Ho hlahisa screw e le 'ngoe ho sebelisa screw e le 'ngoe e potolohang, ha twin screw extrusion e itšetlehile ka li-intermeshing screws bakeng sa motsoako o matlafalitsoeng. Phapang ena e ama boleng ba sehlahisoa le taolo ea ts'ebetso. Bakeng sa tlhahiso e bonolo, e phahameng, aMoqomo o le Mong oa Plastic Screwe loketseng litlhoko tse ngata.Libarele tsa Twin Screw ExtruderleLi-Screws tsa Mafahla Bakeng sa Plastic Extrudersipabola motswakong o rarahaneng.

Ho Hlalosoa ha Screw e le 'Ngoe

Kamoo Sing Screw Extrusion e Sebetsang Kateng

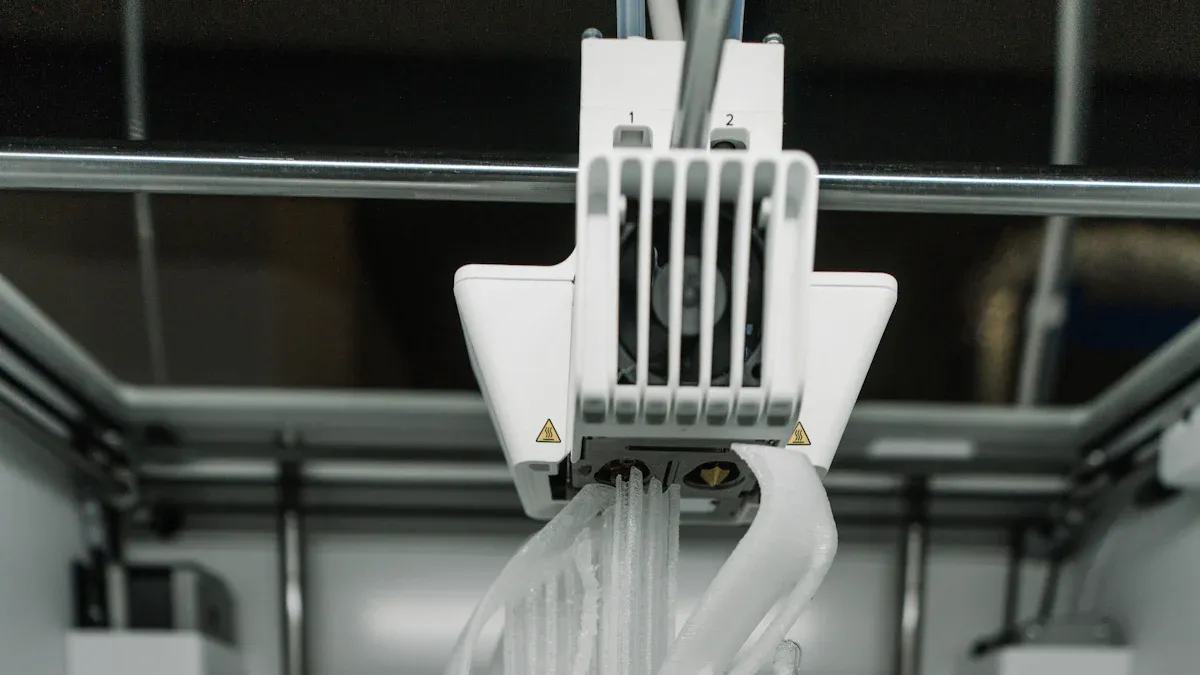

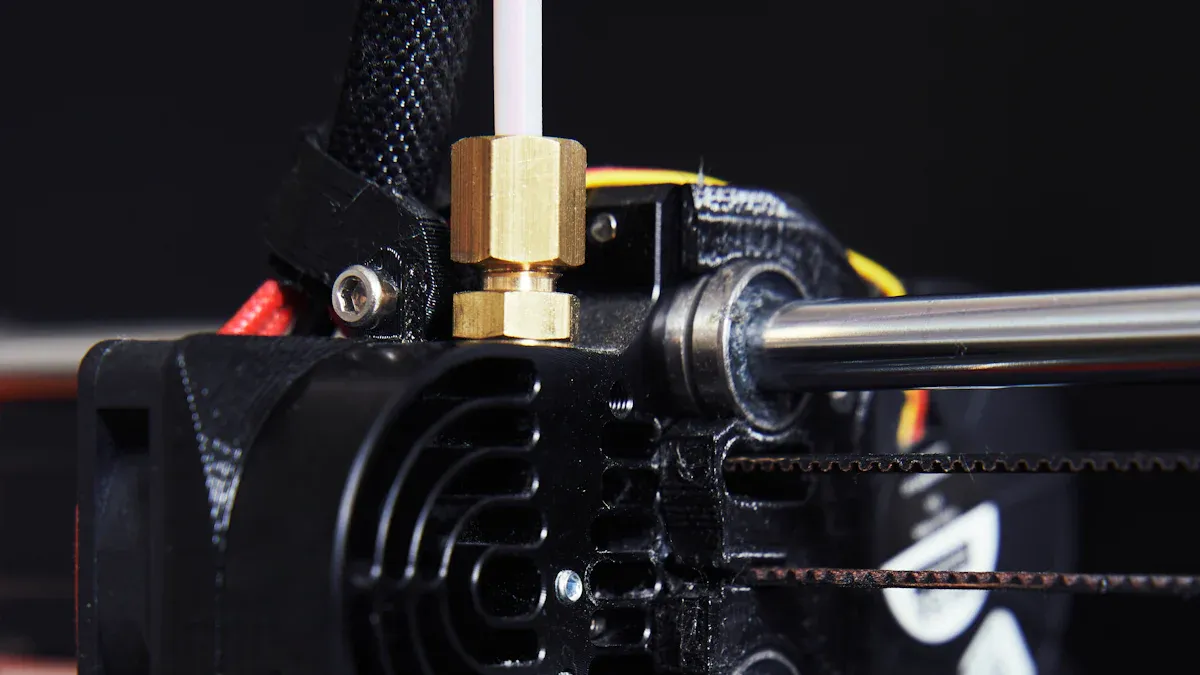

Sekurufu se le seng se sebelisa screw e le 'ngoe e potolohang ka har'a barrel e futhumetseng. Sekurufu se tsamaisa polasetiki e tala kapa thepa ea rabara pele, moo khohlano le mocheso li qhibilihang teng. Thepa e qhibilihisitsoeng e feta ka har'a moferefere ho etsa sebopeho se tsoelang pele. Basebelisi ba laola maemo a bohlokoa a ts'ebetso joalo ka mocheso oa moqomo (hangata 160-180 ° C), lebelo la sekoti, le mocheso o shoang. Lebelo la yuniti ea ho nka le mocheso oa tanka ea metsi li thusa ho laola bophara ba sehlahisoa sa ho qetela le ho bata. The screw e sebetsamesebetsi e meraro ea mantlha: ho tsamaisa, ho qhibilihisa, le ho kopanya. Moralo oa moqomolikarolo tse kang hard tempering le chrome plating li fokotsa khohlano le ho khomarela, ho netefatsa ts'ebetso e bonolo.

