Ha ke sebetsa ka sekoahelo sa polasetiki ea Injection molding, ke bona kamoo moralo oa eona o bōpang karolo e 'ngoe le e 'ngoe eo re e etsang. Lithuto tsa ketsiso li bontša hore esita leliphetoho tse nyane tsa lebelo la sekurufukapa libaka tsa khatello li ka matlafatsa boleng le katleho. Hore na ke sebelisa aMoqomo oa Mafahla a Plastic Screwkapa matha aPlastic Extrusion Production Line, tokeloPlastic Machine Screw Barrele etsa phapang eohle.

Mesebetsi ea moqomo oa sekoti oa ente ea polasetiki

Ha ke sheba pelo ea mochini ofe kapa ofe oa ente, ke bona sekoti se phahamisa boima. Ha se tšupu feela e nang le sekoti se ohiang kahare. Moralo le ts'ebetso ea screw barrel e theha mohato o mong le o mong oa mokhoa oa ho bopa. E re ke arole mesebetsi ea eona ea mantlha le hore na ke hobane'ng ha e 'ngoe le e' ngoe e le ea bohlokoa hakana.

Ho qhibiliha le ho kopanngoa ha li-polymers

Ntho ea pele e etsahalang ka har'a barrel ea screw ke ho qhibiliha le ho kopanya li-pellets tsa polasetiki. Ke tšela li-pellets ka har'a hopper, 'me screw e qala ho potoloha ka har'a moqomo o futhumetseng. Moqomo o na le libaka tse fapaneng tsa mocheso, kahoo polasetiki e futhumatsa butle-butle. Bongata ba ho qhibiliha ha e le hantle bo tsoa ho khohlano le khatello e entsoeng ke sekoti se hohlang khahlanong le li-pellets le lebota la moqomo. Mokhoa ona o etsa hore polasetiki e se ke ea chesa haholo 'me e thusa hore e qhibilihe ka ho lekana.

- The screw barrel e na le "helical screw" e potolohang ka har'a moqomo o sa sebetseng.

- Licheso tsa moqomo li futhumatsa moqomo pele ke qala, kahoo polymer e khomarela ebe e qala ho qhibiliha.

- Hang ha screw e potoloha, boholo ba matla a ho qhibiliha a tsoa ho sekiri pakeng tsa screw le lebota la moqomo.

- Moralo oa screw, haholo-holo tsela eo botebo ba kanale bo fokotsehang ka eona karolong ea khatello, e qobella polasetiki e sa qhibilihang khahlano le lebota la moqomo o chesang. Sena se eketsa ho qhibiliha le ho kopanya.

- Ha polasetiki e ntse e tsoela pele, letamo le qhibilihisang le ntse le hōla ho fihlela ntho e 'ngoe le e' ngoe e qhibiliha. Ho kuta ho tsoelang pele ho kopanya polasetiki e qhibilihisitsoeng le ho feta.

Kamehla ke ela hloko hore na polasetiki e qhibiliha joang le ho kopanya hantle. Haeba ho qhibiliha ho sa tšoane, ke bona mathata a kang streaks kapa matheba a fokolang likarolong tsa ho qetela. Moralo oa screw barrel, ho kenyeletsoa eonabolelele, bophahamo, le botebo ba kanale, e etsa phapang e kholo mabapi le hore na e qhibiliha joang le ho kopanya mefuta e fapaneng ea li-plastiki.

Keletso:Boholo ba matla a ho khanna ka har'a barrel ea screw-hoo e ka bang 85-90% - a kena ho qhibilihisa polasetiki, eseng feela ho e isa pele.

