Matla a shear a bapala karolo ea bohlokoa ts'ebetsong ea "plastic twin screw extruder". E bolela matla a etsang hore likaroloana tsa lintho tse bonahalang li thelle khahlanong le tse ling, tse amang thepa haholo. Ka mohlala, matla a phahameng a ho kuta a ntlafatsa ho kopanya le ho arola mocheso. Ho aMoqomo oa Mafahla a Plastic Screw, moralo oa sebaka sa melting o netefatsa phallo e sebetsang ea thepa ha o ntse o fokotsa li-spikes tsa mocheso, kaha khatello ea 40 bar e ka phahamisa mocheso ka 20 ° C. Ho feta moo, aConical Twin Screw Extruder Screw Barrelka ho eketsehileng optimizes dithulaganyo tsena ka ho leka-lekanya ho kuta matla le throughput, ha a ntse aTwin Screw Barrelmoralo o kenya letsoho katlehong e akaretsang ts'ebetsong ea extrusion.

Lintho tsa motheo tsa Plastic Twin Screw Extruder

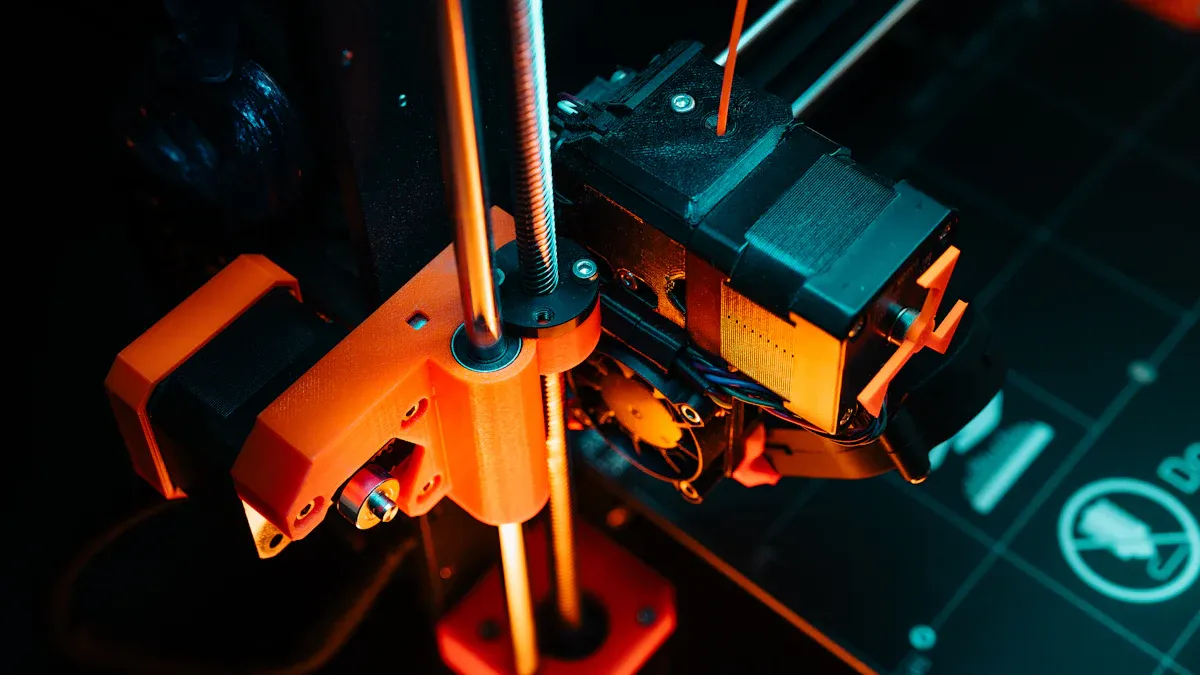

Likarolo tsa Bohlokoa tsa Extruder

A polastiki lefahla sekoti extrudere na le likarolo tse 'maloa tsa bohlokoa tse sebetsang hammoho ho sebetsana le thepa hantle. Tsena li kenyelletsa:

- Hopper: Sebaka sa ho kena moo lisebelisoa tse tala li feptjoang tsamaisong.

