Baetsi le bareki hlokomelaconical twin screw barrelbakeng sa SPC fatše e le khetho e ka sehloohong ka 2025. Ho khetha se nepahetsengMochini oa Twin Screw Extrusione ama boleng ba sehlahisoa, katleho ea ho kopanya, le litšenyehelo tsa ts'ebetso. TheEnte Molding Machine Screw BarrelleTwin Screw ExtrusionTs'ebetso e bapala karolo ea bohlokoa ho sebetsanang le kutlo ea mocheso oa PVC, ho netefatsa liphetho tse tsitsitseng.

Conical Twin Screw Barrel bakeng sa SPC Floor: Karabo e tobileng

Na Conical Twin Screw Barrel Superior ka 2025?

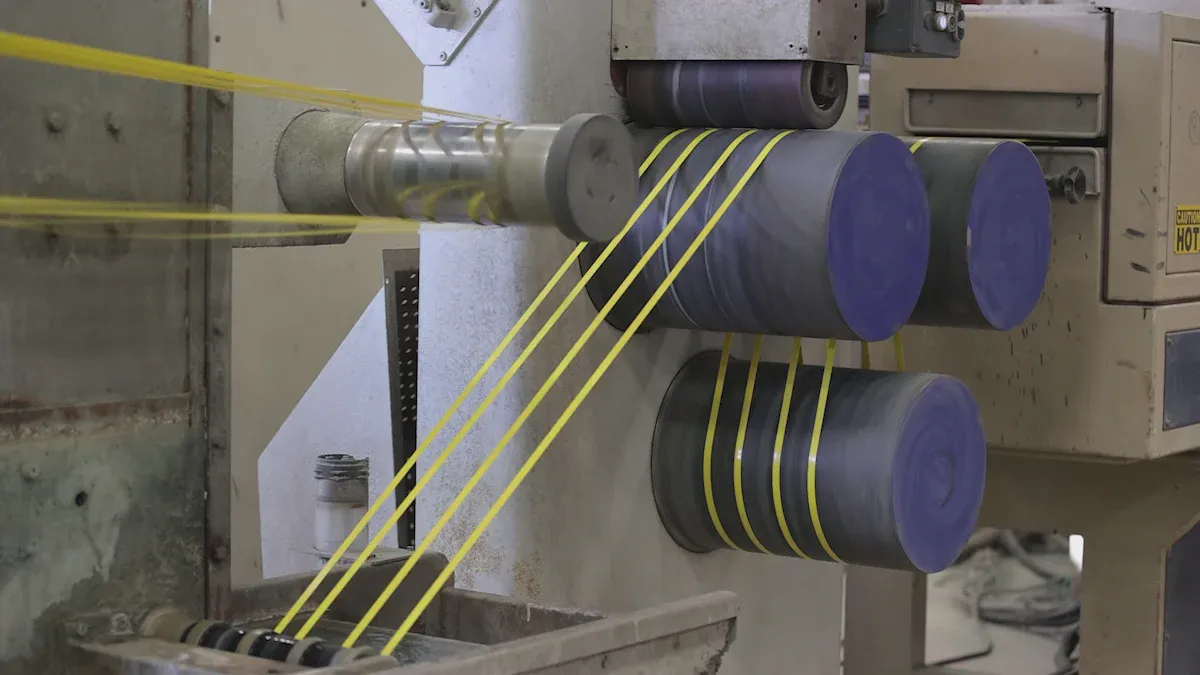

Litsebi tsa indasteri li lumellana horeconical twin screw barrelbakeng sa SPC fatše e hlahella e le khetho e ratoang ka 2025. Moralo ona oa barrel o na le bophara bo fokotsehang butle-butle le tekanyo ea khatello e laoloang. Likarolo tsena li haha khatello e loketseng bakeng sa ho qhibiliha PVC, e tiisang hore ho na le gelation e tšoanang ntle le ho baka mocheso o feteletseng. Baetsi ba rua molemo ka ho hanyetsa ho apara ho phahameng hobane moqomo o sebelisa litšepe tsa alloy tse matla tse tšoaroang ke li-nitriding kapa li-bimetallic linings. Ho tšoarella hona ho bohlokoa bakeng sa ho sebetsana le li-filler tse hlabang ka har'a metsoako ea PVC.

