Ke tšepa PVC Pipe screw barrel bakeng sa extrusion hobane e sebelisa tšepe ea premium alloy le liphahlo tse tsoetseng pele. Ke bona kamoo likarolo tsena li e thusang ho hanela mocheso, khatello le ho khathala. Ha ho bapisoa le likhetho tse tloaelehileng, tefisoPipe ea PVC e nang le sekoti se le senge nka nako e telele ho isa ho makhetlo a tšeletseng. Ke boetse ke itšetlehile ka amoqomo o le mong wa screw bakeng sa ho bopale aPE pipe extruder single screw barrelbakeng sa mesebetsi e boima.

Thepa le Kaho ea PVC Pipe Screw Barrel bakeng sa Extrusion

Khetho ea tšepe ea Premium Alloy

Ha ke khetha PVC Pipe screw barrel bakeng sa extrusion, ke tsepamisa maikutlo holim'a tšepe ea alloy. Tšepe e nepahetseng e etsa phapang eohle ea ho tšoarella le ho sebetsa. Ke itšetlehile ka thepa e kang38CrMoAlA le 42CrMohobane ba fanamatla a phahameng le khanyetso e babatsehang ea ho apara. Litšepe tsena li sebetsana le maemo a thata a extrusion, ho kenyelletsa mocheso o phahameng le khatello. Ke boetse ke batla libarele tse nang le li-bimetallic liner kapa li-stainless steel cladding ha ke hloka tšireletso e eketsehileng khahlanong le ho senyeha ha metsoako ea PVC ea chlorine.

Mona ke tse ling tsa litšepe tsa alloy tse atileng haholo le ts'ebeliso ea tsona:

| Alloy Steel / Thepa | Litšobotsi Tsa Sehlooho | Kopo ka PVC Screw Barrels |

|---|---|---|

| AISI 4140 | Matla a matle, mocheso o phekolehang, o fumaneha hohle | E tloaelehileng bakeng sa boholo ba libarele tsa PVC tsa screw |

| AISI 4340 | Matla a phahameng, ho kenella hantle kalafo ea mocheso | E sebelisoa bakeng sa lifofane tse tebileng kapa li-screw tse nyenyane tsa bophara |

| Nitralloy 135-M | Aluminium bakeng sa nitriding, e ntlafetseng ea ho hanyetsa ho apara | Libaka tse nang le nitrided bakeng sa bophelo bo bolelele |

| 17-4 PH Tšepe e sa hloekang | E matla, e hana ho bola | Li-screws tse nyane tse hlokang ho senyeha |

| D2 le H13 Tool Steels | Ho hanyetsa ho apara ho phahameng, ho ka phekoleha mocheso, ho thibela ho bola | Libaka tse phahameng tsa abrasion, matsoho, li-screws tsa polasetiki |

| CPM Tool Steels (CPM 10V, joalo-joalo) | E phahameng ka ho fetisisa abrasion le corrosion resistance | Metsoako e tletseng, ho hanyetsa ho apara nako e telele |

Kamehla ke khetha kereiti ea tšepe ho latela litlhoko tsa ts'ebetso ea extrusion. Litšepe tse nang le matla a phahameng a alloy le li-alloys tsa bimetallic li mpha kholiseho ea hore PVC Pipe screw barrel bakeng sa extrusion e tla nka lilemo tse ngata tsa tšebeliso e boima.

Meriana e Tsoetseng Pele ea Bokaholimo le Bothata

Liphekolo tsa holim'a metsi li bapala karolo e kholo ea hore na libarele tsa ka tsa screw li nka nako e kae. Ke sebelisa nitriding ho theha lesela le thata holim'a tšepe, le ka fihlang ho 70 HRC. Lera lena le hanela ho roala le khatello ea maikutlo, esita le ha moqomo o tobane le khatello e phahameng le mocheso. Chrome plating e eketsa bokaholimo bo boreleli mme e fokotsa khohlano, e etsa hore ho hloekisoe habonolo le ho ntlafatsa phallo ea ho qhibiliha. Ka linako tse ling, ke khetha li-alloys tsa bimetallic kapa liaparo tsa tungsten carbide bakeng sa ho hanyetsa ho hoholo le ho feta.

