Li-extruder tsa Twin-screw li fetotse ts'ebetso ea polymer ka ho thusa taolo e nepahetseng le ts'ebetso e phahameng. Meetso e tsoetseng pele eaextruder double screw, joalo ka ba ntlafatsang lebelo la ho potoloha, ba fokolitse tšebeliso ea matla ka 45% ha ba ntse ba eketsa khatello ka 65%. Digitalization e boetse e ntlafatsa tlhahlobo ea ts'ebetso, ho netefatsa boleng bo tsitsitseng. Mekhoa e sebetsang hantle ea matla e fokotsa litšila, e ts'ehetsa ts'ebetso ea moshoelella eamochini oa extrusion oa polasetiki. Litlhahiso tsena li bula menyetla e mecha, ho tloha ho hlahisa likarolo tse rarahaneng ho isa ho lisebelisoa tsa ho hloekisa bakeng sa liindasteri tse fapaneng, ho kenyeletsa le tšebeliso eatwin screw for extruderlits'ebetso.

Ho utloisisa Li-Extruders tsa Twin-Screw

Ho hlalosa Twin-Screw Extruders

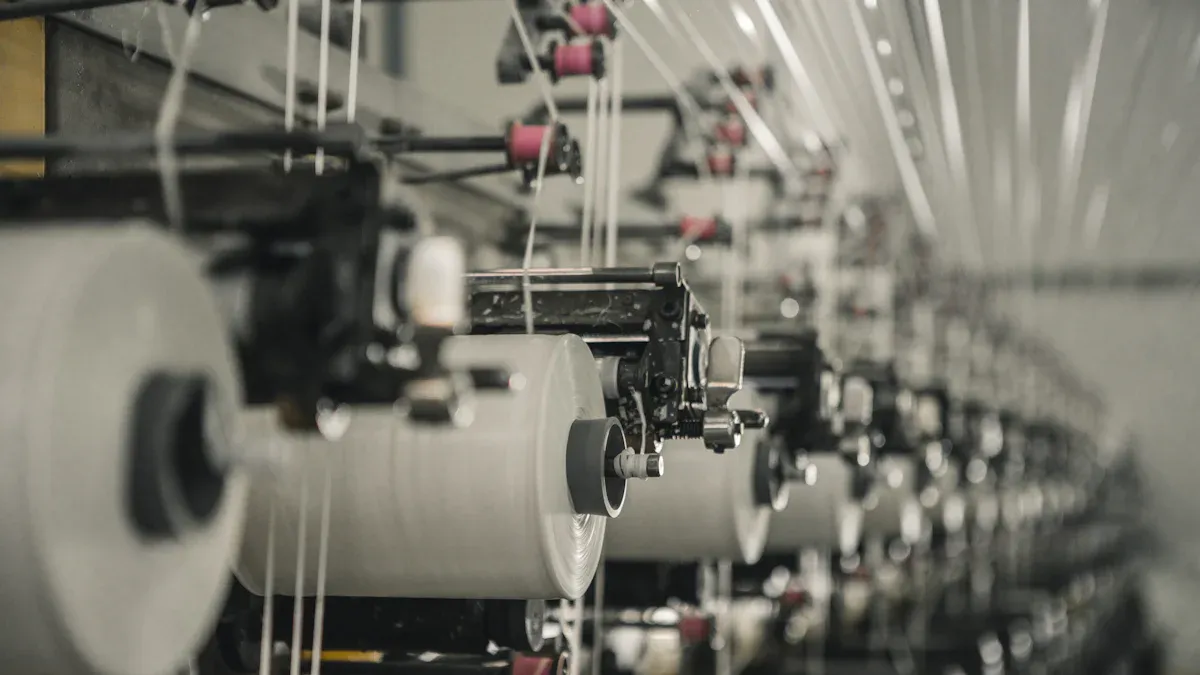

Li-extruders tsa li-twin-screwKe mechini e tsoetseng pele e sebelisoang ha ho etsoa polima ho qhibiliha, ho kopanya le ho bopa thepa. Ho fapana le li-extruder tse nang le sekoahelo se le seng, li na le li-screw tse peli tse harelaneng tse potolohang ka har'a moqomo, tse fanang ka taolo e phahameng holim'a phallo ea thepa le ho kopanya. Moqapi oa tsona o lumella litokiso tse nepahetseng ho kuta, mocheso le khatello, e leng se etsang hore e be tse loketseng bakeng sa lisebelisoa tse rarahaneng.