Melemo ea Single Screw Extrusion

Baetsi ba khethaextrusion ea sekoti se le sengbakeng sa bonolo ba eona le katleho ea eona. Moqapi o lumella ho sebetsa habonolo le tlhokomelo. Matsete a tlase a pele le litšenyehelo tsa ts'ebetso li etsa hore e khahle likhoebo tse ngata.Matla a matlae hlahella, kaha sistimi e sebelisa futhumatsang e ntlafalitsoeng le likarolo tse fokolang tse tsamaeang. Basebelisi ba ka fumana boleng bo ts'oanang ba sehlahisoa ka ho fetola mocheso, khatello le lebelo la screw. Sistimi e sebetsana le mefuta e mengata ea lihlahisoa tse tala, e etsa hore e be le maemo a fapaneng bakeng sa litlhoko tse fapaneng tsa tlhahiso.

Keletso: Tlhokomelo ea kamehla le ho beha leihlo matla ka nako ea 'nete li ka ntlafatsa ts'ebetso le boleng ba sehlahisoa.

Meeli ea Single Screw Extrusion

Extrusion ea screw e le 'ngoe e tobane le mathata. Phello e ka 'na ea fetoha e sa tsitsang ka lebelo le phahameng la screw, ho fokotsa litekanyetso tsa tlhahiso. Ho boloka mocheso oa ho qhibiliha le homogeneity ea lihlahisoa ho ka ba thata, haholo-holo ka thepa e rarahaneng. Ts'ebetso e ka 'na ea thatafalloa ke ho kopanya lintho tse tsoetseng pele kapa metsoako e hlokang taolo e nepahetseng. Boitšoaro ba phepelo le ts'ebetso e boetse e its'etleha haholo holim'a moralo oa li-screw le geometry ea ho bula phepelo.