Theconical mafahla screw barrel bakeng sa SPC fatšee boetse e fana ka likarolo tse ntlafalitsoeng tsa moea le ho kopanya. Likarolo tsena li tlosa moea o koaletsoeng 'me li kopanya li-colorants le li-modifiers ka botlalo. Ts'ebetso ena e thibela likoli tse kang li-pigments tse sa tsitsang kapa ho chesa haholo. Moqomo o fihlella homogeneity e betere ea ho qhibiliha le ho fepa ka holimo ha li-powders ha li bapisoa le mefuta e meng ea screw. Ho futhumala ha libaka tse ngata ka har'a barrel ho lumella taolo e nepahetseng ea mocheso, e bolokang viscosity e ntle ea ho qhibiliha le boleng ba sehlahisoa. Ho fumaneha ha setoko sa lehae ho ts'ehetsa ho tsamaisoa ka potlako le ho fokotsa nako, ho thusa bahlahisi ho boloka tlhahiso e tsoelang pele.

Lintlha tsa Bohlokoa Tse Etsang Hore U Khetha

Lintlha tse 'maloa li khanna ho amoheloa ha libarele tsa conical twin screw tlhahiso ea fatše ea SPC. Litloaelo tsa 'maraka oa lefats'e li bonts'a tlhokahalo e matla ea ts'ebetso e sebetsang hantle, e tsoelang pele e nang le bokhoni bo holimo ba ho kopanya le ho kopanya. Mekhoa ena e thusa ka ho toba tlhahiso ea fatše ea SPC. Tsoelo-pele ea theknoloji ho othomathike le ts'ebetso ea matla e khothaletsa bahlahisi ho khetha lisebelisoa tse tsoetseng pele tsa extrusion joalo ka moqomo oa conical twin screw bakeng sa SPC floor.

Kholiso e potlakileng ea indasteri Asia-Pacific le Amerika Leboea e eketsa tlhoko ea litsamaiso tse tsoetseng pele tsa extrusion. Maiteko a mmuso le ntshetsopele ya meralo ya motheo e eketsa tlhokahalo ya metjhini e sebetsang hantle haholo. Maemo a taolo a amanang le ho ikamahanya le tikoloho le boleng ba sehlahisoa a sutumelletsa bahlahisi ho li-eco-friendly twin screw extruder. Mmaraka oa fatše oa SPC o hola ka potlako hobane bareki ba batla litharollo tsa fatše tse tšoarellang, tse theko e tlaase le tse sa keneleng metsi. Baetsi ba arabela ka ho sebelisa mekhoa e tsoetseng pele ea extrusion e fanang ka bokhoni bo nepahetseng ba ho kopanya le ho kopanya.

Kaho ea litoropo le kholo ea kaho mebarakeng e ntseng e hlaha e hloka mekhoa e matla le e sebetsang ea tlhahiso. Li-extruder tsa sejoale-joale tsa twin screw li fihlela litlhoko tsena ka ho fana ka lisebelisoa tse ikhethileng le tse sebetsang hantle. Ts'ebetso le mekhoa ea taolo e ntse e tsoela pele ho khothaletsa ts'ebeliso ea mochini o bolokang tikoloho le o lumellanang. Kholo ea tikoloho le tlhoko ea lihlahisoa tsa boleng bo holimo li tiisa bohlokoa ba ho khetha moqomo oa conical twin screw bakeng sa SPC floor ka 2025.

Conical vs. Parallel Twin Screw Barrels: Ke Eng e Ba Khethollang?

Phapang ea Moralo le Sebopeho

Moralo oa libarele tse peli tsa screw o bapala karolo ea bohlokoa tlhahisong ea fatše ea SPC.Libarele tse bapetseng tse peli tsa screwsebelisa likurufu tse peli tse nang le bophara bo lekanang ka bolelele ba tsona. Li-screws tsena li potoloha ka mahlakore 'me li fana ka phallo e tsitsitseng ea thepa. Ka lehlakoreng le leng, libarele tsa conical twin screw li na le li-screw tse fokotsehang butle-butle ka bophara. Sebopeho sena se ikhethileng se atametsa li-screw ka lehlakoreng le leng, ho theha libaka tse khethehileng tsa ho kopanya.

