Ho boloka ts'ebetso ea li-twin-screw extruder ho bohlokoa bakeng sa tlhahiso e nepahetseng. Nako ea ho phomola le ho roala li ka eketsa litšenyehelo haholo le ho senya ts'ebetso ea mosebetsi. Ho sebelisa mekhoa e netefalitsoeng ho ntlafatsa ts'ebetso le ho fokotsa litšitiso tsa ts'ebetso. Baetsi ba lokela ho etelletsa pele maano a shebaneng le libarele tsa extruder tse tšoarellang tse peli, libarele tse peli tsa parallel screw, leconical twin screw extruder barrel, hammoho le maemo a ntlafalitsoeng a ho sebetsa bakeng sa libarele tsa polasetiki tse extruder single screw.

Lisosa tsa ho Apara Libarele tse Tšoarehang tsa Twin-Screw Extruder

Sebopeho sa Lintho

Sebopeho sa thepa ea libarele tsa "twin-screw extruder" li phetha karolo ea bohlokoa ho tiiseng le ts'ebetsong ea tsona. Ho khetha thepa e nepahetseng ho ka fokotsa haholo ho roala le ho lelefatsa nako ea bophelo ea likarolo tsena. Lisosa tse tloaelehileng tsa ho roala tse amanang le sebopeho sa thepa li kenyelletsa:

| Sesosa sa Ho Apara | Tlhaloso |

|---|---|

| Khetho e fosahetseng ea thepa | Matla a sa lekaneng a ho sebetsa a screw le barrel a fokotsa nako ea bophelo ba bona. |

| Boima bo sa lekaneng ba phekolo ea mocheso | Boima bo tlaase bo potlakisa ho apara holim'a libaka tse sebetsang. |

| Ho nepahala ha machining ho tlase | Ho se otlolohe hantle le ho kenngoa ho ka lebisa ho khohlano le ho apara ka potlako. |

| Ho ba teng ha li-filler ka thepa e fetisitsoeng | Li-filler tse kang calcium carbonate kapa fiber ea khalase li mpefatsa moaparo. |

Lintho tse kopantsoeng ka har'a lisebelisoa tsa barrel li boetse li susumetsa khanyetso ho abrasion le kutu. Mohlala, Ni60 e bonts'a khanyetso e khahlang khahlano le moaparo o hlephileng, e fokotsang litheko le litšenyehelo tsa ts'ebetso. Alloy ena e boloka botšepehi ba mochine mochesong o phahameng, ho netefatsa botsitso ba ts'ebetso.

Maemo a Ts'ebetso

Maemo a ho sebetsae ama haholo ho roala ha libarele tse tšoarellang tsa twin-screw extruder. Lintho tse kang mocheso, khatello, le mofuta oa thepa e ntseng e sebetsa li ka potlakisa ho senyeha. Maemo a bohlokoa a ts'ebetso a tlatsetsang ho apara a kenyelletsa:

| Ntlha | Tlhaloso |

|---|---|

| Lisebelisoa tsa Abrasive | Ho sebetsana le metsoako e tlatsitsoeng haholo, joalo ka lipolasetiki tse tlatsitsoeng ka khalase kapa li-mineral powders, ho ka potlakisa ho roala ha li-screw le libarele. |

| Mocheso o Phahameng le Khatello | Ho pepeseha ha nako e telele mochesong o feteletseng kapa maemo a khatello e phahameng ho ka fokolisa bokaholimo ba moqomo, ho lebisa ho khoholeho ea mobu. |

| Tlhaselo ea Lik'hemik'hale | Li-polymer tse ling kapa li-additives li ka 'na tsa itšoara ka lik'hemik'hale ka lisebelisoa tsa moqomo, tsa baka kutu kapa ho phunya ha nako. |

| Tlhokomelo e Fosahetseng | Ho hlahlojoa khafetsa le ho lieha ho lokisoa ho etsa hore liaparo tse nyane li fetohe tšenyo e kholo. |

