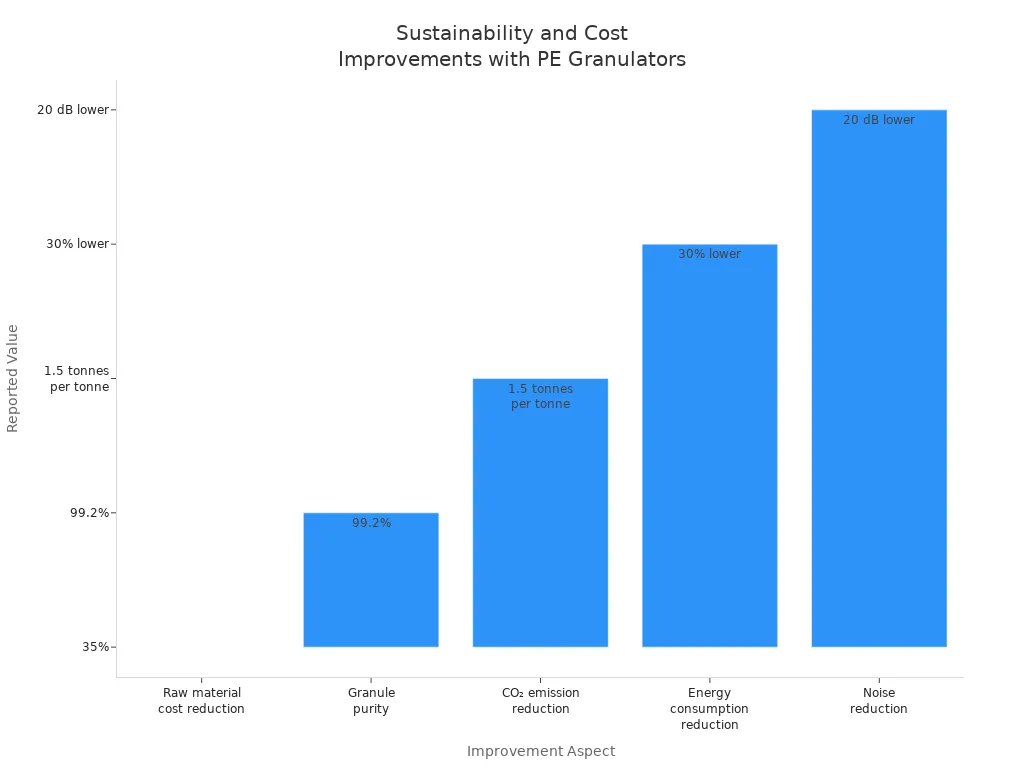

Li-granulator tse nyane tsa tikoloho tsa PE li thusa bahlahisi ho fokotsa tšebeliso ea matla ka likarolo tse bohlale le theknoloji e ncha. Mefuta ea morao-rao e bonts'a liphetho tse khahlisang:

| Metric | Phokotso ea 2025 vs. Lilemo tse Fetileng |

|---|---|

| Tšebeliso ea Matla (kW-h/tonne) | 40% e tlase |

| Likhase tsa Greenhouse Gas | 33% tlase |

| Tšebeliso ea Mafura a Fossil | 45% tlase |

Ba sebelisalienjineri tse sebetsang hantle haholo, ho khutlisa mocheso o litšila, le litsamaiso tse pholileng ka moea. AnTikoloho Mini-Pelletizer MachineleMochini oa Granulator o se nang Metsie khona ho tšoaraPvc Pelletizing Extrusionka bokgabane.

