Theknoloji ea Twin screw extruder e fana ka motsoako o tsoetseng pele le lisebelisoa tse phahameng, e etsa hore e be e loketseng bakeng sa mesebetsi e boima ea ho lokisa polasetiki. Li-extruder tsa screw tse le 'ngoe li lula li tumme ka lebaka la theko e tlase le ts'ebetso ea tsona. Kholo ea 'maraka e bonts'a tlhokahalo e matla, ha liindasteri tse kang ho paka le likoloi li itšetlehile ka mechini ena bakeng sa tlhahiso e kholo.Mafahla a Parallel Screw Barrel SupplierleMafahla Screw Bakeng sa Plastic Extrudersetsa bonnete ba liphetho tse tsitsitseng, haConical Twin Screw Twin Screwmeralo e ntlafatsa ho tenyetseha.

Melao-motheo ea ho Sebetsa le Phapang ea Moqapi

Sebopeho sa Twin Screw Extruder

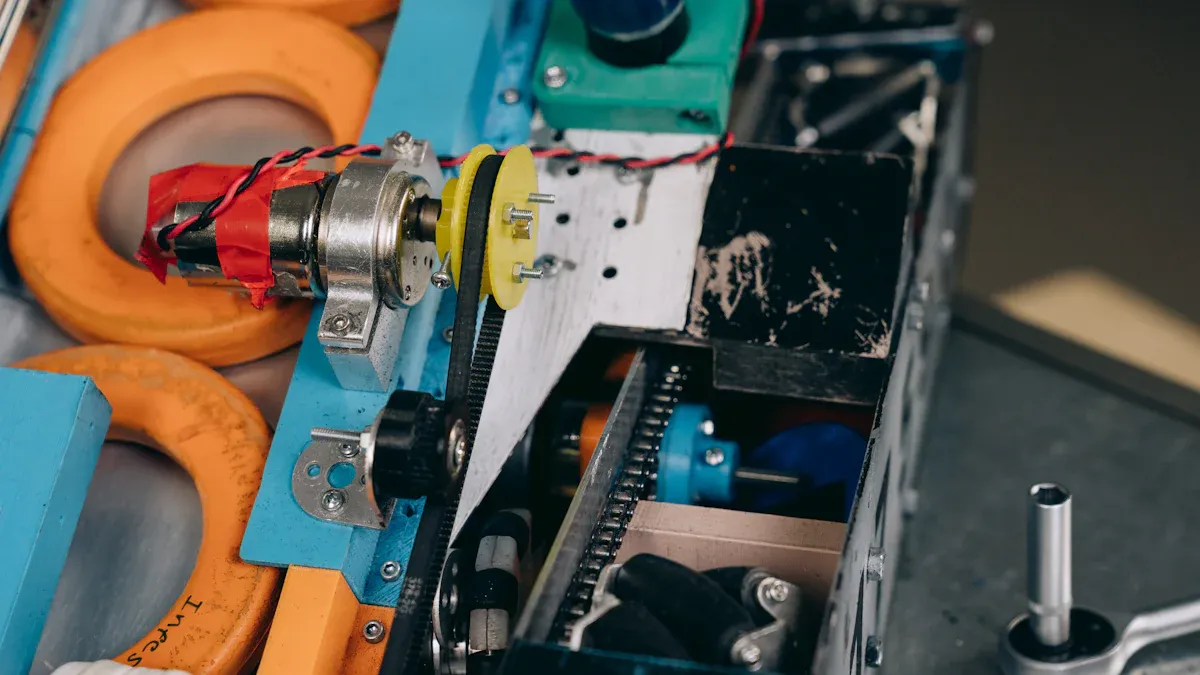

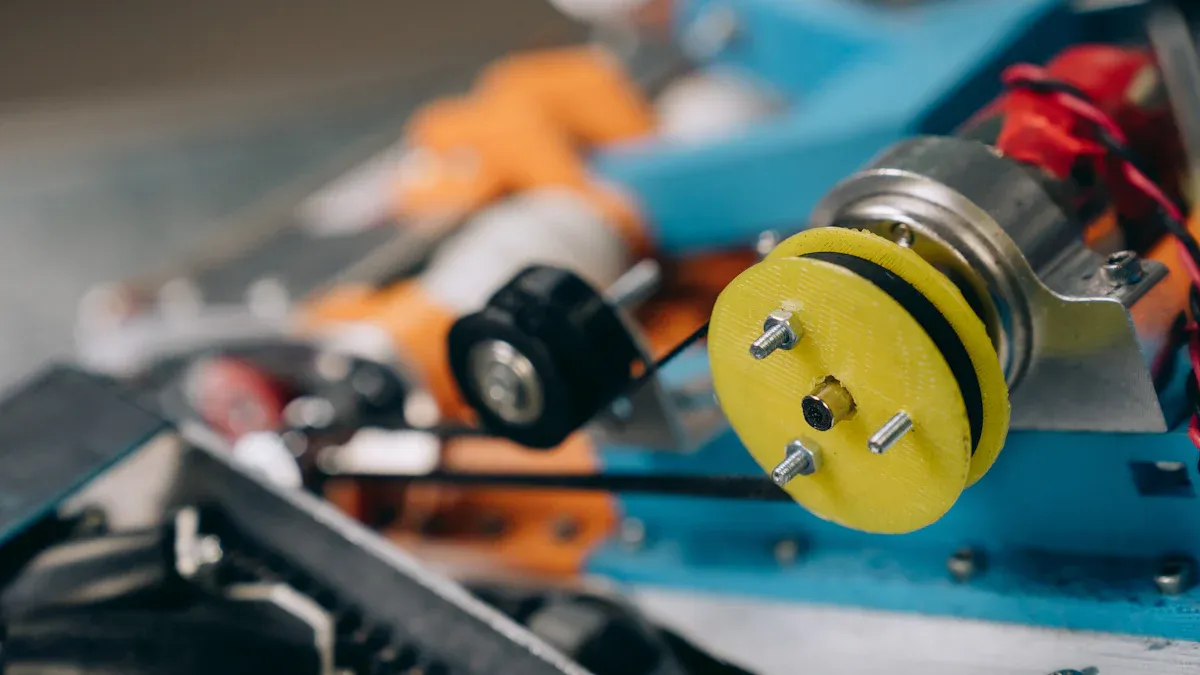

Sebelisa li-extruder tse peli tsa screwli-screw tse peli tse kopanyange potolohang mmoho ka hara moqomo. Li-screws tsena li ka bilika hammoho kapa tsa bilika ka bokhabane, ho ipapisitsoe le ts'ebeliso. Moqapi o lumella ho kopanya ho tsoetseng pele le ho kopanya, ho etsa hore ho khonehe ho sebetsana le lisebelisoa tse ngata. Baenjiniere ba ka fetola bophara ba screw, profil le