Ho tsamaisa le Homogenization

Hang ha polasetiki e qala ho qhibiliha, barrel ea screw e nka mosebetsi o mong oa bohlokoa: ho tsamaisa thepa pele le ho etsa bonnete ba hore e tšoana ka ho feletseng. Ke nahana ka sena e le sebaka sa "taolo ea boleng" kahare ho mochini. The screw barrel e arotsoe ka likarolo tse tharo tse kholo, e 'ngoe le e' ngoe e na le mosebetsi oa eona:

| Screw Zone | Litšobotsi Tsa Sehlooho | Mesebetsi ea mantlha |

|---|---|---|

| Fepa Zone | Channel e tebileng, botebo bo sa feleng, bolelele ba 50-60%. | E tsamaisa li-pellets tse tiileng ka har'a moqomo; e qala ho futhumatsa pele ka khohlano le conduction; compacts material e ntshang mekotlana ya moya |

| Compression Zone | Butle-butle ho fokotseha ha botebo ba mocha, bolelele ba 20-30%. | E qhibilihisa li-pellets tsa polasetiki; compresses thepa e ntseng e eketseha khatello; e tlosa moya ho qhibidiha |

| Sebaka sa Metering | Seteishene se sa tebang ka ho fetesisa, botebo bo sa feleng, bolelele ba 20-30%. | Homogenizes qhibiliha mocheso le sebopeho; e hlahisa khatello bakeng sa extrusion; e laola sekhahla sa phallo |

Ke hlokometse hore geometry ea "screw barrel" - joalo ka bophahamo le botebo ba sefofane sa screw - e ama ka kotloloho tsela eo polasetiki e tsamaeang hantle le ho tsoakana ka eona.Libarele tse koetsoeng, ka mohlala, thusa ho boloka khatello e tsitsitse le ho ntlafatsa hore na ke lintho tse ngata hakae tseo nka li sebetsanang, esita le ka lebelo le phahameng. Haeba ke batla ho eketsa tlhahiso, nka eketsa molumo oa sekoti kapa ka sebelisa sebaka se seholoanyane sa phepelo. Li-tweaks tsena kaofela tsa moralo li thusa "screw barrel" ho fana ka mokelikeli o tsitsitseng, o ts'oanang, ho bolelang hore ho na le mefokolo e fokolang le likarolo tse tsitsitseng.

- Taolo ea mocheso oa moqomoe bohlokoa bakeng sa ho qhibiliha ho tšoanang le ho sebetsa hantle ha tšebetso.

- Libaka tse ngata tsa ho futhumatsa tse nang le mocheso o ntseng o eketseha butle-butle ho isa lefung li fokotsa bofokoli le ho ntlafatsa linako tsa potoloho.

- Sebopeho sa screw se ntlafatsa ho kopanya le ho fetisa bokhoni.

Ente le ho Tlatsa hlobo

Ka mor'a hore polasetiki e qhibilihe 'me e kopane, moqomo oa screw o itokisetsa motsotso o moholo: ho kenya polasetiki e qhibilihisitsoeng ka har'a hlobo. Mona ke kamoo ke bonang ts'ebetso e ntse e tsoela pele:

- Moqomo oa screw o fumana li-pellets tse tala tsa polasetiki ho tsoa ho hopper.

- Screw e potoloha ebe e ea pele ka har'a barrel e futhumetseng, ea qhibiliha, e kopanya, 'me e etsa homogenizing polasetiki.

- Ho kuta ka mochini ka sekurufu ho hlahisa mocheso o ferekaneng, ho fokotsa viscosity ea polasetiki hore e khone ho phalla.

- Thepa e entsoeng ka ho qhibilihisoa e bokellana ka pele ho sekurufu, e etsa "sethunya" e leng palo e nepahetseng feela ea ho tlatsa hlobo.

- Sekurufu se kenya sethunya se qhibidihileng ka kgatello e kgolo mme se potlakele ka hara lesoba la hlobo.

- Sekoti se boloka khatello ea ho paka ho etsa bonnete ba hore hlobo e tlala ka ho feletseng 'me e lefella shrinkage leha e le efe.

- Ka mor'a hore hlobo e tlale, screw e khutlela morao ho itokisetsa potoloho e latelang ha karolo e ntse e pholile.