Lisebelisoa tse Tloaelehileng tsa Single Screw Extrusion

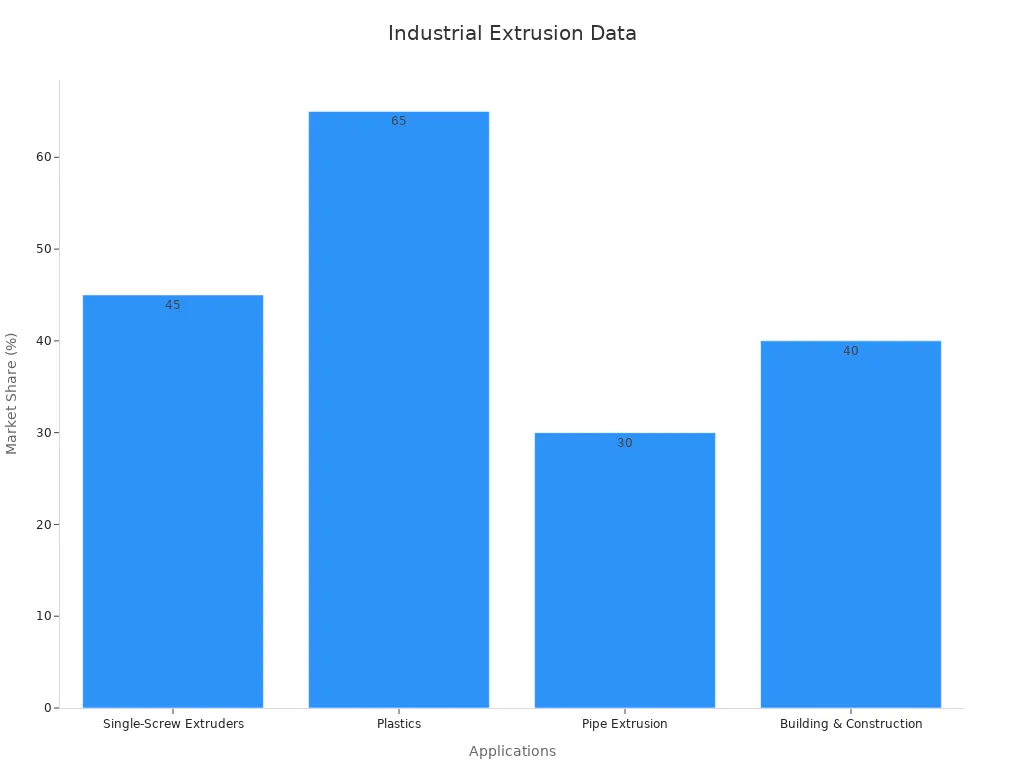

Single screw extrusion e fumana ts'ebeliso liindastering tse ngata. Ho paka ho etella pele 'maraka, ka karolo e ka bang 60%, ho hlahisa lifilimi le maqephe ho tsoa ho li-polymers tse kang PE, PP, le PVC. Lefapha la kaho le e sebelisa bakeng sa liphaephe le litlaleho, ha baetsi ba likoloi ba itšetlehile ka eona bakeng sa likarolo tsa ka hare le tsa ka ntle. Liindasteri tsa bongaka, thepa ea bareki le tsa elektroniki le tsona li rua molemo theknolojing ena.

| Mofuta oa Mohlala | Screw Diameter (mm) | L:D Karolelano | Matla a Enjene (kW) | Bokhoni ba tlhahiso (kg/hr) | Lintlha ka Sebetsa le Maemo |

|---|---|---|---|---|---|

| Screw e le 'ngoe e sebetsang hantle haholo | 60 - 120 | 38:1 | 110 - 315 | 465 - 1300 | 20-30% tekanyo e phahameng; Siemens AC motors, CE-certified |

| Tloaelehileng Standard Sing Screw | 60 - 120 | 33:1 | 55 - 315 | 150-900 | Likarolo tsa boleng bo tloaelehileng |