Keletso: Nitriding e etsa lesela la nitride le ka bang botebo ba 0.5-0.8mm, le sireletsang moqomo hore o se ke oa senyeha kapa oa bola. Chrome plating, hangata 10-50 microns botenya, e boloka bokaholimo bo thella mme e thusa ho thibela ho bokellana ha thepa.

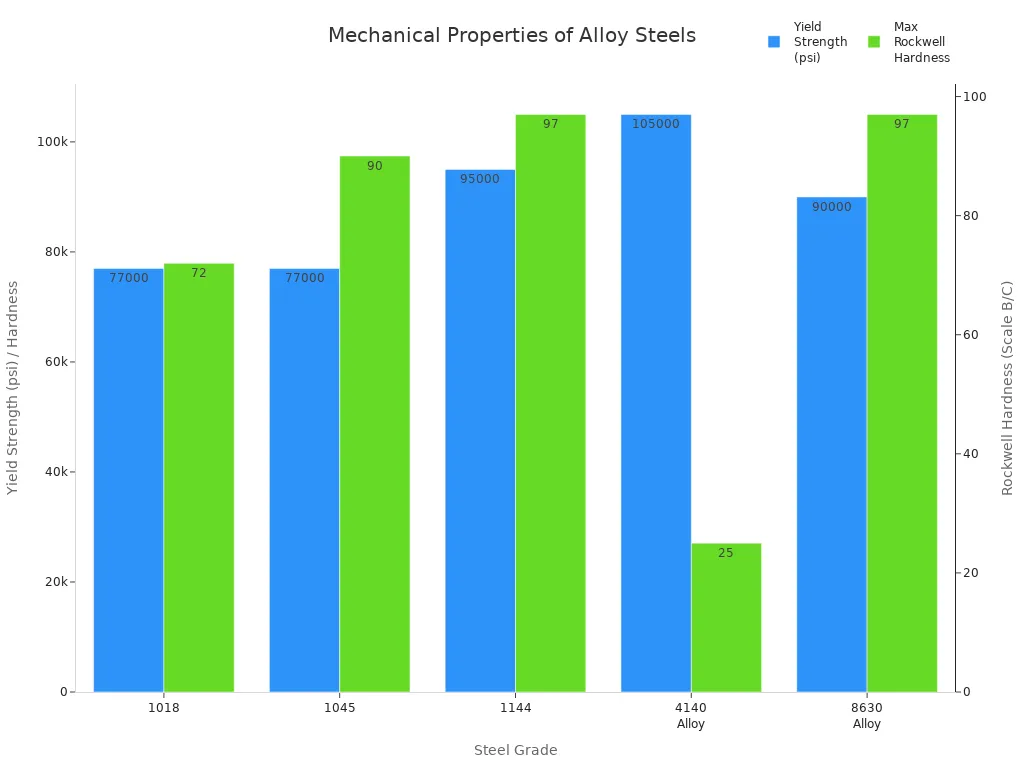

Mona ke ho sheba ka potlako litšobotsi tsa mochini oa litšepe tseo ke li sebelisang:

| Kereiti ea tšepe | Yield Strength (psi) | Max Rockwell Hardness (Sekala) | Lintlha mabapi le Thepa le Tšebeliso |

|---|---|---|---|

| Motsoako oa 4140 | 60,000 - 105,000 | C20 – C25 | E thata, e boreleli, ha e koalehe |

| 17-4 PH E se nang litšila | 110,000 | C40 | E matla, e hana ho bola |

| D2 Tool Steel | 90,000 | C55 | Ho hanyetsa ho apara ho phahameng, ho hanyetsa ho bola |

Kamehla ke bapisa phekolo e ka holimo ho mofuta oa polasetiki le li-additives tseo ke li sebelisang. Ka tsela ena, sekoti sa ka sa PVC Pipe bakeng sa extrusion se lula se tšepahala ebile se sebetsa hantle.