Ke lula ke shebile ts'ebetso ea screw barrel nakong ena. Haeba mocheso oa ho qhibiliha kapa sekhahla sa phallo se sa tsitsane, ke fumana ho tlatsoa ha hlobo kapa linako tse telele tsa potoloho. Bokhoni ba "screw barrel" ha ho qhibiliha le ho tsamaisa polasetiki kapele ho nthusa ho boloka linako tse khutšoane le karolo ea boleng bo holimo. Ke ka lebaka leo ke lebisang tlhokomelo e kholo ho moralo le boemo ba sekoti sa polasetiki ea Injection molding - e hlile e laola ts'ebetso eohle ho tloha qalong ho isa qetellong.

Screw Design le Tšusumetso ea Eona ho Liphetho tsa Molding

Ho bapisa Screw Geometry le Mefuta ea Resin

Ha ke khetha screw bakeng sa mochini oa ka, ke lula ke nahana ka mofuta oa resin eo ke rerang ho e sebelisa. Ha se sekoti se seng le se seng se sebetsang hantle le polasetiki e 'ngoe le e' ngoe. Mabenkele a mangata a sebelisa li-screws tsa morero o akaretsang, empa ke bone kamoo tsena li ka bakang mathata a kang ho qhibiliha ho sa tšoaneng le li-specks tse ntšo sehlahisoa sa ho qetela. Ke hobane li-resin tse ling li hloka meralo e khethehileng ea screw ho qoba matheba a shoeleng le ho boloka junifomo ea ho qhibiliha.

- Li-barrier screws li arola li-pellets tse tiileng ho tloha ho polasetiki e qhibilihisitsoeng, e thusang ho qhibilihisa thepa kapele le ho theola tšebeliso ea matla.

- Likarolo tse kopanyang, joalo ka Maddock kapa li-zig-zag mixers, etsa bonnete ba hore mocheso o qhibilihang le 'mala o lula o lekana, kahoo ke bona matšoao a fokolang a phallo le mela ea weld.

- Meralo e meng ea li-screw, joalo ka screw ea ho kopanya CRD, sebelisa phallo e telele ho fapana le ho kuta. Sena se etsa hore polymer e se ke ea senyeha mme e nthusa ho qoba li-gel le ho fetoha ha mebala.

Lithuto tsa indasteri li bonts'a hore ho fihla ho 80% ea mechini e na le mathata a ho senyeha ha resin a amanang le moralo oa screw. Kamehla ke bapisa screw geometry le mofuta oa resin ho boloka likarolo tsa ka li le matla ebile li se na likoli.

Liphello tsa ho qhibiliha, ho tsoaka, le boleng ba ho tsoa

Geometry ea screw e bopa hore na polasetiki e qhibiliha, e tsoakana le ho phalla hantle hakae. Ke hlokometse hore meralo e tsoetseng pele ea li-screw, joalo ka lifofane tse thibelang lifofane le likarolo tse kopanyang, li sutumelletsa polymer e sa qhibilihang haufi le lebota la moqomo. Sena se matlafatsa mocheso oa ho kuta 'me se thusa ho qhibiliha hore e be ntho e tšoanang.

Mona ke pono e potlakileng ea hore na li-screw geometries li sebetsa joang:

| Mofuta oa Geometry oa Screw | Matla a ho qhibiliha | Ho Kopanya ka Katleho | Boleng ba Sephetho |

|---|---|---|---|

| Barrier Screw | Phahameng | E itekanetseng | Ho lokile, haeba tlhahiso e nepahetse |

| Karolo e meraro ea Screw | E itekanetseng | Phahameng | E ntle haholo ka ho kopanya hantle |

| Maddock Mixer | E itekanetseng | Phahameng | Molemo ka ho fetisisa bakeng sa ho tšoana ha 'mala le mocheso |

Kamehla ke ikemiselitse ho leka-lekanya. Haeba ke sutumelletsa bakeng sa phallo e phahameng, ke ipeha kotsing ea ho lahleheloa ke homogeneity. Themoralo o nepahetseng oa screwka har'a sekoti sa ka sa polasetiki ea Ente ea polasetiki e nthusa ho boloka mocheso o qhibilihang o tsitsitse, ho fokotsa likoli, le ho fana ka likarolo tse sa fetoheng potolohong e 'ngoe le e 'ngoe.