Tafole e ka tlase e totobatsa liphapang tse kholo:

| Sebopeho/Sebopeho | Parallel Twin Screw Barrel | Conical Twin Screw Barrel |

|---|---|---|

| Screw Diameter | Uniform ka bolelele | Butle-butle ea fokotseha |

| Screw Orientation | Lehlakore ka lehlakore, parallel | Haufi hammoho, angled |

| Kopanya Libaka | Lifofane tsa motheo, tsa mokhoa oa ho palama | E khethehileng bakeng sa ho kopanya ka ho feletseng |

| Litšobotsi tsa ho fepa | Lijo tse tloaelehileng | Phepo e ntlafalitsoeng, ho sebetsa hantle pele ho nako |

| Khatello Botsitso | E sa rarahanang | E ntlafalitsoe ho pholletsa le libaka tsa ho kopanya |

| Bokhoni ba ho hlahisa | Phaello e phahameng | Tlhahiso e itekanetseng, taolo e betere |

| Matla a Matla | E sebetsa hantle haholoanyane | Tšebeliso e phahameng hanyane |

| Taolo le Boiketsetso | Litaolo tsa mantlha | Advanced PLC, taolo e bohlale |

| Ho loketse bakeng sa SPC Flooring | Molemo ka ho fetisisa bakeng sa mesebetsi e bonolo, e phahameng | Molemo ka ho fetisisa bakeng sa mesebetsi e rarahaneng, e nepahetseng |

Tšusumetso ho Tlhahiso ea Flooring ea SPC

Theconical twin screw barrelbakeng sa SPC fatše e fana ka melemo e mengata ea tlhahiso. Geometry ea eona ea tiisaho kopanya ho holimo le homogenization, e lebisang ho fokotseng liphoso sehlahisoa sa ho qetela. Moqomo o boloka mocheso o ts'oanang haholoanyane, o ntlafatsa boleng ba ho qhibiliha le ho tsoa. Libaka tse ngata tsa ho futhumatsa li lumella taolo e nepahetseng, e bakang botenya bo tsitsitseng le libaka tse boreleli.

Basebelisi ba hlokomela ho qhibiliha ka potlako le ho etsoa ka polasetiki, e leng ho fokotsang litekanyetso tsa matlakala le tšebeliso ea matla. Lisebelisoa tse tsoetseng pele le liphekolo tse holimo li eketsa nako e telele, e lebisang ho bophelo bo bolelele ba lisebelisoa le nako e fokolang ea ho theoha. Likarolo tsena li etsa hore conical twin screw barrel bakeng sa mokatong oa SPC e be khetho e ntle haholo bakeng sa bahlahisi ba hlokang tlhahiso ea boleng bo holimo, e tšepahalang ea SPC.

Melemo ea Conical Twin Screw Barrel bakeng sa SPC Floor

Pheliso ea Khatello le Tšebeliso ea Lintho

Theconical twin screw barrelbakeng sa SPC mokatong baka khatello e matla nakong extrusion. Khatello ena e thusa ho qhibilihisa PVC le lisebelisoa tse ling ka potlako. Moralo oa moqomo o tsamaisa thepa hantle ho tloha sebakeng sa phepelo ho ea sebakeng se qhibilihang. Basebelisi ba bona litšitiso tse fokolang le taolo e betere holim'a phallo. Moqomo o sebetsana le li-powders le li-filler habonolo, ho fokotsa kotsi ea ho ba le polasetiki e mpe kapa ho kopanya ho sa tšoaneng.