Tafole e latelang e totobatsa lintlha tsa bohlokoa tse hlalosang li-twin-screw extruder:

| Karolo | Tlhaloso |

|---|---|

| Geometry | E na le li-screws tse peli tse nang le geometry e kopanyang, ho fapana le mechini e le 'ngoe. |

| Mokhoa | E sebelisa mokhoa o ikhethileng oa ho qhibilihisa, ho kopanya le ho pompa lisebelisoa. |

| Lisebelisoa | E loketse lits'ebetso tse tsoetseng pele joalo ka ho kopanya mekhahlelo e mengata le extrusion e sebetsang. |

| Ho rarahana | E hloka moralo o khethehileng le nomenclature ka lebaka la sebopeho sa eona se rarahaneng. |

| Papiso | E fetisa li-extruder tse nang le sekoaelo se le seng ka ho kopanya, taolo ea mocheso, le ho feto-fetoha ha maemo. |

Litšobotsi tsena li etsa hore li-extruder tse peli-screw e be tsa bohlokoa haholo indastering e hlokang ho nepahala le ho sebetsa hantle haholo.

Bohlokoa ho Ntlafatso ea Polymer le ho Kopanya

Li-extruder tse peli-screw li bapala karolo ea bohlokoa hoho sebetsa ha polymerka ho thusa ho kopanya, ho kopanya, le ho senya. Bokhoni ba bona ba ho sebetsana le lisebelisoa tse fapaneng, ho kenyeletsoa thermoplastics, elastomers, le li-fillers, li ba etsa lisebelisoa tse ngata tse fapaneng tlhahisong.

Lipatlisiso li bonts'a hore li-extruder tse nang le li-twin-screw li ka sebetsa habeli ts'ebetsong ea lebelo le holimo ntle le ho hlahisa mocheso o feteletseng. Bokhoni bona bo bakoa ke moralo oa bona o tsoetseng pele oa screw, o ntlafatsang phallo ea thepa le ho kopanya. Ho feta moo, taolo ea bona ea mocheso e phahameng e netefatsa boleng bo tsitsitseng ba sehlahisoa, esita le lits'ebetsong tse hlokang.

Tafole e ka tlase e bapisa bokhoni ba bona le li-extruder tsa "screw" tse le 'ngoe:

| Sebopeho | Twin-Screw Extruder | Mokokotlo o le Mong oa Mokokotlo |

|---|---|---|

| Ho kopanya | Bokhoni ba ho kopanya bo phahameng ka lebaka la ho potoloha | Bokhoni bo fokolang ba ho kopanya |

| Taolo ea Shear | Taolo e ntlafalitsoeng ea ho kuta bakeng sa lisebelisoa tse fapaneng | Taolo e sa nepahaleng haholo ea ho kuta |

| Mokhoa oa ho Fetolana | Ho feto-fetoha ha maemo ho sebetsa ka lisebelisoa tse fapaneng | E fokolang ho ikamahanya le maemo |

| Taolo ea Mocheso | Taolo e betere ea litlaleho tsa mocheso | Taolo e sa sebetseng hantle |

| Kopo | E loketse lits'ebetso tse rarahaneng joalo ka ho kopanya mekhahlelo e mengata | Mesebetsi ea mantlha ea ts'ebetso |

Melemo ena e entse li-extruder tse mafahla e le khetho e ratoang bakeng sa ho kopanya polymer, e leng ho nolofalletsang bahlahisi ho hlahisa thepa ea boleng bo holimo ka katleho.