geometry ea barrel ho ntlafatsa sekhahla sa tlhahiso le boleng ba sehlahisoa. Kaho ea moqomo oa moqomo le litsamaiso tse tsoetseng pele tsa taolo li thusa ho boloka mocheso o nepahetseng le khatello. Likarolo tsena li ntlafatsa ho tšoana ha sehlahisoa le thepa ea mochini, haholo lits'ebetsong tse hlokang joalo kaTlhahiso ea liphaephe tsa PVC.

Hlokomela:Moralo oa li-intermeshing o eketsa katleho ea ho kopanya le ho ts'ehetsa ho itlhoekisa, e leng ho fokotsang nako ea ho phomola.

Moralo o le Mong oa Screw Extruder

Li-extruder tsa screw tse le 'ngoe li na le moralo o bonolo haholoanyane o nang le sekoti se le seng sa helical ka har'a moqomo. Moralo ona o sebelisa likarolo tse fokolang tse tsamaeang, ho etsa hore ho be bonolo ho sebetsa le ho hlokomela. Sekoti se sutumelletsa thepa pele haholo-holo ka phallo ea ho hula, e sebetsang hantle bakeng sa thepa ea ho phalla e tsitsitseng. Pholiso ea ka hare ea screw le sebopeho sa khoele ea khutlonnetsepa li thusa ho laola mocheso le ho netefatsa ts'ebetso e tsitsitseng. Boholo ba compact le kaho e otlolohileng li etsa hore li-scruders tse le 'ngoe li be le chelete e ngata ebile li loketse tlhahiso e kholo.