Ho Kopanya ka Katleho le Boleng ba Sehlahiswa

Baetsi ba itšetleha ka conical twin screw barrel bakeng sa SPC floor ho fihlela katleho e phahameng ea ho kopanya. Li-screws li kopanya mebala, li-modifiers le li-filler ka ho lekana. Ts'ebetso ena e thibela liphoso tse kang li-pigment tse sa arohaneng kapa likaroloana tse se nang letho. Sebopeho sa barrel se ts'ehetsa ho kopanya ka ho feletseng, e leng se lebisang ho boleng bo tsitsitseng ba sehlahisoa. Liphanele tsa fatše tsa SPC li bonts'a botenya bo ts'oanang le libaka tse boreleli.

Keletso: Ho lula u lekola boleng ba thepa e tala le moaparo oa lisebelisoa ho thusa ho thibela mathata a tloaelehileng joalo ka matheba a matšo, litšepe tse robehileng, le borokho ba ho pata.

Tšebeliso ea Matla le Litšenyehelo tsa Ts'ebetso

SZJZ-180 conical twin screw extruder model e bonts'a bokhoni bo phahameng ba tlhahiso ka litšenyehelo tse tlase tsa matla. Baetsi ba hlahisa lithane tse 80-100 tsa fatše tsa SPC letsatsi le leng le le leng ha ba ntse ba sebelisa motlakase o fokolang ho feta mefuta e meng ea extruder. Li-extruder tsa Twin screw li fana ka ts'ebetso e betere le boleng ba ho kopanya, ho bolelang ts'ebeliso e ntlafalitsoeng ea matla. Tšebeliso e tlaase ea matla e fokotsa litšenyehelo tsa ts'ebetso le ho tšehetsa tlhahiso e tsitsitseng.

Tlhokomelo le Bophelo bo Bolelele

Basebelisi ba fumana seoconical twin screw barrelhloka tlhokomelo e fokolang khafetsa. Moqomo o sebelisa litšepe tsa alloy tse matla le kalafo e tsoetseng pele ea mocheso. Likarolo tsena li eketsa ho hanyetsa ho senya le ho senya. Lisebelisoa li nka nako e telele 'me nako ea ho fokotseha e fokotseha. Ho hloekisa kamehla le ho hlahloba ho thusa ho boloka ts'ebetso le ho lelefatsa bophelo ba tšebeletso.

- Mathata a tloaelehileng a ts'ebetso a kenyelletsa:

- Matheba a matšo ho tsoa ho lisebelisoa tse tala kapa ho chesa ho feteletseng

- Litšepe tse robehileng ka lebaka la litšila kapa ho kuta ho fokolang

- Likaroloana tse se nang letho tse tsoang ho mosi o mobe kapa mocheso o tlase

- Litaba tse fosahetseng tsa ho fepa ka lebelo le sa tsamaisaneng

- Ho thibela mathata ho tsoa ho tlatsetso kapa mongobo

Baetsi ba sebetsana le mathata ana ka ho fetola mekhoa ea ts'ebetso le ho boloka lisebelisoa.

Mefokolo ea Conical Twin Screw Barrel bakeng sa SPC Floor

Meeli ea Sekala sa Tlhahiso

Hangata bahlahisi ba khetha lisebelisoa ho latela litlhoko tsa tlhahiso.Conical mafahla screw barrelsebetsa hantle bakeng sa mela ea fatše ea SPC ea boemo bo mahareng. Lifeme tse kholo li ka fumana hore li-parallel twin screw barrel li sebetsana le tlhahiso e phahameng haholoanyane. Lithupelo tse nyane ka linako tse ling li thatafalloa ho lokafatsa letsete la litsamaiso tse tsoetseng pele tsa conical. Lebelo la tlhahiso le boholo ba batch li ka fokotsa ho nepahala ha meralo ea conical bakeng sa ts'ebetso e ngoe le e ngoe.

Mathata a Tšebelisano le Lintho

Tlhahiso ea fatše ea SPCe sebelisa mefuta e fapaneng ea lihlahisoa tse tala. Li-additives tse ling kapa li-fillers li hloka ho tšoaroa ka mokhoa o khethehileng. Li-conical twin screw barrel li sebetsa hantle ka mefuta e tloaelehileng ea PVC. Leha ho le joalo, metsoako e ikhethang kapa ea liteko e ka 'na ea se sebetse hantle. Basebelisi ba tlameha ho leka lisebelisoa tse ncha pele ho tlhahiso e felletseng. Mohato ona o thusa ho qoba mathata a sa lebelloang nakong ea extrusion.

