Baetsi ba khetha lintlafatso tsa bohlokoa bakeng sa tlhahiso e ngata ea Twin Screw Plastic Extruder ho matlafatsa ts'ebetso le ho tšoarella. Lintlafatso tse tloaelehileng li kenyelletsa theknoloji e se nang metsi, libarele tse ncha tsa lisekoere, le likarolo tse nchafalitsoeng, joalo ka ha ho bonts'itsoe ka tlase:

| Ntlafatsa Sebopeho | Tlhaloso | Melemo |

|---|---|---|

| Theknoloji e sa omeletseng | E tlosa mehato ea ho omisa | E boloka matla le sebaka |

| New Square Barrels | Linako tse potlakileng tsa ho futhumatsa | E fokotsa nako ea ho phomola |

| Likarolo tse nchafalitsoeng | E etselitsoe bophelo bo bolelele | E eketsa bokhoni |

Theknoloji e tsoetseng pele ea CNC kaMoqomo oa Mafahla a Plastic ScrewleMochini oa Extrusion Single Screw Barreltlhahiso e eketsa ho nepahala, ho tšoarella, le ho fokotsa tlhokomelo. Thepolastiki lefahla sekoti extrudermelemo ho tsoa lintlafatsong tsena ka bokhoni bo ntlafalitsoeng ba ho kopanya le taolo e ntlafalitsoeng ea lisebelisoa.

Lintlafatso tsa Bohlokoa bakeng sa Tlhahiso ea Bongata ba Twin Screw Plastic Extruder

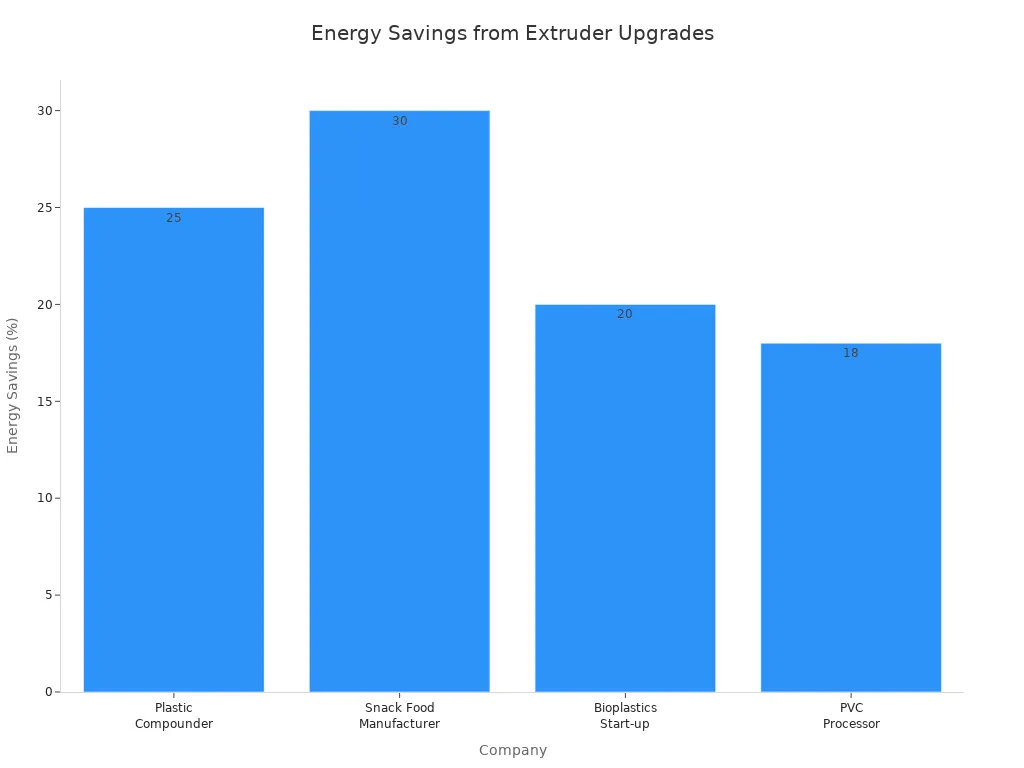

Mathata a Ts'ebetso ho Tlhahiso ea Molumo o Phahameng

Baetsi ba tobana le litšitiso tse 'maloa ha ba sebetsa litsamaiso tsa Twin Screw Plastic Extruder bakeng sa tlhahiso e ngata. Ho phahama ha litšenyehelo bakeng sa thepa le matla ho baka khatello ea ho ntlafatsa katleho. Theko ea tšepe e sa hloekang ea boemo bo phahameng e eketsehile ka 14% ho tloha 2022 ho ea 2023. Litšenyehelo tsa motlakase bakeng sa lisebelisoa tsa indasteri li nyolohile ka 11% Europe. Liphetoho tsena li qobella lik'hamphani ho batla taolo e ntlafetseng ea matla le tšebeliso ea thepa.

