Moqomo oa screw oa ente ea polasetiki o eme bohareng ba ts'ebetso e 'ngoe le e' ngoe ea ho bopa. Ha ba khetha boleng ba boleng bo holimoPlastic Machine Screw Barrelkapa aPlastic Twin Screw Extruder Barrel, bahlahisi ba bona ho phalla ha thepa hamonate, ho fokotseha ho fokolang, le litšenyehelo tse tlaase.Stainless Steel Twin Screw Extruder Barrellikhetho li boetse li thusa ho lelefatsa bophelo ba lisebelisoa le ho fokotsa nako.

Likarolo tsa Bohlokoa tsa Ente ea Plastiki Molding Screw Barrel

Ho qhibiliha le Homogenizing thepa ea polasetiki

Moqomo oa screw oa ente ea polasetiki o bapala karolo e kholo ho fetoleng li-pellets tse tiileng tsa polasetiki hore e be thepa e boreleli, e qhibilihisitsoeng. Ka hare ho barrel, screw e potoloha ebe e sutumelletsa li-pellets pele. Ha li-pellets li ntse li sisinyeha, lihlopha tsa likhohlano le heater lia qhibiliha. Moqomo o boloka mocheso o lekana, kahoo polasetiki e qhibiliha ka lebelo le nepahetseng. Ts'ebetso ena e thusa ho qoba maqhubu kapa matheba a batang a thepa.

Keletso: The screw barrel e na le libaka tse tharo tse kholo-feed, compression, le metering. Sebaka ka seng se na le mosebetsi o khethehileng. Sebaka sa phepelo se tsamaea le ho chesa li-pellets pele. Sebaka sa compression se qhibilihisa polasetiki ebe se tlosa moea. Sebaka sa metering se etsa bonnete ba hore melting e boreleli 'me e loketse ente.

| Sebaka | Mesebetsi ea mantlha |

|---|---|

| Fepa Zone | E tsamaisa li-pellets, e li futhumatsa pele, 'me li kopanya ho ntša lipokotho tsa moea. |

| Compression Zone | E qhibilihisa polasetiki ebe e tlosa moea ka khatello le ho kuta. |

| Sebaka sa Metering | Homogenizes ho qhibiliha, ho haha khatello, le ho tsitsisa phallo bakeng sa ente. |

Ho laola mocheso ho bohlokoa haholo. Mohlala, UPVC e thata e hloka ho futhumatsoa ka hloko lipakeng tsa 180-190°C. The screw barrel e sebelisa liheater ka ntle le motsamao oa screw ho etsa mocheso o nepahetseng. Tekanyo ena e etsa hore polasetiki e se ke ea tuka kapa ea khomarela. Lebelo la screw le boetse le ama tsela eo polasetiki e qhibilihang ka eona. Haeba screw e fetoha butle haholo, ho qhibiliha ho ka 'na ha se chese ka ho lekaneng. Haeba e phethoha ka potlako haholo, polasetiki e ka chesa haholo. Moqomo oa screw oa ente ea polasetiki o etsa bonnete ba hore ho qhibiliha ho nepahetse bakeng sa thunya e ngoe le e ngoe.

Ho Kopanya Li-additives le ho etsa bonnete ba hore mebala e lumellana

Hangata bahlahisi ba eketsa mebala kapa li-additives tse khethehileng ho polasetiki. Moqomo oa screw oa ente ea polasetiki o kopanya metsoako ena ho qhibiliha. Moralo oa screw, ka likarolo tse khethehileng tsa ho kopanya, o thusa ho kopanya ntho e 'ngoe le e' ngoe ka ho lekana. Ho kopanya hona ho emisa li-streaks kapa matheba ho hlaha sehlahisoa sa ho qetela.

Ho lumellana ha mebala ho ka ba ntho e qhekellang. Ka linako tse ling,li-pigments tse omeletseng li khomarela ka hare ho hopper kapa u se ke ua kopanya hantle. Mongobo o ka senya boleng ba resin le pigment. Ho bohlokoa ho sebelisa li-colorants ka mokhoa o nepahetseng. Mechini e sebelisa li-blender tsa gravimetric ho lekanya palo e nepahetseng. Moqapi oa hlobo o boetse o thusa ho boloka mebala esita le likarolong tse fapaneng.

