'ebetso tse fapaneng. Mechini ena e lumella bahlahisi ho rala meralo ea screw ho latela ts'ebetso e itseng ea yuniti, joalo ka ho kopanya, devolatilization, kapa kompone. Karolo e 'ngoe le e' ngoe ea screw e na le sepheo se ikhethileng, 'me liphetoho tse nyane li ka ama liphetho tsa ts'ebetso ea thepa haholo.

Likarolo tsa bohlokoa tsa ho itlhophisa li kenyelletsa:

- Litlhophiso tse bonolo tsa screw ho ntlafatsa motsoako le phallo ea thepa.

- Likarolo tse hlophisitsoeng hape tsa libarele ho ntlafatsa ts'ebetso ea extrusion ntle le liphetoho tse ngata.

Boemo bona ba ho ikamahanya le maemo bo netefatsa hore bahlahisi ba ka fihlela litlhoko tse ikhethang tsa tlhahiso ha ba ntse ba boloka ts'ebetso ea litšenyehelo. Mohlala, liindasteri tse hlokang lisebelisuoa tse nang le viscosity e phahameng kapa libopeho tse rarahaneng li rua molemo ho tsoa ho likarolo tsena tseo u ka li khethang.

Metrics ea Ts'ebetso: Torque, Lebelo, le Ts'ebetso ea Ts'ebetso

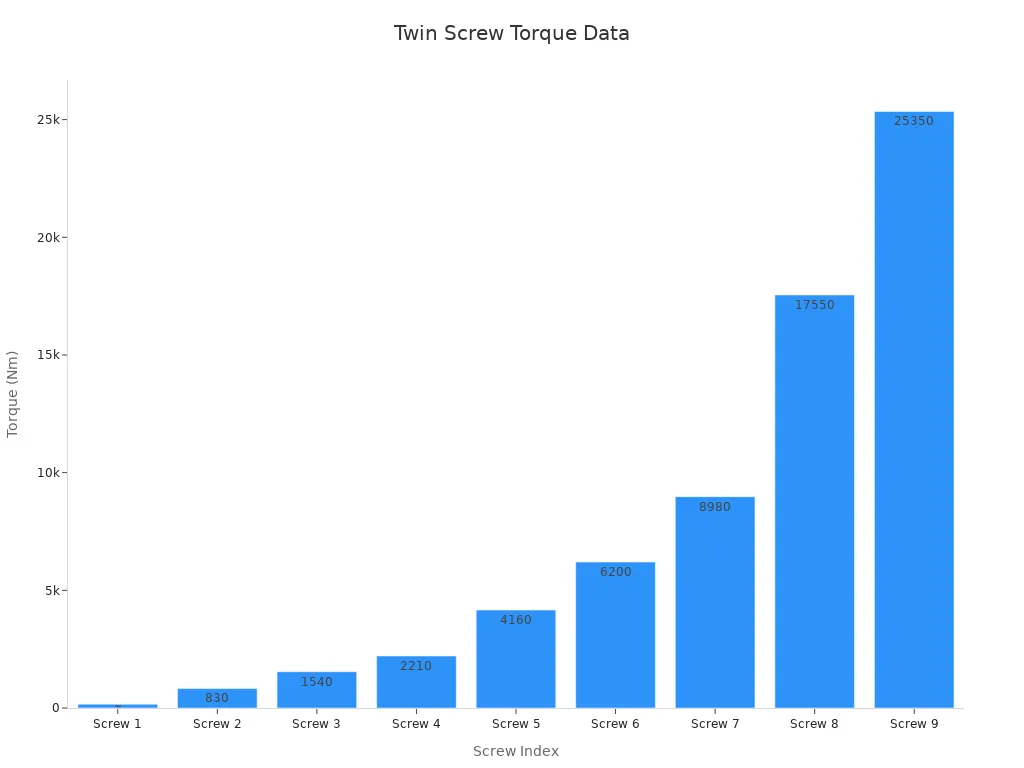

Metrics ea ts'ebetso e bapala karolo ea bohlokoa ho lekanyeng ts'ebetso ea li-extruder tsa polasetiki tse mafahla.Torque density, screw speed, 'me lisebelisoa tsa thepa ke litekanyo tsa bohlokoa tse susumetsang bokhoni ba mochine ba ho sebetsana le thepa ka katleho. Mohlala o phahameng oa torque, o lumella extruder ho sebetsana le lits'ebetso tse boima, joalo ka ho kopanya li-polymers tse matlafalitsoeng kapa ho sebetsana le lisebelisoa tse nang le viscosity e phahameng.