| Tlhaloso ea Moqapi / Ntho ea Litšenyehelo | Litšobotsi tsa Single Screw Extruder |

|---|---|

| Bonolo ho Moralo | Likarolo tse tsamaeang tse fokolang, ho bonolo ho sebetsa le ho li hlokomela |

| Chelete le Litšenyehelo tsa Ts'ebetso | Litsenyehelo tse tlase tsa matsete le tlhokomelo |

| Matla a Matla | E sebelisa matla a fokolang bakeng sa mesebetsi e bonolo |

| Tlhokomelo | Ho qhaqha ka potlako le ho hloekisa |

| Phello | E phahameng bakeng sa lisebelisoa tse bonolo |

Phallo ea Boitsebiso le Mokhoa oa ho Kopanya

Phallo ea lintho tse bonahalang ka har'a "twin screw extruder" e kenyelletsa phallo ea ho hula, phallo ea khatello le phallo ea ho lutla. Li-screws tsa intermeshing li etsa hore ho be le litlama le ho luba, tse ntlafatsang ho kopanya le ho hasana ho eketsehileng. Li-screws tse pota-potileng li ntlafatsa bokhoni ba ho kopanya le ho thusa ho laola mocheso, ho fokotsa kotsi ea ho senyeha ha thepa. Ka lehlakoreng le leng, li-extruder tsa screw e le 'ngoe li itšetleha haholo ka phallo ea ho hula, e fokotsang bokhoni ba ho kopanya empa e netefatsa tlhahiso e tsitsitseng bakeng sa lisebelisoa tse bonolo. Screw geometry, lebelo, le viscosity ea lintho tsohle li susumetsa phallo le ts'ebetso ea ho kopanya.

Likarolo tsa ho Degassing le ho Itlhoekisa

Li-extruder tse peli tsa "twin screw" li sebetsa hantle haholo ha li senya hobane li-intermeshing screws li eketsa sebaka sa ho ntša khase. Lisebelisoa tse ling li matlafatsa ts'ebetso ea ho tlosa metsi ka 500% ha e bapisoa le meralo e le 'ngoe ea screw. Likarolo tsa ho itlhoekisa, joalo ka ts'ebetso ea screw ea ho itlhakola, e thusa ho boloka ts'ebetso e tsitsitseng le ho fokotsa nako. Sistimi e tsoetseng pele ea ho sefa le taolo e nepahetseng ea liparamente tsa extrusion li ts'ehetsa melemo ena. Li-extruder tsa screw tse le 'ngoe li fana ka tlhoekiso e hlakileng ka lebaka la kaho ea tsona e bonolo, empa ha li tsamaellane le ts'ebetso e ntle ea ho tlosa likhase ea li-screws tsa mafahla.

Papiso ya Tshebetso

Ho Kopanya Bokhoni le Homogeneity

Boleng ba ho kopanya bo eme e le ntho e hlalosang ts'ebetso ea extrusion. Li-extruder tsa Twin screw li fana ka motsoako o phahameng ka lebaka la li-screws tsa tsona tse peli tse intermeshing. Li-screws tsena li hasanya le ho aba li-additives ka mokhoa o atlehileng, li hlahisa ho qhibiliha ho homogeneous. Mokhoa oa ho itlhatsoa pakeng tsa li-screws o thibela ho haha lisebelisoa le ho tiisa ho kopanya ka ho feletseng. Lithutong tse laoloang, li-fin screw extruders li hlahisitse motsoako o omileng oa ho hema phofo kakopanya ho ts'oana le ts'ebetso ea aerosole lekanang kapa e betere hofeta tlhaka e ngata e kutang batch. Bafuputsi ba fumane hore mekhoa ea ts'ebetso e kang lebelo la screw le sekhahla sa phepelo ha ea ka ea ama haholo ho tsitsa ha sehlahisoa sa ho qetela. Ho tiea hona ho lumella bahlahisi ho finyella metsoako e ts'oanang le boleng bo tsitsitseng ba sehlahisoa, esita le ka mekhoa e rarahaneng.

Li-extruder tsa twin screw li lumella ho ikamahanya ha matla a ho kopanya ka ho lokisa li-screw profiles le likarolo. Ho feto-fetoha ha maemo ho etsa hore ho be bonolo ho sebelisa lisebelisoa le lits'ebetso tse ikhethileng, 'me sena se fella ka ho hasana le ho kopanya ho ts'oanang.

Phethahatso le Phello e sa Tšoaneng

Ho sebetsa le ho tsitsa hoa bohlokoa bakeng sa tlhahiso ea indasteri. Twin screw extruders finyellalitefiso tse phahameng tsa tlhahisole ho sebetsana le lisebelisoa ka katleho ho feta mefuta e le 'ngoe ea screw. Ba boloka taolo e nepahetseng ea ts'ebetso, e lebisang ho boleng bo tsitsitseng ba sehlahisoa le mefokolo e fokolang. Tafole e ka tlase e akaretsa liphapang tsa bohlokoa:

| Mofuta oa Extruder | Litšobotsi tsa Phallo | Litšobotsi tsa ho tsitsa ha Sephetho |

|---|---|---|

| Sehlahisoa sa "twin screw". | Phello e phahameng; ts'ebetso e sebetsang hantle; matla a sebetsang hantle | Taolo ea ts'ebetso e nepahetseng; ho kopanya ho holimo; boleng bo tsitsitseng ba sehlahisoa; likoli tse fokolang le litšila tse fokolang |

| Sesebelisoa se le seng sa screw extruder | Phello e itekanetseng; e bonolo ebile e na le chelete e ngata | Mathata a nang le khatello ea maikutlo; bokhoni bo fokolang ba ho kopanya; monyetla oa ho ajoa ha thepa e sa lekaneng le mefokolo ea lihlahisoa |