Tlhokomeliso: Meralo e tsoetseng pele ea li-screw, joalo ka mekoallo kapa li-screw tsa Maddock, li qhetsola maqeba le ho ala mebala hantle. Meetso ena e kaeketsa katleho ea ho kopanya ka ho feta 20% le ho fokotsa litheko tsa maqheku ka 30%. Ho hloekisa khafetsa le ho hlokomeloa ho etsa hore screw barrel e sebetse hantle, kahoo mebala e lula e le 'nete ho tloha ka bongata ho isa ho bongata.

Ho tsamaisa le ho Enta Plastiki e Khōlotsoeng

Hang ha polasetiki e qhibilihisoa 'me e tsoakane, moqomo oa screw o tsamaisa thepa e qhibilihisitsoeng ho ea hlobo. Screw e potoloha ka hare ho barrel e futhumetseng, e sutumelletsa ho qhibiliha pele. Ha thepa e lekaneng e bokellana, screw e sebetsa joalo ka plunger. E kenya polasetiki e qhibilihisitsoeng ka har'a hlobo ka khatello e phahameng.

Mona ke kamoo ts'ebetso e sebetsang kateng:

- Li-pellets tsa polasetiki li kena karolong ea phepelo 'me li tsoele pele ha screw e fetoha.

- Khohlano le mocheso li qhibilihisa li-pellets.

- The screw compresses ho qhibiliha, ho etsa bonnete ba hore boreleli le ho lekana.

- Screw e tsoela pele ebe e kenya polasetiki e qhibilihisitsoeng ka har'a hlobo.

Themoqomo wa ho bopa ka polasetikie boloka tsohle di tsamaya hantle. E laola khatello le ho phalla, kahoo thunya ka 'ngoe e tlatsa hlobo ka mokhoa o phethahetseng. Lisebelisoa tse thata tsa moqomo li ema hore li ka senyeha, ho etsa bonnete ba hore ts'ebetso e lula e tšepahala ha nako e ntse e feta.

Ho Ntlafatsa Ts'ebetso ka Moqomo o nepahetseng oa Ente ea Plastiki Molding Screw Barrel

Tšusumetso ea Screw Geometry le Moralo oa Barrel

Hlakola geometrye bopa kamoo polasetiki e qhibilihang le ho tsoakana ka hare ho moqomo. Bolelele, sebōpeho sa khoele, bophahamo le lebelo la sekurufu kaofela li phetha karolo. Ha lienjineri li lokisa liparamente tsena, li ka laola hore na polasetiki e fumana mocheso o mokae le ho kuta. Sena se thusa ho etsa hore ho qhibilihe ho tšoanang le ho fokotsa likoli tse kang li-streaks kapa bubble.

Karo-karolelano ea khatello, e bapisang botebo ba sefepi sa screw le libaka tsa metering, e ama tsela eo polasetiki e pakiloeng ka eona. Karo-karolelano e phahameng e eketsa bongata le ho tsoakana empa e ka 'na ea se ke ea lumellana le li-plastiki tse mamellang mocheso. Khatello ea mokokotlo le eona e bohlokoa. E sutumelletsa resin e qhibilihisitsoeng ka thata, e pshatla likotoana tse sa qhibilihang le ho ntlafatsa ho kopanya. Leha ho le joalo, khatello e matla haholo ea mokokotlo e ka senya lisebelisoa tse bobebe.