Tafole e ka tlase e fana ka sets'oants'o sa data ea ts'ebetso bakeng sa li-twin screw extruder:

| Paramethara | Boleng |

|---|---|

| Torque Density | Matla a phahameng ho fihla ho 18 Nm/cm³ |

| Torque ho Screw ka 'ngoe (Nm) | 160, 830, 1540, 2210, 4160, 6200, 8980, 17550, 25350 |

| Screw Speed (rpm) | 1200 bakeng sa mefuta e mengata, e meng e le 500 |

| Tlhahiso ea lintho tse bonahalang | Bokhoni ba 2,700 kg / h ho kopo ea fiber ea khalase ea PP + |

Metrics ena e totobatsa ts'ebetso e phahameng ea li-twin screw extruder ha li bapisoa le maemo a indasteri, e leng se etsang hore e be khetho e tšepahalang bakeng sa tlhahiso ea molumo o phahameng.

Litšenyehelo le Likhakanyo tsa Lichelete

Litšenyehelo ke ntlha ea bohlokoa ha u khetha "twin screw plastic extruder". Baetsi ba tlameha ho leka-lekanya litšenyehelo tsa pele tsa matsete le katleho ea nako e telele ea ts'ebetso. Le hoja li-extruder tse sebetsang hantle haholo li ka ba le litšenyehelo tse holimo, matla a tsona a sebetsang hantle, ho tšoarella nako e telele, le litlhoko tse fokotsehileng tsa tlhokomelo hangata li baka litšenyehelo tse tlase tsa beng ba tsona.

Lintlha tse susumetsang litšenyehelo li kenyelletsa:

- Screw and barrel material quality.

- Litlhoko tsa tlhophiso.

- Likarolo tse tsoetseng pele joalo ka litaolo tse itirisang le litsamaiso tsa ho beha leihlo.

Ho tsetela ho extruder ea boleng bo holimo ho tsoa ho moetsi ea tsebahalang ho netefatsa ts'ebetso e ntle le ho fumaneha ha likarolo tse ling, ho fokotsa litšenyehelo tsa nako le tlhokomelo.

Litlhoko tsa ho Tšepahala le tsa Tlhokomelo

Ho tšepahala ho bohlokoa bakeng sa ho boloka boleng bo tsitsitseng ba tlhahiso. Li-extruder tsa polasetiki tse habeli tse nang le likarolo tsa boleng bo holimo, joalo ka likurufu, libarele le li-gearbox, li fana ka ts'ebetso e tšoarellang hantle le ts'ebetso. Tlhokomelo ea kamehla e bohlokoa ka ho lekana ho thibela ho hloleha ha mochini le ho lelefatsa bophelo ba mochini.

Mekhoa ea bohlokoa ea tlhokomelo e kenyelletsa:

- Tlhokomelo ea mekhoa ea ts'ebetso ho tseba mathata a ka bang teng esale pele.

- Ho kenya ts'ebetsong mananeo a tlhokomelo ea thibelo ho fokotsa ho senya le ho senya.

- Koetlisa basebetsi ho lemoha mekhoa ea mekhoa e metle bakeng sa ho rarolla mathata.

Li-scruder screws le barrel li sebetsa ha nako e ntse e ea, tse ka amang litekanyetso tsa tlhahiso le mocheso oa mocheso. Baetsi ba lokela ho nahana ka litlamorao tsa moruo tsa ho fetola likarolo tse tsofetseng ho boloka phaello. Ho khetha extruder e tšepahalang ho fokotsa mathata ana, ho netefatsa katleho ea ts'ebetso ea nako e telele.

Ho lekola Baetsi le Bafani ba thepa

Mehato ea ho Khetha Moetsi ea Hlomphehang

Ho khetha moetsi ea nepahetsengbakeng sa li-extruder tsa polasetiki tse mafahla li bohlokoa ho netefatsa katleho ea nako e telele ts'ebetsong ea ho bopa ente. Bahlahisi ba tumileng ba bonts'a boitlamo ba ho ntlafatsa, boleng, le khotsofalo ea bareki. Ho lekola maano a bona le boteng ba 'maraka ho fana ka leseli la bohlokoa mabapi le ho ts'epahala ha bona.

| Mofuta oa Leano | Tlhaloso |

|---|---|

| Tšebetso e Tsoelang Pele | Likhamphani li tsetela ho R&D ho ntlafatsa ts'ebetso le katleho ea li-extruder, ho fihlela litlhoko tse fapaneng tsa indasteri. |

| Likamano tsa Leano | Likamano le libapali tsa indasteri le litsi tsa lipatlisiso ho matlafatsa boitseanape le ho holisa lits'ebetso. |

| Likopano le ho Fumana | Ho matlafatsa bokhoni ba tlhahiso le phihlello ea mebaraka ka ho kopanya maano le ho fumana thepa. |