- Moqomo: Kamore e ka sehloohong moo lisebelisoa li qhibilihang le ho kopanngoa.

- Screw Conveyor: E ikarabella bakeng sa ho tsamaisa thepa ka extruder.

- Sistimi ea ho futhumatsa: E fana ka mocheso o hlokahalang bakeng sa ho qhibiliha metsoako ea polasetiki.

- Taolo ea Mocheso: E netefatsa maemo a ts'ebetso a tsitsitseng.

- Hlooho ea Extrusion: E theha thepa ka mokhoa o lakatsehang ha e tsoa ka har'a extruder.

Karolo e 'ngoe le e' ngoe e bapala karolo ea bohlokoa ho netefatsa hore extruder e sebetsa hantle 'me e fana ka tlhahiso ea boleng bo holimo. Mohlala, lebelo le feto-fetohang la screw le lumella taolo e nepahetseng holim'a ts'ebetso ea extrusion, athe dies e ka nkeloang sebaka e thusa tlhahiso ea libopeho le boholo bo fapaneng.

Karolo ea Screw le Barrel ho Shear Force Generation

Li-screws le barrel li bohareng ba ho hlahisa matla a ho kuta ka har'a polasetiki ea mafahla a screw extruder. Li-screws li potoloha ka har'a barrel, li baka khohlano le khatello e qhibilihang ebe e kopanya thepa. Lintho tse kang lebelo la screw, die diameter le boits'oaro ba lintho tse bonahalang li ama matla a ho kuta haholo. Ka mohlala:

| Paramethara | Tšusumetso ho Shear Force Generation |

|---|---|

| Screw Speed | Lebelo le phahameng le eketsa matla a ho feta le ho felloa ke matla, ho matlafatsa matla a ho kuta. |

| Die Diameter | Li-diameter tse kholo li fokotsa khatello le matla, li ama matla a ho kuta. |

| Boitšoaro ba Lintho | Lisebelisoa tse fokotsang li-shear li bonts'a khatello e tlase le matla ha li bapisoa le maro a Newtonian. |

Litšebelisano tsena li netefatsa ts'ebetso e sebetsang ea thepa le ho kopanya ho tšoanang.

Material Flow Dynamics ho Extruder

Matla a phallo ea lintho tse bonahalang ka har'a polasetiki ea mafahla a screw extruder a etsa qeto ea boleng ba ho kopanya le sehlahisoa sa ho qetela. Mekhoa e tsoetseng pele ea likhomphutha, joalo ka CFD, e ntlafalitse kutloisiso ea matla ana. Mekhoa e kang ea volume-of-fluid (VOF) le mekhoa e behiloeng boemong ba ho latela mekhoa ea metsi nakong ea ho kopanya, ho netefatsa hore ho na le taolo e nepahetseng holim'a ts'ebetso. Li-extruder tsa Twin screw li sebelisoa haholo liindastering tse kang tsa meriana ka lebaka la bokhoni ba tsona bo holimo ba ho kopanya. Tlas'a maemo a tloaelehileng (30 kg / hr, 200 rpm), khatello e ka kamoreng e le 'ngoe e nang le sebōpeho sa C e fihla hoo e ka bang 2.2 MPa, ka marotholi a 0.3 MPa sebakeng sa intermeshing le 0.5 MPa karolong e ka morao ea screw. Metrics ena e totobatsa bokhoni ba extruder ho sebetsana le lisebelisoa tse fapaneng.

