Conical Twin Screw Barrels e se e le ea bohlokoa haholo tlhahisong ea sejoale-joale. Moralo oa bona o ikhethang o netefatsa ho ts'oaroa ha thepa ka nepo, ho kopanya ka mokhoa o ts'oanang, le ho qhibiliha ka mokhoa o nepahetseng, tse bohlokoa bakeng sa ho hlahisa lihlahisoa tsa boleng bo holimo. Ho theosa le mashome a lilemo, meralo ea li-screw e bile teng haholo, 'me bolelele ba bolelele ho isa bophara (L/D) bo eketseha ho tloha ho 20:1 ho isa ho 40:1, e leng se nolofalletsang ts'ebetso e betere. Litheknoloji tse tsoetseng pele, joalo ka li-in-line PAT probes tse sebelisang Raman spectroscopy, li matlafatsa matla a tlhahiso ka ho lekola boleng ba thepa ka nako ea nnete. Litlhahiso tsena boemo baConical le Parallel Twin Screw Barrels, hammoho leTapered Twin Screw Barrel le Screw, e le likarolo tsa bohlokoa mekhoeng ea ho bopa extrusion le ente. Ho feta moo, theMoqomo o le mong oa Conical Twin Screw Barrele fana ka melemo e ikhethang bakeng sa lits'ebetso tse ikhethileng, e ntse e atolosa ho feto-fetoha ha lisebelisoa tsena tsa bohlokoa tsa tlhahiso.

Mekhoa ea morao-rao ea Conical Twin Screw Barrels

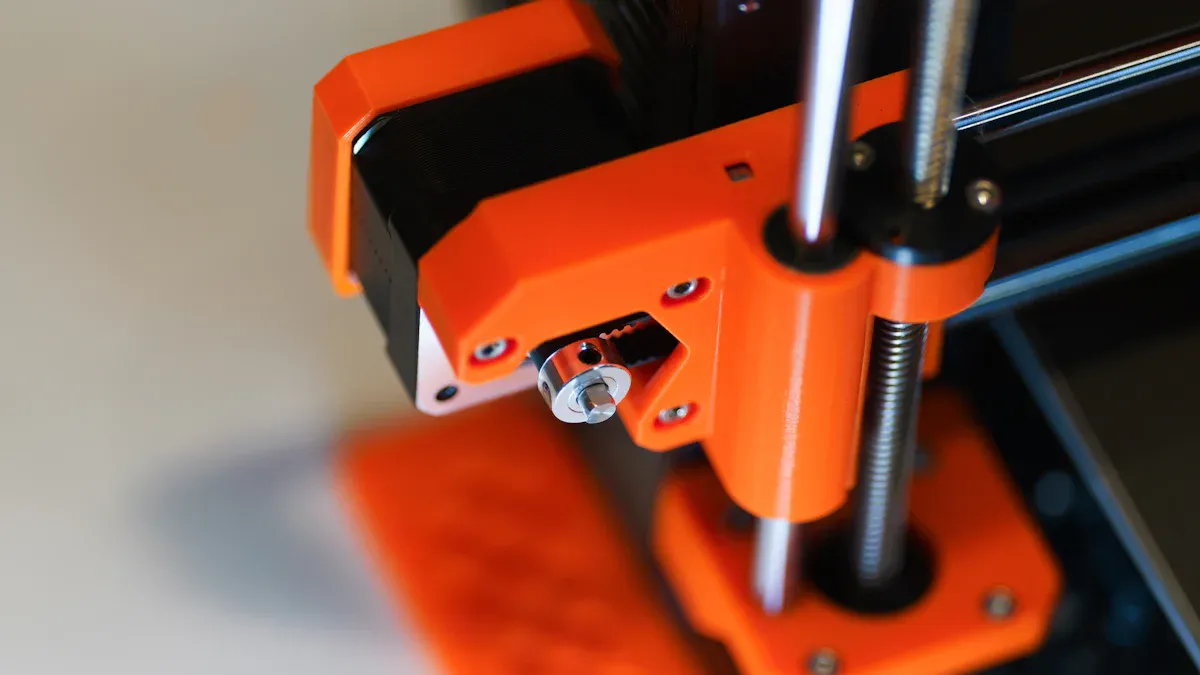

Tsoelo-pele ho Moralo oa Barrel

Meetso ea sejoale-joale ea libarele e fetola tšebetso ea libarele tsa conical twin screw. Baenjineri ba sebelisa mekhoa ea ho etsa tlatsetso le mekhoa e nepahetseng ea ho etsa li-screw tse hlophisitsoeng hantle. Lintlafatso tsena li thusa ho etsa prototyping ka potlako le potoloho e potlakileng ea ntlafatso ea lihlahisoa.