Tlhahiso e Nepahetseng le Botšepehi ba Sebopeho

Ho etsa ka nepo ke mokokotlo oa moqomo o tšoarellang oa screw. Ke ts'epa hore mochini oa CNC o tla boloka mamello e tiile, ka linako tse ling e nepahetse joalo ka ± 0.01 mm. Ho nepahala hona ho netefatsa sekoti le mesh ea moqomo hantle, e leng bohlokoa bakeng sa phetiso e nepahetseng ea PVC le ho kopanya. Ke ela hloko ka ho fetisisa ho screw geometry-lifofane, botebo ba mocha, sekontiri se phahameng le tekanyo ea khatello. Likarolo tsena li nthusa ho laola khatello le mocheso, ho thibela ho senyeha ha thepa.

- Ke sebelisa likarolo tsa vacuum vent le lintho tse kopanyang ho tlosa likhase tse qabeletsoeng le ho kopanya lisebelisoa hantle.

- Lintho tse futhumatsang le likanale tse pholileng ka har'a barrel li ntumelle ho laola libaka tsa mocheso, ho boloka ho qhibiliha ho tsitsitse.

- Litsamaiso tse kopaneng tsa taolo li ntumella ho beha leihlo le ho lokisa ts'ebetso ka nako ea nnete, ho boloka ho nepahala ha maemo le ho thibela liphoso.

Ha ke hlokomela ho kheloha hofe kapa hofe, ke nka khato kapele. Esita le liphetoho tse nyenyane li ka fokotsa bokhoni ba ho fetisa le ho sebetsa hantle ka polasetiki, ho lebisa ho marako a liphaephe a sa lekaneng kapa likaroloana tse sa qhibilihang. Ka ho boloka ho nepahala, ke netefatsa hore sekoti sa ka sa PVC Pipe bakeng sa extrusion se fana ka boleng bo tsitsitseng le bophelo bo bolelele ba ts'ebeletso.

Moralo le Melemo ea Ts'ebetso ea PVC Pipe Screw Barrel bakeng sa Extrusion

Optimized Screw Geometry le Phepo e sa Tšoaneng

Ha ke khetha PVC Pipe screw barrel bakeng sa extrusion, ke ela hloko geometry ea screw. Moralo o nepahetseng o nthusa ho fumana phepo e ntle le e ts'oanang ea thepa ea PVC. Ke batla likarolo tse tšehetsang lipalangoang tse sebetsang hantle le ho kopanya. Mona ke lintlha tsa bohlokoa tsa moralo tseo ke li nahanang:

- Lifofane tse tebileng le likanale tse karolong e tsamaisang thepa li tsamaisa thepa kapele ntle le ho kuta haholo.

- Botebo ba mocha bo fokotseha ho tloha sebakeng sa phetisetso ho ea sebakeng sa metering, se lekanyang ho qhibiliha le ho kopanya.

- Sebaka se seholo sa sefofane se tsamaisa lintho tse ngata ka matla a fokolang, ha likarolo tse ka morao li thusa ho laola ho phalla le ho ntlafatsa ho kopanya.

- Karolo ea phepo e boloka thepa e phalla le ho thibela li-blockages.

- Karolo ea compression e qhibiliha ebe e kopanya PVC, e sebelisa mocheso o tsoang ho khohlano.

- Karolo ea metering e netefatsa tlhahiso e tsitsitseng ea thepa e qhibilihisitsoeng.

Kamehla ke etsa bonnete ba hore screw geometry e lumellana le thepa ea PVC le litlhoko tsa ts'ebetso ea extrusion. Moralo ona o hlokolosi o nthusa ho qoba liphoso le ho boloka thepa e phallang e tsitsitse.