Mekhoa e mecha ho Twin-Screw Extruders

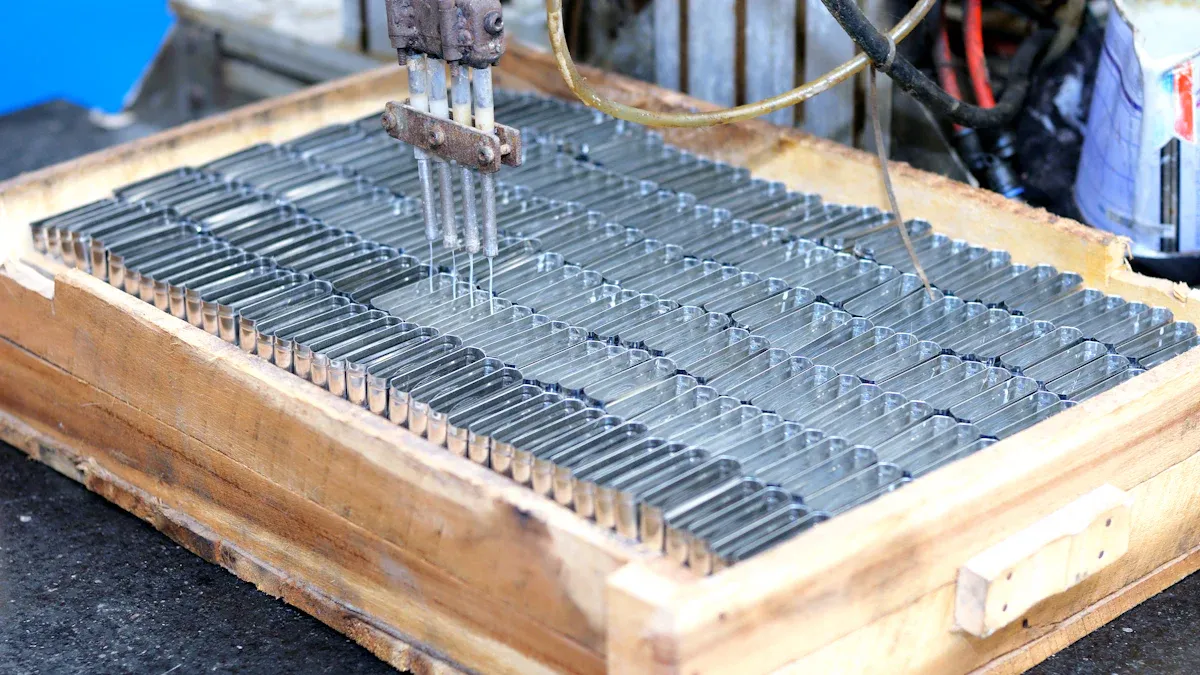

Meetso e tsoetseng pele ea Screw

Lintlafatso tsa morao-rao tsa meralo ea li-screw li ntlafalitse haholo ts'ebetso ea li-twin-screw extruder. Litlhahiso tsena li shebane le ho ntlafatsa ts'ebetso, ho tšoarella le ho nepahala. Lintlafatso tsa mantlha li kenyelletsa:

- Meetso e Ntlafetseng ea Potoloho ea Ball: Sistimi e ntlafalitsoeng e fokotsa lerata le ho thothomela, e netefatsa hore ts'ebetso e sebetsa hantle le ho se khathatse ho fokolang.

- Libopeho tsa Lota tse Phahameng ka ho Fetisisa: Libopeho tse ntlafalitsoeng tsa lead li eketsa bokhoni ba mojaro le katleho ea ts'ebetso.

- Lisebelisoa tse tsoetseng pele: Lisebelisoa tsa boemo bo phahameng li ntlafatsa ho tšoarella le ho hanyetsa ho bola.

- Mekhoa e nepahetseng ea ho Etsa: Ho mamellana ho thata le ho qeta holimo holimo ho fokotsa khohlano le ho ntlafatsa ho nepahala.

- Ho Tiisa le ho Lubrication Innovations: Theknoloji e ncha e eketsa nako ea bophelo ea likarolo ha e ntse e boloka katleho.

- Meetso ea Nut: Litlhophiso tse ncha li fokotsa papali ea axial le ho ntlafatsa ho nepahala.

- Ho kopanya le Electronics: Li-screws tsa bolo tse bohlale li thusa ho lokisoa esale pele ka ho lekola ts'ebetso.

- Miniaturization: Meralo e menyenyane ea screw e sebetsana le lits'ebetso tse nepahetseng.

- Boikemisetso: Litharollo tse hlophisitsoeng li sebetsana le litlhoko tse khethehileng tsa kopo.

- Matla a Matla: Lintlafatso tsa moralo li fokotsa tšebeliso ea matla nakong ea ts'ebetso.

Lipatlisiso li totobatsa hore li-processor tse ngata li ntse li itšetlehile ka meralo ea khale ea screw, e fokotsang tlhahiso ea bona. Ka ho sebelisa meralo e tsoetseng pele ea li-screw, bahlahisi ba ka fihlela ts'ebetso e ntle ea ho qhibiliha le ho feta, e lebisang ho ntlafatseng ts'ebetso ka kakaretso.