Hlokomela: Geometry e ntlafalitsoeng ea barrel e ntlafatsa phallo ea thepa, e netefatsa ho qhibiliha ho tšoanang le ho kopanya.

Lefapha la extrusion ea polasetiki le ruile molemo o moholo ho tsoa lits'ebetsong tsena. Mohlala, li-extruder tsa conEX NG joale li fihlela liphetho ho tloha ho 80 ho isa ho 550 lb/hr bakeng sa liprofaele le ho fihla ho 1000 lb/hr bakeng sa liphaephe. Ho feta moo, ho kenya libarele ka botlalo ho fokotsa tahlehelo ea mahlaseli, ho kenya letsoho ts'ebetsong ea matla.

| Leano | Tšusumetso ho Katleho |

|---|---|

| Ho ntlafatsa Motor le Drive Systems | E fokotsa litšila tsa matla haholo, e boloka 10-15% ka ho tlosa li-gearbox tse sa sebetseng hantle. |

| Mekhoa e Ntlafetseng ea ho futhumatsa | Sistimi ea induction e ntlafalitsoeng e fokotsa matla a futhumatsang ka 10%. |

| Moralo o ntlafalitsoeng oa Sisteme ea ho Pholisa | E fokotsa nako ea potoloho le ho theola tšebeliso ea matla ka ho fokotsa ho bata ho feta tekano. |

| Pheliso ea Mocheso oa litšila | E ka khutlisa ho fihla ho 15% ea matla a lahlehileng, a fokotsa litšenyehelo tsa ts'ebetso. |

Lisebelisoa tse phahameng tsa ts'ebetso le ho tšoarella

The durability ea conical twin screw barrel e fihlile bophahamong bo bocha ka lebaka la ts'ebeliso ealisebelisoa tsa ts'ebetso e phahameng. Hona joale bahlahisi ba sebelisa li-alloys tse tsoetseng pele tse fanang ka matla a ikhethang a mochini, ho hanyetsa torque, le ho hanyetsa deformation. Lisebelisoa tsena li netefatsa hore libarele li ka mamella mocheso o phahameng le likhatello nakong ea ts'ebetso.

- Matla a Mechini: E bohlokoa bakeng sa ho hanela khohlano le kutu.

- Torque Resistance: E bohlokoa bakeng sa ts'ebetso e tsoelang pele ea thepa tlas'a maemo a phahameng a lebelo.

- Ho hanyetsa ha Deformation: E boloka ts'ebetso tlas'a maemo a feteletseng, ho netefatsa hore polasetiki e sebetsang hantle.

Tsoelo-pele ea lisebelisoa tsena e boetse e fokolitse litšenyehelo tsa tlhokomelo bakeng sa basebelisi, kaha joale libarele li na le nako e telele ea bophelo. Likamano tsa maano lipakeng tsa bahlahisi le litsi tsa lipatlisiso li potlakisa tlhahiso ea tharollo e tšoarellang le ho feta.

Tšebeliso e Ntle ea Matla le Katoloso ea Litšenyehelo

Ho sebetsa hantle ha matla ho fetohile motheo oa theknoloji ea sejoale-joale ea conical twin screw barrel. Baetsi ba kopanya ho tsilatsila le li-motor tsa synchronous, tse tlalehiloeng hore li boloka ho fihlela ho 20% ea tšebeliso ea matla. Sistimi e ntlafalitsoeng ea ho futhumatsa le ho pholisa e tsoela pele ho ntlafatsa ts'ebetso ka ho fokotsa linako tsa potoloho le ho fokotsa tšenyo ea matla.

- Lipalo tse ntseng li eketseha tsa polasetiki, ho tloha ho 104 g/s ho ea ho 120 g/s, li hlokometsoe.

- Linako tsa ho hlaphoheloa li theohile ho tloha ho metsotsoana e 18 ho ea ho metsotsoana e 9 feela.

- Kakaretso ea linako tsa potoloho e fokotsehile ho tloha ho metsotsoana e 30 ho isa ho metsotsoana e 15.