Sistimi ea khale ea extruder e kenya letsoho ho sekhahla se phahameng sa litšila. Mohlala, lisebelisoa tsa litšila lits'ebetsong tse thata tsa liphaephe tsa PVC hangata li lekana le 1.5%. Li-screw tse tsofetseng li ka nyolla sekhahla sena ho 10%, e leng se lebisang ho nyolloeng ha litšenyehelo tsa tlhahiso. Ho se sebetsane le li-screw wear ho fella ka litlamorao tse turang ho bahlahisi.

Keletso: Tlhokomelo ea kamehla le lintlafatso tse nakong li thusa ho fokotsa litšila le ho laola litšenyehelo lits'ebetsong tse phahameng haholo.

Baetsi ba boetse ba tobana le mathata a ho laola thepa le mocheso. Lintlafatso tse kang litsamaiso tse pholileng tsa khatello e phahameng le li-gaskets tsa ho kenya letsoho li ntlafatsa phapanyetsano ea mocheso le ho boloka maemo a tsitsitseng a ts'ebetso. Ho kenya tšebetsong phepelo ea lehlakore ho eketsa maemo a ho tlatsa li-filler, ha likarolo tse telele tsa sekoti li eketsa phallo ea thepa le ho thibela litšitiso.

Tšebeliso ea matla e ntse e le taba ea bohlokoa. Ho ntlafatsa moralo oa screw le ho sebelisa litsamaiso tse tsoetseng pele tsa taolo ea mocheso ho lebisa polokong e kholo ea matla. Ho khutlisetsa morao ka theknoloji ea servo motor ho matlafatsa ts'ebetso e sebetsang. Litokiso moralong oa li-screw le phepelo ea phepelo li ka ama ts'ebeliso ea matla ka kotloloho.

Hobaneng ha Lintlafatso li Potlakile bakeng sa Maraka ea Kajeno

Mmaraka oa theknoloji ea Twin Screw Plastic Extruder e ntse e tsoela pele ho fetoha ka potlako. Baetsi ba tlameha ho arabela mekhoa e mecha le litlhoko tsa bareki hore ba lule ba le tlhōlisano. Tafole e ka tlase e totobatsa mekhoa ea mantlha ea mmaraka e tsamaisang tlhoko ea lintlafatso tsa hanghang:

| Mofuta oa Mokhoa | Tlhaloso |

|---|---|

| Multi-functionality | Li-twin screw extruder joale li sebeletsa polymer, lijo, fepa le liindasteri tse ling. |

| Tlhahiso e kholo | Litsi tse kholo li fokotsa litšenyehelo le ho tšehetsa litlhoko tsa indasteri ea petrochemical. |

| Nepahalo | Lihlahisoa tsa boleng bo holimo li hloka extrusion e nepahetseng, joalo ka lifilimi tse kopantsoeng ka bongata. |

| Theknoloji e bohlale | Tlhokomelo le taolo ea nako ea 'nete li ntlafatsa ho nepahala le botsitso. |

Bareki ba lebeletse boleng bo phahameng ba sehlahisoa le ho tsitsisa. Litsamaiso tsa Twin Screw Plastic Extruder li fana ka motsoako o phahameng le ho senya, o fokotsang likoli le ho ntlafatsa tlhahiso. Likarolo tsena li ipaka li le bohlokoa bakeng sa likarolo tsa tekheniki tse nang le litlhoko tse tiileng tsa boleng. Lintlafatso tsa theknoloji ea extruder li ntlafatsa ho nepahala le taolo, athe litsamaiso tse bohlale li lumella litokiso tsa nako ea nnete ho maemo a bohlokoa.