Likarolo tsa ho Boloka Matla tsa PE Small Environmental Granulators

Litsamaiso tsa Likoloi tse Phahameng ka ho Fetisisa

Li-granulator tse nyane tsa tikoloho tsa PE ka 2025 li sebelisa theknoloji e tsoetseng pele ea makoloi ho boloka matla le ho matlafatsa ts'ebetso. Mechine ena e itšetlehile ka lisebelisoa tsa motlakase tse nang le matla a motlakase ho tloha ho 22 kW ho ea ho 110 kW, ho itšetlehile ka boholo ba mohlala. Li-motor li sebetsa ka matla ho tloha ho 200 ho isa ho 1200 kg / h, e leng se etsang hore e be tse phethahetseng bakeng sa ts'ebetso e nyenyane le e mahareng ea ho tsosolosa. Tafole e ka tlase e bonts'a lintlha tse ling tsa bohlokoa tsa tekheniki:

| Tlhaloso | Lintlha |

|---|---|

| Lebelo la Matla a Enjene | 22 kW ho isa ho 110 kW |

| Mofuta oa Drive | Lisebelisoa tsa motlakase |

| Matla a ho khanna a thusang | 1.1 kW |

| Sebaka sa Matla | 200-1200 lik'hilograma / hora |

| Kopo | PE le granulation tse ling tsa polasetiki |

Li-motor tsena tse sebetsang hantle haholo li sebelisa li-drive tsa servo le li-control tse bohlale. Li thusa basebelisi ho boloka matla a fetang 40% ha a bapisoa le li-motor tsa khale. Tlhokomelo ea nako ea 'nete le boiketsetso li boloka sistimi e sebetsa hantle, e fokotsa nako ea ho theoha le ho fokotsa litšenyehelo tsa motlakase.

Optimized Blade le Transmission Design

Sistimi ea blade le phetisetso ho li-granulator tse nyane tsa tikoloho ea PE e bapala karolo e kholo ho bolokeng matla. Baetsi ba sebelisa li-blade tsa tloaelo tse entsoeng ka li-alloys tsa premium joalo ka tungsten carbide kapa tšepe ea lebelo le holimo. Lisebelisoa tsena li nka nako e telele 'me li khaola ka katleho. Mona ke litsela tse ling tsa ho thusa li-blades optimized:

- Li-angles tsa blade tse nepahetseng li fokotsa boima ba enjene le tšebeliso ea matla.

- Liaparo tse tsoetseng pele, tse kang titanium nitride, li fokotsa khohlano ka 40%.

- Ho hloekisa kamehla ka ultrasonic ho boloka mahare a le bohale 'me ho thibela ho bokellana ha masala.

- Li-blade tse bataletseng li sebetsa hantle bakeng sa lipolasetiki tse bonolo, li theola khanyetso le ho boloka matla.

- Lisebelisoa tse thata haholo li eketsa bokhoni ba tlhahiso ka 30%.

Setsi sa Jeremane sa ho sebelisa matla se bone ho tlola holimo ka 22% le phokotseho ea 14% ea tšebeliso ea matla ka tone ka mor'a ho fetohela ho lisebelisoa tse betere tsa blade. Ha li-blade li lula li le bohale 'me li hloekile, mochine oohle o sebetsa hantle 'me o sebelisa matla a fokolang.

Smart Automation le Taolo ea Ts'ebetso

Smart automation e etsa hore li-granulator tse nyane tsa tikoloho tsa PE li sebetse hantle le ho feta. Mechini ena e sebelisa litsamaiso tsa taolo ea PLC le li-skrini tsa touch bakeng sa ts'ebetso e bonolo. Likarolo tsa Automation li kenyelletsa:

- Taolo ea ho fepa ka boiketsetso bakeng sa phallo e tsitsitseng ea thepa.

- Sistimi ea li-filter tse peli tse lumellang basebelisi ho fetola skrini ntle le ho emisa.

- Sistimi ea li-back-flush filter bakeng sa ho qhalla litšila ka boiketsetso.

- Ho fetola lebelo la thipa ea pelletizing le khatello ea li-pellets tse tšoanang.

- Tharollo ea mathata a Marang-rang le ho ntlafatsa li-parameter ka taolo ea leru.