Kakaretso ea Twin Screw Extrusion

Kamoo Twin Screw Extrusion e Sebetsang Kateng

Sekorufu sa mafahlae sebelisa likurufu tse peli tsa intermeshing tse potolohang ka har'a moqomo o futhumetseng. Basebelisi ba fepa lisebelisoa tse tala joalo ka li-pellets kapa phofo ka har'a hopper. Li-screws li tsamaisa thepa pele, li e hatella le ho e luba. Mocheso o tsoang moqomong le likhohlano tse tsoang ho li-screws li qhibilihisa thepa. Lintho tse khethehileng tsa screw li kopanya le ho etsa homogenize ho qhibiliha, ho netefatsa hore esita le ho hasana ha li-additives. Joale ntho e entsoeng ka ho qhibilihisoa e feta ka har'a setofo ho etsa sehlahisoa sa ho qetela. Libarele tsa modular tse nang le libaka tse futhumatsang le tse pholileng li lumella taolo e nepahetseng ea mocheso. Libaka tsa moea li tlosa moea le li-volatile, ho ntlafatsa boleng ba sehlahisoa.

Matla a Twin Screw Extrusion

Twin screw extrusion e fana ka melemo e mengata:

- Ho kopanya ho holimo le homogenization ka lebaka la li-screws tsa intermeshing.

- Matla a phahameng a ho kutantlafatsa ho kopanya le ho lumellana ha lihlahisoa.

- Moralo oa modular o lumella phetoho e bonolo bakeng sa lisebelisoa tse fapaneng.

- Taolo e ntlafalitsoeng ea mocheso e fokotsa ho senyeha ha mocheso.

- Tlhahiso e phahameng le tlhahiso e tšehetsa tlhahiso e kholo.

- Litlhophiso tse bonolo tsa screw li ntlafatsa ts'ebetso ea lipolymer tse fapaneng.

- Taolo e ntle ea ts'ebetso ka phetoho e ikemetseng ea lebelo la screw le mocheso.

- Bophelo ba nako e telele ea lisebelisoa ha mojaro o arolelanoa pakeng tsa li-screw tse peli.

| Sebopeho sa Theknoloji | Tlhaloso |

|---|---|

| Superior Mixing & Homogenization | Li-screws tsa intermeshing li etsa sekiri le litlamorao tsa ho luba bakeng sa ho kopanya junifomo. |

| Phaello e Phahameng & Tlhahiso | Li-screws tse pota-potileng li etsa hore ho be le litekanyetso tse phahameng tsa tlhahiso le katleho. |

| Ho feto-fetoha ha maemo | E khona ho sebetsana le li-polymer tse fapaneng le libopeho tse rarahaneng. |

Mefokolo ea Twin Screw Extrusion

- Li-extruder tse peli tsa screw li na le sebopeho se rarahaneng le litšenyehelo tse phahameng.

- Ho phalla ha thepa ka hare ho extruder ho thata ho etsa mohlala le ho bolela esale pele.

- Ho fetoha ha khatello ho ka etsahala ka lebaka la screw geometry.

- Ho beha leihlo boholo ba likaroloana le botsitso ba tšebetso ho hlahisa mathata.

- Ho nyoloha ho tloha lab ho ea ho tlhahiso ho hloka phetoho e hlokolosi.