Shear Force Mechanism ho Twin Screw Extrusion

Moloko oa Matla a Shear ka Ts'ebetsong ea Extrusion

Matla a ho kuta ka har'a ts'ebetso ea "screw extrusion" ea mafahla a hlaha ho tsoa ho tšebelisano lipakeng tsa li-screws tse potolohang le moqomo o emeng. Ha li-screws li ntse li potoloha, li baka khohlano le khatello, e leng se etsang hore thepa e holofale le ho phalla. Deformation ena e hlahisa matla a ho kuta a bapalang karolo ea bohlokoa ho qhibiliheng, ho kopanya le ho etsa homogenizing thepa. Moralo o kopanyang oa li-screw o netefatsa hore lisebelisoa li na le ho kuta ka mokhoa o tsitsitseng nakong eohle ea ts'ebetso.

Litlhahlobo tsa lipalo tse sebelisang mokhoa oa "volume-of-fluid" (VOF) li senotse mekhoa ea hydrodynamic e amehang ts'ebetsong ena. E totobatsa kamoo matla a ho kuta, li-viscosity ratios, le turbulence li susumetsang microstructure ea li-alloys tse sa tšoaneng nakong ea ho kopanya. Liphuputso tsena li totobatsa bohlokoa ba matla a ho kuta ho khetholla boitšoaro ba rheological le ts'ebetso e akaretsang ea ts'ebetso ea extrusion.

Lithuto tsa liteko li ts'ehetsa mokhoa ona hape. Mohlala, liphuputso mabapi le li-nanocomposites tsa letsopa tsa polypropylene li bonts'itse hore li-scruder tse mafahla li fihlella phallo e phahameng ha li bapisoa le li-scruder tse le 'ngoe. Sena se bakoa ke matla a phahameng a ho kuta a hlahisoang ka har'a li-screws tsa mafahla, tse matlafatsang exfoliation ea lisebelisoa le ho ntlafatsa thepa ea tsona ea mochine le ea mocheso.

Lintlha tse Amang Matla a Shear

Lintlha tse 'maloa li susumetsa moloko le boholo ba matla a ho kuta ka har'a sekoti sa polasetiki sa twin screw extruder. Tsena li kenyelletsa lebelo la screw, screw geometry, le viscosity ea lintho tse bonahalang.

- Screw Speed: Ho eketsa lebelo la screw ho phahamisa sekhahla sa ho kuta, ho lebisa ho matla a phahameng a ho kuta. Leha ho le joalo, lebelo le feteletseng le ka baka ho senyeha ha thepa kapa ho chesa ho feteletseng.

- Screw Geometry: Moralo oa li-screws, ho kenyeletsoa le bophahamo ba tsona, botebo ba sefofane, le angle ea intermeshing, e ama ka kotloloho ketso ea ho kuta. Ka mohlala, li-screws tse nang le lifofane tse tebileng li hlahisa matla a tlaase a ho kuta, ha li-angles tse harelaneng li eketsa matla a ho kuta.

- Viscosity ea lintho tse bonahalang: Lisebelisoa tse phahameng tsa viscosity li hloka matla a maholo a ho kuta ho finyella ho kopanya hantle le ho qhibiliha. Ka lehlakoreng le leng, lisebelisoa tse tlaase tsa viscosity li ka phalla habonolo, tsa fokotsa katleho ea ketso ea ho kuta.

Lithuto tsa lipalo-palo li hlahlobile lintlha tsena ka botlalo. Mohlala, liphuputso li senotse hore khatello e bokelletsoeng e eketseha ka lebelo la screw empa e fokotseha ka sekhahla sa phepelo. Maemo a nepahetseng a ho sebetsa, joalo ka sekhahla sa phepelo sa 3.6 kg/h ka lebelo la screw la 95 rpm, se eketsa mocheso ha se ntse se fokotsa ho robeha ha fiber. Liphuputso tsena li totobatsa tlhoko ea ho leka-lekanya lintlha tsena ho fihlela extrusion e sebetsang hantle.