Baetsi ba tsetelang boiphihlelong ba lintlafatso tsa bohlokoadipoelo tse bohlokwa. Litšenyehelo tse tlase tsa tlhokomelo le ho fokotsa nako ea ho fokotsa nako li fella ka ho boloka nako e telele. Meralo e matla e netefatsa ho tšoarella le tlhahiso e ntlafalitsoeng, e etsa hore sistimi ea Twin Screw Plastic Extruder e be khetho e tšepahalang bakeng sa tlhahiso e ngata.

CNC e tsoetseng pele le theknoloji ea Nitriding bakeng sa Twin Screw Plastic Extruder

CNC Precision and Consistency in Extruder Manufacturing

Tlhahiso ea sejoale-joale e hloka ho nepahala le ho pheta-pheta. Theknoloji e tsoetseng pele ea CNC e fana ka litšoaneleho tsena bakeng sa likarolo tsa Twin Screw Plastic Extruder. Mechini ea CNC e sebelisa taolo ea komporo ho bopa likurufu le libarele ka litekanyo tse nepahetseng. Ts'ebetso ena e etsa bonnete ba hore karolo e 'ngoe le e' ngoe e lumellana hantle 'me e sebetsa ka botšepehi tlhahiso e phahameng.

Likarolo tsa bohlokoa tsa sistimi e tsoetseng pele ea CNC li kenyelletsa bohlale ba maiketsetso, li-sensor tse tsoetseng pele, le li-extruder tse tsamaisoang ke servo. Likarolo tsena li sebetsa 'moho ho ntlafatsa ts'ebetso ea extrusion. Ka mohlala, bohlale ba maiketsetso bo hlahloba lintlha le ho bolela esale pele liphello, ho lumella liphetoho tsa nako ea sebele ho mocheso le khatello. Li-sensor tse tsoetseng pele li lekola likarolo tsa bohlokoa, li fana ka maikutlo a potlakileng bakeng sa litokiso. Li-extruder tse tsamaisoang ke servo li laola lebelo la screw le khatello, tse netefatsang ho ts'oana sehlahisoa sa ho qetela. Liheaters tse sebetsang hantle haholo le litsamaiso tsa ho laola tse itšebetsang li tsoela pele ho ntlafatsa tšebeliso ea matla le boleng ba sehlahisoa.

| Sebopeho | Tlhaloso |

|---|---|

| Artificial Intelligence (AI) | E ntlafatsa lits'ebetso tsa extrusion ka ho sekaseka datha, ho bolela sephetho, le ho nolofalletsa liphetoho tsa nako ea nnete ho li-parameter joalo ka mocheso le khatello. |

| Li-Sensors tse tsoetseng pele | E lekola mocheso, khatello, le litekanyetso tsa phallo ea thepa ka nepo e phahameng, e fana ka maikutlo a nako ea nnete bakeng sa litokiso tsa hang-hang. |

| Li-Extruders tse tsamaisoang ke servo | E fana ka ho nepahala ho laola lebelo la screw le khatello, ho netefatsa ho tšoana ho lihlahisoa tse extruded. |

| Matla a Matla | Liheaters tse sebetsang hantle haholo li fokotsa tahlehelo ea matla 'me li fana ka mocheso o potlakileng, o ts'oanang bakeng sa ts'ebetso e tsitsitseng. |

| Mekhoa ea ho laola e ikemetseng | Fetola maemo a ts'ebetso ka matla ka nako ea 'nete ho ntlafatsa ts'ebetso le boleng ba sehlahisoa. |

Lintlafatso tsena li thusa bahlahisi ho fumana liphetho tse tsitsitseng, ho fokotsa litšila, le ho boloka maemo a holimo sehlopheng se seng le se seng.

Nitriding bakeng sa ho tšoarella ho matlafalitsoeng le ho se mamele

Theknoloji ea nitriding e bapala karolo ea bohlokoa ho lelefatsa nako ea bophelo ea li-screw le libarele ho li-Twin Screw Plastic Extruder systems. Ts'ebetso ena e tšoara bokaholimo ba tšepe sebakeng sa naetrojene e phahameng hoo e ka bang 950 ° F (510 ° C). Sephetho ke lera le ka ntle le thata le boima ba nyeoe pakeng tsa 55 le 65 Rc. Lera lena le thata le hanana le ho roala ha thepa e senyang 'me le boloka matla a lona ka nako.