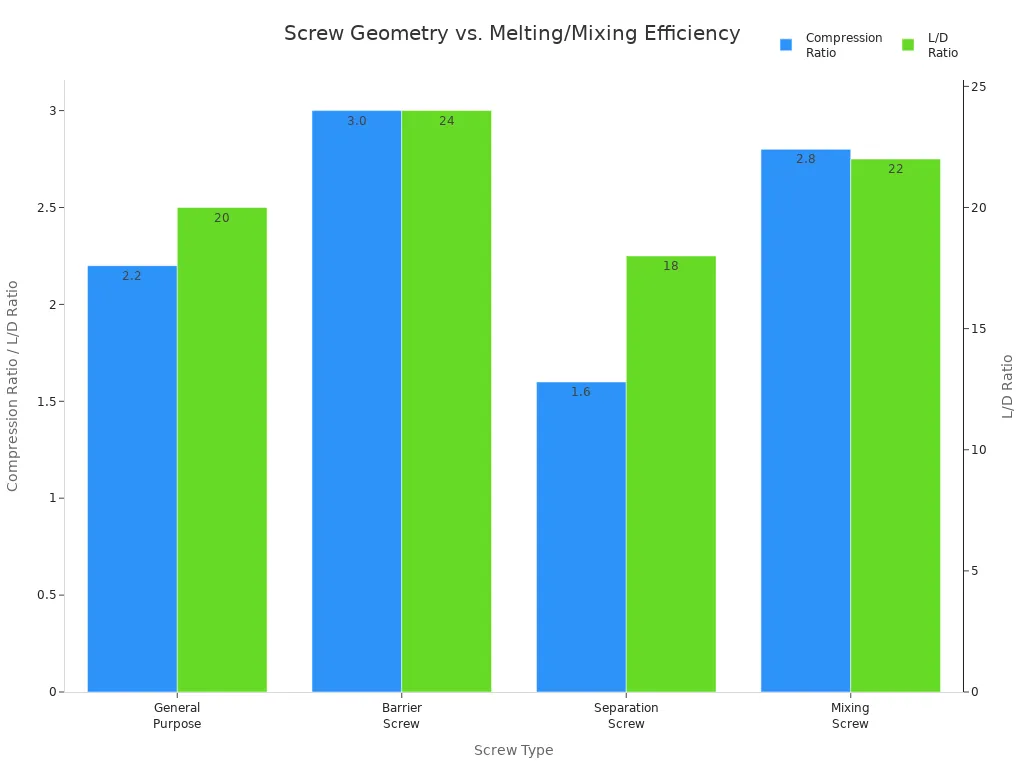

Mona ke tafole e bontšang kamoo mefuta e fapaneng ea li-screw le geometry ea tsona e amang ho qhibiliha le ho kopanya hantle:

| Mofuta oa Screw | Lisebelisoa tse Loketseng | Compression ratio | Karolelano ea L/D | Tšebeliso e Tloaelehileng | Phello ho Ts'ebetso ea ho Qhibiliha le ho Kopanya |

|---|---|---|---|---|---|

| Sepheo se Akaretsang | ABS, PP, PE | 2.2:1 | 20:1 | Matlo a Lisebelisoa | Ho qhibiliha ho feto-fetohang le ho kopanya le ho kuta ho itekanetseng le ho tšoana. |

| Barrier Screw | PA+GF, PC | 3.0:1 | 24:1 | Likarolo tsa Sebopeho | Ho kuta e phahameng le ho kopanya, ho molemo ho qhibiliha homogeneity le boleng ba sehlahisoa. |

| Karohano Screw | PVC, POM | 1.6:1 | 18:1 | Liphaephe, Likaroloana | E laola ho kuta, ho fokotsa ho senyeha, ho netefatsa ho qhibiliha ho tsitsitseng. |

| Ho Kopanya Screw | PMMA, PC+GF | 2:8:1 | 22:1 | Leseli Likoahelo | Ho kopanya ho ntlafalitsoeng, ho qhibiliha ho tšoanang, ho ntlafatsa thepa ea optical. |

Hangata lienjiniere li sebelisa lichate ho bapisa screw geometry. Chate e ka tlase e bonts'a hore na karo-karolelano ea compression le karo-karolelano ea L/D li fapana joang bakeng sa mefuta e fapaneng ea screw:

Sekoti se entsoeng hantle sa Plastic Injection molding screw barrel e nang le geometry e nepahetseng e tiisa polasetiki e tsitsitseng, mocheso o tsitsitseng oa ho qhibiliha, le ho phalla ha thepa e boreleli. Sena se etsa hore ho be le khanya e ntle ea bokaholimo, bofokoli bo fokolang, le likarolo tse bōpiloeng tse matla.

Khetho ea Boitsebiso bakeng sa ho tšoarella le ho hana ho apara

Ho khetha lisebelisoa tse nepahetseng bakeng sa barrel ea screw ho etsa phapang e kholo mabapi le hore na e nka nako e kae le hore na e sebetsa hantle hakae. Baetsi ba sebelisa litšepe tse thata le lirafshoa tse tsoetseng pele ho loantša ho senyeha le ho senya. Ka mohlala, 38CrMoAlA nitrided steel e sebetsa hantle bakeng sa mesebetsi e tloaelehileng, ha tšepe ea SKD61 (H13) e sebetsana le li-resin tse thata tsa boenjiniere. Libarele tsa Bimetallic tse nang le tungsten carbide kapa li-alloys tse thehiloeng ho nickel li fana ka khanyetso e phahameng ka ho fetisisa ea ho senya le lik'hemik'hale.