Tlhokomeliso: Kamehla buisana le litsebi tsa tekheniki ha u hlahisa lisebelisoa tse ncha ts'ebetsong ea extrusion. Teko e nepahetseng e netefatsa boleng bo tsitsitseng ba sehlahisoa.

Matsete a Pele le Lintlha tsa Litšenyehelo

Litsenyehelo tsa pele tsa conical twin screw barrel system li ka ba holimo ho feta likhetho tse ling. Boenjiniere bo nepahetseng le lisebelisoa tse tsoetseng pele li eketsa theko. Baetsi ba bang ba bona sena e le tšitiso, haholo-holo ha ba qala mela e mecha ea tlhahiso. Litšenyehelo tse tsoelang pele tsa tlhokomelo li lula li le tlase, empa letsete la pele le hloka moralo o hlokolosi. Likhamphani li lokela ho lekola melemo ea nako e telele khahlano le litšenyehelo tsa nako e khuts'oane.

Mehopolo e sebetsang bakeng sa ho khetha Moqomo o nepahetseng oa Twin Screw

Ho Bapisa Mofuta oa Moqomo le Litlhoko tsa Tlhahiso

Baetsi ba tlameha ho nahana ka lintlha tse 'maloa ha ba khetha moqomo oa marang-rang bakeng sa tlhahiso ea fatše ea SPC.

- Khetha lisebelisoa tsa barrel le liphahlo tse kang nitriding kapa bimetallic layers, ho ntlafatsa ho hanyetsa le ho lelefatsa bophelo ba tšebeletso.

- Khetha tekanyo e nepahetseng ea barrel-to-diameter (L/D). Karolelano e phahameng e eketsa katleho ea ho kopanya le ho qhibiliha, e thusang ka tlhahiso e phahameng ea lihlahisoa.

- Netefatsa taolo e nepahetseng ea mocheso le ho kopanya hantle ho boloka mocheso oa ho qhibiliha o tsitsitse le boleng ba sehlahisoa bo sa fetohe.

- Ela hloko ho senyeha ha lintho ka ho sebelisa liphahlo tse nepahetseng le ho hlophisa tlhokomelo ea kamehla.

- Sebelisa libarele tse etselitsoeng lisebelisoa tsa ho tlatsa lintho tse ngata, joalo ka PVC e nang le calcium carbonate, ho thibela li-clog le ho sebetsana le li-filler tse senyang.

- Iketsetse moralo oa barrel ho tsamaisana le moralo oa thepa le lipheo tsa tlhahiso.

- Litlhaloso tsa ho bapisa screw le barrel, joalo ka bophara le karo-karolelano ea L/D, ho sephetho se lakatsehang le boleng ba sehlahisoa.

Keletso: Tlhokomelo ea kamehla le phetoho e hlokolosi ea li-parameter tsa ts'ebetso li thusa ho boloka tlhahiso e tsitsitseng le ho fokotsa liphoso.

Katleho ea Litšenyehelo bakeng sa Boholo bo Fapaneng ba Baetsi

Theko e ntle ea libarele tse peli tsa screw e itšetlehile ka boholo ba moetsi. Tafole e ka tlase e bontša kamoo mefuta e fapaneng e lumellanang le litlhoko tse fapaneng tsa tlhahiso:

| Boholo ba Moetsi | Mohlala oa Extruder | Likarolo tsa Bohlokoa | Bokhoni ba Tlhahiso | Boemo ba boiketsetso | Lintlha tsa Tšebeliso ea Litšenyehelo |

|---|---|---|---|---|---|

| Tse nyane (li-SME) | Mohlala oa Motheo | Bolulo ba PVC bo sa sebetseng hantle | Phaello e tlase, boiketsetso ba motheo | Boiketsetso bo fokolang | Matsete a tlase a pele, a lumellana le tlhahiso e fokolang |

| Mahareng | Mohlala o tsoetseng pele | Phaello e phahameng (~ 350 kg / h), semi-automation | Tlhahiso e mahareng | Semi-automated | Ho leka-lekanya litšenyehelo le tlhahiso, e loketseng tlhahiso ea bohareng ba tekanyo |

| E kholoanyane | Mohlala oa Pro | Boleng ba Premium, automation e felletseng, karo-karolelano e tsoetseng pele ea L / D | Tlhahiso e phahameng (~500 kg/h) | Ka ho feletseng | Litsenyehelo tse phahameng tsa pele, li fokotsa bofokoli ka 40%, li ntlafatsa ts'ebetso le boleng |