Baetsi ba etelletsang maano ana pele hangata ba fana ka litharollo tsa maemo a holimo tse ipapisitseng le litlhoko tsa indasteri. Mohlala, Zhejiang Jinteng Machinery Manufacturing Co., Ltd. e beha mohlala oa mokhoa ona ka ho kopanya bokhoni bo tsoetseng pele ba moralo le lisebelisoa tsa machining tse nepahetseng. Tsepamiso ea bona ea boqapi le taolo ea boleng e netefatsa ts'ebetso e tsitsitseng le khotsofalo ea bareki.

Karolo ea Litlhahlobo tsa Bareki le Bopaki

Maikutlo a bareki le bopaki bo fana ka lintlha tse bohlokoa mabapi le botumo ba moetsi le ho tšepahala ha sehlahisoa. Litlaleho tsena tsa batho ka bomong li totobatsa liphihlelo tsa sebele tsa lefatše, li thusa bareki ba ka bang teng ho etsa liqeto tse nang le tsebo. Maikutlo a matle hangata a totobatsa lintlha tsa bohlokoa tse kang ho tšoarella ha sehlahisoa, ho sebetsa habonolo, le tšehetso ea ka mor'a thekiso.

Keletso: Batla litlhahlobo tse qaqisang ts'ebetso ea nako e telele le boiphihlelo ba tlhokomelo. Lintlha tsena hangata li senola boleng ba 'nete ba extruder ho feta theko ea eona ea pele.

Bopaki bo tsoang ho litsebi tsa indasteri le bona bo ka netefatsa likopo tsa moetsi. Ka mohlala, maikutlo a tsoang ho lik'hamphani tse sebelisang li-scruder tse peli bakeng sa lisebelisoa tse nang le viscosity e phahameng kapa mekhoa e rarahaneng e ka tiisa bokhoni ba mochine. Mokhoa o tsitsitseng oa litlhahlobo tse ntle o bontša boitlamo ba moetsi ho boleng le khotsofalo ea bareki.

Bohlokoa ba Litiisetso le Tšehetso ea Theknoloji

Litiisetso le tšehetso ea tekheniki li bapala karolo ea bohlokoa ho netefatsa hore ts'ebetso ea tlhahiso e sa sitisoe. Tiisetso e felletseng e bonts'a ts'epo ea moetsi mabapi le ho tšoarella le ts'ebetso ea sehlahisoa sa bona.Tšehetso e tšepahalang ea tekhenikie fokotsa nako ea ho theoha le ho rarolla mathata a ts'ebetso ka katleho.

Melemo ea bohlokoa ea tšehetso e matla ka mor'a ho reka e kenyelletsa:

- Tlhokomelo e tšepahalang e netefatsa katleho ea ts'ebetso.

- Ho fihlella habonolo likarolong tse ling ho fokotsa tieho ea tlhahiso.

- Ts'ehetso e felletseng ea tekheniki e thusa ts'ebetso e sa sitisoeng.

Baetsi ba fanang ka liwaranti tse pharalletseng le lits'ebeletso tsa tšehetso tse arabelang ba bonts'a boitlamo ba katleho ea bareki. Mohlala, lik'hamphani tse nang le lisebelisoa tse tsoetseng pele tsa tlhahlobo le tlhahlobo li ka fana ka tlhahlobo e nepahetseng le liqeto tse potlakileng. Boemo bona ba ts'ehetso ha bo phahamise bophelo bo bolelele ba mochini feela empa bo boetse bo aha tšepo ho bareki.

Hlokomela: Kamehla netefatsa boteng ba likarolo tse ling le ho arabela ha lihlopha tsa tšehetso ea tekheniki pele u phethela ho reka. Lintlha tsena li ama haholo ts'ebetso ea nako e telele ea ts'ebetso.

Ho khetha sekoahelo se nepahetseng sa polasetiki ea mafahla ho kenyelletsa ho lekola tšebelisano, ho itlhophisa, ts'ebetso, litšenyehelo, le ts'epahalo. Baetsi ba lokela ho etelletsa pele bafepedi ba thepa ba nang le botumo bo botle ka diwaranti tse matla le tshehetso ya botekgeniki. Ho qoba liqeto tse potlakileng ho tiisa katleho ea nako e telele.

Keletso: Theha lethathamo la litlhoko 'me u bapise likhetho ka mokhoa o hlophisehileng ho reka ka tsebo.

Nako ea poso: May-22-2025