Mekhoa ea ho Laola Matla a Shear

Ho laola matla a ho kuta ho bohlokoa bakeng sa ho ntlafatsa ts'ebetso ea extrusion le ho netefatsa boleng bo tsitsitseng ba sehlahisoa. Ho ka sebelisoa mekhoa e mengata ho laola matla a ho kuta ka har'a mafahla a screw extruder:

- Ho fetola lebelo la Screw: Basebelisi ba ka eketsa kapa ba fokotsa lebelo la screw ho fetola sekhahla sa ho kuta le ho fihlela thepa e lakatsehang.

- Customize Screw Design: Ho lokisa screw geometry, joalo ka ho fetola molumo kapa botebo ba sefofane, ho lumella taolo e nepahetseng holim'a ketso ea ho kuta.

- Ho Sebelisa Meetso ea Shear-Thinning: Mefuta ena e thusa ho bolela esale pele boitšoaro ba lintho tse bonahalang tlas'a maemo a fapaneng a ho kuta, e leng ho nolofalletsang taolo e ntlafetseng ea ts'ebetso. Leha ho le joalo, ho itšetleha feela ka mehlala ena ho ka lebisa ho nyenyefatseng likarolo tsa bohlokoa tse kang khatello le viscosity.

- Ho kenya ts'ebetsong mekhoa e tsoetseng pele ea ho beha leihlo: Tlhokomelo ea nako ea 'nete ea li-parameter tse kang mocheso, khatello le torque e fana ka lintlha tsa bohlokoa mabapi le ts'ebetso ea extrusion. Lintlha tsena li ka sebelisoa ho etsa liphetoho le ho boloka maemo a nepahetseng a matla a ho kuta.

Lipatlisiso li bonts'itse hore karolo ea screw phetisong ea mocheso e bohlokoa bakeng sa ho laola matla a ho kuta. Sebopeho sa potoloho ea recirculation ka har'a extruder, e thusang ho aba mocheso ka mokhoa o ts'oanang le ho thibela ho futhumala ha libaka. Sena se etsa bonnete ba hore polymer e qhibiliha ka mokhoa o ts'oanang, e ntlafatsa katleho ea kakaretso ea ts'ebetso ea extrusion.

Tšusumetso ea Matla a Shear ho Thepa ea Lintho

Liphello ho Kopana le Homogeneity

Matla a shear a bapala karolo ea bohlokoa ho finyelleng ho kopanngoa ha junifomo le homogeneity ho thepa e sebetsitsoeng ke sekoti sa polasetiki sa mafahla a extruder. Tšebelisano pakeng tsa li-screws le barrel e baka khohlano, e thusang ho kopanngoa ha li-polymers le li-additives. Ts'ebetso ena e netefatsa hore sehlahisoa sa ho qetela se bonts'a thepa e ts'oanang ho pholletsa le sebopeho sa eona.

Boithuto bo matla bo totobatsa likarolo tse 'maloa tsa phello ea matla a ho kuta:

| Karolo ea Shear Force Impact | Tlhaloso |

|---|---|

| Ho robeha ha Fiber | Matla a ho kuta ka har'a matrix a qhibilihisitsoeng a lebisa ho robeheng ha fiber, ho ama thepa ea sebopeho sa sehlahisoa sa ho qetela. |

| Moloko oa Mocheso | Hoo e ka bang 80% ea mocheso o hlokahalang bakeng sa ho qhibiliha o hlahisoa ke khohlano ka lebaka la ho kuta pakeng tsa likurufu le barrel. |

| Ho Kopanya Tšebetso | Moralo oa libaka tse kopanyang tse nang le likarolo tse tsamaisang pele le tse khutlisetsang morao li susumetsa matla a khatello le katleho ea ho kopanya ka kakaretso. |

| Kabo ea Nako ea Bolulo | RTD e ama haholo litšobotsi tsa sehlahisoa ka ho tseba nako ea ho pepeseha mocheso, khatello le ho kuta. |

Ho phaella moo, ho eketseha ha lebelo la rotor nakong ea polypropylene-sisasal melt-mixing ho fella ka ho senyeha ha fiber e ngata, ho hlahisa bolelele bo fokolang ba fiber. Ketsahalo ena, e bonoang likhoeleng tsa tlhaho, e etsahala hobane ho kuta ho arola likhoele tse ngata, ho fokotsa bophara ba tsona. Liphuputso tsena li totobatsa bohlokoa ba ho ntlafatsa matla a ho kuta ho leka-lekanya katleho ea ho kopanya le botšepehi ba thepa.