Keletso: Ke hlahloba boleng ba ho qhibiliha ka ho sheba ho lumellana ha mebala le matla a karolo. Sekoti se entsoeng hantle se etsa hore sena se be bonolo.

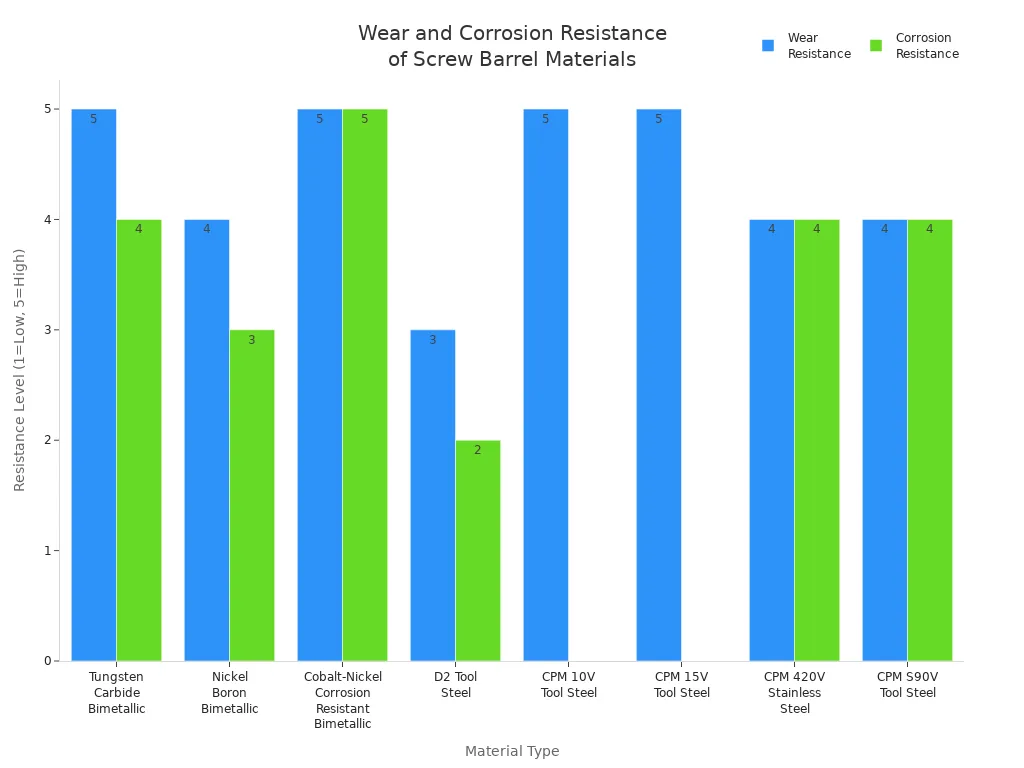

Khetho ea Lintho bakeng sa Moqomo oa Ente ea Plastiki ea ho bopa

Khanyetso ea ho Wear le Corrosion

Ha ke khetha thepa bakeng sa aPlastiki Ente ea ho bopa moqomo, Ke lula ke nahana kamoo mosebetsi o leng boima kateng. Lipolasetiki tse ling li na le likhoele tsa khalase kapa liminerale tse sebetsang joalo ka sandpaper, li roala sekoti le moqomo kapele. Tse ling, joalo ka PVC kapa li-resin tse thibelang malakabe, li ka senya haholo. Ke batla hore thepa ea ka e tšoarelle, kahoo ke batla lisebelisoa tse emang hore li se ke tsa senyeha kapa tsa senyeha.