Li-extruder tsa screw tse le 'ngoe li ka ba le ho feto-fetoha ha khatello le mathata a phallo ea thepa, tse ka amang ho tšoana ha tlhahiso. Ka lehlakoreng le leng, li-extruder tsa Twin screw li fana ka ts'ebetso e tsitsitseng le liphetho tse tšepahalang, tse etsang hore e be tse loketseng bakeng sa tlhahiso e kholo.

Ho Tšoaroa ha Lintho le ho Fetolana

Ho sebetsana le lintho tse bonahalang le ho feto-fetoha ha maemo ho etsa qeto ea hore na extruder e ikamahanya hantle le lisebelisoa tse tala le libopeho tse fapaneng. Li-extruder tse peli tsa screw li ipabola tabeng ea ho lokisa liphofshoana, thepa eo ho leng thata ho e fepa, le metsoako e rarahaneng. Li fana ka motsoako o pharalletseng oa ho qhalakanya le oa ho aba, li sebetsana le mefuta e mengata ea viscosity, 'me li kenyelletsa li-additives tse ngata habonolo. Tafole e ka tlase e totobatsa liphapang tsena:

| Sebopeho | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Foromo ea Boitsebiso | Molemo ka ho fetisisa bakeng sa li-pellets le granules | Ho molemo bakeng sa li-powders le lisebelisoa tse thata ho fepa |

| Ho Kopanya Bokgoni | E lekanyelitsoe ho kopanya kabo | Motsoako o phahameng oa ho qhalakanya le oa ho aba |

| Boikutlo ba Mocheso | Nako e telele ea ho lula | Nako e khuts'oane, e laoloang haholoanyane ea bolulo |

| Additive Incorporation | Kenyelletso ea mantlha ea tlatsetso | E sebetsana le litlolo tse rarahaneng tse nang le li-additives tse ngata |

| Sebaka sa Viscosity | Sebaka se lekanyelitsoeng | Bokhoni ba mefuta e mengata ea viscosity |

Li-extruder tsa Twin screw li boetse li fana ka taolo e ntlafalitsoeng ea ts'ebetso, ho kenyelletsa taolo e nepahetseng ea mocheso le linako tse khuts'oane tsa bolulo. Likarolo tsena li ruisa thepa e sa utloeng mocheso le litlolo tse rarahaneng. Single screw extruders lula a bitsa chelete e ngata le e ka tšeptjoang bakeng sa pellet junifomo empa ba haelloa ke ho feto-fetoha lebokhoni bo tsoetseng pele ba ho kopanyaea li-screw system tse peli.

Katleho ea ho Degassing

Degassing e tlosa likhase tse koaletsoeng le mongobo ho tloha linthong nakong ea extrusion. Li-extruder tsa Twin screw li fana ka ts'ebetso e ntle haholo ea ho senya ka lebaka la moralo oa tsona oa intermeshing screw, o eketsang sebaka sa ho tsoa ha khase. Tšobotsi ena e ipaka e le ea bohlokoa ka ho khetheha lits'ebetsong tse hlokang bohloeki bo phahameng ba sehlahisoa kapa ha ho sebetsa lisebelisoa tse atisang ho etsoa ke khase. Ho hloekisoa ha metsi ho matlafalitsoeng ho lebisa ho fokotseng mefokolo le boleng bo ntlafetseng ba sehlahisoa. Li-extruder tsa screw tse le 'ngoe li fana ka mokhoa oa ho tlosa metsi empa ha li khone ho ts'oana le ts'ebetso ea li-scruder tse mafahla lits'ebetsong tse hlokahalang.