Tšusumetso ho Thermal Properties le Kabo ea Mocheso

Matla a shear a susumetsa haholo thepa ea mocheso le kabo ea mocheso nakong ea extrusion. Khohlano e hlahisoang ke lisekere e baka hoo e ka bang 80% ea mocheso o hlokahalang ho qhibilihisa metsoako ea polasetiki. Kabo ena ea mocheso e tiisa ho qhibiliha ho tšoanang le ho thibela ho futhumala ha libaka, ho ka senyang boleng ba thepa.

Moralo oa libaka tsa ho kopanya tsa extruder o eketsa ho fetisa mocheso. Lintho tse tsamaisang pele le tse khutlisetsang morao li theha matla a khatello a ntlafatsang mocheso oa mocheso. Kabo ea nako ea bolulo (RTD) le eona e phetha karolo ea bohlokoa. Lisebelisoa tse pepesehileng ho matla a ho kuta a tsitsitseng li fumana mocheso o tšoanang, o bakang botsitso bo betere ba mocheso.

Mohlala, lipapiso tsa lipalo li senola hore matla a ho kuta a ama sebopeho sa microstructure ea li-alloys tse sa bonahaleng nakong ea ho kopanya. Matla ana a susumetsa karo-karolelano ea viscosity le turbulence, ho netefatsa hore esita le kabo ea mocheso ho pholletsa le thepa. Liphuputso tse joalo li totobatsa bohlokoa ba matla a ho kuta ho boloka tekano ea mocheso nakong ea extrusion.

Liphetoho ho Thepa ea Mechini le Matla a Lintho

Matla a shear a ama ka kotloloho thepa ea mochini le matla a lisebelisoa tse extruded. Ho fapana ha matla a ho kuta ho ka fetola sebopeho sa limolek'hule, ho lebisa phetohong ea matla a tsitsitseng, elasticity, le ho tšoarella.

Lipatlisiso tsa lipalo li bontša liphello tsena:

- Matla a ho kuta a tlhōrō a mefuta e fapaneng ea li-angle tse kopantsoeng a eketseha ka tsela e se nang moeli ka khatello e tloaelehileng, ha matla a ho kuta a setseng a bontša kamano e fokolang le morphology ea manonyeletso.

- Ka khatello e tlase e tloaelehileng, mehlala e bonts'a dilatancy ea ho kuta, e fokotsehang maemong a phahameng a khatello ea maikutlo. Boitšoaro bona bo bonts'a kamano e mpe lipakeng tsa phallo e tloaelehileng le ea tangential.

- Litšobotsi tsa ho hloleha li fapana ka li-angles tse kopaneng. Likarolo tse nang le li-angle tse phahameng li bonts'a mapetsong a theohileng le a ho kuta, ha libaka tse nang le mahlakore a tlaase li bontša ho hlōleha ha ho kuta ka tsela ea ho kuta.

Liphuputso tsena li totobatsa tlhoko ea ho laola matla a ho kuta ho fihlela thepa e lakatsehang ea mochini. Mohlala, ho kuta ho feteletseng ho ka baka ho phatloha ha fiber, ho fokotsa matla a thepa. Ka lehlakoreng le leng, ho kuta ho sa lekaneng ho ka baka ho tsoakana ho sa fellang, ho beha boleng ba sehlahisoa kotsing.