Ho feto-fetoha ha mocheso le khatello nakong ea ts'ebetso le hona ho ka ama bophelo ba libarele tsa "twin-screw extruder" haholo. Lithempereichara tse phahameng tsa ts'ebetso, hangata tse kaholimo ho 200 ° C, li kopantsoe le khatello e phahameng, li kenya letsoho ho taboheng le ho bola ha barrel le screw. Liphello tse senyang tsa ho qhibiliha le khatello ea mochine nakong ea ts'ebetso li mpefatsa litaba tsena, tse lebisang ho lahleheloa ke thepa le ho hlōleha ho qetella.

Lintlha tsa Khatello ea Mechini

Mabaka a khatello ea mochine ke ntlha e 'ngoe ea bohlokoa e tlatsetsang ho hloleheng pele ho nako ka har'a libarele tsa "twin-screw extruder". Likhatello tsena li ka hlaha ka lebaka la maemo a fapaneng a ts'ebetso, ho kenyelletsa:

- Ho roaleha ho bakoang ke likaroloana tse thata ka har'a sekoti sa polymer eroding le holim'a barrel.

- Ho roala ha mocheso ho bakoang ke mocheso o feteletseng le ho futhumala ho sa lekaneng ha silinda.

- Ho khathala ho bakoang ke khatello ea maikutlo khafetsa le linako tsa khatello, ho fokolisa likarolo tsa screw ka nako.

Ho kenya libaesekele ho ka boela ha kenya letsoho mokhathala le ho roala likarolo tsa li-barrel tse peli-screw extruder.Likhatello tsa torsional le ho kobehae ka qala le ho jala mapetsong, ha li-deposit tse mahoashe tsa carbide li lebisa ho li-micro-cracks holim'a shaft. Litšitiso tse kang likoti le li-sediments li tlatsetsa khōlong e potlakileng ea crack le ho hlōleha.

Ho utloisisa lisosa tsena tsa ho roala libarele tse tšoarellang tsa twin-screw extruder ho lumella bahlahisi ho kenya tšebetsong maano a sebetsang bakeng sa tlhokomelo le ho ntlafatsa, qetellong ba ntlafatsa katleho ea tlhahiso.