Nitriding e fana ka melemo e mengata ho feta liphekolo tse ling tse holimo. E fana ka khanyetso e ntle ea ho roala ho feta carburizing, e nang le lesela le nang le nitrided le bonts'ang 50% e tlase ea ho apara ka tlas'a meroalo e tšoanang. Liphuputso tsa tribological li tiisa hore nitriding e feta carburizing, le ha lesela la carburized le le letenya. Ts'ebetso e etsa hore ho be le nyeoe e tšesaane, e thata e fokotsehang butle-butle ka thata, e thusang ho sireletsa khahlanong le tšenyo ea holim'a metsi.

- Theknoloji ea nitriding e fana ka khanyetso e phahameng ea ho apara ha e bapisoa le carburizing bakeng sa li-screws le libarele tsa extruder.

- Lera le nang le nitrided le bonts'a matla a tlase a 50% a ho roala tlas'a maemo a tšoanang a mojaro.

- Liphuputso tsa Tribological li bonts'a hore nitriding e na le molemo ho feta carburizing ka lebaka la thepa ea ho apara hantle leha ho na le lera le letenya la carburized.

- Nitriding e kenyelletsa ho tšoara li-screw kapa libarele sebakeng se phahameng sa naetrojene sebakeng se ka bang 950 ° F (510 ° C), se bakang ho thatafala ha maemo a phahameng (55 - 65 Rc).

- Ts'ebetso ea nitriding e theha nyeoe e tšesaane e fokotsang ho thatafala, e thusang ho boloka khanyetso ea ho roala khahlano le lisebelisoa tsa abrasive.

- Litšepe tse nepahetseng tsa nitriding, joalo ka Crucible Nitriding 135, li matlafatsa boima bo fihlelletsoeng ka ts'ebetso.

Nitriding e boetse e thusa ho thibela mekhoa e tloaelehileng ea ho hloleha ho likarolo tsa extruder. Tsena li kenyelletsamokhathala o fokolang oa potoloho e tlase, ho robeha ha brittle, le mokhathala oa ho kopana. Tafole e ka tlase e hlalosa mekhoa ena ea ho hloleha le hore na nitriding e sebetsana le eona joang.

| Mokhoa oa ho hloleha | Tlhaloso |

|---|---|

| Mokhathala o fokolang oa ho kobeha | Mokhoa o ka sehloohong oa ho hloleha o lebisang ho robeheng ha brittle gear ea pinion. |

| Ho robeha ha brittle | E bakoang ke mokhathala o fokolang oa potoloho e tlaase, e bontšang ntlha ea bohlokoa ea ho hlōleha. |

| Carburization le ho qeta holimo | Carburization ea linyeoe tse feteletseng le ho felloa ke matla holim'a metsi ho theola moeli oa mokhathala, ho kenya letsoho ho robeheng. |

| Kopana le mokhathala | Ho hloleha ha lisebelisoa ho tloaelehile, ho lebisang ho mathata a bohlokoa a ts'ebetso. |

| Mokhathala o kobehang leino | Mokhoa o mong o atileng oa ho hloleha ha likere, hangata o mpefatsoa ke kalafo e mpe ea thepa. |

Ka ho khetha nitriding, bahlahisi ba eketsa ho tšoarella ha lisebelisoa tsa bona tsa Twin Screw Plastic Extruder le ho fokotsa kotsi ea ho senyeha ho theko e boima.

Mehato e Sebetsang ea ho Ntlafatsa Li-Twin Screw Plastic Extruders

Ho ntlafatsa lisebelisoa tse teng tsa Twin Screw Plastic Extruder ho hloka moralo o hlokolosi. Baetsi ba lokela ho qala ka ho lekola boemo ba hajoale ba lisebelisoa tsa bona. Ba hloka ho tseba hore na ke likarolo life tse tla u tsoela molemo haholo ho tsoa ho mochini oa CNC kapa kalafo ea nitriding.