Bahlahisi ba mahareng le ba kholo ba rua molemo mefuteng e tsoetseng pele e nang le boits'oaro bo phahameng le tlhahiso. Likhoebo tse nyane li ka khetha mehlala ea mantlha bakeng sa matsete a bona a tlase le ts'ebetso e bonolo.

Lintho tse Fetohang le Ho lumellana

Ho feto-fetoha ha lintho ho lula ho le bohlokoa tlhahisong ea fatše ea SPC. Hangata bahlahisi ba sebelisa PVC e kopantsoeng le maemo a phahameng a calcium carbonate le lisebelisoa tse ling. Li-barrel li tlameha ho sebetsana le li-filler tsena tse senyang ntle le ho roala ho feteletseng. Ho khetha litlolo tse nepahetseng le mefuta ea tšepe, joalo ka 38CrMoAlA kapa SKD61, e thusa ho lelefatsa bophelo ba moqomo. Basebelisi ba lokela ho beha leihlo maemo a ts'ebetso joalo ka mocheso, lebelo, le lubrication ho boloka tlhahiso e tsitsitseng le ho qoba liphoso. Ho sebelisa li-additives, tse kang ACR, ho tšehetsa polasetiki le ho boloka ho qhibiliha ho le matla nakong ea ho koloha. Tlhokomelo ea kamehla le litokiso tse hlokolosi tsa li-screw-barrel clearances li netefatsa boleng bo tsitsitseng ba sehlahisoa, leha o sebelisa lisebelisoa tse nchafalitsoeng kapa ho fetola liforomo.

The conical twin screw barrel bakeng sa SPC floor e ntse e le khetho e holimo ka 2025. Litsebi li totobatsa khetho ea thepa, ho seta mochini, le ts'ebetso ea ts'ebetso e le lintlha tsa bohlokoa.

| Ntlha | Bohlokoa |

|---|---|

| Khetho ea lintho tse bonahalang | E thibela mefokolo |

| Ho hlophisoa ha mochini | E laola boleng |

| Ntlafatso ea ts'ebetso | E netefatsa phallo e bonolo |

| Baetsi ba lokela ho bapisa lisebelisoa le litlhoko tsa bona tsa tlhahiso. |

LBH

Ke eng e etsang hore conical twin screw barrel e be e loketseng bakeng sa fatše SPC?

Sebopeho sa conical se etsa khatello e matla le ho kopanya ho babatsehang. Sena se tiisa hore ho qhibiliha ho tšoanang le liphanele tsa boleng bo holimo tsa SPC nako le nako.

Ke hangata hakae basebetsi ba lokelang ho boloka conical twin screw barrel?

Basebelisi ba lokela ho hlahloba le ho hloekisa barrel khafetsa. Baetsi ba bangata ba khothaletsa tlhokomelo lihora tse ling le tse ling tsa tlhahiso ea 1,000 bakeng sa ts'ebetso e ntle ka ho fetisisa.

A na conical twin screw barrel e khona ho sebetsana le lisebelisoa tse nchafalitsoeng?

E, ts'ebetso ea conical twin screw barrelMetsoako ea PVC e nchafalitsoengka bokgabane. Basebelisi ba lokela ho beha leihlo boleng ba thepa le ho fetola maemo a ts'ebetso bakeng sa liphetho tse ts'oanang.

Keletso: Kamehla hlahloba boleng ba thepa e tala pele u qala tlhahiso. Sena se thusa ho thibela mefokolo le ho roala ha lisebelisoa.

Nako ea poso: Aug-22-2025