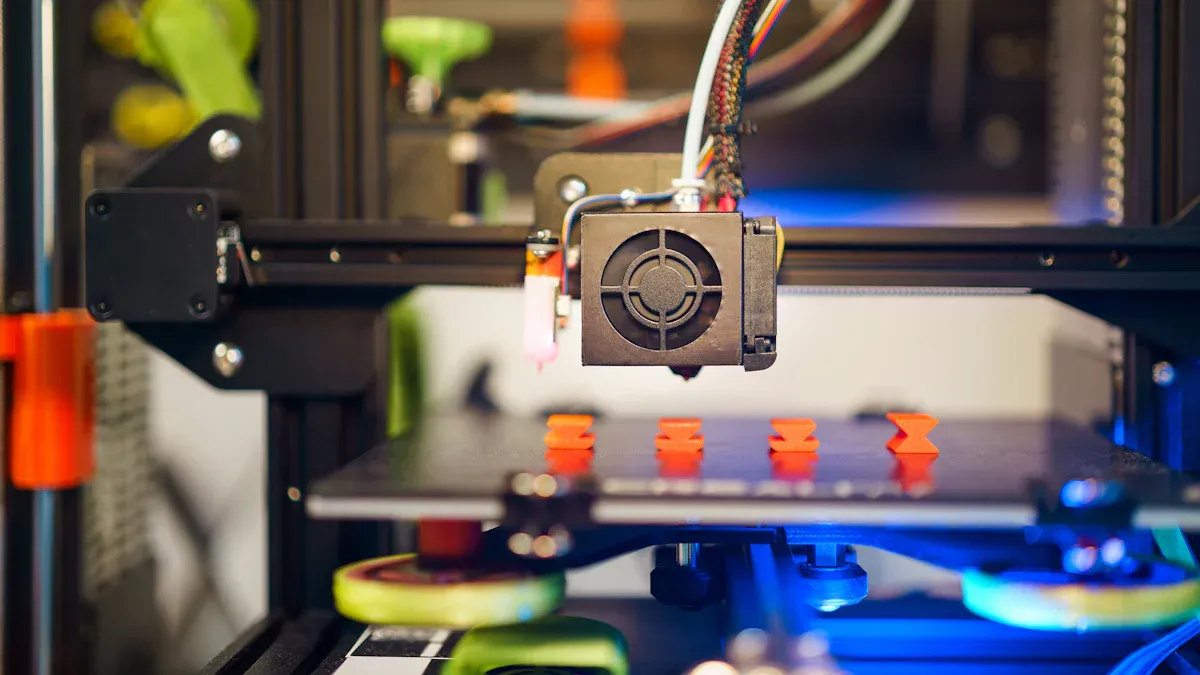

Matshwao a ho Wear ho Sheba ka Melaneng ya Twin-Screw Extruder

Ho Fokotsa Ts'ebetso

Basebelisi ba lokela ho lekola ts'ebetso ea ts'ebetso ka hloko ho li-extruder tsa twin-screw. Matšoao a pele a kenyelletsa:

- Keketseho ea tumello ea ho fofa ka lebaka la ho senyeha ha malebela a sefofane.

- Tlhokahalo ea ho eketsa lebelo la screw ho boloka sekhahla sa phallo se sa feleng.

- Lithempereichara tse phahameng tse hlahisoang ke ho fokotseha ha coefficient ea ho fetisa mocheso.

Ho senyeha ha ts'ebetso ho ka ama boleng ba sehlahisoa haholo. Ka mohlala, ho fapana ha mocheso ho ka thibela ho senyeha ha thepa e sa utloeng mocheso, ho netefatsa hore ho qhibiliha ho tšoanang. Kamano pakeng tsa lebelo la screw le torque e boetse e ama ho kuta e sebelisoang nakong ea ts'ebetso. Mabelo a phahameng a ka ntlafatsa ho kopanya empa a ka lebisa ho futhumala ho feteletseng.

| Ntlha | Tšusumetso ho boleng ba Sehlahisoa |

|---|---|

| Mocheso | E thibela ho senyeha ha thepa e thibelang mocheso le ho netefatsa ho qhibiliha ho tšoanang. |

| Screw Speed le Torque | E ama ho kuta e kentsoeng; mabelo a phahameng a ntlafatsa ho kopanya empa a ka baka ho futhumala ho feteletseng. |

| Ho Hlakola ka Katleho | E tlosa likhase tse koaletsoeng, e thibela mefokolo le ho etsa bonnete ba hore lintho li lumellana le matla. |

Lipontšo Tsa Tlhahlobo ea Pono

Litlhahlobo tse bonoang ke tsa bohlokoa bakeng sa ho bona ho roala ha libarele tsa mafahla a li-extruder. Basebelisi ba lokela ho batla:

- Bokaholimo ba Delamination: Mekhahlelo e fokolang e ka hlaha e le e ebolang kapa e phuphuselang.

- Ho fetoha mmala: Li-streaks tsa mebala kapa li-patches tse sa tloaelehang li ka bontša matla a fokotsehileng.

- Splay Marks: Silvery kapa cloudy streaks e fana ka maikutlo a likarolo tse brittle le ho se amehe hantle.

Ho bohlokoa ho hlahloba matšoao a hlakileng a tšenyo ea bokaholimo, joalo ka li-grooves tse tebileng holim'a li-screw elements. Basebelisi ba boetse ba lokela ho hlahloba hore na ha ho na tšenyo e khōlō ea mochine karolong e ka hare ea moqomo 'me ba hlahlobe hore na ha ho na mapetsong a ntlha ea screw shaft.