| Mofuta oa Boitsebiso | Apara Resistance | Khanyetso ea Corrosion | Boima bo Tloaelehileng | Lintlha-khōlō Tsa Kopo |

|---|---|---|---|---|

| 38CrMoAlA Nitrided Steel | ★★★☆☆ | ★★☆☆☆ | ~1000 HV (Nitrided) | E ka tšeptjoa bakeng sa likopo tse tloaelehileng |

| SKD61 (H13) Tool Steel | ★★★★☆ | ★★★☆☆ | 48–52 HRC | Li-resin tse thata tsa boenjiniere, khatello ea mocheso |

| Libarele tsa Bimetallic | ★★★★★ | ★★★★☆ | 60–68 HRC | Abrasive, fiberglass, retardant flame, lipolasetiki tse recycled |

Likhetho tse ling tse tsebahalang li kenyelletsa litšepe tsa AISI 4140 le 4340 tsa alloy bakeng sa tšebeliso e akaretsang, lisebelisoa tsa D2 le CPM bakeng sa lipolasetiki tsa abrasive, le Hastelloy kapa Inconel bakeng sa tikoloho e senyang. Liphekolo tsa holim'a metsi joalo ka nitriding le chromium plating li matlafatsa boima le nako ea bophelo. Ha bahlahisi ba khetha thepa e nepahetseng, ba fokotsa nako le litšenyehelo tsa tlhokomelo, ho boloka tlhahiso e sebetsa hantle.

Keletso: Libarele tsa Bimetallic tse nang le tungsten carbide e ngata li tšoarella nako e telele, haholo ha li sebetsana le lipolymer tse abrasive kapa tse tlatsitsoeng.

Ho bapisa Screw Barrel le Plastiki e fapaneng

Ha se li-plastiki tsohle tse itšoarang ka tsela e tšoanang nakong ea ho bōptjoa. Mofuta o mong le o mong o hloka moralo o ikhethileng oa screw barrel ho fumana liphetho tse ntle. Baenjenere ba leba mogote o o gakologang wa polasetiki, botlhaga jwa yone le go tsepama ga yone. Li tsamaisana le li-screw geometry, botebo ba groove, le liaparo tsa moqomo ho latela litlhoko tsa thepa.

Ka mohlala, polycarbonate (PC) e hloka sekoti se selelele se nang le tekanyo ea ho hatella butle-butle le karolo ea ho kopanya ho thibela ho senyeha. Nylon (PA) e hloka screw mutant e nang le tekanyo e phahameng ea compression le lekhalo le lenyenyane pakeng tsa screw le barrel ho laola ho kuta. PVC e hloka moqomo o hanang ho bola le sekoti se setang se tlase ho qoba mocheso o feteletseng le ho bokellana ha thepa.

| Mofuta oa polasetiki | Screw Design Parameters | Tšusumetso ho Boleng |

|---|---|---|

| Polycarbonate (PC) | Karolelano e kholo ea L / D (~ 26), screw butle-butle, tekanyo ea compression ~ 2.6, karolo ea ho kopanya | Plastiki e ntle, e thibela ho senyeha, e ntlafatsa homogeneity |

| Nylon (PA) | Mutant screw, L/D 18-20, compression ratio 3-3.5, lekhalo le lenyenyane | E thibela ho chesa haholo, e laola ho kuta, e boloka boleng ba ho qhibiliha |

| PMMA | Butle-butle screw, L/D 20-22, compression ratio 2.3-2.6, kopanya reng | Ho qhibiliha ka nepo, ho thibela litaba tsa mongobo, ho boloka ho nepahala |

| PET | L/D ~ 20, sekoahelo se tlase sa shear, tekanyo ea compression 1.8-2, ha ho sebaka sa ho kopanya | E thibela ho futhumala ho feteletseng, e laola ho kuta, e loketseng lisebelisoa tse tsosolositsoeng |

| PVC | Sekurufu se tlase sa ho kuta, moqomo o hanang ho bola, L/D 16-20, ha ho selikalikoe sa cheke | E thibela ho chesa le ho senya, ho laola mocheso o tsitsitseng |

Ho bapisa sekoahelo sa sekoti sa polasetiki le mofuta oa polasetiki ho thusa ho qoba likoli tse kang ho fifala, ho qhibiliha ho sa phetheheng, kapa ho loana. E boetse e ntlafatsa linako tsa potoloho le matla a matla.