Lintlafatso tsena ha li fokotse litšenyehelo tsa ts'ebetso feela empa hape li tsamaisana le tlhoko e ntseng e hola ea mekhoa e tsitsitseng ea tlhahiso.

Boikemisetso bakeng sa Likopo tse Khethehileng tsa Indasteri

Tlhokahalo ea libarele tse ikhethileng tsa conical twin screw e ntse e eketseha ho pholletsa le liindasteri tse fapaneng. Litharollo tse hlophisitsoeng li se li fumaneha ho fihlela litlhoko tse ikhethang tsa likarolo tse kang tsa meriana, lipolasetiki le phetoho ea polymer.

| Sebopeho/Molemo | Tlhaloso |

|---|---|

| Theknoloji ea Tlhokomelo e Bohlale | E ntlafatsa ts'ebetso ka ho khutlisetsa li-screw press tse teng, ho sebetsana le ho se sebetse hantle. |

| Smart Control Systems | E lumella litokiso tse nepahetseng ho thempereichara, khatello, le lebelo la screw bakeng sa liphetho tse nepahetseng. |

| Matla a Matla | E kenyelletsa mekhoa ea ho khanna e sebetsang hantle ka matla, ho fokotsa litšenyehelo tsa ts'ebetso le phello ea tikoloho. |

| Optimized Screw Geometry | E fokotsa tahlehelo ea matla, ho netefatsa phetoho e sebetsang ea mochine ho matla a mocheso. |

| Ho ikamahanya le maemo | E lumella litokiso ho li-diameter tsa barrel ho ntlafatsa litefiso tsa tlhahiso le boleng ba ho qhibiliha. |

| Boleng bo Tšoanang ba Sephetho | E netefatsa 'mala o ts'oanang le botsitso ba sebopeho ka lebelo le laoloang la screw le torque. |

Mmaraka oa Feed Screw Barrel o ntse o hola haholo ka lebaka la tsoelopele ena. Mechini e sebetsang hantle haholo le likarolo tse nepahetseng li ntse li hlokahala bakeng sa ho sebetsana le lisebelisoa tse rarahaneng, tse tsamaisang tlhoko ea tharollo e ikhethileng.

Litlhahiso tsa Bohlokoa ho Conical Twin Screw Barrel Technology

Digitalization le Smart Controls

Digitalization e fetotse ts'ebetso ea conical twin screw barrel, e nolofalletsang bahlahisi ho fihlela maemo a sa lebelloang a ho nepahala le ho sebetsa hantle. Marang-rang a tsoetseng pele a sensor joale a lekola maemo a bohlokoa joalo ka sekhahla sa phallo, tlhahiso ea torque, le ho roala likarolo ka nako ea nnete. Li-sensor tsena li fana ka lintlha tse sebetsang, tse lumellang basebelisi ho etsa liphetoho hanghang ho ntlafatsa ts'ebetso.

Litsamaiso tse bohlale tsa taolo, tse tsamaisoang ke theknoloji ea mafahla a dijithale, li etsisa ts'ebetso eohle ea tlhahiso. Tlhahiso ena e thusa bahlahisi ho bolela esale pele likhatello tsa ts'ebetso, ho tseba mathata, le ho fokotsa ho emisa. Mohlala, lik'hamphani tse kang ExxonMobil li atlehile ho kenya tšebetsong mafahla a dijithale ho ntlafatsa moralo oa tlhahiso le ho ntlafatsa ho etsa liqeto. Li-analytics tsa predictive li ntlafatsa le ho feta litsamaiso tsena, li nolofalletsa linako tsa tlhokomelo le ho fokotsa nako.

Melemo ea bohlokoa ea digitalization e kenyelletsa:

- Litlhahlobo tsa nako ea sebelebakeng sa liphetoho tse tsoelang pele.

- Tlhokomelo e thehiloeng ho boemoho lelefatsa bophelo ba lisebelisoa.

- Moralo o ntlafalitsoeng oa ts'ebetsoka litsebo tse boletsoeng esale pele.

Likhatelo-pele tsena li netefatsa hore conical twin screw barrel e lula e le motheo oa tlhahiso ea sejoale-joale, e fanang ka liphetho tse ts'oanang lits'ebetsong tse fapaneng.