Ha ke hlokomela hore sekoti, ke nka khato kapele. Esita le liphetoho tse nyenyane tsa geometry li ka baka phallo e sa tšoaneng le mefokolo phala ea ho qetela. Ka ho boloka screw e le sebopeho se holimo, ke boloka extrusion ea boleng bo holimo le ho fokotsa litšila.

Mekhoa e Kopantsoeng ea ho futhumatsa le ho futhumatsa

Taolo e nepahetseng ea mocheso e bohlokoa bakeng sa ho hlahisa liphaephe tse matla le tse tsitsitseng tsa PVC. Ke itšetlehile ka lisebelisoa tse tsoetseng pele tsa ho futhumatsa le ho pholisa tse hahiloeng ka har'a barrel ea screw. Lisebelisoa tsena li nthusa ho boloka mocheso o nepahetse nakong ea mohato o mong le o mong oa extrusion.

| Mofuta oa Sistimi | Tlhaloso | Boemo ba Kopo |

|---|---|---|

| Sistimi ea ho futhumatsa | Mekhoa ea ho futhumatsa motlakase, e kang ho kenya le ho futhumatsa ho hanyetsa, e sebelisoa ka ntle ho moqomo | E fana ka mocheso o hlokahalang ho qhibilihisa PVC |

| Mokhoa oa ho Pholisa | Lisebelisoa tsa ho futhumatsa metsi kapa moea; pholiso ea moea bakeng sa li-extruders tse nyane, metsi bakeng sa tse kholoanyane | E thibela ho futhumala ho feteletseng le ho boloka mocheso o tsitsitse |

Ke sebelisa li-sensor tsa mocheso ho lekola ts'ebetso ka nako ea nnete. Litaolo tse itirisang li lokisa ho futhumatsa le ho tsidifatsa ha ho hlokahala. Seta sena se boloka mocheso oa ho qhibiliha o tsitsitse, e leng sa bohlokoa bakeng sa boleng ba liphaephe le ho nepahala ha boholo.

- Taolo ea mocheso sebakeng se seng le se seng e tiisa hore PVC e qhibiliha ka ho feletseng le ka ho lekana.

- Mocheso o nepahetseng oa mocheso o thibela phala hore e se ke ea theoha kapa ea tiea kapele haholo.

- Mekhoa e pholileng e thusa phala ho boloka sebōpeho sa eona le ho fokotsa khatello ea kelello ka hare.

Ka litsamaiso tsena, ke khona ho ikamahanya le liphetoho kapele le ho qoba likoli joalo ka mabota a sa lekaneng kapa libaka tse makukuno.

Ho Hanela ho Rua, Corrosion, le Khatello e Phahameng

PVC Pipe screw barrel bakeng sa extrusion e tobane le maemo a thata. Ke khetha libarele tse entsoeng ka li-alloys tse khethehileng le tse nang le liaparo tse tsoetseng pele tse thibelang ho senya le ho senya. Ts'ebetso ea PVC e ka lokolla hydrochloric acid, e hlaselang tšepe e tloaelehileng. Ho thibela sena, ke sebelisa libarele tsa bimetallic tse nang le li-liner tse nang le nickel le liphahlo tse thata joaloka tungsten carbide.

- Sekhomaretsi se etsahala ha likarolo tsa tšepe li hohlana.

- Ho apara ka mokhoa o senyang ho tsoa ho li-fillers tse kang likhoele tsa khalase kapa liminerale ho PVC.

- Ho senya ho bakoa ke lik'hemik'hale tse lokolloa nakong ea ts'ebetso.

Hape ke etsa bonnete ba hore lisebelisoa tsa screw le barrel lia lumellana. Sena se thibela mathata ho tloha litekanyetso tse fapaneng tsa ho atolosa ha ho futhumala. Licheke le ho li hlokomela kamehla li nthusa hore ke bone lintho tse aparoang esale pele le ho qoba ho lokisa lintho tse khōlō.