Tlhokomeliso: Ho ntlafatsa li-screw barrel bakeng sa polasetiki e itseng ho ka eketsa ts'ebetso ka 25% le ho fokotsa likoli, ho boloka nako le chelete.

Malebela a Tlhokomelo a Bophelo bo Bolelele le ho Tšepahala

Tlhokomelo ea kamehla e etsa hore screw barrel e sebetse hantle. Basebelisi ba lokela ho hlahloba barrel hore na ha e senyehile, ha e mengoapo, kapa e kotiloe neng kapa neng ha screw e tlosoa. Ho hloekisa ka metsoako ea khoebo ea ho hloekisa ho tlosa mesaletsa le ho thibela carbon buildup. Ho beha leihlo khatello, mocheso le lebelo la screw ho thusa ho bona mathata esale pele.

Litlhahiso tse sebetsang tsa tlhokomelo ke tsena:

- Hlahloba sekoti ka mahlo le ka li-gauge nako le nako ha screw e tlosoa.

- Hloekisa barrel beke le beke bakeng sa ho matha khafetsa, kapa matsatsi a mang le a mang a 2-3 haeba u fetola polasetiki khafetsa.

- Tlotsa likarolo tse tsamaeang letsatsi le letsatsi 'me u li tlotse beke le beke ka mafura a boleng bo holimo.

- Sebelisa lisebelisoa tse tala 'me u li boloke hantle ho qoba tšoaetso.

- Koetlisa basebetsi ho lemoha matšoao le ho boloka lintlha tse qaqileng tsa tlhokomelo.

- Likarolo tse ling tsa stock ho fokotsa nako ea ho theoha.

- Kamora ho koala, tsamaisa screw ka lebelo le tlase ho aba polasetiki e setseng, hloekisa ka lisebelisoa tse khethehileng, 'me u tšele oli e sireletsang.

Callout: Libarele tsa Bimetallic tse nang le li-liner tse thehiloeng ka tšepe li ka nka nako e telele ka makhetlo a mararo ho feta li-screws tse tloaelehileng.Ho tsamaisana hantle le lubricationeketsa nako ea bophelo le ho fokotsa khafetsa ea tlhokomelo.

Sekoti se hlokometsoeng hantle sa Plastic Injection molding screw barrel se fana ka boleng bo tsitsitseng, se fokotsa nako, 'me se tšehetsa tlhahiso e sebetsang hantle.

The Plastic Injection molding screw barrel e phetha karolo ea bohlokoa ho faneng ka boleng bo tsitsitseng ba sehlahisoa le tlhahiso e sebetsang.

- Li-screw barrel tsa boleng bo holimo li ntlafatsa ts'ebetso ea ho qhibiliha, li fokotsa sekhechana le ho matlafatsa ts'ebetso.

- Tlhokomelo ea kamehla e thibela nako ea ho theoha le ho lelefatsa bophelo ba lisebelisoa.

- Ho boloka thepa le matla ho eketseha ka potlako.

- Liphetoho tse potlakileng li eketsa bokhoni le phaello.

LBH

Ke matšoao afe a bontšang hore moqomo oa screw o hloka ho nkeloa sebaka?

Basebelisi ba hlokomela ho qhibiliha ho sa tšoaneng, bokooa bo eketsehang, kapa ho tsamaea butle. Ba boetse ba bona boea bo bonahalang, mengoapo kapa likoti ka har'a moqomo.

Motho o lokela ho hloekisa barrel ea screw hangata hakae?

Baetsi ba bangata ba hloekisa barrel beke le beke. Haeba ba fetola li-plastiki khafetsa, ba li hloekisa ka mor'a matsatsi a mabeli ho isa ho a mararo.

Na sekoti se le seng se ka sebetsa bakeng sa lipolasetiki tsohle?

Che, mofuta o mong le o mong oa polasetiki o hloka moralo o khethehileng oa sekoti. Ho sebelisa motsoako o nepahetseng ho ntlafatsa boleng ba sehlahisoa le ho fokotsa litšila.

Nako ea poso: Aug-15-2025