Lithuto-kholo: Boitšoaro ba Lintho Tlas'a Maemo a Fapaneng a Shear

Lithuto tsa mohlala li fana ka leseli la bohlokoa mabapi le hore na matla a ho kuta a ama boitšoaro ba lintho tse bonahalang joang. Lipatlisiso ka li-nanocomposites tsa letsopa la polypropylene li bontša seoli-fin screw extrudersfumana phallo e phahameng ha e bapisoa le litsamaiso tse le 'ngoe tsa screw. Matla a phahameng a ho kuta a ntlafatsa exfoliation, a ntlafatsa thepa ea mochine le ea mocheso.

Phuputso e 'ngoe e mabapi le likhoele tsa tlhaho e senola hore ho kuta ha ho sebelisoa ha ho kopanngoa ho arola likhoele tse ngata, ho fokotsa bophara ba tsona. Ts'ebetso ena e ntlafatsa homogeneity ea thepa empa e ka senya ts'ebetso ea eona ea sebopeho.

Lits'ebetsong tsa indasteri, ho ntlafatsa matla a ho kuta ho ipakile ho hlokahala bakeng sa ho hlahisa lihlahisoa tsa boleng bo holimo. Ka mohlala, ho lokisa lebelo la screw le geometry ka polasetiki ea twin screw extruder ho netefatsa ho kopanya ho ts'oanang le thepa e tsitsitseng. Lithuto tsena li totobatsa bohlokoa ba ho loants'a matla a ho kuta ho latela lits'ebetso tse ikhethileng.

Maano a ho ntlafatsa bakeng sa Plastic Twin Screw Extruder

Screw Design le Configuration Liphetoho

Ho ntlafatsa moralo oa screwe bohlokoa bakeng sa ho ntlafatsa ts'ebetso ea "plastic twin screw extruder". Litokiso ho screw geometry, joalo ka molumo, botebo ba sefofane, le angle intermeshing, li susumetsa ka kotloloho tlhahiso ea matla a ho kuta le phallo ea thepa. Ka mohlala, li-screw tse nang le lifofane tse tebileng li fokotsa matla a ho kuta, ha li-angles tse harelaneng li matlafatsa ho kopanya hantle.

Hangata li-operators li etsa tlhophiso ea li-screw ho lumellana le thepa e itseng. Li-plastiki tse nang le viscosity e phahameng li rua molemo ho li-screw tse entsoeng ka botebo bo boholo ba sefofane ho thusa ho phalla hamonate. Ka lehlakoreng le leng, lisebelisoa tse nang le viscosity e tlase li hloka li-angles tse thata tse kopanyang ho netefatsa ho kuta ho lekaneng. Liphetoho tsena li ntlafatsa homogeneity ea thepa le ho fokotsa tšebeliso ea matla nakong ea extrusion.

Ho leka-lekanya Matla a Shear le Mocheso

Ho boloka ho leka-lekana pakeng tsa matla a ho kuta le mocheso ke habohlokoa bakeng sa ho finyella boleng bo tsitsitseng ba extrusion. Matla a mangata a ho kuta a ka lebisa mochesong o feteletseng, ha ho kuta ho sa lekaneng ho ka fella ka ho sa phethoe ho kopanya. Ho laola khatello ka har'a extruder ho phetha karolo ea bohlokoa ho laola mefuta ena.

Mohlala, foromo e bonts'ang kamano lipakeng tsa khatello le mocheso: ∆T (°C) = ∆P (bar) ÷ 2. Ho sebetsa 500 kg / h ka khatello ea 40 bar ho ka eketsa mocheso oa ho qhibiliha hoo e ka bang 20°C. Ho kopanya pompo ea gear ho fokotsa khatello ea ho tsoa, ho fokotsa likhahla tsa mocheso le ho roala li-screw. Taolo ea khatello ea loop e koetsoeng e eketsa botsitso ba extrusion, ho netefatsa kabo ea mocheso o ts'oanang le thepa e nepahetseng ea thepa.