Mona ke ho sheba ka potlako likhetho tse ling tse tloaelehileng:

| Mofuta oa Boitsebiso | Apara Resistance | Khanyetso ea Corrosion | Molemo ka ho fetisisa Sebelisa Nyeoe |

|---|---|---|---|

| Nitrided Steel | E ntle | Mafutsana | Li-resin tse sa tlatsoang, tse sa senyang |

| Libarele tsa Bimetallic | E kgabane | E ntle / e ntle | Lisebelisoa tse tlatsitsoeng, tse hohlang kapa tse senyang |

| Tool Steel (D2, CPM series) | Phahameng | E mahareng/ E phahameng | Khalase/minerale e tlatsitsoeng kapa metsoako e thata |

| Li-Barrels tse koahetsoeng tse khethehileng | Holimo Haholo | Phahameng | Ho roala ho feteletseng / ho bola, li-resin tse mabifi |

Ke bone hore ho sebelisa libarele tsa bimetallic kapa lisebelisoa tsa lisebelisoa ho ka lelefatsa bophelo ba thepa ea ka. Lisebelisoa tsena li hanana le tlhaselo ea ho hlaba le ea lik'hemik'hale. Ha ke sebelisa motsoako o nepahetseng, ke qeta nako e fokolang ke lokisoa le nako e ngata ea ho etsa likarolo tse ntle.

Keletso: Haeba ke sebetsana le lipolasetiki tse ngata tse tletseng likhalase kapa tse thibelang malakabe, kamehla ke khetha libarele tse nang le liaparo tse tsoetseng pele kapa li-bimetallic liner. Sena se boloka kemiso ea ka ea tlhokomelo e lebelloa esale pele le nako ea ka ea phomolo e le tlase.

Ho khetha lisebelisoa bakeng sa li-polymers tse khethehileng le li-additives

Plastiki e 'ngoe le e' ngoe e na le botho ba eona. Tse ling li bonolo, ha tse ling li sa sebetse ka thepa. Ha ke khetha lisebelisoa bakeng sa screw le barrel, ke li bapisa le li-plastiki le li-additives tseo ke li sebelisang haholo.

- Lithaele tsa khalase le liminerale li hlafuna litšepe tse bonolo, kahoo ke batla li-alloys tse thata kapa litlolo tsa tungsten carbide.

- Li-plastiki tse senyang, tse kang PVC kapa fluoropolymers, li hloka libarele tse entsoeng ka li-alloys tse entsoeng ka nickel kapa tšepe e sa hloekang.

- Li-resin tsa mocheso o phahameng li ka baka mokhathala oa mocheso, kahoo ke hlahloba horesekoti le moqomoatoloha ka sekgahla se tshwanang.

- Haeba ke sebelisa lisebelisoa tse ngata tse fapaneng, ka linako tse ling ke khetha meralo ea modular screw. Ka tsela eo, ke khona ho chencha likarolo tse tsofetseng ntle le ho khutlisa screw kaofela.

Ke lula ke bua le mofani oa ka oa resin bakeng sa keletso. Ba tseba hore na ke lisebelisoa life tse sebetsang hantle ka polasetiki ea bona. Ka ho khetha lisebelisoa tse nepahetseng, ke boloka sekoti sa ka sa Plastic Injection molding se ntse se sebetsa hantle 'me ke qoba ho senyeha ho makatsang.

Litlhahiso tse entsoeng ka polasetiki ea Ente ea ho bopa screw barrel Technology

Li-Coatings tse tsoetseng pele le Phekolo ea Bokaholimo

Ke bone hore na litlolo tse tsoetseng pele le liphekolo tse holimo li ka etsa phapang e kholo hakae hore na libarele tsa ka tsa screw li nka nako e kae. Ha ke sebelisa libarele tse nang le li-bimetallic linings kapa liaparo tsa tungsten carbide, ke hlokomela ho fokotseha ho fokolang le ho fokotseha ho fokolang. Mekhabiso ena e thusa moqomo hore o hane ho hohla le ho bola, leha ke sebelisa lisebelisoa tse thata joalo ka likhalase tse tlatsitsoeng ka khalase. Liaparo tse ling li sebelisa li-nano-materials, tse thusang ho senya mocheso le ho boloka ts'ebetso e tsitsitse. Hape ke rata hore liphekolo tsena li fokotsa ho kopana ho tloha ho tšepe ho ea ho tšepe, kahoo sekoti le moqomo li se ke tsa sila kapele.