Keletso: Smart automation ha e boloke matla feela empa e boetse e fokotsa tlhoko ea mosebetsi oa matsoho. Basebelisi ba ka tsepamisa maikutlo mesebetsing e meng ha mochini o sebetsana le liphetoho tse tloaelehileng.

Meralo e kopaneng e kopanya li-shredders, li-compactor le li-extruder ho sistimi e le 'ngoe. Setupo sena se boloka ts'ebetso e sebetsa ntle le khefu e telele, e bolelang matla a fokolang a senyehileng le tlhahiso e phahameng.

Pheliso ea Mocheso oa Litšila le Tšebeliso

Li-granulator tse nyenyane tsa PE ha li lumelle mocheso oa bohlokoa hore o senyehe. Nakong ea ts'ebetso, mechine ena e hlahisa mocheso. Ho e-na le ho lahleheloa ke eona, tsamaiso e tšoara le ho tsosolosa mocheso ona bakeng sa mehato e meng ea tlhahiso, e kang lisebelisoa tsa ho futhumatsa pele kapa ho futhumatsa sebaka sa mosebetsi. Mokhoa ona o fokotsa tlhoko ea lisebelisoa tse eketsehileng tsa ho futhumatsa le ho fokotsa tšebeliso ea matla ka kakaretso.

- Ho khutlisa mocheso oa litšila ho tšehetsa merero ea tikoloho ka ho fokotsa ho tsoa ha likhase tse futhumatsang lefatše.

- Ho sebelisa mocheso hape ho thusa bahlahisi ho fihlela litekanyetso tse tiileng tsa matla le tikoloho.

- Ts'ebetso e boetse e boloka litšenyehelo tsa ts'ebetso li theoha, e etsa hore li-granulator e be letsete le bohlale.

Ka ho kopanya tsenalikarolo tsa ho boloka matla, Li-granulator tse nyane tsa tikoloho tsa PE li behile maemo a macha a ts'ebetso le ts'ebetso ea ts'ebetso ea polasetiki.