Litsamaiso tsa Tlhokomelo ea Predictive

Sistimi ea ho lokisa esale pele e fetotse tsela eo bahlahisi ba tsamaisang thepa ea bona ka eona. Ka ho sebelisa li-sensor tse atileng le li-analytics tsa nako ea nnete, litsamaiso tsena li lekola mekhahlelo e fapaneng ho lebela litaba tse ka bang teng pele li eketseha. Mokhoa ona o fokotsa nako e sa reroang mme o fokotsa litšenyehelo tsa ho lokisa haholo.

Lithuto tsa liketsahalo tsa indasteri li totobatsa katleho ea tlhokomelo e boletsoeng esale pele:

| Indasteri/Khampani | Tlhaloso ea Sephetho | Phokotso ea Nako ea ho Pholosa / Litšenyehelo |

|---|---|---|

| Mokhanni oa lifofane | Ho fokotseha ka 25% ea ho senyeha ho lebisang ho popelong ka potlako le litšenyehelo tse tlase tsa tokiso. | 25% e fokotsehile ka ho senyeha |

| Feme ea Oli le Khase | E pholositse limilione ka ho lebella mathata a lisebelisoa, ho nkela litokiso tsa tšohanyetso. | Ho boloka litšenyehelo tse kholo |

| Moetsi oa Matla a Matla | Fokotsa ho tima ho sa reroang ka 30%, ho ntlafatsa nako ea thepa. | Phokotso ea 30% ea ho tima |

| General Motors (GM) | Ho fokotsa nako e sa lebelloang ka 15%, ho boloka $ 20 milione selemo le selemo. | Phokotso ea 15% ea nako ea ho theoha |

Bakeng sa libarele tsa conical twin screw, tlhokomelo e boletsoeng esale pele e netefatsa ts'ebetso e nepahetseng ka ho sebetsana le ho senyeha ha nako. Sistimi ena ha e eketse nako ea bophelo ea lisebelisoa feela empa e boetse e eketsa tlhahiso ka kakaretso.

Likarolo tse tsepamisitsoeng tsa Moshoelella

Sustainability e se e le taba ea bohlokoa ho nts'etsopele ea theknoloji ea conical twin screw barrel. Baetsi ba sebelisa lisebelisoa tse bolokang tikoloho le maano a ho fokotsa litšila ho fihlela litlhoko tsa taolo le litebello tsa bareki. Litlhahiso tsena li tsamaisana le ts'ebetso ea lefats'e ea mekhoa ea tlhahiso e tala.

Khatelo-pele ea mahlale a ho penta le motsoako oa li-alloy li matlafalitse le ho feta ho tšoarella ha libarele tsena. Liaparo tse tsoetseng pele li fokotsa likhohlano le ho roala, ho fokotsa tšebeliso ea matla nakong ea ts'ebetso. Ho feta moo, lits'ebetso tsa ho khutlisa mocheso oa litšila li khutlisa ho fihla ho 15% ea matla a lahlehileng, a fokotsa haholo litšenyehelo tsa ts'ebetso.

Lintlha tsa bohlokoa tsa ts'ebetso li kenyelletsa:

- Lisebelisoa tsa eco-friendlytse fokotsang tšusumetso ea tikoloho.

- Meetso e baballang matlaho fokotsa tshebediso ya mohlodi.

- Mekhoa ea ho fokotsa litšilabakeng sa mekhoa ea tlhahiso e hloekileng.

Likarolo tsena li netefatsa hore conical twin screw barrel e lula e le tharollo e sebetsang bakeng sa liindasteri tse ikemiselitseng ho leka-lekanya ts'ebetso le boikarabello ba tikoloho.

Meralo ea Modular le Ho Fetolana

Meetso ea modular e hlahisitse boemo bo bocha ba ho feto-fetoha ha maemo ho li-conical twin screw barrel system. Meetso ena e lumella bahlahisi ho etsa libarele le li-screw bakeng sa lits'ebetso tse ikhethileng, ho netefatsa ts'ebetso e nepahetseng ho liindasteri tse fapaneng. Mekhoa e meng ea ho etsa lintho le mekhoa e nepahetseng ea ho etsa lintho e ntlafalitse ho feto-fetoha hona, ho nolofalletsa prototyping le nako e potlakileng ea ho rekisa lihlahisoa tse ncha.