Digitalization le Smart Controls

Digitalization e fetotse li-extruder tse peli ka ho kopanya li-control tse bohlale le lits'ebetso tse tsoetseng pele tsa ho beha leihlo. Mahlale ana a ntlafatsa ts'ebetso, a fokotsa nako, 'me a ntlafatsa boleng ba sehlahisoa.

| Selemo | Khampani | Tlhaloso ea Theknoloji | Katleho Melemo |

|---|---|---|---|

| 2023 | Copeion GmbH | E tsebisitse letoto le lecha la li-extruder tse mafahla kamatla a matla a ntlafetseng | Matla a matla a ntlafetseng |

| Litsamaiso tse ntlafetseng tsa taolo bakeng sa ho sebetsana le lipolasetiki tse tsosolositsoeng | Ntlafatso ea ts'ebetso ea ts'ebetso | ||

| Khokahano ea mahlale a indasteri ea 4.0 (IoT, AI, ML) ho li-extruder | Bokhoni ba ho hlokomela esale pele |

Lithuto-pale li bonts'a katleho ea lintlafatso tsena. Mohlala:

- Moetsi oa lipeipi tsa PE o kentse sistimi e bohlale ea PLC e nang le tlhaiso ea IoT. Sena se ile sa fokotsa sekhahla sa ho hloleha ha lisebelisoa ka 20%, sa ntlafatsa boleng ba lihlahisoa, 'me sa fokotsa tšebeliso ea matla ka 15%.

- Moetsi oa profil ea PVC o amohetse sistimi ea mafahla a dijithale, a fokotsa litefiso tsa bofokoli ho tloha ho 4% ho isa ho 1.2% mme a khutsufatsa nako ea ho lokisa bothata ka 30%.

Mehlala ena e totobatsa kamoo digitalization e thusang bahlahisi ho ntlafatsa ts'ebetso le ho fumana liphetho tse holimo.

Matla a Matla le Moshoelella

Ho sebetsa hantle ha matla ho fetohile motheo oa moralo oa sejoale-joale oa twin-screw extruder. Hona joale bahlahisi ba etelletsa pele ho fokotsa tšebeliso ea matla ha ba ntse ba boloka litefiso tse phahameng tsa tlhahiso.

| Boholo ba Extruder | Sebaka sa Tšebeliso ea Matla | Sekhahla sa Tšebeliso (kWh/kg) |

|---|---|---|

| Nyenyane (10–50 mm) | 5–50 kW | Matla a tlaase: 0.10–0.30 |

| Boholo bo Bohareng (50–120 mm) | 50-300 kW | Boima bo itekanetseng: 0.30–0.60 |

| Indasteri e kholo (120+ mm) | > 500 kW | Matla a Phahameng: 0.60–1.00 kapa ho feta |

Maano a ho ntlafatsa joalo ka li-motor tse bolokang matla, meralo e tsoetseng pele ea li-screw, le litsamaiso tsa taolo ea ts'ebetso li eketsa ts'ebetso. Li-extruder tsa Twin-screw li boetse li fokotsa litšila le ho holisa tlhahiso, li kenya letsoho mekhoeng ea ho etsa eco-friendly. Bokhoni ba bona ba ho fana ka ho kopanya hantle le ho fana ka thepa ho fokotsa matla a hlokahalang bakeng sa ho sebetsa, ho ntlafatsa phallo ea volumetric le katleho ka kakaretso.

Lintlha tse matla li tšehetsa liqoso tsena, tse bonts'ang hore ho ntlafatsa palo ea tlhahiso le ho fokotsa nako ea ts'ebetso e sa sebetseng ho ka fokotsa tšusumetso ea tikoloho haholo. Dikgatelopele tsena di tsamaellana le tsepamiso ya maikutlo e ntseng e hola ya indasteri hodima tlhahiso ya moshwelella.