Tšebeliso e Tloaelehileng bakeng sa Twin Screw Extrusion

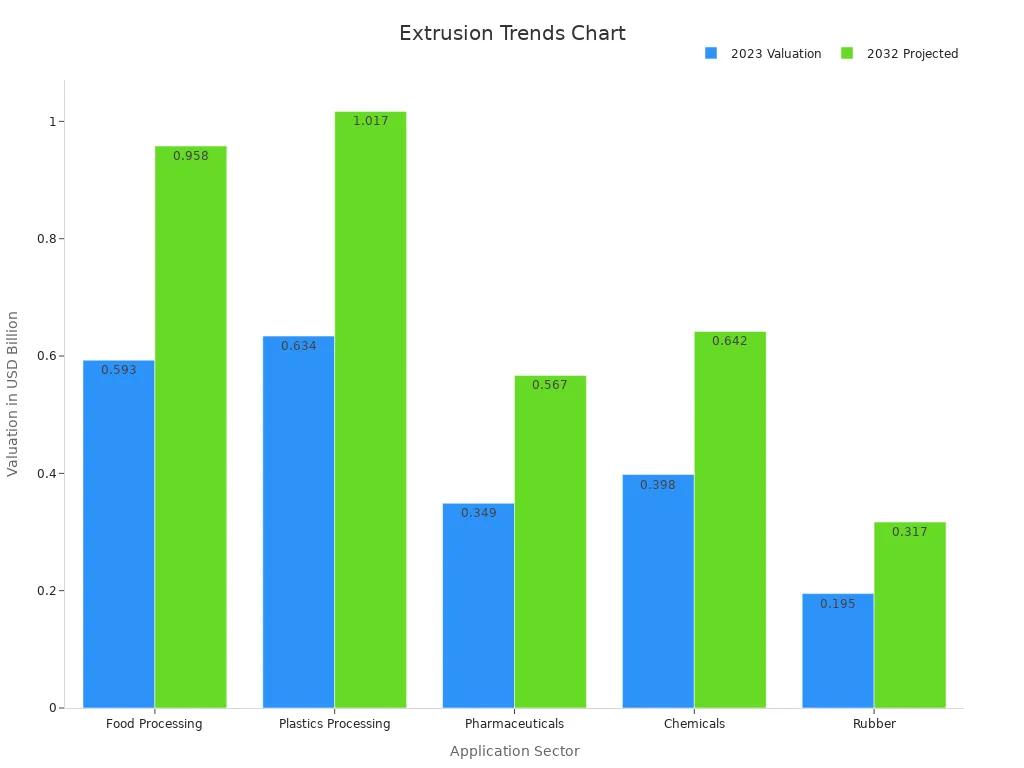

Li-twin screw extruder li bapala karolo ea bohlokoa liindastering tse ngata. Baetsi ba li sebelisa bakeng sa ho kopanya lipolasetiki, ho lokisa thepa e tsosolositsoeng, le ho hlahisa bioplastics. Indasteri ea lijo e itšetlehile ka tsona bakeng sa lijo tse bobebe, lijo-thollo le lijo tsa liphoofolo tse ruuoang lapeng. Likhamphani tsa meriana li sebelisa twin screw extrusion ho etsa mefuta e tiileng ea litekanyetso. Makala a lik'hemik'hale le rabara le 'ona a rua molemo ho tsoakaneng le taolong ea ona e nepahetseng. Mmaraka oa li-screw extruder tse peli o ntse o hola, o tsamaisoa ke tlhoko ea Asia-Pacific, Europe le Amerika Leboea.

Single Screw Extrusion vs Twin Screw Extrusion: Lipapiso tse ka Sehloohong

Phapang ea Moralo le Mecha

Extrusion ea screw e le 'ngoee sebelisa screw e le 'ngoe e pota-potileng ka mokhoa o bonolo oa helical. Moralo ona o sutumelletsa thepa pele ka har'a moqomo. Ka lehlakoreng le leng, li-fin screw extruder li na le li-screws tse peli tse intermeshing. Li-screw tsena li ka potoloha ka tsela e ts'oanang kapa e fapaneng 'me hangata li kenyelletsa li-blocks bakeng sa ho kopanya hantle. Tafole e ka tlase e totobatsa liphapang tse kholo tsa tekheniki:

| Karolo | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Screw Design | Sekurufu se le seng se bilikang se nang le paterone e bonolo ea helical e sutumelletsang thepa pele. | Li-screws tse peli tsa intermeshing, mohlomong li kopane kapa li pota-pota, tse nang le lijeometri tse rarahaneng tse kenyeletsang li-blocks. |

| Ho Kopanya Bokgoni | E loketse lisebelisoa tsa homogeneous le ho kopanya habonolo. | Ho kopanya ho holimo ka lebaka la li-screws tsa intermeshing, ho nolofalletsang ho hasana ho molemo ha li-additives le li-filler. |

| Sephetho le Sephetho | Ka kakaretso ho theola sekhahla sa tlhahiso le sephetho. | Tlhahiso e phahameng le tlhahiso, e loketseng tlhahiso e kholo. |

| Taolo ea Mocheso | Taolo ea mantlha holim'a mocheso, lebelo la screw, le khatello ea moqomo. | Taolo e ntlafalitsoeng ea mocheso ka libaka tse futhumatsang / tse pholileng haufi le barrel. |

| Ho Tšoara Lintho | E sebetsa hantle bakeng sa thermoplastics, elastomers, le polasetiki e sebelisoang hape e nang le boleng bo sa fetoheng ba sehlahisoa. | E loketse hantle bakeng sa li-viscosity tse phahameng, tse thibelang mocheso, le libopeho tse rarahaneng tse hlokang taolo e nepahetseng. |

| Mokhoa oa ho Fetolana | Ts'ebetso e bonolo, e bonolo le tlhokomelo. | Ho tenyetseha ho hoholo ka lebaka la moralo oa screw oa modular le liparamente tse feto-fetohang. |

| Degassing Bokhoni | Matla a fokolang a ho senya le ho senya. | Ho senya ka katleho le ho senya, ho bohlokoa bakeng sa taolo ea boleng. |

| Mehlala ea Tšebeliso | Lifilimi tsa polasetiki, liphaephe, ho kopanya, ho roala terata, extrusion ea lakane, ho lokisa lijo. | Ho kopanya polymer, ho lokisa lijo, meriana, le ho lokisa thepa e rarahaneng. |