Likopo tse ntseng li hlaha tlhahisong ea meriana le phetoho ea polymer li tsamaisitse tlhoko ea taolo e matla holim'a liparamente tsa ts'ebetso. Meetso ea modular e sebetsana le litlhoko tsena ka ho lumella litokiso ka har'a li-diameter tsa barrel, li-screw configuration, le lisebelisoa tsa ho futhumatsa. Ho ikamahanya le maemo ho netefatsa boleng bo tsitsitseng ba tlhahiso le katleho e ntlafetseng.

| Metric | Boleng |

|---|---|

| CAGR e lebelletsoeng | 5% |

| Bolele ba nako | Lilemo tse hlano tse tlang |

| Lintlha tsa Bohlokoa | Tsoelo-pele lits'ebetsong tsa tlhahiso, katoloso ea likarolo tsa indasteri, ts'ebeliso ea li-alloys tse tsoetseng pele, mekhoa e nepahetseng ea tlhahiso. |

Mokhoa oa modular ha o ntlafatse feela ho feto-fetoha ha libarele tsa conical twin screw, empa hape o li beha joalo ka tharollo ea bopaki ba bokamoso bakeng sa litlhoko tse tsoelang pele tsa indasteri.

Indasteri Impact ea Conical Twin Screw Barrel Advancements

Sebetsa se Ntlafetseng sa Tlhahiso

Tsoelo-pele hoconical twin screw barrelba ntlafalitse haholo katleho ea tlhahiso. Meetso ea sejoale-joale e thusa ho kopanya lintho tse nepahetseng ka ho kuta ka li-high-shear ka li-increments tse nyane. Sena se tiisa ho kopanya ho tšoanang le ho fokotsa nako ea ho sebetsa. Ho feta moo, ho feto-fetoha ha libarele tsena ho lumella bahlahisi ho sebetsana le mefuta e mengata ea lisebelisoa, ho kenyeletsoa le polasetiki e thata ho e sebelisa hape.

| Metric/Cost Aspect | Tlhaloso |

|---|---|

| Motsoako o Matlafalitsoeng le Ts'ebetso | Li-extruder tse peli tsa screw li fana ka sekoli se phahameng ka li-increments tse nyane bakeng sa motsoako o nepahetseng oa thepa. |

| Mefuta e fapaneng ea ho sebetsa ha lintho | E khona ho sebetsana le mefuta e mengata e fapaneng ea lisebelisoa, ho kenyeletsoa le polasetiki e thata ho e sebelisa hape. |

| Phokotso ea Litšenyehelo | E fokotsa litšenyehelo tse amanang le ho lahloa ha litšila le theko ea thepa e tala. |

| Boleng bo ntlafetseng ba Sehlahiswa | Elongation e matlafalitsoeng nakong ea khefu ea li-plastiki tse sa sebelisoang hape, ho eketsa nako e telele. |

Lintlafatso tsena li tsamaisa mekhoa ea tlhahiso, li fokotsa nako, 'me li ntlafatsa katleho ea ts'ebetso ka kakaretso.

Phokotso ea Litšenyehelo le Phokotso ea Litšila

Ho kopanngoa ha theknoloji e tsoetseng pele ea conical twin screw barrel ho lebisitse ho hlokomelehengho boloka litšenyehelo. Ka ho ntlafatsa tšebeliso ea thepa le ho fokotsa litšila, bahlahisi ba ka fokotsa litšenyehelo tse amanang le ho reka le ho lahla thepa e tala. Lits'ebetso tsa ho khutlisa mocheso o litšila le tsona li kenya letsoho phokotsong ea litšenyehelo ka ho khutlisa ho fihla ho 15% ea matla a lahlehileng.

Keletso: Lik'hamphani tse sebelisang theknoloji ena hangata li tlaleha ho fokotseha ho hoholo ha litšenyehelo tsa ts'ebetso, e leng se etsang hore e be letsete la bohlokoa bakeng sa ts'ebetso ea nako e telele.

Katoloso ea Lisebelisoa tse fapaneng

Ho ikamahanya le maemo ha libarele tsa conical twin screw ho butse mamati a lisebelisoa tse fapaneng tsa indasteri. Libarele tsena li se li sebelisoa haholo makaleng a kang a meriana, polasetiki le phetoho ea polymer. Bokhoni ba bona ba ho sebetsana le lisebelisoa tse rarahaneng ka nepo bo etsa hore e be tsa bohlokoa haholo bakeng sa ho hlahisa lihlahisoa tsa boleng bo holimo liindastering tse fapaneng.