Litšusumetso ho Liindasteri tsa Polymer

Boleng bo ntlafetseng ba Sehlahiswa

Lintlafatso tsa li-twin-screw extruder li ntlafalitse boleng ba sehlahisoa haholo indastering ea polymer.Meetso e tsoetseng pele ea screwle lisebelisoa tsa ho hlahloba nako ea sebele li netefatsa hore ho na le taolo e nepahetseng holim'a li-parameter tsa bohlokoa, tse hlahisang tlhahiso e tsitsitseng le e phahameng. Mohlala, li-extruder tsa sejoale-joale li sebelisa mahlale a kang haufi-infrared (NIR) le Raman spectroscopy ho lekola litšobotsi tsa boleng ka nako ea nnete. Lisebelisoa tsena li fana ka maikutlo a hang-hang, ho nolofalletsa bahlahisi ho boloka maemo a matle nakong eohle ea ts'ebetso.

Tafole e latelang e totobatsa mehato ea bohlokoa ea ntlafatso ea boleng e tsamaisoang ke mahlale a marang-rang a extruder:

| Lekanya | Tlhaloso |

|---|---|

| Mongobo | E behiloe leihlo ho netefatsa maemo a nepahetseng a granulation. |

| API Content Uniformity | E lekoa ho boloka phepelo ea metsoako ea meriana e tsitsitseng. |

| Kopanya Uniformity | E hlahlojoa ho netefatsa homogeneity ka motsoako pele ho granulation. |

| Kabo ea boholo ba Granule | D10, D50, le D90 likaroloana li behiloe leihlo ho lekola phapang ea boholo ba likaroloana ka nako ea nnete. |

| Boemo bo tiileng ba motsoako o sebetsang | Ho netefatsoa ho boloka ts'ebetso ea motsoako o sebetsang nakong eohle ea ts'ebetso. |

| Lisebelisoa tsa Tlhokomelo ea Nako ea 'Nete | Lisebelisoa tse sebelisitsoeng joalo ka NIR le Raman spectroscopy bakeng sa maikutlo a hanghang mabapi le litšobotsi tsa boleng. |

Litlaleho tsa indasteri li tiisa tsoelopele ena. Mohlala, "Twin Screw Extruders Market size, Growth, Trends, Report 2034" e totobatsa kamoo lintlafatso tsa mahlale a meralo ea li-screw le mekhoa ea ho pholisa li ntlafatsang ts'ebetso ea tlhahiso le ho ntlafatsa boleng ba sehlahisoa.

Tšebeliso ea Litšenyehelo le Nako

Li-extruder tse peli tsa "twin-screw" li hlalositse litšenyehelo le nako e sebetsang hantle ha ho etsoa polymer. Bokhoni ba bona ba ho sebetsana le ts'ebetso e rarahaneng ka tšebeliso e fokolang ea matla bo fokotsa litšenyehelo tsa ts'ebetso. Likhamphani tse sebelisang meralo e ntlafalitsoeng ea li-screw li tlaleha ntlafatso e fihlang ho 20% ts'ebetsong ea matla a matla, e ntlafatsa ts'ebetso ea ho kopanya le ho tšoana ha sehlahisoa. Ho feta moo, ho kopanngoa ha litsamaiso tsa Model Predictive Control (MPC) ho eketsehile ho feta ka 15% ha ho ntse ho fokotsa thepa ea off-spec ka 10%.

Likhatelo-pele tse ling tse hlokomelehang li kenyelletsa tšebeliso ea lisebelisoa tsa mocheso bakeng sa ho hlaphoheloa ha matla a mocheso, e leng se lebisitseng phokotsong ea 12% ea tšebeliso ea matla. Litlhahiso tsena ha li fokotse litšenyehelo tsa tlhahiso feela empa hape li fokotsa tšusumetso ea tikoloho.

Melemo ea mantlha ea moruo e kenyelletsa:

- E ntlafalitse ts'ebeliso ea matla ea matla ka meralo e tsoetseng pele ea li-screw.

- Phallo e ntseng e eketseha ka litsamaiso tsa taolo ea esale pele.

- Litšila tse fokolitsoeng ka li-automated extrusion systems.

The North America Plastic Extrusion Machinery Marketing Market e totobatsa bohlokoa ba moruo ba li-twin-screw extruder. Karolo ea bona ho hlahiseng liphutheloana tse feto-fetohang, li-tubing tsa bongaka, le lihlahisoa tse ling tse batloang haholo li bonts'a boleng ba tsona ba ho fihlela tlhahiso e theko e tlaase le e sebetsang hantle.