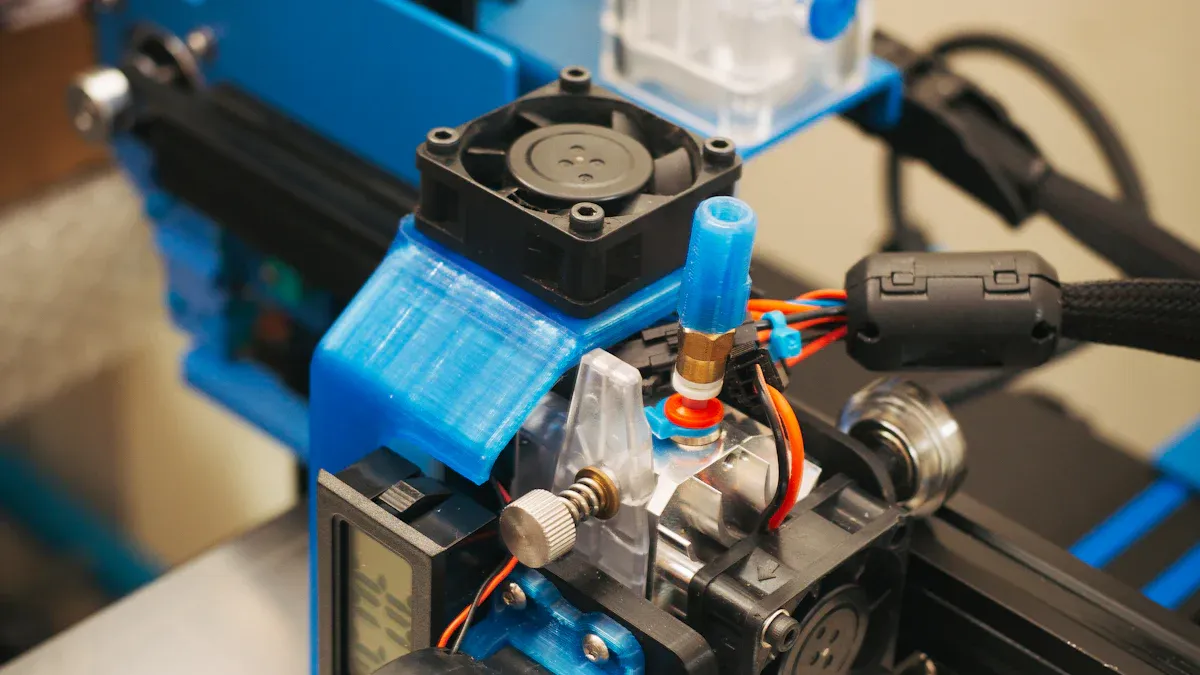

Tekanyo ea Mamello

Litekanyo tse tloaelehileng li thusa ho lekola boemo ba libarele tsa twin-screw extruder. Mekhoa e khothalelitsoeng e kenyelletsa:

- Ho hloekisa ka botebo barele ea extruder ka likarolo tsa ho hloekisa.

- Ho sebelisa sekala sa "dial bore gauge" le micrometer ho lekanya li-intshi tse ling le tse ling tse peli ho isa ho tse tharo ho theosa le moqomo.

- Ho hlahloba sebaka sa lesoba la phepelo bakeng sa mapetsong, matheba a ho hlatsoa, ho kobeha, le liphoso tse ling.

Basebelisi ba lokela ho lekanya bolelele ba kakaretso ka ho sebelisa teipi ho tloha pheletsong ea nko ho isa pheletsong ea nko. Ba boetse ba lokela ho lekanya bolelele ba shank le bolelele ba ho jara. Ho sebelisa lisebelisoa tse kang dial caliper le micrometer ho netefatsa litlhahlobo tse nepahetseng tsa moaparo.