Lisebelisoa tse ntseng li hlaha li kenyelletsa tlhahiso ea li-polymer tsa boemo ba bongaka le li-composite tse tsoetseng pele, moo taolo e tiileng holim'a maemo a ts'ebetso e leng bohlokoa. Ho feto-fetoha hona ho tiisa hore libarele tsa conical twin screw li lula li sebetsa mebarakeng e ntseng e tsoela pele.

Boleng bo ntlafetseng ba Sehlahisoa le ho tsitsisa

Meetso e tsoetseng pele ea libarele e fetotse boleng ba sehlahisoa le ho tsitsa. Mohlala oa JT Series single screw barrel, mohlala, e fokotsa likoti lihlahisoa tse felileng ka 90%, e netefatsa boleng bo holimo ba ho qhibiliha. Sena se eketsa matla a filimi le elasticity, ho etsa hore lihlahisoa li tšoarelle le ho tšepahala.

- Moralo o netefatsa hore ho na le mongobo o tsitsitseng bakeng sa granulation e nepahetseng.

- Lisebelisoa tsa nako ea sebele tsa ho beha leihlo, tse kang NIR le Raman spectroscopy, li fana ka maikutlo a hang-hang mabapi le litšobotsi tsa boleng.

- Ho lumellana ho ntlafalitsoeng ha motsoako le kabo ea boholo ba granule li ntlafatsa ts'ebetso ea sehlahisoa ka kakaretso.

| Lekanya | Tlhaloso |

|---|---|

| Mongobo | E behiloe leihlo ho netefatsa maemo a nepahetseng a granulation. |

| API Content Uniformity | E lekoa ho boloka phepelo ea metsoako ea meriana e tsitsitseng. |

| Kopanya Uniformity | E hlahlojoa ho netefatsa homogeneity ka motsoako pele ho granulation. |

| Kabo ea boholo ba Granule | D10, D50, le D90 likaroloana li behiloe leihlo ho lekola phapang ea boholo ba likaroloana. |

| Boemo bo tiileng ba motsoako o sebetsang | Ho netefatsoa ho boloka ts'ebetso ea motsoako o sebetsang nakong eohle ea ts'ebetso. |

Lintlafatso tsena li totobatsa phello ea phetoho ea libarele tsa conical twin screw lits'ebetsong tsa tlhahiso, ho netefatsa boleng bo tsitsitseng ba tlhahiso le ho fihlela maemo a thata a indasteri.

Mathata le Menyetla 'Maraka oa Conical Twin Screw Barrel

Ho Hlōla Litšenyehelo tse Phahameng tsa Pele

Litsenyehelo tse phahameng tsa qalong hangata li sitisa bahlahisi ho amohela tse tsoetseng peleconical twin screw barrel. Leha ho le joalo, litšenyehelo tsena li ka fokotsoa ka melemo ea nako e telele joalo ka litšenyehelo tse fokotsehileng tsa tlhokomelo le ts'ebetso e ntlafalitsoeng ea ts'ebetso. Likhamphani li ntse li tsoela pele ho fana ka likhetho tsa lichelete le mananeo a ho hira ho etsa hore mahlale ana a fihlellehe haholoanyane. Ho feta moo, tsoelo-pele lits'ebetsong tsa tlhahiso, joalo ka tlhahiso ea li-additive, e theotse litšenyehelo tsa tlhahiso, e leng se etsang hore libarele tsena li be bonolo haholoanyane.

Keletso: Ho tsetela ka libarele tsa boleng bo holimo ho fokotsa nako ea ho theoha le ho ntlafatsa tlhahiso, ho lebisang ho bolokeng litšenyehelo tse kholo ha nako e ntse e ea.

Ho sebetsana le Khaello ea Tsebo ea Basebetsi

Indasteri e tobane le khaello ea basebetsi ba nang le litsebo ba khonang ho sebetsa le ho hlokomelamechine e tsoetseng pele. Ho rarolla bothata bona, bahlahisi ba kenya tšebetsong mananeo a koetliso le ho fana ka litifikeiti ho basebetsi ba hloahloa. Litsamaiso tsa othomathike le tse bohlale tsa taolo le tsona li fokotsa ho its'etleha ka ho kenella ka letsoho, ho nolofatsa ts'ebetso ho basebetsi ba nang le boiphihlelo bo fokolang. Mehato ena e netefatsa hore basebetsi ba lula ba hlomeletsoe ho sebetsana le theknoloji e ntseng e tsoela pele.