E nolofalletsa Lisebelisoa tse Ncha

Tsoelo-pele ea morao-rao ea theknoloji ea twin-screw extruder e butse mamati a lisebelisoa tse ncha ho pholletsa le indasteri. Litlhareng tse nepahetseng, mechini ena e thusa ho theha litlhare tse ikhethileng, tse netefatsang liphekolo tse etselitsoeng bakuli ka bomong. Ho kopanngoa ha bohlale ba maiketsetso ho tsoela pele ho ntlafatsa katleho ea ts'ebetso ka ho etsa hore ho lokisoe esale pele le ho ntlafatsa ts'ebetso.

Litlhahiso tse shebaneng le ts'ebetso le tsona li atolositse boholo ba li-twin-screw extruder. Mechini ena hona joale e sebetsana le lisebelisoa tse bolokang tikoloho joalo ka li-polymer tse ka bolang le lipolasetiki tse nchafalitsoeng, tse tsamaellanang le boiteko ba lefats'e ba ho fokotsa tšusumetso ea tikoloho. Ho feta moo, ho tenyetseha ha bona ho ts'ehetsa tlhahiso ea lisebelisoa tse sebetsang hantle haholo bakeng sa indasteri ea likoloi, ea sefofane le thepa ea bareki.

Litlaleho tsa lipatlisiso tsa 'maraka li totobatsa lintlafatso tsena. Mohlala, "Rubber Twin-Screw Extrusion Equipment Market" e totobatsa tsoelo-pele ea mahlale a thepa le boiketsetso, e tsamaisang ho amoheloa ha meralo ea li-twin-screw bakeng sa tlhahiso e phahameng le boleng ba sehlahisoa se holimo. Litlhahiso tsena li ntse li tsoela pele ho sutumelletsa meeli ea seo li-extruder tse peli-screw li ka se finyellang, ho nolofalletsa baetsi ho hlahloba meeli e mecha ea ho sebetsa ha polymer.

Li-extruder tsa Twin-screw li ntse li tsoela pele ho hlalosa ts'ebetso ea polymer ka ho ntlafatsa ts'ebetso, ts'ebetso le ts'ebetso e fapaneng. Litlhahiso tsa morao-rao, tse kang meralo ea modular le li-screw tse tsoetseng pele, li thusa bahlahisi ho ikamahanya le litlhoko tse fetohang kapele.

- Hona joale mechine ena e tšehetsa mekhoa e tsitsitseng, ho kenyelletsa le lits'ebetso tsa litšila ho ea sehlahisoa le tlhahiso ea li-plastiki tse thehiloeng ho likokoana-hloko.

- Litheknoloji tsa boiketsetso le tse bohlale ho nahanoa hore li tla eketsa tlhahiso ka 20%, ho netefatsa boleng bo tsitsitseng le ts'ebetso e sebetsang hantle.

Ho lula u tseba ka tsoelo-pele ena ho tla thusa liindasteri ho fumana tharollo e tsoetseng pele bakeng sa kholo ea nako e tlang.

LBH

Melemo ea mantlha ea li-twin-screw extruder ho feta li-extruder tsa single-screw ke life?

Li-extruder tsa Twin-screw li fana ka motsoako o phahameng, taolo e betere ea mocheso, le maemo a phahameng a ho feto-fetoha ha maemo. Likarolo tsena li li etsa hore li tšoanelehe bakeng sa lits'ebetso tse rarahaneng tsa polymer.

Meralo e tsoetseng pele ea screw e ntlafatsa ts'ebetso ea extrusion joang?

Meralo e tsoetseng pele ea li-screw e ntlafatsa phallo ea thepa, e fokotsa tšebeliso ea matla, le ho ntlafatsa ho nepahala ha motsoako. Litlhahiso tsena li netefatsa boleng bo tsitsitseng ba sehlahisoa le katleho e phahameng ea ts'ebetso.

Na li-extruder tsa li-twin-screw li ka tšehetsa tlhahiso e tsitsitseng?

Ee, li-extruder tsa li-twin-screw li fokotsa litšila le ho sebetsana le thepa e ka senyehang kapa e sebelisoang hape. Sistimi ea bona e baballang matla e hokahana le mekhoa ea tlhahiso ea eco-friendly. ♻️

Keletso: Tlhokomelo ea kamehla e tiisa ts'ebetso e nepahetsengle ho lelefatsa nako ea bophelo ea li-twin-screw extruder.

Nako ea poso: May-30-2025