Bafuputsi ba kang Shen et al. le Sastrohartono et al. li bonts'itse hore li-extruder tse mafahla li fana ka likarolo tse tsoetseng pele tsa moralo, joalo ka ho cheka ho betere le ho sebetsa hantle ha matla, haholo bakeng sa lisebelisoa tse rarahaneng.

Ho Kopanya le Ho sebetsa Matla

Bokhoni ba ho kopanya le ho sebetsa bo arola mahlale ana a mabeli. Single screw extrusion e sebetsa hantle bakeng sa lisebelisoa tse bonolo, tse homogeneous. E khona ho sebetsana le mesebetsi ea mantlha ea ho kopanya, empa e loantšana le ho tsoakoa ho tsoetseng pele kapa libopeho tse hlokang taolo e nepahetseng. Li-extruder tsa twin screw li ipabola ho tsoakeng. Li-screws tsa tsona tsa intermeshing li etsa hore ho be le matla a ho kuta le ho luba. Ketso ena e tiisa esita le ho hasana ha li-additives le li-filler, tse bohlokoa bakeng sa lihlahisoa tsa boleng bo phahameng. Basebelisi ba ka fetola likarolo tsa screw le libaka tsa barrel ho lokisa ts'ebetso ea lisebelisoa tse fapaneng. Ka lebaka leo, li-screws tsa mafahla li tšehetsa litlolo tse rarahaneng le litlhoko tse hlokahalang tsa tlhahiso.

Tlhokomeliso: Bakeng sa bahlahisi ba hlokang ho kopanya li-polymer tse ngata kapa ho eketsa li-filler, li-extruder tsa mafahla li fana ka monyetla o hlakileng oa ho kopanya ts'ebetso.

Tšebeliso le Sebetsa

Ts'ebetso le katleho li bapala karolo e kholo ho khethoeng lipakeng tsa litsamaiso tsena. Single screw extrusion hangata e fana ka ts'ebetso e tlase, e e etsa hore e tšoanele lipehelo tse nyane tsa tlhahiso. E sebetsa ka lebelo le tlase la ho sebetsa 'me e fana ka liphetho tse tsitsitseng bakeng sa lihlahisoa tse tloaelehileng. Ka lehlakoreng le leng, li-extruder tsa twin screw li fihlella ho feta le lebelo la ho sebetsa ka potlako. Li tšehetsa litlhoko tse kholo tsa bokhoni le ho boloka boleng ba sehlahisoa esita le ka granulation e rarahaneng. Tafole e ka tlase e bapisa metrics ea bohlokoa:

| Metric | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Phello | Phaello e tlase, e loketseng lipehelo tse tlase tsa tlhahiso | Phallo e phahameng, e loketseng litlhoko tse kholo tsa bokhoni |

| Ho sebetsa Lebelo | Ho sebetsa butle ka lebelo | Lebelo la ho sebetsa ka potlako |

| Boleng ba Sehlahiswa | Matla a fokolang a ho kopanya, granulation e fokolang haholo | Ho kopanya ho ntlafatsa, ho tšehetsa granulation e rarahaneng |

| Litšenyehelo tsa Ts'ebetso | Litsenyehelo tse tlase tsa ts'ebetso ka lebaka la bonolo le matla a matla | Litšenyehelo tse phahameng tsa ts'ebetso ka lebaka la ho rarahana le tlhokomelo |

| Ho tenyetseha | Ts'ebetso e fokolang, e bonolo haholoanyane | Ho feto-fetoha ho hoholo, ho ka sebetsana le libopeho tse rarahaneng |

| Litefiso tse hlahisoang | Ka kakaretso litheko tse tlase tsa tlhahiso | Litefiso tse phahameng tsa tlhahiso |

Hangata li-extruder tsa Twin screw li lokafatsa litšenyehelo tsa tsona tse phahameng tsa ts'ebetso ka tlhahiso e eketsehileng le bokhoni ba ho sebetsana le lisebelisoa tse thata haholoanyane.