Melemo e Sebetsang le Phello ea Tikoloho

Tšebeliso e tlase ea Matla a Ts'ebetso

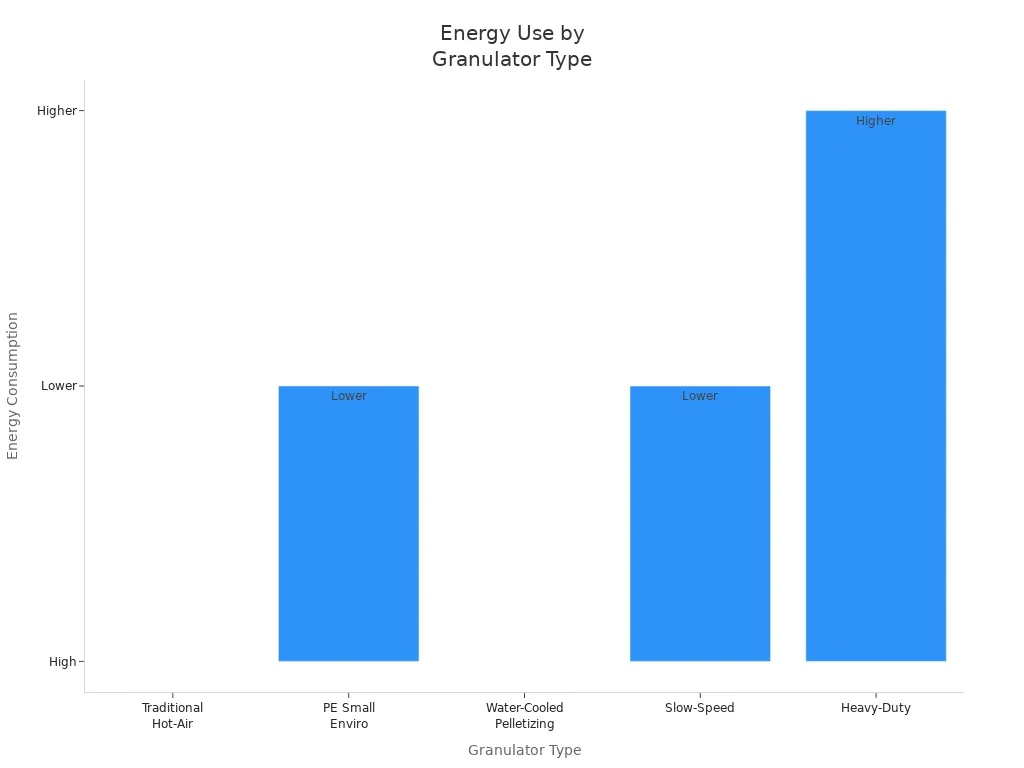

Li-granulator tse nyane tsa tikoloho tsa PE li hlahella ka lebaka la tšebeliso ea tsona e tlase ea matla. Li-granulator tse ngata tsa setso, joalo ka lisebelisoa tse futhumatsang moea o chesang kapa tse pholileng ka metsi, li sebelisa motlakase o mongata le ho baka tšilafalo e eketsehileng. Tafole e ka tlase e bonts'a hore na mefuta e fapaneng ea granulator e bapisoa joang:

| Mofuta oa Granulator | Tšebeliso ea Matla | Tšusumetso ea Tikoloho | Lintlha tsa Ts'ebetso |

|---|---|---|---|

| Traditional Hot-Air Plastic Granulators | Phahameng | Tšilafalo e kholo | Ho feta 75% ea lisebelisoa; e hloka lintlafatso |

| Li-Granulator tsa PE tse Nyane tse Sebeletsang Tikoloho | E tlase ka lebaka la pholileng ea moea le ts'ebetso ea mocheso o tlase | Mesi e fokotsehileng ka lebaka la ho baballa matla | E sebelisa lisebelisoa tse nchafalitsoeng le ho senya mocheso ho hlaphoheloa |

| Mekhoa ea Pelletizing e Fokotseng ka Metsi | Phahameng (metsi le motlakase) | Moroalo oa tikoloho o bakoang ke tšebeliso ea metsi | Ts'ebetso e kholo, ts'ebetso e rarahaneng |

| Li-Granulator tse tsamaeang butle | Tlase | Lerata le tlaase le ho apara | E ntle bakeng sa likarolo tse nyane, ntle le tšebeliso ea khatiso |

| Li-Granulator tsa Boima | E phahameng | E phahameng ka lebaka la ho feta | Bakeng sa lisebelisoa tse thata; matla a fokolang a matla |

Ts'ebetso e pholileng ea moea, ea mocheso o tlase e thusa li-granulator tsena ho sebelisa matla a fokolang. Ba boetse ba tlōla mohato oa ho omisa, o bolokang matla le ho feta.

Ho Fokotseha ha Carbon Footprint le Tumellano

Mechini ena e thusa lik'hamphani ho fokotsa khase ea tsona. Ba sebelisa matla a fokolang 'me ba sebelisa litšila tsa polasetiki sebakeng, ho bolelang hore literaka li fokotsehe tseleng le tšilafalo e fokolang.Mechini e menyenyane ea polasetiki e sebelisoang hapehape u boloke litšila libakeng tsa lithōle. Ka ho fetola polasetiki ea khale hore e be li-pellets tse ncha, ba fokotsa tlhoko ea lisebelisoa tse ncha. Hona joale lik'hamphani tse ngata li kopana le melao e thata ea tikoloho ka lebaka la lintlafatso tsena.

Tlhokomeliso: Moetsi oa likoloi oa Jeremane o boloka lithane tse 300 tsa polasetiki e ncha selemo se seng le se seng ka ho sebelisa litšila tse nyane ka li-granulator tse nyane.