- Tekanyo ea Tape

- Sehlopha sa li-Calipers

- Letsetsa Caliper

- 0-7 ″ li-Micrometer

- .500″ e tenya parallel bar

- 25' Tekanyo ea Theipi

Litharollo tse Atlehang tsa ho Fokotsa Nako ea ho Phokotsa Nako ka Meqomong ea Twin-Screw Extruder

Ho ntlafatsa ts'ebetso ea li-twin-screw extruder, bahlahisi ba tlameha ho kenya tšebetsong litharollo tse sebetsang tse fokotsang nako. Litharollo tsena li kenyelletsa maano a khetho ea thepa, maemo a ntlafetseng a ts'ebetso, le mekhoa ea thibelo ea tlhokomelo.

Maano a Khetho ea Lintho

Ho khetha thepa e nepahetsengbakeng sa libarele tsa "twin-screw extruder" li bohlokoa bakeng sa bophelo bo bolelele le ts'ebetso. Tafole e latelang e bontša mefuta e fapaneng ea lisebelisoa le melemo ea tsona ea bohlokoa:

| Mofuta oa Boitsebiso | Melemo ea Bohlokoa |

|---|---|

| Tšepe ea carbon | Ho tšoarella ha motheo |

| Ts'epe e sa beng le mabali | Khanyetso e ntle ea kutu |

| Tšepe ea motsoako | Lisebelisoa tse ntlafalitsoeng tsa mochini |

| Tšepe ea phofo ea metallurgy | Ho apara ka mokhoa o phahameng le ho hanyetsa kutu, sebopeho se setle sa lijo-thollo, matla a phahameng a mochine, bophelo bo bolelele ba tšebeletso |

Ho sebelisa litlolo tse tsoetseng pele kapa kalafo ea holim'a metsi ho ka ntlafatsa le ho feta ho hanyetsa ho apara. Mohlala, liphekolo tsa nitriding li ka lelefatsa bophelo ba li-screws ka makhetlo a mabeli ho isa ho a mararo. Ho feta moo, chromium le molybdenum plating li matlafatsa ho thatafala le ho se mamelle, ho ntlafatsa haholo ts'ebetso ea moqomo.

Optimized Processing Conditions

Ho theha libaka tse loketseng tsa ho sebetsa ho bohlokoa bakeng sa ho boloka ts'ebetso e tsitsitseng ea thepa. Ho kenya ts'ebetsong mekhoa e tloaelehileng ea ts'ebetso ho ka laola mekhoa ea ts'ebetso ka katleho. Litharollo tse latelang li ka ntlafatsa maemo a ts'ebetso:

- Laola Mocheso le Khatello: Boloka mocheso o tsitsitseng le khatello ea ho thibela ho roala ha mocheso le ho etsa bonnete ba ho phalla ha lintho tse tsitsitseng.

- Lekola Sebopeho sa Lintho: Kamehla hlahloba sebopeho sa lisebelisoa tse ntseng li sebetsoa ho qoba ho roala ho tsoa ho li-fillers.

- Fetola Lebelo la Screw: Ntlafatsa lebelo la screw ho leka-lekanya katleho ea ho kopanya le ho hlahisa mocheso, ho thibela ho chesa haholo.

Ka ho sebelisa mekhoa ena, bahlahisi ba ka fokotsa haholo ho roala libarele tse tšoarellang tsa twin-screw extruder le ho ntlafatsa katleho ea tlhahiso ka kakaretso.