Ho feto-fetoha ha maemo le ho feto-fetoha ha maemo

Ho tenyetseha le ho feto-fetoha ha maemo ho bohlokoa bakeng sa tlhahiso ea sejoale-joale. Single screw extrusion e fana ka ts'ebetso e tšepahalang bakeng sa lihlahisoa le lisebelisoa tse tloaelehileng. Leha ho le joalo, e fana ka ho feto-fetoha ha maemo ha ho fetoha pakeng tsa mefuta e fapaneng ea libopeho kapa mefuta ea lihlahisoa. Li-extruder tse peli tsa screw li hlahella sebakeng sena. Pontšong ea khoebo ea K 2016, likhoele tse tsoetseng pele tse peli li bonts'itse liphetoho tse potlakileng lipakeng tsa thepa, mebala le botenya. Litsamaiso tse ling li fetotse lifomate ka metsotso, eseng lihora. Li-extruder tsena li ile tsa sebetsana le lifilimi tse nang le likarolo tse ngata tse nang le likarolo tse ka bang 11, tse sebetsanang le lisebelisoa tse kang EVOH, nylon le limaraka tse fapaneng tsa polyethylene. Lintlha tsa tlhahiso li bonts'itse aPhokotso ea 45.8% ea litšila tsa lintho tse bonahalangle hoo e ka bang 29% ea ho baballa matla ka mor'a ho ntlafatsoa ho ea ho li-flexible twin screw systems. Puseletso ea nako ea matsete le eona e khutsufalitsoe ka ho feta 26%. Lintlafatso tsena li totobatsa melemo ea ts'ebetso ea li-twin screw extruder libakeng tse rarahaneng, tse nang le lisebelisoa tse ngata.

Litšenyehelo le Tlhokomelo

Litšenyehelo le tlhokomelo li susumetsa qeto ea ho qetela ho bahlahisi ba bangata. Sistimi e le 'ngoe ea extrusion ea screw e bitsa chelete e tlase ho reka le ho sebetsa. Moqapi oa bona o bonolo o bolela likarolo tse fokolang tsa ho boloka le ho fokotsa tšebeliso ea matla. Tlhokomelo ea kamehla e bonolo, 'me nako ea ho phomola e lula e le nyenyane. Li-extruder tse peli tsa screw li hloka matsete a holimo. Sebopeho sa bona se rarahaneng le likarolo tse tsoetseng pele li lebisa litlhoko tse eketsehileng tsa tlhokomelo le tšebeliso e phahameng ea matla. Leha ho le joalo, bakeng sa lik'hamphani tse hlahisang lihlahisoa tsa boleng bo phahameng kapa tse rarahaneng, melemo ea ho feto-fetoha ha maemo, ho feta, le boleng hangata e feta litšenyehelo tse eketsehileng. Ho khetha tsamaiso e nepahetseng ho itšetlehile ka ho leka-lekanya lintlha tsena le lipakane tsa tlhahiso le tekanyetso.

Ho Khetha Extruder e nepahetseng bakeng sa Litlhoko tsa Hao

Ho Tšoaneleha ha Lintho

Ho khetha extruder e nepahetseng ho qala ka ho utloisisa ho lumellana ha lintho. Likarolo tsa bohlokoa tsa mochini joalo kalebelo la screw, bophara, le karo-karolelano ea bolelele ho isa ho bopharaama kamoo extruder e sebetsanang hantle le lisebelisoa tse fapaneng. Ka mohlala, litekanyetso tse phahameng tsa L / D li thusa ka thepa e rarahaneng e hlokang ho qhibiliha ka ho feletseng le ho kopanya. Moralo oa meqomo, ho kenyeletsoa libaka tsa mocheso le moea, o ts'ehetsa lisebelisoa tse bobebe kapa tse ntlafalitsoeng. Litaelo tsa indasteri li khothaletsa ho tsamaisana le extruder le mocheso oa thepa, viscosity, le sekhahla sa phallo. Single screw extrusion e sebetsa hantle bakeng sa ts'ebetso ea bongata ba thermoplastics, ha li-scruder tse peli li sebetsana le metsoako e rarahaneng indastering ea lijo, ea meriana le ea polymer.