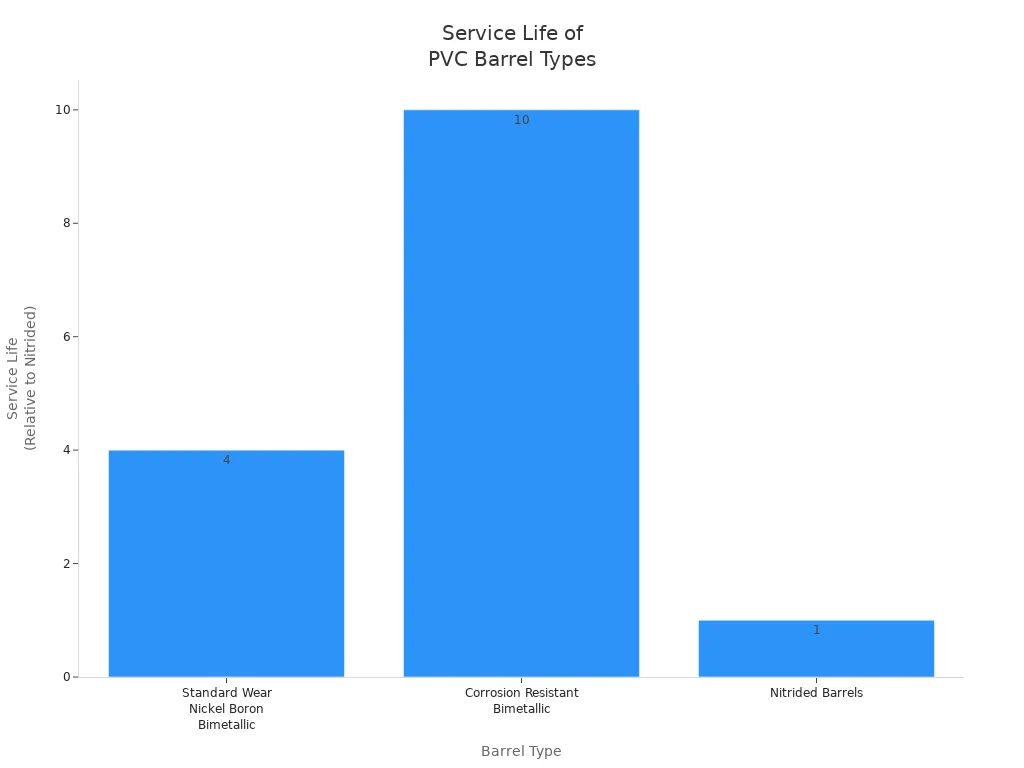

| Mofuta oa Moqomo | Apara Resistance | Khanyetso ea Corrosion | Bophelo ba Tšebeletso ha bo Bapisoa le Nitrided Barrels |

|---|---|---|---|

| Standard Wear Nickel Boron Bimetallic | E babatsehang ho abrasion ho hanyetsa | Ho hanyetsa kutu e itekanetseng | Bonyane makhetlo a 4 ho feta |

| Bimetallic e hanyetsanang le Corrosion | E babatsehang ho apara ho hanyetsa | E ntle haholo khahlanong le HCl le acid | Ho feta makhetlo a 10 libakeng tse senyang |

| Nitrided Barrels | Bothata bo phahameng ba bokahodimo | Khanyetso e mpe ea kutu | Motheo (1x) |

Ka ho sebelisa lisebelisoa tsena le meralo, ke lelefatsa bophelo ba lisebelisoa tsa ka mme ke boloka tlhahiso e ntse e sebetsa hantle, esita le tlas'a khatello e phahameng le ka thepa e senyang.