Ho nahanoa ka litšenyehelo ho bapala karolo e kholo ho ntlafatsa liqeto. Boholo ba extruder, litšenyehelo tsa thepa, le ho rarahana ha tlhahiso kaofela li ama matsete kaofela. Li-extruder tse nyane li na le litšenyehelo tse tlase tsa thepa le litlhoko tse bonolo tsa tlhahiso. Li-extruder tse mahareng le tse kholo li hloka lisebelisoa tse ngata le theknoloji e tsoetseng pele, e eketsang litšenyehelo.

| Boholo ba Extruder | Litšenyehelo tsa Lintho | Ho rarahana ha Tlhahiso |

|---|---|---|

| Nyenyane | Tlase | E bonolo |

| Mahareng | E itekanetseng | E itekanetseng |

| E kholoanyane | Phahameng | Rara |

Baetsi ba boetse ba lokela ho nahana ka ho lumellana ha thepa le bokhoni ba tlhahiso. Li-extruder tse fapaneng li sebetsana le lisebelisoa tse fapaneng, tse ka amang litšenyehelo tsa ntlafatso. Ts'ebetso e phahameng haholo e kanna ea hloka likarolo tse tsoetseng pele, joalo ka li-automation le litsamaiso tse baballang matla. Le hoja likarolo tsena li eketsa litšenyehelo tsa pele, hangata li lebisa polokelong ea nako e telele ka tlhokomelo e fokotsehileng le tšebeliso ea matla.

- Ho lumellana ha thepa ho ama litšenyehelo tsa ntlafatso.

- Bokhoni ba tlhahiso bo etsa qeto ea tlhokahalo ea li-extruder tse phahameng.

- Likarolo tsa theknoloji, joalo ka ho iketsetsa le ho sebetsa hantle ha matla, li hloka matsete a holimo empa li fana ka poloko ea nako e telele.

Keletso: Ho sebelisana le bahlahisi ba nang le boiphihlelo, joalo ka Zhejiang Jinteng Machinery Manufacturing Co., Ltd., ho netefatsa phihlello ea CNC e tsoetseng pele le theknoloji ea nitriding. Bokhoni ba bona bo thusa ho ntlafatsa ts'ebetso ea ntlafatso le ho ntlafatsa ts'ebetso ea lisebelisoa.

Ka ho latela mehato ena, bahlahisi ba ka ntlafatsa lits'ebetso tsa bona tsa Twin Screw Plastic Extruder, ba ntlafatsa ts'ebetso, le ho lelefatsa bophelo ba lisebelisoa.

Baetsi ba fihlela katleho e phahameng le ho tšoarella ka ho ntlafatsa li-extruder ka CNC le theknoloji ea nitriding. Tafole e ka tlase e totobatsa melemo ea nako e telele:

| Molemo | Tlhaloso |

|---|---|

| Phatlalatso e Phahameng ea Tlhahiso | E ntlafatsa ts'ebetso, e eketsa bophelo ba ts'ebeletso, 'me e eketsa nako e tsoelang pele ea ho sebetsa ea mechini. |

| Ho tsitsisa le ho Nepaha | E hlahisa likarolo tse nang le mamello e thata le ho nepahala ho phahameng bakeng sa tlhahiso e tsitsitseng. |

| Litšenyehelo-Ka katleho | E fokotsa litšila, e fokotsa litšila, 'me e eketsa tšebeliso ea thepa. |

Mehato e latelang: Tsetela ho litheknoloji tse tsoetseng pele, tsepamisa maikutlo ho lisebelisoa tse bolokang tikoloho, le basebetsi ba literene bakeng sa ts'ebetso e nepahetseng ea sistimi.

LBH

Ke melemo efe eo theknoloji ea CNC e e tlisetsang lintlafatso tse peli tsa screw extruder?

Theknoloji ea CNCe netefatsa tlhahiso e nepahetseng. E ntlafatsa ho tsitsisa ha karolo le ho fokotsa litšila. Baetsi ba fumana katleho e phahameng le boleng bo betere ba sehlahisoa ka lintlafatso tsa CNC.

Nitriding e lelefatsa bophelo ba li-scruder screws le barrel joang?

Nitriding e etsa sebaka se thata sa bokaholimo. Lera lena le hanana le ho roala le ho khojoa. Lisebelisoa li nka nako e telele 'me ha li hloke ho nchafatsoa khafetsa.

Na li-extruder tse teng li ka ntlafatsoa ka CNC le theknoloji ea nitriding?

Ee. Baetsi ba ka khutlisa litsamaiso tsa hajoale. Lintlafatso li ntlafatsa ts'ebetso, li eketsa nako e telele, 'me li fokotsa litšenyehelo tsa tlhokomelo.

Keletso: Ikopanye le bahlahisi ba nang le boiphihlelo bakeng sa litharollo tse ntle ka ho fetisisa tsa ntlafatso tse etselitsoeng litlhoko tse khethehileng tsa tlhahiso.

Nako ea poso: Sep-02-2025