Sekhahla sa Tlhahiso le Sephetho

Sekhahla sa tlhahiso le litlhoko tsa tlhahiso li bapala karolo e kholo ho khethoeng ha extruder. Litefiso tse phahameng tsa tlhahiso li ka eketsa litlhoko tsa tšebeliso ea matla le tlhokomelo. Litlhophiso tsa li-screw tsa modular li lumella ho ntlafatsa le ho sebetsa hantle. Liphuputso li bontša seotlhahiso le ho tlatsa boemo bo ama boleng ba sehlahisoa le katleho ea ho kopanya. Li-extruder tse kholo li hloka phetoho e hlokolosi ea liparamente tsa ts'ebetso ho boloka liphetho tse ts'oanang. Likhamphani li tlameha ho leka-lekanya lipakane tsa tlhahiso le litšenyehelo tsa ts'ebetso le ho rarahana ha tekheniki.

Lintlha tsa Tekanyetso le Litšenyehelo

Litšenyehelo li kenyelletsa litšenyehelo tsa pele le tse tsoelang pele. Tafole e ka tlase e hlakisa lintlha tsa bohlokoa tsa litšenyehelo:

| Litšenyehelo Factor | Tlhaloso | Tšusumetso ea Lichelete |

|---|---|---|

| Theko ea Pele | E fapana ka boholo le mofuta | Chelete e kholo ea pele |

| Setifikeiti | ISO 9001, CE, joalo-joalo. | E ka eketsa theko |

| Tlhokomelo | Ho hlokahala litšebeletso tsa kamehla | Litefiso tse tsoelang pele tsa selemo |

| Tšebeliso ea Matla | Mekhoa e sebetsang hantle e boloka litšenyehelo tsa nako e telele | E phahameng ka pele, e tlase khoeli le khoeli |

| Koetliso | Ho hlokahala bakeng sa tshebetso e nepahetseng | 1-3% ea theko ea theko |

Baetsi ba Asia-Pacific hangata ba rua molemo litšenyehelong tse tlase tsa ts'ebetso ka lebaka la melemo ea libaka.

Litlhahiso tse thehiloeng ho Kopo

Nengho khetha tsamaiso ea extrusion, lik'hamphani li lokela ho nahana ka bophahamo ba tlhahiso, ho tenyetseha ha bafani ba thepa, le litlhoko tsa boleng. Bakeng sa lihlahisoa tsa mantlha le li-run tse nyane, extrusion ea screw e le 'ngoe e fana ka bonolo le litšenyehelo tse tlase. Li-extruder tsa Twin screw li lumellana le lihlahisoa tsa boleng bo holimo, tse rarahaneng, kapa tse ncha tse hlokang ho tsoakoa le ho tenyetseha ha maemo. Liindasteri tse kang tsa makoloi, lijo, le meriana hangata li khetha li-screws tse peli bakeng sa ho feto-fetoha ha tsona le boleng ba sehlahisoa. Likhamphani tse ikemiselitseng ho khetholla 'maraka li ka fetohela ho "twin screw extrusion" ho fihlela likarolo tse ikhethang tsa sehlahisoa.

- Li-fin screw extruderssebelisa li-screw tse peli bakeng sa ho kopanya hantle le ho phalla ha thepa e tsitsitseng.

- Ba sebetsana le mefuta e mengata ea thepa mme ba fana ka tlhahiso e phahameng.

- Extrusion ea screw e le 'ngoe e sebetsa hantle bakeng sa lisebelisoa tse bonolo, tse nang le viscosity e tlase.

- Bakeng sa lihlahisoa tse rarahaneng kapa ts'ebetso e phahameng, lik'hamphani li lokela ho khetha li-twin screw extruder.

LBH

Phapang e kholo ke efe lipakeng tsa screw e le 'ngoe le twin screw extrusion?

Extrusion ea screw e le 'ngoe e sebelisa screw e le 'ngoe bakeng sa ts'ebetso ea mantlha. Twin screw extrusion e sebelisa li-screw tse peli bakeng sa ho kopanya hantle le ho sebetsana le lisebelisoa tse rarahaneng.

Ke extruder efe e sebetsang hantle bakeng sa ho sebelisa polasetiki hape?

Li-extruder tse peli tsa screw li sebetsana ka katleho le lipolasetiki tse tsosolositsoeng. Ba fana ka ho kopanya hantle le ho laola, e leng ho ntlafatsa boleng ba sehlahisoa.

Tlhokomelo e bapisoa joang pakeng tsa mefuta ee e 'meli?

Li-extruder tsa screw tse le 'ngoe li hloka tlhokomelo e fokolang.Li-extruder tsa twin screw li hloka tlhokomelo e eketsehilengka lebaka la moralo oa bona o rarahaneng le likarolo tse eketsehileng.

Nako ea poso: Jul-08-2025