Mona ke seo ke se batlang ho li-coatings tse tsoetseng pele:

- Li-alloys tse manganga tse tsamaellanang le lisebelisoa tseo ke li sebetsang

- Phekolo ea holim'a metsi e sebetsanang le mocheso o phahameng le lik'hemik'hale tse mabifi

- Liaparo tse bolokang ts'ebetso e tsitsitse le ho fokotsa nako ea ho phomola

Ha ke khetha seaparo se nepahetseng, ke qeta nako e fokolang ke lokisa 'me ke qeta nako e ngata ke etsa likarolo tse ntle. Litsebi tsa metallurgical li hlile li bohlokoa mona. Motsoako o nepahetseng oa alloy le ho roala o ka habeli kapa esita le makhetlo a mararo bophelo ba tšebeletso ea thepa ea ka.

Meetso e Tloaelehileng bakeng sa Likopo tse Khethehileng

Ka nako e 'ngoe, ke hloka ho fetang feela moqomo o tloaelehileng oa screw. Meralo e ikhethileng e nthusa ho rarolla mathata a ikhethang a ho bopa. Mohlala, ke sebelisitse libarele tsa conical twin screw ho ntlafatsa ho kopanya le taolo ea mocheso. Ke boetse ke bone li-screw tse etselitsoeng ho potlakisa linako tsa potoloho, ho ntlafatsa boleng ba ho qhibiliha, le ho fokotsa ho kuta ho feta tekano.

Tse ling tsa likhetho tseo ke li nahanang bakeng sa meralo e ikhethileng:

- Lisebelisoa le libarele tse entsoeng ka litšepe tse khethehileng tse kang D2 Tool Steel kapa limaraka tsa CPM

- Lintho tse thata tse kang Stellite kapa Colmonoy bakeng sa ho tšoarella ho eketsehileng

- Lithako tsa libarele tse etselitsoeng lisebelisoa tse ikhethileng, joalo ka setsi sa nickel se nang le carbide bakeng sa lipolima tse tlatsitsoeng ka khalase.

- Likopano tsa li-valve tse ikhethileng le likatiba tsa ho qetela tse nang le liphahlo tse tsoetseng pele

Litharollo tsa tloaelo li ntumelle ho bapisa lisebelisoa tsa ka le litlhoko tse nepahetseng tsa ts'ebetso ea ka. Sena se bolela boleng bo betere ba karolo, lipotoloho tse potlakileng, le nako e fokolang. Ke lula ke sebetsa le sehlopha sa meralo se utloisisang kopo ea ka mme se khona ho fana ka bokhabane ba boleng bo holimo.

Ho Khetholla le ho Rarolla Mathata a Screw Barrel

Matšoao a Tloaelehileng a ho Apara kapa ho Hlōleha

Ha ke tsamaisa mechini ea ka, ke lula ke lebetse ho bona matšoao a hore ho na le ho hong ho phoso ka barrel ea screw. Ho bona litaba tsena esale pele ho nthusa ho qoba mathata a maholo hamorao. Lintho tseo ke li shebellang ke tsena:

- Lintho tse lutlang ho potoloha barrel, eo hangata e bolelang litiiso tse tsofetseng kapa ho hlaka haholo.

- Likarolo tse tsoang ka boholo bo sa tsitsang kapa li-specks tse ntšo-hangata li supa ho tsoakaneng ho fokolang kapa tšilafalo.

- Lithempereichara tse phahameng tsa ts'ebetso, ka linako tse ling li bakoa ke khohlano kapa k'habone ka har'a moqomo.

- Lerata kapa ho thothomela ho makatsang nakong ya tshebetso. Tsena li ka bolela ho se lumellane, li-bearings tse robehileng, kapa esita le ntho esele ka hare.

- Li-spikes tsa khatello kapa phallo e mpe ea ho qhibiliha, e leng ho etsang hore ho be thata ho tlatsa hlobo hantle.

- Li-blockages kapa lintho tse hahelletsoeng ka har'a barrel, tse lebisang ho theolelo ea nako le likarolo tse mpe.