Ho Itlhoekisa le ho Itlhokomela

Lintho tsa ho itlhoekisa li fokotsa nako ea ho phomola le ho nolofatsa tlhokomelo. Li-extruder tsa li-twin screw li sebelisa ketso ea ho itlhakola ho thibela ho bokellana le ho ts'ehetsa ts'ebetso e tsoelang pele. Lintlha tsa liteko li bonts'a hore ho lokisa liparamente tsa extruder joalo ka bophara le bophahamo ba lera ho ka ntlafatsa bokaholimo le ho koloba, ho ntlafatsa ts'ebetso ea ho itlhoekisa. Lisebelisoa tse kang li-elastomer tsa thermoplastic li bonts'a linomoro tse phahameng tsa ho itlhoekisa, tse fetolelang ho fokotsa litšenyehelo tsa ho itlhoekisa ka letsoho le litšenyehelo tse tlase tsa tlhokomelo. Li-extruder tsa "screw extruder" li bonolo ho arola le ho hloekisoa ka lebaka la moralo oa tsona o bonolo, empa ha li fane ka boemo bo ts'oanang ba ho itlhoekisa ka boiketsetso joalo ka li-twin screw systems.

Tlhokomelo ea kamehla le litlhophiso tse ntlafalitsoeng tsa extruder li thusa ho boloka ts'ebetso e phahameng le ho lelefatsa bophelo ba lisebelisoa.

Ho Tšoaneleha Kopo

Plastic Twin Screw Extruder Applications

A polastiki lefahla sekoti extrudere sebeletsa mefuta e mengata e fapaneng ea liindasteri tse hlokang ho tsoakana ho tsoetseng pele, taolo e nepahetseng, le maemo a bonolo. Baetsi ba sebelisa mechini ena bakeng sa ho kopanya, ho hlahisa masterbatch, ho kopanya polymer, le ho lokisa lipolasetiki tse tsosolositsoeng. Moralo oa modular o lumella baenjiniere ho fetola li-screw profiles bakeng sa lisebelisoa tse ikhethileng, ho ntlafatsa ts'ebetso le boleng ba sehlahisoa. Likhamphani tse lekaleng la likoloi le tsa kaho li itšetleha ka li-scruder tse peli bakeng sa likarolo tse sebetsang hantle haholo. Litlaleho tsa tekheniki li totobatsa lintlafatso molemong oa tlhahiso le boleng ba foromo, haholo lits'ebetsong tse joalo ka phetoho ea polasetiki ea boenjiniere le ts'ebetso ea thepa e sebelisoang hape. Mmaraka oa libarele tsa extruder o ntse o tsoela pele ho fetoha, ka keketseho e ntseng e eketseha ea li-extruder tsa mafahla le li-multi-screw likarolong tse phahameng haholo le tse hlokang ho nepahala tse kang tsa meriana le ho lokisa lijo.

Molemo ka ho Fetisisa bakeng sa Single Screw Extruders

Li-extruder tsa screw e le 'ngoelula e le khetho e ratoang bakeng sa mesebetsi e bonolo, e phahameng ea tlhahiso. Mechini ena e ipabola ho hlahiseng lihlahisoa tse entsoeng ka mokhoa o sa fetoheng, o ommeng, joalo ka pasta, lijo tsa liphoofolo tsa lapeng, le lijo tse bobebe tse entsoeng ka raese. Moralo oa bona o otlolohileng o netefatsa litšenyehelo tse tlase tsa tlhokomelo le ts'ebetso. Tafole e ka tlase e akaretsa maemo a molemo ka ho fetisisa a tšebeliso:

| Mofuta oa Sehlahisoa | Mofuta o Ratoang oa Extrusion | Ho beha mabaka |

|---|---|---|

| Paseka | Screw e le 'Ngoe | Sebopeho se bonolo se omeletseng, ho kopanya ho fokolang |

| Lijo tsa mantlha tsa liphoofolo tse ruuoang lapeng | Screw e le 'ngoe kapa Twin Screw | Ka bobeli li sebetsa, screw e le 'ngoe e na le chelete e ngata |

| Li-snacks tsa raese tse phehiloeng | Screw e le 'Ngoe | Keno e tsitsitseng e omileng, phallo e phahameng |

Moetsi oa li-snack ea hlahisang libolo tsa raese tse ikhohomosang o fumane li-scruders tse le 'ngoe tse loketseng liresepe tse bonolo. Leha ho le joalo, ha ba fetohela ho lihlahisoa tsa multigrain, ba ne ba hloka "twin screw extruder" bakeng sa ho kopanya hantle le ho fokotsa litšila.

Mehlala ea Indasteri

- Likhamphani tsa lijo tse kang Nestlé le Kellogg li tsetela mochining oa extrusion ho fihlela tlhoko e ntseng e hola ea lijo tse feliloeng.

- Makala a kaho le a likoloi a ipapisitse le likarolo tse pharalletseng, 'me lifeme tse kang Bausano le KraussMaffei li fana ka litharollo tse ikhethileng.