Mekhoa ea Thibelo ea Tlhokomelo

Moralo o tiileng oa tlhokomelo o bohlokoa bakeng sa ho fokotsa nako e sa reroang. Tafole e latelang e totobatsamekhoa e sebetsang ea ho thibela ho boloka:

| Itloaetse | Tlhaloso |

|---|---|

| Mananeo a Tloaelo a Tlhokomelo | Tlhokomelo ea kamehla e tiisa hore mechini e sebetsa hantle 'me e qoba ho senyeha ho sa lebelloang. |

| Koetliso ea Basebetsi | Basebelisi ba rutehileng ba ka tseba matšoao a pele a ho khathala le ho rarolla mathata a manyane pele a ka mpefala. |

| Spare Parts Inventory | Ho boloka lethathamo la likarolo tsa bohlokoa ho netefatsa litokiso tse potlakileng le ho fokotsa nako ea ho theoha. |

| Lisebelisoa tsa boleng bo holimo | Likarolo tse entsoeng ka thepa e tšoarellang li ntlafatsa ts'ebetso le ho fokotsa litlhoko tsa tlhokomelo. |

| Lubrication e nepahetseng | Lisebelisoa tsa boleng bo holimo li fokotsa khohlano, li lelefatsa bophelo ba likaroloana, 'me li ntlafatsa ts'ebetso e akaretsang. |

| Litlhahlobo Tsa Kamehla | Ho hlahloba hore na ha ho na ho senyeha ho ka thibela ho lokisoa ha theko e boima le nako e fokolang, ho boloka boleng bo tsitsitseng ba sehlahisoa. |

Litlhahlobo tsa tlhokomelo li lokela ho etsahala khafetsa ho ntlafatsa nako ea ts'ebetso ea libarele tse peli tsa screw extruder. Mohlala, ho fetola oli le oli e tlotsang lihora tse ling le tse ling tse 4000 le ho hlahloba liaparo tsa kotara ho ka thibela mathata a bohlokoa.

Ka ho kenya ts'ebetsong litharollo tsena tse sebetsang hantle, bahlahisi ba ka fokotsa nako ea ho theoha haholo le ho ntlafatsa katleho ea mesebetsi ea bona ea mafahla-screw extruder.

Baetsi ba ka fokotsa haholo nako ea ho theoha le ho apara ka ho sebelisa mekhoa e sebetsang ea tlhokomelo. Litlhahlobo tsa khafetsa, licheke tsa ho tlotsa, le litokiso tse nakong li netefatsa ts'ebetso e nepahetseng.Ho theha likamano tse matla tsa bafani ba thepae matlafatsa phihlello ea likarolo tsa boleng bo holimo le tšehetso ea litsebi. Tšebelisano ena e fana ka litharollo tse ikhethileng tse lumellanang le litlhoko tse ikhethileng tsa ts'ebetso, 'me qetellong li tsamaisa tlhahiso le katleho.

Liketso tsa Tlhokomelo ea Bohlokoa:

- Litlhahlobo tsa pono tsa letsatsi le letsatsi le licheke tsa lubrication

- Litlhahlobo tsa khoeli le khoeli tsa screw le barrel

- Liphetoho tsa selemo le selemo tsa sistimi e felletseng

Ka ho beha mekhoa ena pele, bahlahisi ba ka fumana katleho ea ts'ebetso ea nako e telele.

LBH

Sesosa se ka sehloohong sa ho roala libarele tsa twin-screw extruder ke eng?

Lebaka le ka sehloohong la ho roala le bakoa ke ho hlophisoa ha thepa, maemo a ts'ebetso, le mabaka a khatello ea mochine nakong ea ts'ebetso.

Ke hangata hakae ke lokelang ho hlahloba libarele tsa "twin-screw extruder"?

Hlahloba libarele tsa "twin-screw extruder" khafetsa, hantle khoeli e 'ngoe le e 'ngoe, ho tseba hore na li senyehile le ho thibela ho lokisoa ho bitsang chelete e ngata.

Ke lisebelisoa life tse molemo ka ho fetisisa bakeng sa libarele tsa twin-screw extruder?

Alloy steel le powder metallurgy steel li fana ka khanyetso e phahameng ea ho apara le ho tšoarella nako e telele, e matlafatsang nako ea bophelo ea libarele tsa mafahla a extruder.

Nako ea poso: Sep-05-2025