Poloko ea Litšenyehelo le Katleho ea Tlhahiso

Baetsi ba bona chelete ea 'nete ka li-granulator tsena. Li-motor tse sebetsang hantle haholo le li-automation tse bohlale li theola likoloto tsa motlakase. Mosebetsi o fokolang oa matsoho o bolela liphoso tse fokolang le nako e fokolang. Lethathamo le ka tlase le bontša kamoo amokhoa o hlophisitsoeng o eketsa katleho le phaello:

| Sethala | Tlhaloso | Liketso tsa Bohlokoa |

|---|---|---|

| Ho rera | Hlalosa lipheo le li-KPI | Ipehele lipakane tsa SMART, aba lisebelisoa |

| Phethahatso | Etsa liphetoho ho env e laoloang | Merero ea liteko, etsa koetliso ea maemo |

| Tlhahlobo | Lekola tsoelo-pele 'me u bokelle maikutlo | Sebelisa data analytics, fetola ha ho hlokahala |

| Katoloso | Eketsa mekhoa e atlehileng | Kopanya lithuto tse ithutoang, koetlisa |

Ho theoha ha 20% nakong ea potoloho ho ka lebisa ho chelete e ngata. Ho lahleheloa ke mocheso le tšebeliso e tlaase ea matla le hona ho fokotsa litšenyehelo.

Boholo bo Compact le Sebetsa sa Sebaka

Moralo o kopaneng oa li-granulator tsena o boloka sebaka sa bohlokoa sa fatše. Lithupelo tse nyane le litsi tsa ho li sebelisa hape li ka li lekana ntle le ho fetola sebopeho sa tsona. Basebelisi ba li fumana li le bonolo ho li hlokomela le ho li hloekisa, ho bolelang hore nako e fokotsehile. Setupo sa modular se ts'ehetsa ts'ebetso ea ts'ebetso e koetsoeng, e etsa hore ts'ebetso eohle e sebetse hantle le ho tšoarella.

Keletso: Sebaka se senyenyane sa maoto se bolela sebaka se eketsehileng bakeng sa lisebelisoa tse ling kapa katoloso ea nako e tlang.

Li-granulator tse nyane tsa tikoloho tsa PE li behile maemo a macha a ho sebetsa hantle ha matla ka 2025. Baetsi ba bona melemo ea 'nete:

- Litšenyehelo tse tlase le litšila tse fokolang

- Litefiso tse phahameng tsa ho tsosolosa

- Tšehetso bakeng sa lipakane tsa ts'ebetso

- Puseletso e potlakileng le ho latela melao e matla

LBH

Granulator e nyane ea tikoloho ea PE e thusa joang ho boloka matla?

Granulator e sebelisa li-motor tse sebetsang hantle haholo le li-automation tse bohlale. Likarolo tsena li fokotsa tšebeliso ea motlakase le ho boloka tlhahiso e tsitsitse.

Keletso: Litaolo tse bohlale li lumella basebedisi ho fetola li-setting kapele bakeng sa ho boloka le ho feta.

Na lithupelo tse nyane li ka sebelisa granulator ee?

E, ba ka khona. Boholo ba compact bo lumellana le libaka tse thata. Basebelisi ba fumana ho le bonolo ho kenya le ho hlokomela.

- E lumellana le mela e menyenyane ea tlhahiso

- Ho bonolo ho sebetsa

Ke lisebelisoa life tse ka etsoang ke PE e nyane ea granulator ea tikoloho?

E tšoaraPE le lipolasetiki tse ling. Mochine o sebetsa hantle bakeng sa ho sebelisa litšila tsa polasetiki ho li-pellets tse ncha.

| Mofuta oa Boitsebiso | E loketse bakeng sa Granulation? |

|---|---|

| PE | ✅ |

| PP | ✅ |

| PVC | ✅ |

Nako ea poso: Aug-14-2025