- Tlhahiso e eketsang e hokahana le extrusion bakeng sa tlhahiso e ikhethileng, joalo ka ha ho bonoa ho CEAD le Arburg.

- Litloaelo tsa taolo le tikoloho li etsa hore ho amoheloe lisebelisoa tsa extrusion tse baballang matla, tse bolang le tse sebetsang hantle.

Lintlafatso tsa theknoloji, ho kenyeletsoa li-automation le khokahanyo ea IoT, li tsoela pele ho ntlafatsa katleho ea tlhahiso le boleng ba lihlahisoa liindastering tsohle.

Litlhaloso tsa ts'ebetso

Bonolo ba Tšebeliso le Koetliso

Basebelisi ba fumana litsamaiso tsa sejoale-joale tsa extruder tse bonolo ho sebelisa ka lebaka la li-interfaces tse tsoetseng pele tsa taolo. Lits'ebetso tsena li bonts'a data ea nako ea nnete, lialamo, le lipapiso tse akaretsang, tse thusang basebelisi ho beha leihlo le ho lokisa tšebetso kapele. Litlhoko tsa koetliso li itšetlehile ka mofuta oa extruder. Li-extruder tsa screw tse le 'ngoe li na le moralo o otlolohileng, kahoo basebelisi ba bacha ba ka ithuta ts'ebetso ea mantlha le ho rarolla mathata ka nako e khuts'oane.Li-fin screw extrudersfana ka likarolo tse ling, joalo ka taolo ea risepe le ho rarolla mathata hole, tse hlokang koetliso e eketsehileng. Litsamaiso tsa ho laola tse nang le lintlha tsa liketsahalo le pokello ea lintlha li thusa basebetsi ho arabela liphetohong le ho boloka boleng ba sehlahisoa.

Keletso: Ho tsetela ho koetliso ea opareitara ho ntlafatsa botsitso ba ts'ebetso le ho fokotsa kotsi ea liphoso.

Tlhokomelo le Nako ea Phomolo

Tlhokomelo ea kamehla e boloka li-extruder li sebetsa hantle le ho lelefatsa nako ea tsona ea bophelo. Mananeo a tlhokomelo a fapana lipakeng tsa screw e le 'ngoe le li-twin screw extruders. Tafole e ka tlase e totobatsa likarolo tsa bohlokoa:

| Mofuta oa Extruder | Libaka tse Lebisitsoeng ho Tlhokomelo | Kemiso ea Lintlha-khōlō |

|---|---|---|

| Screw e le 'Ngoe | Fepa pholiso ea 'metso, ho roala ha sekoti/barrel, cheke ea thrust bearing | Oli e fetoha lihora tse ling le tse ling tse 4,000-5,000 |

| Twin Screw | Ho tsamaisana ha screw, kabo ea torque, ho lekola karolo ea barrel | Sistimi ea ho pholisa e hloekisoa likhoeli tse ling le tse ling tse tšeletseng |

Lirekoto tsa tlhokomelo li latela tlhahlobo, litokiso le likarolo tse ling tse ncha. Litlaleho tsena li thusa lihlopha ho bona mathata a hlahang khafetsa le ho rera thibelo ea thibelo. Tlhokomelo e thibelang e kafokotsa nako ea ho theoha ho fihlela ho 45%le ho eketsa lilemo ho bophelo ba lisebelisoa.

- Li-logs tsa tlhokomelo li tšehetsa ho rarolla mathata le kemiso e sebetsang hantle.

- Ho hlokomoloha litlaleho ho lebisa linakong tse telele tsa ho theoha le ho lokisoa khafetsa.

Litšenyehelo le Return ho Investment

Litšenyehelo le ho khutlisa matsete (ROI) li bapala karolo e kholo ho khethoeng ha extruder. Extrusion molding hangata e hloka aletsete la pele le tlaseho feta mekhoa e meng, joalo ka ho bopa ka ente. Mekhoa e ikemetseng e fokotsa litšenyehelo tsa basebetsi le litšila tsa thepa, ho ntlafatsa katleho ea tlhahiso. Ts'ebetso e tsoelang pele e boetse e theola nako ea ho theoha, e matlafatsang ROI bakeng sa merero e phahameng haholo. Hangata lik'hamphani li khetha extrusion bakeng sa likarolo tse bonolo ho eketsa chelete ea ho boloka litšenyehelo, athe likarolo tse rarahaneng, tse nepahetseng haholo li ka lokafatsa litšenyehelo tse phahameng tsa pele lits'ebetsong tse ling. Tlhahlobo e hlokolosi ea litšenyehelo tsa lisebelisoa, tšebeliso ea thepa, le litlhoko tsa basebetsi li netefatsa boleng bo botle ba nako e telele.