Tailoring Shear Force bakeng sa Lisebelisoa tse khethehileng tsa Plastiki

Ho lokisa matla a ho kuta ho latela lits'ebetso tse ikhethileng ho ntlafatsa ts'ebetso ea lisebelisoa tsa polasetiki. Mohlala, ho kenyelletsa li-plasticizer ho li-composites tsa PLA ho ntlafatsa ho tenyetseha, ho hanyetsa tšusumetso, le thepa ea mochini. Lits'oants'o tsa electron microscopy (SEM) li senola hore PLA e entsoeng ka polasetiki e na le ductility e kholoanyane ha e bapisoa le metsoako e sa etsoang ka polasetiki, e bontšang boitšoaro bo hlephileng.

Liteko tsa Flexural li bonts'a hore metsoako ea polasetiki e na le litekanyetso tse tlase tsa flexural modulus, tse bontšang ho fetoha ha maemo. Ho feta moo, ho eketsoa ha li-plasticizers ho fokotsa mocheso oa phetoho ea khalase (Tg), ho nolofalletsa ho sebetsa habonolo. Litokiso tsena li totobatsa bohlokoa ba ho ikamahanya le matla a ho kuta ho fihlela litlhoko tse ikhethang tsa lisebelisoa tse fapaneng tsa polasetiki.

Mekhoa ea Tekolo ea Nako ea 'Nete ea Tekolo le Tekanyo

Mekhoa ea ho hlahloba nako ea sebelefana ka lintlha tsa bohlokoa mabapi le ts'ebetso ea extrusion, e nolofalletsang basebetsi ho ntlafatsa matla a ho kuta ka katleho. Li-sensor li lekanya likarolo tsa bohlokoa joalo ka mocheso, khatello le torque, tse fanang ka taolo e nepahetseng holim'a maemo a extrusion.

Mekhoa e tsoetseng pele ea ho beha leihlo, joalo ka litsamaiso tse koalehileng, li boloka litlhophiso tse tsitsitseng tsa khatello le ho thibela ho feto-fetoha ho ka senyang boleng ba sehlahisoa. Litsamaiso tsena li boetse li lemoha ho haella ha phallo ea thepa, e lumellang basebelisi ho etsa liphetoho hanghang. Ka ho sebelisa lintlha tsa nako ea 'nete, bahlahisi ba netefatsa hore sekoaelo sa polasetiki sa mafahla se sebetsa hantle haholo, se fana ka tlhahiso ea boleng bo holimo.

Matla a shear e lula e le lejoe la sekhutlo la polasetiki ea mafahla a li-scrusion, a bōpa thepa ea thepa e kang ho kopanya, botsitso ba mocheso le matla a mochine. Ho ntlafatsa matla ana ho ntlafatsa boleng ba sehlahisoa le katleho ea ts'ebetso.

Boqapi bo tsoelang pele taolong ea matla a shear bo tla bula menyetla e mecha ea ho sebetsa ka polasetiki. Bafuputsi le baenjiniere ba lokela ho hlahloba mekhoa e tsoetseng pele ea ho ntlafatsa sephetho sa extrusion ho ea pele.

LBH

Mosebetsi oa mantlha oa matla a ho kuta ke ofe ka har'a twin screw extrusion?

Matla a shear a thusa ho qhibiliha, ho kopanya le ho homogenization. E netefatsa boleng bo tsitsitseng ba sehlahisoa ka ho susumetsa thepa ea mocheso le mechine nakong ea extrusion.

Basebelisi ba ka laola matla a ho kuta joang ka har'a sekoti sa mafahla sa extruder?

Basebelisi ba lokisa lebelo la sekoti, ba iketsetse jometri ea screw, 'me ba shebe liparamente tsa nako ea nnete joalo ka khatello le torque ho laola matla a ho kuta ka nepo.

Hobaneng ho leka-lekanya matla a ho kuta le mocheso ho le bohlokoa?

Ho leka-lekanya matla a ho kuta le mochesoe thibela ho senyeha ha thepa, e tiisa ho kopanya ho ts'oanang, le ho boloka maemo a nepahetseng a extrusion bakeng sa tlhahiso ea boleng bo phahameng.

Nako ea poso: Jun-11-2025