Boleng bo tsitsitseng ba Extrusion le Bophelo bo Atolositsoeng ba Tšebeletso

Kea tseba hore boleng bo tsitsitseng ke senotlolo sa tlhahiso ea liphaephe tsa PVC. Ke beha leihlo likarolo tsa bohlokoa joalo ka mocheso, khatello, le lebelo ho boloka ts'ebetso e tsitsitse. Ke sebelisa lisebelisoa tse nepahetseng ho lekola boholo ba phala le ho sheba bofokoli. Sistimi ea othomathike e nthusa ho tšoara mathata esale pele le ho boloka ts'ebetso e ntse e le teng.

- Ke latedisa bophahamo ba modumo, sekgahla, le tshebediso ya matla ho lekanya tshebetso.

- Tlhokomelo ea kamehla le ho hlahloba maemo ho nthusa ho qoba ho fokotsa nako.

- Li-screw barrel tse tšoarellang tse nang le masela a bimetallic li fokotsa hore na ke hloka ho emisa hangata hakae bakeng sa litokiso.

Ha ke tsetela ho PVC Pipe screw barrel ea boleng bo holimo bakeng sa extrusion, ke bona ho senyeha ho fokolang le litšila tse fokolang. Litšenyehelo tsa ka tsa ho hlokomela lia theoha, 'me ke khona ho sebetsana le thepa e sebelisoang hape habonolo. Ke boetse ke hlokomela tšebeliso e tlaase ea matla hobane thepa e sebetsa hantle haholoanyane.

Boiphihlelong ba ka, melemo ena e eketsa ho boloka litšenyehelo tse kholo le tlhahiso e phahameng. Ke khona ho fihlela linako tsa ho fihla 'me ke boloke bareki ba ka ba thabile.

Ke tsetela ho PVC Pipe screw barrel bakeng sa extrusion hobane e fana ka ts'ebetso e tšoarellang nako e telele le boleng bo tsitsitseng ba phala.

- Meetso ea moqomo le lisebelisoa tse tsoetseng pele li fokotsa litšenyehelo tsa nako le tlhokomelo.

- Ho hlahlojoa khafetsa le ho roala liaparo tse loketseng ho nthusa ho finyella litekanyetso tsa indasteri.

| Molemo | Sephetho |

|---|---|

| High durability | Litsenyehelo tse tlase tsa ts'ebetso |

| Theknoloji e tsoetseng pele | Khotsofalo e ntlafalitsoeng ea bareki |

LBH

Ke boloka barrel ea ka ea PVC Pipe screw bakeng sa extrusion joang?

Ke hloekisa moqomo kamehla. Ke hlahloba hore na ha e senyehile kapa ha e na kutu. Ke kenya likarolo tse tsofetseng kapele. Ke sebelisa litlolo tse khothalelitsoeng le ho beha leihlo maemo a mocheso.

Keletso: Etsa tlhahlobo ea khoeli le khoeli ho fumana matšoao a pele a ho khathala.

Ke phekolo efe ea holim'a metsi e sebetsang hantle bakeng sa extrusion e phahameng ea PVC?

Ke khetha nitriding bakeng sa mesebetsi e mengata. Ke sebelisa liaparo tsa bimetallic kapa tungsten carbide ha ke sebetsana le metsoako ea abrasive. Litlhare tsena li lelefatsa bophelo ba ts'ebeletso mme li hana ho roala.

A na nka etsa screw geometry bakeng sa boholo bo fapaneng ba lipeipi tsa PVC?

Ke sebetsa le bahlahisi ho lokisabophara ba sekoti, ho phahama le ho teba ha sefofane. Geometry e tloaelehileng e nthusa ho fumana phallo e nepahetseng ea ho qhibiliha le boleng bo sa fetoheng ba phala bakeng sa boholo bofe kapa bofe.

| Khetho ea ho iketsetsa | Molemo |

|---|---|

| Diameter | E tsamaisana le botenya ba liphaephe |

| Pitch | E laola ho phalla ha lintho |

| Botebo ba Sefofane | E ntlafatsa boleng ba ho kopanya |

Nako ea poso: Aug-27-2025