Tataiso ea Liqeto

Ho Khetha Ho Thehiloe ho Litlhoko tsa Ts'ebetso

Ho khetha sistimi e nepahetseng ea extruder ho itšetlehile ka tlhahlobo e hlokolosi ea litlhoko tsa ts'ebetso. Baetsi ba bangata ba sebelisameralo ea ho etsa liqetotse kopanyang tlhahlobo ea techno-economic, mehlala ea likhakanyo tsa litšenyehelo, le lisebelisoa tse thusoang ke AI. Merero ena e thusa basebelisi ho bapisa likhetho tse ipapisitseng le litšenyehelo, nako ea kaho, thepa ea thepa, le litlhoko tse ikhethileng indastering. Mekhoa e mengata ea ho etsa liqeto, joalo ka AHP, TOPSIS, le VIKOR, e lumella lihlopha ho lekola lintlha tsa bongata le tsa boleng. Li-chatbots tsa AI tse sebetsang joale li fana ka tlhaiso-leseling e lokiselitsoeng, e hohelang litsing tse kholo tsa lipatlisiso ho ts'ehetsa likhetho tse nang le tsebo. Liphuputso tse entsoeng li bontša hore mokhoa ona o ntlafatsa ho nepahala ha liqeto, ka likhakanyo tsa litšenyehelo tse amanang haufi-ufi le mantsoe a qotsitsoeng a lefatše la sebele bakeng sa likarolo tse fapaneng. Mokhoa ona o fa basebelisi matla a ho etsa liqeto tse ikemetseng ka ho hlahisa lintlha tse felletseng, ho fapana le ho qobella tharollo e le 'ngoe.

Keletso: Sebelisa lisebelisoa le lithuto tsa liketsahalo ho bapisa ts'ebetso, litšenyehelo, le tšebelisano ea thepa pele u etsa khetho ea ho qetela.

Lipotso Tsa Bohlokoa Tseo U ka Nahanang ka tsona

Ha u khetha pakeng tsa aSekurufu se le seng kapa sekoti se mafahla, lihlopha li lokela ho hlahloba tse 'maloalintlha tsa mochini le ts'ebetso:

- Ke matla afe a ho khanna le a hanyetsang a amehang ts'ebetsong ea extrusion?

- Ke mochini ofe oa extrusion o loketseng ts'ebeliso?

- Moralo oa kamore o ama khatello le phallo ea extrusion joang?

- Ke tlhophiso efe ea thepa e tla ntlafatsa boleng ba sehlahisoa?

- Na likarolo tse tsoetseng pele joalo ka motsoako oa bobeli kapa matlafatso lia hlokahala?

- Lintho tse bonahalang le liparamente tsa ts'ebetso li sebelisana joang?

| Ho nahanela | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Mokhoa oa ho Fetolana | Ha e tenyetsehe, ho bonolo ho e sebetsa le ho e hlokomela | E feto-fetoha haholoanyane, e ts'ehetsa phapang e pharaletseng ea sebopeho |

| Litšenyehelo tsa Pele | Theko e tlase ea ho reka | Matsete a pele a holimo |

| Litšenyehelo tsa Ts'ebetso | Ho fokotsa tšebeliso ea matla le litšenyehelo tsa tlhokomelo | Litšenyehelo tse phahameng tsa ts'ebetso le tlhokomelo |

| Phatlalatso ea Tlhahiso | Taolo e bonolo, ho rarahana ho tlase, tlhahiso e tlase | Phaello e phahameng, ho kopanya hantle, ho ntlafatsa boleng ba sehlahisoa |

| Ho lumellana ha Lintho | E loketse mefuta e mengata ea lisebelisoa | Ho molemo bakeng sa mekhoa e rarahaneng le mekhoa e tsoetseng pele |

Litsebi tsa indasteri li khothalletsa ho hlahlobisisa lipakane tsa tlhahiso, litšenyehelo tsohle, le litlhoko tsa thepa. Ho buisana le litsebi ho ka thusa ho netefatsa hore extruder e khethiloeng e fihlela litlhoko tsa hajoale le tsa nako e tlang.