- Mathata a ho kopanya mebala kapa tšilafalo, hangata ho tsoa ho thepa e setseng kapa taolo e mpe ea mocheso.

- Ho bola ho bonahalang kapa likoti, haholo-holo haeba ke sebelisa li-resin tse senyang.

- Lifofane tse tsofetseng tsa li-screw kapa li-barrel line, tseo ke li bonang hangata ha ke sebelisa li-filler tse senyang joalo ka fiber ea khalase.

- Ho qhibiliha butle, likhahla tse ngata, le linako tse telele tsa potolohoha thepa e senyeha.

Haeba ke hlokomela leha e le efe ea matšoao ana, kea tseba hore ke nako ea ho hlahloba sekoti pele lintho li mpefala.

Malebela a Sebetsang a Tharollo ea Mathata le Tlhokomelo

Ho boloka mechine ea ka e sebetsa hantle, ke latela kemiso ea kamehla ea ho e lokisa. Mona ke se sebetsang hantle ho nna:

- Ke sebelisa feela mafura a khothaletsoang ke moetsi.

- Ke hlahloba maemo a oli ea hydraulic letsatsi le leng le le leng ebe ke khutlisa oli ka kemiso.

- Ke shebella mocheso oa oli 'me ha ho mohla ke o lumellang hore o chese haholo.

- Ke hlahloba li-hoses, lipompo, le li-valve hore na ha li lutle kapa ha li senyehile.

- Ke hloekisa le ho tiisa lihlopha tsa hitara khoeli le khoeli.

- Ke sebelisa setšoantšo sa mocheso ho bona mathata a ho futhumatsa pele.

- Ke beha leihlo linako tsa libaesekele, litefiso tsa likhahla, le tšebeliso ea matla ho fumana mathata pele a hola.

- Ke hloekisa screw le barrel khafetsa ho thibela ho bokellana.

- Ke etsa bonnete ba hore screw e lula e otlolohile ebile e tsitsitse nakong ea ho kenya.

- Ke koetlisa sehlopha sa ka ho bona matšoao a pele le ho boloka maemo a ts'ebetso a tsitsitse.

Ho lula ka holim'a mesebetsi ena ho nthusa ho qoba ho senyeha le ho boloka mohala oa ka oa tlhahiso o sebetsa hantle.

Ha ke tsepamisitse maikutlo ho mahlale a ka morao ho moqomo oa screw oa Plastic Injection, ke bona liphetho tsa 'nete. Ke fumana likarolo tse betere, lipotoloho tse potlakileng, le nako e fokolang.

- Litšenyehelo tse tlase tsa tlhokomelo

- Boleng ba sehlahisoa bo ntlafalitsoeng

- Bophelo ba lisebelisoa tse telele

Ho lula u le bohlale ka mahlale a screw barrel ho boloka tlhahiso ea ka e tšepahala ebile e sebetsa hantle.

LBH

Ke matšoao afe a mpolellang hore moqomo oa ka oa screw o hloka ho nkeloa sebaka?

Ke hlokomela matheba a mangata a matšo, likarolo tse sa lekanang, kapa lerata le makatsang. Ha ke bona tsena, ke sheba hore barrel ea screw ha e sebetse kapa e senyehile hang-hang.

Ke lokela ho hloekisa barrel ea ka ea screw hangata hakae?

Ke hloekisa barrel ea ka ea screw ka mor'a phetoho e 'ngoe le e 'ngoe ea lintho tse bonahalang. Bakeng sa ho matha kamehla, ke e hlahloba le ho e hloekisa bonyane hang ka beke ho thibela ho haha.

A na nka sebelisa screw barrel bakeng sa mefuta eohle ea polasetiki?

- Ke qoba ho sebelisa sekoti se le seng bakeng sa polasetiki e 'ngoe le e 'ngoe.

- Lipolasetiki tse ling li hloka lisebelisoa tse khethehileng kapa lirafshoa ho thibela ho senyeha kapa ho senya.

Nako ea poso: Aug-20-2025