Kholo ea Kholo Limmarakeng Tse Hlahang

Mebaraka e ntseng e hola e fana ka menyetla ea kholo ea kholo bakeng sa libarele tsa conical twin screw. Likhamphani li shebile libaka tse nang le tlhoko e phahameng le tlholisano e tlase ho holisa karolo ea bona ea mmaraka.

- Limmaraka tse ntseng li hola ka potlako bakeng sa lipompo tse peli tsa screw li bonts'a monyetla o ts'oanang oa libarele tsa conical twin screw.

- Ho hlopha lintlha tsa thepa ho latela naha le sekhahla sa kholo ho thusa ho tseba libaka tse tšepisang.

- Mawa a shebane le ho kena mebarakeng e nang le tlhokahalo e phahameng ya mahlale a extrusion le a ente.

Boiteko bona bo bea bahlahisi hore ba sebelise menyetla e sa sebelisoang moruong o ntseng o tsoela pele.

Tšebelisano 'moho le Menyetla ea Boqapi

Tšebelisano lipakeng tsa bahlahisi le bafani ba thekenoloji e tsamaisa boqapi indastering ea conical twin screw barrel. Merero e atlehileng ea lintlafatso e bonts'a monyetla oa ho boloka litšenyehelo le ntlafatso ea ts'ebetso.

| Khampani | Katleho Metrics |

|---|---|

| Lik'hamphani tse holimo | E bolokoa ka holimo ho $5 barrel e le 'ngoe ea oli e lekanang le eona ka lipatlisiso le ho cheka tse kentsoeng ke theknoloji. |

| Lik'hamphani tse tlase | E bolokoa ho feta $1 barrel ha e ntse e matlafatsa ho fumaneha ha thepa le phaello. |

| Woodside Energy | Ho fokotsa litšenyehelo tsa ts'ebetso ka 30% ho sebelisa AI le automation. |

| Khampani ea Oli ea Kuwait | Lipheo tse ntlafalitsoeng tsa tlhahiso ka ho iketsetsa lits'ebetso le phallo ea mosebetsi. |

| Chevron | Taolo e ntlafalitsoeng ea li-portfolio ho fana ka lintlha tse sebetsang bakeng sa tšebelisano e ntle. |

Litšebelisano tsena li totobatsa phello ea phetoho ea botsebi le lisebelisoa tse arolelanoang, ho bula tsela bakeng sa tsoelopele ea nako e tlang indastering.

Tsoelo-pele ea theknoloji ea conical twin screw barrel e fetotse mekhoa ea tlhahiso. Litlhahiso tsa moralo, lisebelisoa, le digitalization li netefatsa ts'ebetso le ts'ebetso e tsitsitseng.

Libarele tsena li tsamaisa ho nepahala le ho boloka matla, ho etsa hore e be tsa bohlokoa haholo indastering ea sejoale-joale. Bokamoso ba bona bo ho ho nolofalletsa tlhahiso e tala ha ba ntse ba kopana le litlhoko tse fapaneng tsa ts'ebeliso.

Baetsi ba tsoela pele ho hlahloba menyetla e mecha, ho netefatsa kholo ea nako e telele ea indasteri.

LBH

Ke liindasteri life tse ruang molemo haholo ho tsoa ho conical twin screw barrel?

Li-conical twin screw barrel li sebelisoa haholo lipolasetiki, meriana, le indastering ea phetoho ea polymer. Ho ikamahanya le maemo ho netefatsa ts'ebetso e sebetsang ea lisebelisoa tse rarahaneng ho pholletsa le lits'ebetso tse fapaneng.

Meetso ea modular e ntlafatsa ts'ebetso ea tlhahiso joang?

Meetso ea modular e lumella bahlahisi hore ba iketsetse libarele le likurufu bakeng sa litlhoko tse itseng. Ho feto-fetoha ha maemo ho ntlafatsa ts'ebetso, ho fokotsa nako, 'me ho netefatsa boleng bo tsitsitseng ba sehlahisoa.

Na libarele tsa conical twin screw li na le tikoloho?

Ee, meralo ea sejoale-joale e kenyelletsa lisebelisoa tse bolokang tikoloho, litsamaiso tse baballang matla le maano a ho fokotsa litšila. Likarolo tsena li ikamahanya le lipheo tsa lefatše ka bophara le ho fokotsa tšusumetso ea tikoloho.

Nako ea poso: Jun-06-2025