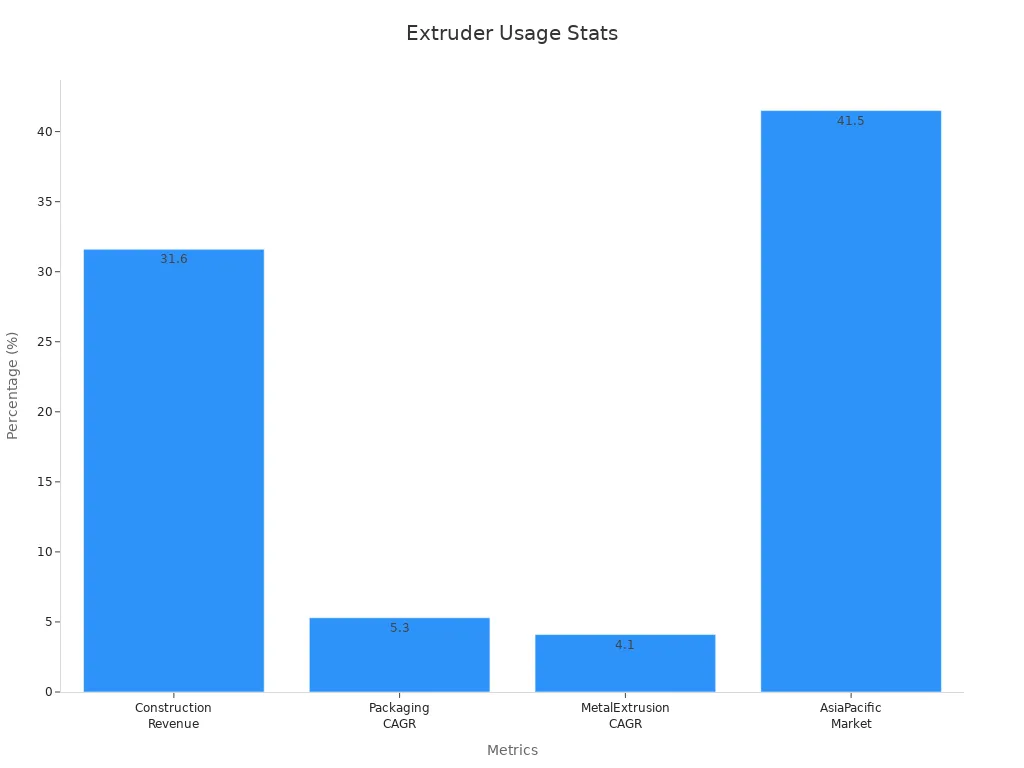

Theknoloji ea "twin screw extruder".e tšehetsa ho kopanya ho tsoetseng pele le ho feto-fetoha ha maemo bakeng sa ts'ebetso e rarahaneng ea polasetiki. Li-extruder tsa screw tse le 'ngoe li lula li loketse mesebetsi e bonolo, e phahameng haholo. Lintlha tsa 'maraka li bonts'a 6% CAGR e lebelletsoeng bakeng sa li-scruder tse peli tse bonts'ang tlhokahalo e matla le bohlokoa bo pharaletseng ba indasteri.

| Karolo | Tloaelo/Tlhaloso |

|---|---|

| CAGR ea 'maraka | ~6% (2024-2033) |

| Lisebelisoa tsa indasteri | Plastiki, lijo, meriana, lik'hemik'hale |

| Karolo ea Lihlahisoa | Li-extruder tsa "twin screw" tse potolohang li tsamaisa kholo |

LBH

Ke lisebelisoa life tse ka etsang tšebetso ea mafahla a polasetiki a screw extruder?

A polastiki lefahla sekoti extrudere sebetsana le polyethylene, polypropylene, PVC, ABS, le polasetiki ea boenjiniere. E ts'ehetsa ho kopanya, ho kopanya, le tlhahiso ea masterbatch bakeng sa liindasteri tse fapaneng.

Mafahla a "scruder extruder" a ntlafatsang ho kopanya joang ha a bapisoa le "scruder" e le 'ngoe?

Li-fin screw extruder li sebelisa li-intermeshing screws. Li-screws tsena li theha matla a matla a ho kuta le ho luba. Ketso ena e netefatsa phallo e ntle ea tlatsetso le sehlahisoa se ts'oanang.

Na mochini oa mafahla oa "screw extruder" o loketse lipolasetiki tse nchafalitsoeng?

Ee. Ts'ebetso ea mochini oa "twin screw extruder".lipolasetiki tse nchafalitsoengka bokgabane. Ba fana ka taolo e nepahetseng ea mocheso le motsoako o tsoetseng pele, o ntlafatsang boleng ba tlhahiso ea thepa e tsosolositsoeng.

Nako ea poso: Jun-26-2025